Rotor mower for a walk.behind tractor: views and device

Rotor mower for a walk.behind tractor is a removable mechanized element designed to mow small and medium vegetation. Has various configurations of the types of internal structure and the mechanisms of fasteners to the leading unit. The scope of its application depends on the technical characteristics of the equipment.

This device and its modifications are used in several areas:

- hay blade;

- mowing cereals;

- purification of land from wild plants;

- refinement of lawns, personal plots.

In order to get good hay, the grass must be cut closer to the root. This effect is allowed to achieve specialized nozzles on the rotary haying grinder. Others chop the plants during mowing. “Chopped” vegetation is not suitable for feeding livestock, but quickly rolls, turning into fertilizers. This method is used when you just need to clean the space of weeds.

When harvesting, a paired nozzle for grass is used. She carefully cuts off the ears and puts them in a special way. In most cases, cereal crops are sown in industrial volumes, so motor blocks with removable equipment are rarely used.

Rotary mowers help maintain the level of lawn grass in good condition. A special structure of cutting mechanisms makes it possible to minimize the height of the cut.

The efficiency of this device is determined by the features of the terrain. The uneven surface of the Earth can complicate the passage of the walk.behind tractor with the nozzle and interfere with the full mowing.

Varieties

Rotary mowers are divided into several types determined by the name of the final result.

Depending on this, they can:

Depending on the aggregative properties of the mower are classified into two types.

- Suspended. The host can change the height of the cut by raising or lowering the motor block body.

- Traction. The braid for the grass stretches behind the driving node, cutting the grass at a certain height.

Each type of mower is designed for a certain type of work. They can vary externally, constructively and in functionality. The discrepancy of the modification of the mechanism to the type of targeted work negatively affects their implementation. The use of equipment corresponding to target parameters gives the best efficiency.

How and how to lubricate the shafts in the rod of motorcycles

Many new motorcycles, even sold in collection, do not have a lubricant on the shaft of the bar. As a result, it warms up, wears out, a light whistling rattle is gradually added to the sound of a working motor and vibration appears. To protect the technique from premature wear, it is enough to devote 10 minutes and just grease the shaft.

Materials:

First you need to disassemble the bar. In a conventional benzos, it is enough to disconnect it from the upper and lower reducer for this.

If a braid for grass has a collapsible bar, consisting of two parts, then it is even easier. It is only required to remove the connecting coupling in the center and dilute half.

If the braid for the grass has already worked, then when examining the shaft, or shafts in the case of a collapsible bar, you can notice scuffs from the central bushings. Such places and need lubrication.

A small amount of lubrication must be squeezed on a rag or fingers and process the shaft without passes. It is applied with a non.weed layer, but everywhere. Particular attention should be paid to the slots, since they are on the highest load, especially at the time of the knife of the knife braid for grass on stones and other objects.

The greased shaft is inserted back into the stack with a slight scroll. Thanks to this, part of the extra lubricant will remain on the central bushings, where it should be. Rotation will also help the hills to get into their seat on the gearboxes.

If a straight lawn mower with a non.vegetable bar is served, then it is simply attached back to the gearboxes. In the case of a two.part bar, short shafts are inserted into each half. After this, part of the rods join the center. If their slots did not hit, then you can simply twist your lower gearbox with your hand. Further, the jointed rod is clamped back with a coupling.

If the lawn mowing is inflow, such a rod maintenance should be carried out every season. The cord’s lubricant used well withstands high temperature, which excludes oil stoops with long operation of braids for grass. The same composition can also be used for lubrication of gearboxes. In them it can be pressed with a syringe if the tube does not have a nose. The lubrication frequency of gearboxes is higher than the shaft. Typically, manufacturers recommend this every 5 mothers.

How to lubricate the rotary mower to the walk.behind tractor

Group in VK VK.COM/JR_17. After buying a new rotary mower, you need to check the presence of oil in gearboxes. As practice has shown, there is very little it there. Therefore, it is imperative to open and check, in addition, the lubrication procedure must be repeated through a certain period of work. About the amount of lubrication, lubrication points and the period, in this video.

