Review of chain saw attachments on angle grinder from TMG, Sturm, Wolverine and from Aliexpress, as well as how to make their own hands

The chain attachment on the angle grinder is a special adapter that allows you to turn the angle grinder into a small but productive electric saw. They can be used to trim smaller branches on trees or shrubs in the garden. Review of the most popular models, their technical characteristics, as well as ways to make such a device at home, we will consider in today’s article.

An adapter that converts your hand-held angle grinder into a hand-held chain saw. Designed for work on the angle grinder with a disc diameter of 115. 125 mm. Length of guide bar. 30 cm. It is quite enough for small garden works, as well as for making firewood for the winter. It is made of iron-silicon alloy, which gives the construction flexibility, strength and reliability.

Saw chain with 3/8″ pitch for precise and clean cuts in wood. The nozzle is completed with a cistern, which provides continuous forced lubrication of the saw blade.

Metal handle with rubberized inlay provides a secure grip in the hands of the user. Additional ease of use is provided by metal hitching teeth. stop.

- Brand. Neroff;

- model. 125;

- The native land of the brand. China;

- the country of manufacture. China;

- class. household;

- bar length, cm/inch. 30/11,5;

- chain thickness, mm. 1,3;

- Warranty period, months. 12;

- weight, kg (bar, chain). 1,52;

- price, in rubles. 1400.

Watching the video you can see the detailed process of angle grinder conversion to a manual chain saw and familiarize yourself with the equipment included.

Model range of power saws Lesnik

Today the company offers the buyer four models of electric saws. They do not have too big differences and all belong to the household class of tools. However, according to the reviews of the owners, all Lesnik electric chain saw models are quite reliable in use, have durable engines and good performance.

Forester 1814

The model belongs to the household class of tools, is very popular among rural residents and owners of small summer cottages. The electric saw is equipped with a 1.8 kW motor, which allows it to be used for repair and construction work, sawing firewood, garden and hedge maintenance. The tool has a compact size, high maneuverability and low weight (3.8 kg). We note the high-strength plastic from which the Lesnik 1814 electric saw is made and the good moisture and dust protection of the case.

Today, this model can be purchased at a price of 4. 100 rubles.

Forester L1814

A more advanced version of the previous model. Features an improved anti-vibration system and greater performance. At the same time, the engine power remained the same. 1800 watts. The saw is equipped with a 35 cm bar and a 52 link saw chain. The Lesnik L1814 model has gained wide popularity among builders due to its high performance, low weight and the absence of harmful emissions. Also, the tool can be used for harvesting firewood, longitudinal and transverse sawing of wood.

Russian online stores offer this electric chain saw at ranging from 4 to 300 rubles.

Forester 1816

The main difference between this model and the previous ones is an improved engine, which made it possible to increase the length of the saw bar up to 40 centimeters. The electric saw can be used for various chores, repairs and construction of residential and other premises. It should be noted the high quality of the plastic from which the body is made, the presence of a lock against accidental start and excellent ergonomics of the tool. The manufacturer of the electric saw Lesnik 1816 took care of the presence of an engine protection system against overheating and overloads, as well as the “Soft Start” function.

Today this is the most popular model of this manufacturer; you can buy a Lesnik 1816 electric chain saw at a price of 5. 200 rubles.

Forester 2016

Unlike previous models, this electric saw is equipped with a more powerful 2,0 kW motor. In addition, the automatic lubrication system of the saw set has been improved here, due to which the unit began to consume 20-30% less oil than previous models. The saw has excellent operational characteristics, differs in the ergonomic case and attractive design. Operator safety is ensured by an inertial chain stop brake and an accidental activation lock button. The manufacturer also took care of protecting the tool from overheating and overload. The Lesnik 1820 electric saw can be used for felling medium-sized trees, harvesting and sawing wood, and other household needs.

Today, this model can be purchased at a price of 5 to 500 rubles.

Chisel, Half-Chisel and Chipper

There are three basic kinds of teeth on modern saw chains: chisel, half-chisel and chipper.

The sharp corners of the chisel chain easily separate wood fibres and give the fastest and most efficient way of cutting soft wood.

The half chisel is a slightly rounded tooth. This keeps the tooth sharp for longer, especially when cutting hard or frozen wood and in dirty environments where a saw chain with chisel teeth dulls quickly. A chipper chain is similar to a sledgehammer chain, but the angle of the teeth is even more rounded.

Cold start

When the engine is warm, the saw is started without the choke. Follow the instructions above, skipping the points about the choke. If the engine is difficult to start, open the choke halfway. The half-open position is reached by using the choke lever, after which the lever returns to its original position.

How to fit a chain on your chain saw

A chainsaw may be used for quite a bit of work. The main cutting element of such a tool is represented by a chain with various blades. Modern designs are characterized by self-service. The cutting edge wears out quickly if you cut for long periods of time or if you don’t follow the basic recommendations. This is why it is necessary to remove and sharpen the chain, and then install it. There are quite a few things you should know about this procedure.

Useful hints on how to attach the chain to the chain saw

On one end of the bar there is a slit and two holes on either side of the bar. When you install the guide bar, the slit on the special pins on the body of the electric saw, and one of the holes on the tensioning mechanism pin.

The second hole on the bar is for transferring lubricant from the oil channel to the bar groove.

The chain is pulled onto the chain drive sprocket on the body of the saw, and onto the sprocket at the end of the guide bar. When installing the chain, you must consider the correct direction of rotation, which is usually indicated on the product itself.

After a chain has been installed, the chain drive sprocket is covered with a guard, the clamping nut of which is not screwed all the way in to make sure the bar is not completely clamped.

