How to use the alternator on a power tiller correctly

To create an electric generator for 220 with their own hands at home for domestic use, it is necessary to perform a number of activities. To begin with a scheme and already according to it determine the details and the order of assembly.

List of main parts

To assemble an electric generator for 220 V with your own hands, it is necessary to choose in advance all the main parts of which it consists of.

- It is very rare to find a 220 volt generator without an engine. It can be assembled independently. But in this case, the entire process will take quite a lot of time. To reduce the procedure for making a generator, the engine can be borrowed from the damaged equipment. Optimal options are engines from washing machines, pumping stations, power tillers, chainsaws. For more powerful ones, you can remove the car engine.

- Electric starter. It is desirable to use a prefabricated part that has a winding.

- Electrical wires and insulating tape.

- To achieve a stable supply of electricity, it is necessary to use transformer or rectifier designs. It is relevant in those cases where the result is electricity with different power. With a transformer you can increase or decrease the power.

Assembling principle

Once all the components are found and prepared, proceed directly to the assembling of the self-made alternator 220 V. The principle consists of several steps.

- Initially it is necessary to make a calculation of the power of a homemade power plant. To do this, connect the motor to the mains and determine the number of revolutions. A special device called a tachometer will help perform the calculations. The result should be increased by 10%, which is allotted to compensate for the load. It will be able to prevent overheating of the motor during operation.

- The next step is to select the capacitors. At the same time it is necessary to take into account the power, for which the generator is designed. In this process, special tables, which are in all normative documents, SNiP and GOSTs, can help.

- An important point. grounding. Since we are dealing with electricity, its absence can lead to a traumatic situation. In addition, without grounding the terms of operation of the device are significantly reduced.

To assemble the self-made alternators of alternating current of 220 V is quite simple. Prepared parts are connected to each other in the following sequence: capacitors are connected to the motor, as indicated in the diagram

Pay attention to the fact that the capacitance of each subsequent capacitor is the same as the previous one

Notes on usage

The considered variant is very simple both in assembly and in use, but has certain drawbacks:

- It is necessary to constantly monitor the temperature of the engine, because you can not give him to overheat.

- The duration of operation is insignificant: the more the generator works, the less its power becomes. Therefore, from time to time give the homemade power plant an opportunity to rest. The optimal engine temperature is 40-45 degrees.

- The lack of automation will require the presence of the user during operation. It will be necessary to take different readings and monitor the process.

Electric generators can work not only on gasoline. For them any energy resource will do, for example, firewood or wind version. But the power of such devices is insignificant, and the resources themselves will need quite a lot, which becomes costly.

How to properly put a generator on a single axle tractor with your own hands

Many farmers are interested in how to put a generator on a single-axle tractor. The generator is installed for powering the headlights of the cultivator and charging the battery device. Installing a generator for a power tiller, it is necessary to take into account that the power of the machine must be greater than the applied load. This is done so that there are no power surges in the generator when the equipment is running.

All connections, whether in a single phase or three-phase network are made completely identically, except for the number of power wires. The only important nuance concerns the so-called control phase. if you connect a starter to the network, its main contacts connect and disconnect power wires from the network, and power for the electromagnetic coil must also be taken from somewhere.

In a single-phase network there is no problem. there is one phase and there is no such an issue, but in three-phase it’s a bit more complicated. there are L1, L2 and L3. Without going into technical details, the answer here is one. any of the phases can be used for control circuits, but only one. Т. е. if the coil KM1 is energized from phase L3, then the control of the other starters, the “start” and “stop” buttons must also be “hung up” only on it. To do this is not difficult. just mark what color wire on the desired phase, and if the cable with single-colored strands, then glue or draw markers on them.

Electrical connection diagram of the generator

When carrying out the installation and connection of the generator, remember that the wrong connection of the electrical circuit will cause a short circuit in the winding of the generator. To avoid this, you must connect the device strictly according to the instructions in the algorithm below:

- Connect the alternator to the electronic unit of the agricultural unit by means of two wires. The unit itself is equipped with 4 wires, 2 of which are blue. this is where you connect the power converter;

- After that, you will be left with black and red wire. Connect the first of them to the mass of the engine of the motor block;

- The red wire provides converted voltage that is needed to power all the electrics on the power tiller without the battery: the headlights and the horn. If an alternator is installed on a single-axle tractor with a battery, the converted energy is fed to the battery and the electric starter of the unit. information about connecting an alternator to a single axle tractor can be found in the following video.

A generator connected in this way works according to a fairly simple scheme: The single-axle tractor-mounted alternator generates electrical energy, after which it goes to the rectifier available in the electrical unit. The unit contains a current regulator and a voltage equalizer designed to protect the electrical system from voltage fluctuations and control the amount of energy generated.

