How to lengthen a peorator drill

An excellent electric drill that will allow you to perform a variety of operations with maximum efficiency. In one minute the device makes more than 200 revolutions, which has a positive effect on the overall performance and allows you to finish most of the work in a couple of days. Maximum diameter of the drill is 120 mm.

The device is made of quality components that have an increased service life. Its weight is 6.7 kg, so a little effort is required for transportation. The main power element is the rechargeable battery.

StrikeMaster Lithium 40V

It is an excellent professional electric drill, which allows you to work at any complexity. It can be used for industrial drilling or bought by people who plan to do such work by themselves. With some drilling skill it will pay for itself after 2 to 3 months of intensive work.

The body and the rest of the elements are of premium quality, which is a guarantee of reliability and safety. Having bought such a tool once and timely engaged in maintenance, it will serve for more than a dozen years and will benefit not only the owner’s plot, but also the neighbors, if they want it.

- Excellent professional equipment;

- Efficiency at the level of industrial machines;

- Quality assembly;

- Can be used for fishing and at home.

CARVER AG-52

Great gasoline-powered device that can handle any soil in a short amount of time. The device is equipped with a two-stroke engine, with a maximum power of 1.9 л.с. Big advantage. semi-transparent tank, which will give the user full control over the current state of the liquid, which will allow timely refill. It is possible to use augers of different diameters, it is an effective solution that will give an opportunity to adjust to any type of work.

Assembling quality is made at a decent level. No backlashes or squeaks noticed. The power drill will operate for more than 5 years without complaint. Fuel tank capacity. 0.8 liters.

- Assembly;

- Price to quality ratio;

- The semi-transparent tank offers the most precise control over the current condition of the fluid;

- Power 1400 watts;

- Max. auger diameter. 500 mm.

7 Best Rotary Hammer Drill

PATRIOT PT AE75D

Great brand name tool, designed for fast drilling of holes in the ground. Can be used for light and demanding construction and garden work. Auger diameter from 40 to 350 mm can be handled with ease. Thanks to this tool, a person will forget about the shovel for a long time, even to loosen the soil, this option is more suitable.

The construction is made of reliable elements that have a long service life. The only disadvantage of this device is that it requires two operators to work properly.

ADA GroundDrill-2

Lightweight and reliable device that almost anyone can handle. It is used for private use. Only one operator is needed to operate it, which helps distribute forces properly. This gasoline auger will do any drilling up to 2 meters when working with normal soil. High level of motor power with auger diameter of 200mm.

The design is made with maximum comfort for the user. No effort for transportation, because the device weighs 9.5 kg. Power. 1800 watts. Fuel tank capacity of 1.2 liters. Gasoline tank is made of translucent material that allows you to add liquid in time.

Characteristic features of the earth drill

The tool used to make holes or bores in the ground is called a pit drill. It is widely used in various areas of economic activity, makes holes that have a circular cross section. Drill for the ground on the peorator is necessary when improving the site, installing poles, creating a pile foundation, building arbors or arches, installing fencing, laying utilities, construction of wells or wells. The nozzle is made of thick-walled pipe, metal sheet, metal drill bit, steel disc.

The attachment for the peorator, which is used to make holes in the ground, is called a pit drill

Drill for peorator (for the ground) is available in two versions, depending on the design of the working part. It can have a spiral shape or be designed as a disc-shaped hemispherical blade. Experienced craftsmen prefer to use the second option.

There are several varieties of the product: augers, garden drills and drills for TISE piles. Garden nozzle is the simplest mechanical device. It is a two-sided product with a tubular rod, a handle and a cutter, which has two blades on the opposite side. Such an earth drill for peorator is used to create shallow holes or boreholes.

The auger drill is equipped, in addition to the cutting blades, with a screw auger. The split design and multiple cutters ensure a high working speed. Increasing the rotation speed of the nozzle contributes to the penetration of the tool to a certain depth.

The TISE earth drill is equipped with a supporting base and supplemented with some elements. A soil extractor with auger plates and special cutters provides fast extraction of soil from the pit. Thanks to the cylindrical drive unit it is possible to make a perfectly flat hole in a vertical position. Extensible boom section helps to adjust the desired depth. If you find obstacles in the ground, the guide pin comes to the rescue.