When buying a new mower, do not be too lazy to manually scroll through the pulley. Disks.Listen and check tactilely. Are there any backlash and beats. eccentric rotors. After the purchase, disassemble the corner gearbox braids. Clean from the factory lubricant (such as lithola and solidol).Prepare a lubricant. A mixture of transmission oil with a lubricant of a clock. The consistency of fluid sour cream. Fill in the interior of the frame with a lubricant by 75-80 %. Close the lids of the gearboxes and. Having attached the mower to m \ b (without disks), scroll for 5 minutes. Check the touch. Are gearboxes warming up. Open gearbox covers and visually estimate the quantity and density of lubrication. Too liquid will flow out and spray. too thick will stick to the buildings. Unlike factory lubrication. This lubricant does not allow gears and they always work in an oil bath. Once a year (before the mowing), it is useful to open and evaluate the quantity and consistency of the lubricant.

We interfere with the lilest from the nigroll to the cream.shaped state and all. Litol is thick for the gear- flying to the sides

Popular models

Domestic manufacturers produce these units in various configurations. A common braid is the one that is produced under the Zarya and Zarya 1 brand. the product of the Kaluga OJSC Kadi.

This multi.purpose model. It is distinguished by high production indicators, ease of management, ease of installation and maintenance. The mechanism of attaching the braid frame to the rotary node of the motor block is simple and universal, approaches almost all domestic cultivators.

Another model widely used by farmers is KR-80. It is suitable for operation in combination with the motoblocks “virgin lands”, “Neva”, “cascade”, “Oka”. You can mow grass, coarse shrub, cereal crops.

Similar characteristics are possessed by the rotational suspension mower KRN-1. Produced in the territory and Belarus. Installed on most leading units. It has modifications designed for industrial field processing.

Before acquiring an installed addition to the walk.behind tractor, it is necessary to find out the characteristics of their compatibility. Daewoo Daewoo Daewoo Cultivator is sometimes sold with additional nozzles from the same company. They easily combine with its leading mechanism. Cosocosers of other manufacturers may constructively differ, which will prevent or nullify the attempt to connect a walk.behind tractor with a suspended unit. When buying this or that agricultural equipment, it is worth paying attention to this issue.

In the case when a hinged mower is not intended for use with a particular engine, you can purchase an adapter. If there is no one, it may require a refinement of the connecting mechanism.

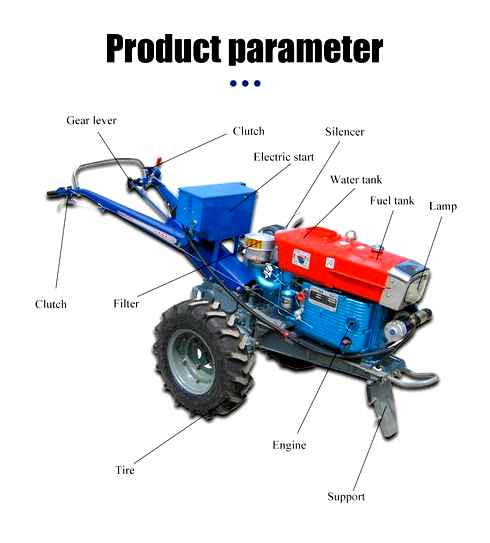

Design features

Devices produced by different companies can vary in external and some technical data. The principle of the functioning of such units is identical and dictates an integral list of nodal blocks included in the design.

Standard rotary braid for grass is made of:

- frames;

- subframe;

- balancing mechanism;

- cutter;

- field divider;

- traction fuse;

- racks;

- protection of the cutting apparatus.

Frame. element designed to attach the nozzle to the walk.behind tractor. Has two axes facing the sides. One of them serves to fix the frame on the lower rods of the leading apparatus. The second is attached to the second from the overload of the rod holding due to bolts and two nuts. An element with a bracket will join the frame, which allows you to install a subframe.