When starting the power tiller, its engine transmits torque to the rotor by means of a belt. During this time, the generator begins to produce the desired amount of energy and feeds it to the electrical unit. Due to the fact that a certain amount of battery power has been expended when starting the motor, all of the electrical appliances on the power tiller will receive power from the unit. As soon as the unit’s battery is charged, it will again become the main source of power for the electric appliances of the power harvester. If the battery is discharged again, the power will come from the electric unit. This process is repeated continuously as long as the single-axle tractor works.

How to make a generator on a single axle tractor. simply about the complicated

Make a generator for a motor-block with your own hands is simple enough, if you follow the correct procedure. The work will require an electric motor, which must be installed on the agricultural machine. The generator manufacturing algorithm is as follows:

- First you need to install the electric motor on the frame of the motoblock. It is best to use for this purpose a pre-made frame, screwed to the frame of the machine by means of screws. Place and mount the electric motor in the frame so that its shaft and the shaft and shaft of the regular motor of the power tiller are strictly parallel to each other;

- Next, you will need to install 2 pulleys. one of them install on the shaft of the gasoline motor of the power tiller, and the second. on the shaft of the used electric motor. For the proper functioning of the whole system the correct choice of the pulley diameter is essential, as it is the pulley diameter that determines the speed of the electric motor. In order for the alternator to run smoothly, the diameter of the pulleys should be the same as the nominal diameter printed on the pulley packing. Even better, if the actual diameter of the pulleys will be 10% larger than the nominal;

- Having completed the mechanical assembly of the generator, you can proceed to connecting it to the power tiller. Use the diagrams in the preceding pages to help you do this.

Self-made generator from an electric motor does not require special care. However, in order to extend the life of the machine, a number of rules should be followed.

Pay attention to such nuances when operating your power tiller:

- if you find that the electric motor installed on the single axle tractor became very warm, then replace the standard capacitors of the motor with elements of lower capacity;

- the voltage of the capacitors installed in the alternator is very important. Capacitors with a voltage of at least 400 volts are considered optimal for operation. If the standard capacitors of the electric motor have a lower value, then replace them with suitable elements;

- try to operate the single axle tractor with an installed generator in dry weather, because moisture, which may get into the electric motor, will inevitably lead to a short circuit inside the electrical system.

Adhering to these rules, you will prevent a failure of the home-made generator and significantly prolong its operating life.

The above methods are suitable for manufacturing and installing generators on the Neva brand motor blocks, as well as agricultural machines of other domestic and imported companies-manufacturers of equipment.

Installation of an alternator on a single axle tractor with their own hands

A generator on a single axle tractor or motocultivator 220 volts is needed to power the electric lamp and headlights, as well as to charge the battery. The latter helps the equipment through the starter to start and further charge all electrical appliances.

To begin with, you need to choose the right alternator. The device power need not necessarily be 220 volts. The main thing is that the power corresponds to the necessary load. For this technique is perfectly suited electric generator from a car or tractor.

If when all the equipment operates the device works normally, without voltage drop, it means that the electric generator is installed and selected correctly.

Installing the generator on the tractor with your own hands is not a difficult task. The main thing is to follow the instructions and familiarize yourself with the key parts of the installation:

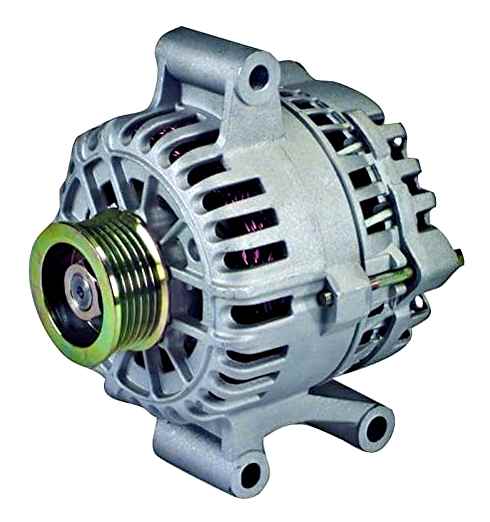

- body. a metal container with tires;

- pulley. transmits mechanical energy by means of a belt to the shaft of the device;

- voltage regulator. when the load level changes, it keeps the voltage at the same level;

- stator. the rewind, within which the power of the motor vehicle is made;

- brush node. an element made of plastic that helps the device to do its job properly and accurately;

- The rotor is a steel shaft with two bushings between which there is an excitation winding.

1.1 Electrical diagram of the installation

To put an alternator from a car on a single axle tractor, it’s worth knowing that if the alternator is not properly connected to the electrical circuitry, the winding is likely to catch fire. The electrical generator is installed with two wires. There are four wires in the unit, two of which are blue. It is with these that the inverter can be connected. The red wire outputs voltage, powers the headlights and signal, and charges the battery. The black wire is connected to the power device array.

The electrical circuit works quite simply. The generator produces electricity, which passes to a rectifier in the power unit, which is equipped with a voltage equalizer and current regulator. The equalizer keeps the voltage from fluctuating, regardless of the amount produced. And the regulator controls the current that goes into the battery.