Chain tensioning Regulation of the chain on Chinese electric saws is carried out by a special tensioning screw, the head of which has a slot under the screwdriver. It is located at the end of the device housing. To tension the chain more fully, turn it clockwise.

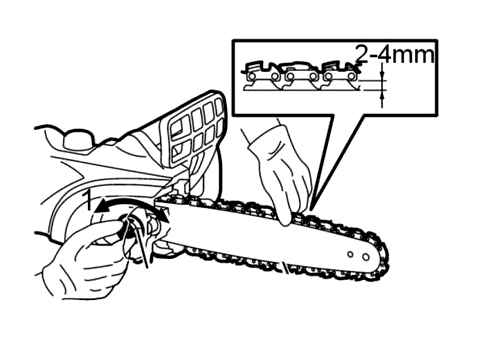

Turn the tensioning screw until there is no more slack in the chain. Then turn it by hand on the bar toward the guide bar body. This is necessary to straighten the chain teeth in the guide bar groove.

If the chain is loose after turning it, retighten it again.Then the bar is taken by its free end, lifted up to the stop and in this position the slack in the chain is removed again.

At the last stage the clamping nut on the cover that covers the drive sprocket must be screwed in completely. The guide bar is held in the “raised” position.When tensioned correctly the chain should come out of the guide bar groove on both sides by about 3-4 mm and when lowered it should fit back into the groove.

Checking tensioning after use When the chain is tensioned, it can only be definitively checked after a short field test. For this reason it is necessary to make some test cuts with it.

It is not uncommon for the chain on the guide bar of a power saw to come loose after test cuts. this happens when the chainrings are contaminated and the grease has dissolved the contaminants during operation.

How To Set Up A Petrol Chainsaw Chainsaw Installation| Tree Cutting Machine petrol Assemble Chainsaw

If this happens, the chain must be retightened by loosening the clamping nut on the guard and lifting the free end of the bar up. Of course before you do this the saw has to be disconnected from the mains.

How to Install and Tension a Chainsaw Bar and Chain

after completing the tensioning adjustment, always check that the chain is running in the correct direction without tension, that it is not overtightened. To this end, it is unlocked by pressing the start button and pushed forward by the teeth with a screwdriver. If it coasts a little, it’s okay.

And lastly. Never adjust the saw chain tension when it is hot or not lubricated otherwise there is a risk that the chain could break during the next sawing session.

Full video on how to tension a chainsaw chain on a chainsaw and electric saw.

Features

The construction of the table consists of only two elements:

If desired, craftsmen can complement the product:

Such a furniture item must be sufficiently strong and reliable. Keep in mind, the more power of the saw, the higher will be the load on the surface of the table.

To the advantages of the homemade table for the circular saw can also be added:

- comfort and convenience in work;

- saving money;

- High productivity of labor;

- Possibility to make a product based on personal needs and workshop specifics.

Material

You can make a circular table with your own hands from different materials. The most common are:

Each individual option has its own advantages. With Laminated chipboard, plywood and fiberboard is easy and simple to work with. In addition, these lumber is characterized by an affordable cost. But the products made of wood have higher durability and technical characteristics.

How to make a device for cutting wood with their own hands

If you have the desire and enough free time to make the attachment “Chainsaw” on the angle grinder can be at home criteria.

The necessary tools, materials, skills

For this, in addition to most angle grinder, will need a welder or a drill or drill press, as well as the ability to use all that. The necessary arsenal of tools should include:

- a guide blade with a chain; ;

- iron tube;

- Iron sheet width of one to two mm;

- Drilling machine or drill;

- drills and metal cutting bits;

- welding semi-automatic machine;

- A set of wrenches;

- grease deep penetration.

What angle grinder to choose for this purpose

If you do decide to make a saw adapter by yourself, it is worth the right approach to the choice of angle grinder. In this case, it should be remembered that the chosen model must have sufficient power, performance and margin of safety.

For domestic use, angle grinders designed to work with disc diameters of one hundred and twenty-five mm are suitable. Power of their motors usually does not exceed one thousand watts. For them, you should select the guide bar length of ten to fourteen inches.

Step by step instructions for making

In order to make a chain attachment to the angle grinder, the following steps must be performed:

- Find a metal tube of the required diameter. It must be dressed on the gearbox of the angle grinder without gaps and backlashes.

- With an angle grinder or a stationary circular machine cut from the pipe billet height of about three centimeters.

- Make the base of the future adapter from a sheet of metal. From the resulting workpiece, cut off the side segment.

- Make a round hole by using a metal cutter or a metal drill bit at the opposite end of the workpiece. Subsequently, the drive sprocket will be installed in it.

- Position the guide rail and mark the position of the fixing bolts on the resulting piece.

- Drill two holes for the bolts.

- Position the bolts in the hole, screw them on and hold the guide rail. It is recommended to weld their heads to the base of the adapter for greater reliability.

- Place the metal ring cut out earlier on the side of the bolt heads and weld it to the base of the workpiece.

- From the metal strip cut two blanks that will later fix the adapter and the angle grinder to each other.

- Drill through holes in the workpieces. They must match the diameter of the fixing holes on the angle grinder.

- Position the blanks at the corresponding places on the tool and weld them to the adapter’s base.

- Set the received workpiece on the angle grinder and tighten the fixing bolts firmly. After that, mount the guide bar, the chain and the drive unit on the shaft.

- Cut a strip from a metal sheet. Bending it to the contour of the adapter, weld it to the base.

If desired, you can deburr the irregularities created in the manufacturing process and paint the nozzle. After that, you can assemble the resulting adapter and get to work.

How to put the chain and guide bar on a chainsaw correctly! ASSEMBLING

By watching the video, you can get acquainted with the nuances of making a chain attachment on the angle grinder and see its application in practice.