Earth drill bits can be screw-type, garden-type or for TISE piles

Tags: earth drill, garden drill, earth drill

Комментарии и мнения владельцев 136

Cool! Let me use it, please)))) for a couple of weekends.

I made a similar one, but with ordinary metal. Made a circle and cut in halves. It’s a good thing, but not everywhere

Make struts from these blades to the main pipe so they don’t sag. It will cut better.

took note, at the cottage need to put a new fence, the old has fallen down. And there’s a bunch of old disks lying around. Thanks

I have and have been using the factory drill (you may see it in the picture below) with interchangeable blades for several years, and I think the teeth are useless here. If they had managed to mount it on two cutting edges, maybe the effect would have been better. It would be nice to make a parting bar on half of it, it would be convenient in shallow drilling.But that’s just my opinion.

Well done!Thanks, I’ll take note, the old disk has been lying around for a long time.

You just can’t turn it if you bump into something while drilling. Those teeth would only get in the way. Apparently the author stepped on this rake and turned the disc back.

The teeth are kind of facing the wrong way? Or am I missing something??

It’s all right there. See the following pictures.

Last year I made it for digging fence posts. Now I want to improve it, i.e. add a rod for deeper drilling.

It’s a great drill, I have two of them, one for 200 and the other for 350. I only cut the disk in half instead of completely and bent it.

My father and I did the same thing. It worked for six years. Recently, one half of the disk broke off. One tip: do not drive it deep or you won’t be able to pull it out. You have to drive it 10-15 cm and pull it out. Drills great! It’s cheap and hard. )))))

In the first photo, the disk is correctly positioned, but in the last photo it is the other way around. imho.It’s a great idea, I’ll bookmark it.

at what maximum depth is it possible to drill, and I need to put up posts for the fence, so I thought about your tool

I got it, I’ll have to make one, thanks for the idea and the instructions!

Just do not drill as deep as possible))), or you will not be able to pull out later.

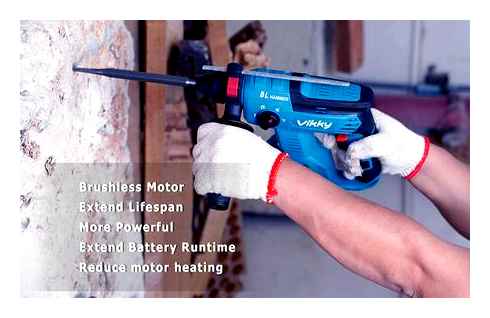

Hammer Drill Vs Rotary Hammer Drill And Why SDS Is A Must

What is the maximum depth you can drill to, as I need to put up posts for the fence, so I thought about your tool

After making it, tested it immediately. I drilled 300 mm for a test run.

The idea is good, but for my taste, I would correct it a little.The disk isn’t cut in half, just half in half. I’m confused. In short, we saw the disk from the edge to the middle hole on one side. Put a slight angle to the pipe, tack, bend to form a spiral, and again tack, then weld completely.This is how I think it will dig into the ground.To be honest, here is a whole bunch of science, and in fact did a long time ago, as written and works great, he dug a fence without much trouble.

It’s not easy to bend the disk without heating it up! It’s not dented, it’s tool steel. Even though it’s Chinese.

Believe me it is not so difficult. We tack one side at the right angle to the pipe. You take a gas wrench, one-inch is enough. Curve. Grab the second side. We’re going to have to weld it hard.I did it myself. Not with the Chinese disk, but with the old, half-abused Soviet one. Hanging in the garage from a sawmill for who knows how many years.I don’t exclude that it was overheated at some point.

When I was making mine, I didn’t just do it at an incline, but with a little overlap with a screw, and now when you take it out of the hole the earth doesn’t spill back through it.

If you think about it, do not press the disc against the ground with your foot because it is fragile.on the border of the seam will break off, I checked it personally.Although I had a disk made of all fasteners, the Soviet and here with pobedit))

Almost every owner has a torch. It is functionally different from a drill in that you can combine the process of drilling with chiseling. Such functionality allows to make a hole in the hardest and most solid surfaces. Sometimes local craftsmen are able to use the peorator even for drilling holes in the ground.