Delco 3 Wire Alternator Conversion Sketchup for Ford Tractor

The engine starts and transmits the torque to the rotor with the help of the belt. The device, in turn, generates a voltage to the electric unit. Starting the motor has reduced the capacity of the battery, which means that the devices will take electricity from the electrical unit. This will be the case until the battery charge is restored and all the devices are powered by the battery again. to the menu

How to make a single axle tractor alternator. simple about complicated

To make a generator for a power tiller with your own hands is simple enough, if you follow the correct order of actions. It will require an electric motor to be installed on the farm machine. The generator manufacturing algorithm is as follows:

- First you need to install the electric motor on the frame of the motoblock. It is best to use for this purpose a pre-made frame, screwed to the frame of the unit by means of screws. Place and fix the electric motor in the frame so that its shaft and the shaft and the shaft of the regular motor of the motoblock are strictly parallel to each other;

- Next, you will need to install 2 pulleys. one of them set on the shaft of the gasoline motor for the motor block, and the second. on the shaft of the used electric motor. An important role for the proper operation of the whole system is played by the correct selection of the diameter of the pulleys used. it is these dimensions that determine the frequency of rotation of the electric motor. Pulleys should have the same diameter as the nominal diameter printed on the pulley packaging to keep the engine running smoothly. Even better, if the real diameter of the pulleys is 10% larger than the nominal one;

- After completing the mechanical assembly of the generator, you can move on to connecting it to the power tiller. To do this, use the circuit diagram above.

Homemade generator from an electric motor does not require special maintenance. To extend the life of your machine, however, you must follow a number of rules.

When operating a power tiller, pay attention to such nuances:

- If you find that the electric motor installed on a single axle tractor has become very warm, then replace the original motor capacitors with elements of lower capacity;

- The voltage of the capacitors installed in the electric motor is very important. Capacitors with a voltage of at least 400 volts are considered optimal for work. If the standard capacitors of your machine have a lower capacity, replace them with a suitable unit;

- try to run a single axle tractor with an alternator installed in dry weather, because moisture that can get into the electric motor will inevitably cause a short circuit inside the electrical system.

Adhering to these rules, you will prevent a breakdown of the homemade generator and significantly prolong the period of its operation.

The above methods are suitable for the manufacture and installation of generators on the motor-block brand Neva, as well as agricultural machinery of other domestic and import companies-manufacturers of equipment.

It’s hard to imagine a single-axle tractor without an alternator. It is it that generates the necessary energy to power the other elements of the device. On how to install it with your own hands, and what nuances should be considered, will be discussed in this article.

Possible problems and solutions

Serious breakdown, of course, without going to a service center or to professional repairers will not solve. But with the current uncomplicated ones are quite feasible for everyone to handle on their own. Among the most common complaints from users are the following:

Otherwise it is clear that the assembly of the motorblade generator is in no way complicated. over, in this case, there is a chance to save significantly on it, as well as to remain in full confidence that it is really made qualitatively, with strict adherence to all norms and recommendations. Of course, this process will not be easy for beginners without experience working with electricity, but what is good, the acquired skill will prove useful in the future.

Block: 5/5 | Number of characters: 829

Alternator Basics, Tips Tricks, 1 wire, Models of GM, FORD, MOPAR from 1960 1980s Autorestomod Episo

How to carry out the installation?

In order to find out how to install the generator on a single–axle tractor with your own hands, you need to know the main parts of the design:

- Pulley. The work of this part is to transfer the mechanical energy coming from the engine to the shaft of the generator through the belt.

- Housing. Often a metal container, consisting of rear and front covers.

- Rotor. Important part, which is a steel shaft with two bushes of the same material. The field winding is located between the two and the field wires are connected to the slip-ring.

- Stator. This is an ordinary rewinder. a set of steel sheets assembled in one package. The part is shaped like a pipe, which is where the unit’s power is generated. The stator can be made at home.

- Voltage regulator. Keeps the voltage at the same level when the load changes.

- Brush Assembly. Plastic part, which plays an important role in the proper operation of the device.

Installation of the generator on a single axle tractor will not take much time, but this is a very important point for the trouble-free operation of the unit. The design is connected to the mini tractor by means of a circuit diagram, which describes and shows in detail all connections.

Possible problems and solutions

Serious failure, of course, without going to the service center or to professional repairers is not solved. But the current uncomplicated ones are quite manageable for everyone on their own. Among the most common complaints of users, however, the following should be noted:

Otherwise, it is obvious that the installation of a motor-block generator does not seem difficult in any way. over, in this case there is a chance to save on it substantially, and also to be fully confident that it is made qualitatively, with strict adherence to all norms and recommendations. Certainly, this process will not be easy for the beginners without experience of work with electrics, but what is pleasant, the acquired skill will appear useful in the future.