The subframe is a welded part connecting the frame and cutting element. It consists of a rectangular case. On the one hand, the tube with bushings introduced into it is welded. In the middle there are “ears” designed for fastening transport traction and device that regulates the height. The side of the bracket is on which the traction fuse is attached to. On the subframe, the drive itself and the protection of the belt transmission are fixed.

The balancing mechanism is designed so that the cutting device repeats the terrain relief. Thus, the best mowing of vegetation is achieved. Using this mechanism, the mower is also converted into transportation mode. Its adjustment is carried out by special tension bolts.

Cutting device performs mowing. Its body serves as a whole crankcase. The cutting elements are based on the soil through a special pallet installed below. The cutting device can have on its body how much rotors. There are usually two of them in the motoblock modification. Rotors are equipped with two knives. The transmission of mechanical effort from the motor to knives occurs by means of a belt of traction, gearboxes, a number of shafts and gears.

Field divisor helps to separate mowed and dwarf grass. It consists of their shield, springs and bolt fasteners. The spring mechanism allows the divider to move back at the time of overflow of the cut vegetation.

During the mowing process, the cutting mechanism may come across an obstacle. In order to avoid a breakdown in this situation, the rotary mower is equipped with a traction fuse. Using this node, a braid for grass can deviate from the working position to the moment established by the user.

The stand helps to hold the hinged unit in a convenient position at the time of its connection to the walk.behind tractor.

The assembly knives rotate at high speed. For the safety of a person using equipment, they are placed in a protective casing. It can be made of light metal or tarpaulin fabric.

Various modifications of rotary braids can differ in the presence of certain details. Some of them can be purchased, and others are made independently.

Peculiarities

As you already understood, you can connect the rotary mower “Dawn” to the walk.behind tractor. The unit has a number of features. Its design is practical and simple. The technique confidently and effectively mowns various types of herbs, including grain crops with a thick stem with a diameter of up to 10 mm. The belt drive interacts with the working part by connecting with the pulley of power selection or direct connection to the engine (Zarya-1).

the DPS Lucio of Overwatch 2

Freely fixed knives make it possible to weaken the effect of soil irregularities on the result of work. In addition, such a design allows you to quench areas with mole.holes, dense edges and roots. As a fuse, in the case of a rigid obstacle, a system of spot welding fixers is provided, which break off when the load is above the norm, which protects the mechanism from damage.

What is the mower

Despite the seemingly difficult difficulty, in fact, a rotary mower for a walk.behind tractor with your own hands can be made by a home master without any problems.

Having made a decision on the need to assemble the hayfield with his own, the master is primarily determined with the type of mechanism design and selects one of the three main ones used most often:

Important! A fairly frequent option in the manufacture of a mower for hay independently is the use of a finished hinged device made at the factory as a base of the design. Find the drawings and perform such a remake is the easiest option.

In order to make a mower for a walk.behind tract and not have problems with its maintenance, repairs and functionality in the future, you need to well deal with the features of each of the listed types of units.

Varieties of self.proceeds. rotary

The rotary type of mowing can be used for hayfields or cutting the lawns, but it is necessary to take into account the fact that in the process of work such a mechanism effectively and purely cuts high plants, but with a stunted grass of lawns the situation is different. it simply “shred” the aggregate finely “chips”.

The rotor mowers are knives installed on a rotating disk as cutting elements. The rotation from the engine to the disks is transmitted by the power selection shaft.

The bearing base for the rotary mower installed on the motor.cultivator is a frame from a metal corner.

Important! The rotor of the future unit may well become a tractor, which is recommended to shorten up to 2-4 cm (based on the traction and engine power)-this will not make the part independently and save material, effort and time.