Rules for safe use of the tool

In order to ensure safe working conditions and effective use of the tool when working with the pen, a number of rules should be followed:

Always use personal protective equipment for eyes, ears, hands and feet; inspect tools before each start of work; when drilling long holes, start with short bits and drill gradually; long continuous work leads to overheating of the gearbox and anchor winding. In this case it is necessary to let the gearbox cool down. Allowable idle and loaded cycles are given in the tool passport or operation manual; keep greasing of drill shanks. it should be done with lithol or solidol every 150-200 drills. Some sources recommend the lubrication of the drill shanks every time the drill is inserted in the chuck; timely maintenance of the tool. the scope of the maintenance work and its intervals are specified in the machine certificate; if you work on hard materials, you should use liquid cooling of the bore; if you work intensively, you should periodically cool the bore. The metal of the working tool (core drill) changes its mechanical properties (hardness, elasticity) irreversibly in the course of overheating. If the core bit is not cooled down in time, it becomes unsuitable for further work. There is no rationing of the working time of the drill. This depends on the power applied to the torch, the material to be drilled, the intensity of the drilling, etc. It is extremely dangerous to determine the temperature of the drill by hand

It is better to pay attention to the heat radiating from the body of the drill. overheated drills often change color to a darker shade, sometimes with a blue tint.

For long-term drilling of especially hard materials and in order to avoid overheating of the drill, a forced liquid cooling system should be used. This system is realized by feeding a cooling emulsion or plain water into the drilling area. use thin tubes or special water sleeves.

In order not to complicate the work, it is enough to cool the drill in a prepared container with water at regular intervals. These intervals are set by experimenting with the temperature of the drill

It is important not to over-calculate the auger. Do not operate it in a condition in which it changes color

When the lights may be blinking?

If your power tool is equipped with warning lights, the warning light may indicate a malfunction or failure of any part or mechanism. If the red light on the torch blinks, you should refer to the instruction manual of the device.

Faults in the chuck

Because the saw works in very hard conditions, it cannot avoid damage. The most frequent failures of the cartridges peoratora. Sometimes the auger may fly out of the pen, indicating that the cartridge ball or washer is worn. In this case it is necessary to replace them according to the manufacturer’s instructions.

If you use the unit incorrectly, the auger in the gauge’s cartridge may be broken. In this case, there are two possible developments.

First. remove washer, plastic cage and stopper. Remove sleeve and ball retainer. The drill shank should be free to come out of the shaft.

Another variant. the rear part of the shank is flattened. In this case it is necessary to disassemble all drill shank in order to “sink” it into the tool’s shank. This procedure can be done by yourself if you have enough experience or if you have at least a detailed disassembly diagram. But it is better to leave this job to professionals.

Important: In order not to break the drill in the torch, it is necessary to regularly remove it, inspect the shank, remove dust and grease, as well as apply new grease.

Use of the tool according to the requirements of the manufacturer will give you many years of reliable service.

Screwdriver bit holder

Why do you need it when you can buy an excellent electric screwdriver for a decent price?? For example, you are a fitter and you use a cordless electric screwdriver, but you also use a peorator. But sometimes it happens that the battery of a screwdriver “died” at the most inappropriate moment, and the replaceable battery turned out to be suddenly zeroed out too (by coincidence. hello to the partner). And sometimes you need to work with fairly large hard fasteners, and a light brand-name electric screwdriver to kill on them is not very willing. The torch will help.

Theoretically, you can put in a jaw chuck with SDS tail. But then the massive tool becomes even heavier and more dimensional. Such chucks “wobble” noticeably in the torch, so it will be harder to work with screws, and there is a feeling that this factory-made device breaks the clamping/impact mechanism of the torch.

It is much easier to simply weld either the bit holder or the bit itself to the broken drill. the short bits in PH2 format, designed for “black” screws, are used most often.

Pit drill

The owners of summer homes or private houses are often faced with the need to dig holes for fence posts or pile supports. To drill the earth, both manual tools and those equipped with an electric or fuel-powered (e.g., gasoline-powered) are used. In the first case, the work will take more time, as well as require more labor costs. Buying or renting powerful devices is not cheap, so craftsmen have invented how to make a homemade drill from a lever.

But homemade tools, compared to their factory counterparts, have the following disadvantages:

Structurally, homemade devices consist of three parts:

The last 2 parts of the device can be made by your own hands. Even a special nozzle (auger) for drilling, which is attached to a powerful peorator or drill is sold. The working tool made in this way is shown in the photo below.

The important thing is the power value and the number of revolutions of the rotary table that will be used with the drilling device. The optimum value of the first parameter for the manual model of the homemade drill is 2 kW. it should be taken into account that, depending on the number of revolutions, the core drill can be connected directly to the drive shaft or through a gearbox. For 2 kW models, the latter is not needed.

the optimal speed for drilling is 60 to 300 revolutions per minute of the working tool. This value depends on the properties of the soil on the site.

In the first case, a more powerful tool (with more torque) is needed.

Algorithm of making a homemade drill

To make your own hands a drill for pits, you will need, in addition to the torch, the following tools and materials:

- angle grinder;

- Welding machine with the appropriate grade of electrode for the metal used;

- electric drill;

- unnecessary peorator drill;

- metal fittings or bars for making the bar;

- material for the cutting part;

- cable and sockets to make the simplest extension cord.

the work of converting the geared auger into a device that can be used for drilling holes in the ground consists directly in making the nozzle. All work is performed in this sequence:

- cut from the rod or tube with the help of an angle grinder a piece of the desired length (about a meter is enough, if the power of the tool 2 kW);

- the blades are attached to the lower end (ways of connection and features of design of the cutting part are considered below);

- cut off the base of the auger to fit the bit into the drill chuck

- weld the cut fragment to the tube.

The simplest version is ready to use in the work. If you do not use the base of the old geared auger, it will be necessary to milling out a seat from the rod for the tool chuck or for the used adapter.

In addition to the manual model, it is possible to make a semblance of a stationary drilling rig, a possible version of which is shown in the photo below.

To ensure the power supply of a homemade hole-drilling machine, you will need to buy or make your own extension cord.

The operation of the created device is shown in the video.

making the cutting part

- disks from circular saws of suitable diameter;

- Complete augers from factory-made power drills or agricultural machinery;

- metal sheet, from which circles with the required diameter are cut out, sharpened and bent.

the cutting part can be detachable (with a bolt connection) or fixed (welded to the rod). both options are shown in the pictures below.

The design of the cutting part must meet the following parameters:

- be larger in diameter (5 mm is enough) than this parameter of the created holes;

- the angle between the blades must be 25-30 degrees;

- the front (cutting) part of the knives should be sharpened at an angle of 45°-60°.

It is desirable to make the tip of the drill from a drill designed for metal drilling, so that the tool enters more easily into the ground mass.

In essence, converting peorator into a vibrator or earth drill is the creation of appropriate functional and size nozzle. Difficulties can arise only if you yourself prepare the planting place on the bars for a chuck or adapter. In general, making the options considered does not require much time and effort.

Pit drill

Many people know that an old wood disc makes quite a good drill bit, which can be rotated by hand or charged into an electric screwdriver. Peorator is also able to automate this difficult task quite well. take a hole-drilling machine and weld the SDS shank to it.

Or weld a disc directly onto the spiral part of a wood drill.

Do not throw away a broken drill bit. useful tips

Masters who regularly work as a drilling machine know that drills are an expendable material. Drills wear out, shrinking in cross-section and preventing the use of fasteners of a given diameter. In an unequal battle with reinforced concrete, they lose their carbide tips, and sometimes break at the shank itself. However, do not immediately throw out your old tools in the trash, because you can make many interesting things with them.

The essence of rework and necessary tools

As a rule, “dabblers” go two ways. Someone uses a broken drill as a convenient metal dummy for making the necessary hand tools. Others let the extant drill shank be used to supplement it with a new working part and use the resulting tooling in the rotary tool (further work can be performed with one of three possible modes: only impact, only drilling, combined mode).

For most modifications of the second type, it is necessary to have an angle grinder with a cutting wheel for metal at hand. You will also need a welding machine. To achieve a decent “culture of installation” does not interfere availability of a vice, to clamp the parts of equipment before welding. In some cases, the sharpener also comes in handy.