Two circles (D = 0.39 m) are cut out of the metal sheet, you can take two trimmed bottoms from barrels. these will be rotating parts of the rotor. In the middle part of the prepared parts welding, the legs are attached, providing rotational movement. In welding work, special attention must be paid to the strength of the connection, since the load on the joints is high.

A lushwind can serve as source of a disk for the lower support of the rotor, the maximum diameter of which is not more than 45 cm, and the metal pipe (up to 3 cm with diameter) should be used as an axis shaft. In addition, to assemble the design, you must find or purchase bearings (number 106 and 180).

On the support, the fastener is drilled under the lower bearing, and the remaining bearing is mounted on the axial pulley. Now the cutting mechanism with knives is planted on the axial shaft, and the pulley and shaft are fastened with welding.

To carry out the assembly work will be needed:

- welding machine;

- locksmith tool;

- bolted and other species of fasteners;

- metal corner;

- metal sheets (you can use old barrels);

- knives (cutting plates);

- wheel axis;

- two wheels.

Varieties of self.proceeds. segment

Segment.type hayfield can be independently made as follows. First you need to find a square pipe of metal 120x5x1.5 cm (you can cut the canvas of an ordinary braid for grass) and make holes with a diameter of 1 cm (12 pieces at an equal distance from each other) for m8 bolts for fasteners for fasteners. A strip of metal (guide) 0.89 meters long is mounted on these bolts, on which teeth and knives are located on both sides of the pipe.

On the knives there are bends with links and clips for the drive lever, and clamping devices are mounted on the pipe on each side.

The frame of the segmented haymaking is equipped with the support wheel, and the capacity selection shaft sets the cutting part of the mechanism in motion.

The segmented mower made independently allows you to ensure effective mowing of plants, without “chink” them at the same time, which is useful for haying.

Varieties of self.proceeds. on the platform

The platform mower is structurally similar to the rotary, but is much more difficult to independently manufacture, while it is much more powerful and multifunctional. Even the hardest grass can be scooped with its help.

Important! A similar type of agricultural device, made and installed on a single tractor with your own hands, can be successfully used both for mowing grass and weeds in the summer-autumn period, and for cleaning snow in the winter-for this summer cutting knife elements is replaced by special star-shaped nozzles. Even icy snow sediment “submit” to him.

Structurally, a similar type of unit consists of two cylinders, which are connected to the frame and conveyor tape by means of hooks. Rama-chassis is welded from metal corners or channels (you can even use pipes, not thin-walled), on which a small diameter is installed (for example, from an old garden car or stroller) and a panel of a metal sheet (can be replaced with a plywood, but this is not Recommended). The most optimal ratio of the parties to the base is 0.8×0.4 meters.

As a material for working cylinders, you can use large cans without bottom and lids closed from the ends with wooden inserts. It is possible to make such cylinders from sheet metal, for which eight circles are cut out of it: 4. with a diameter of 0.2 meters and 4. with a diameter of 0.17 meters. These discs with the help of bolts are fastened in pairs: small with large ones, and knives are attached to the resulting elements. 4 pieces for each cylinder.

Important! To ensure free rotation of the knives, gaps with a 1 mm disk should be ensured, but at the same time, monitoring the strength of the mounting, otherwise the cutting plates can be torn in contact with random stone, the remains of the tree and other obstacles on the ground.

Operating procedure

7.one. When transporting a mowing in the unit from a motor.cultivator to the place of conduct of work (the engine is turned off), remove the 3 axes from the wheel bushes of the wheels is ensured by the wheel rotation.

7.3. Make sure that the mowing clutch mechanism is in the “off” position (the handle of the lever in the lower position).

7.four. Make sure that people are not near the cutting apparatus.

Attention! Due to friction in cuneiform gear, it is possible to move the knives of the mower without turning on the handle of the cutting apparatus.

7.6. After operating the engine engine for 2 3 minutes. Turn on the cutting apparatus with the handle.

7.7. Smooth inclusion of the clutch of the motor.cultivator will cause the movement of the wheels and the movement of the mowing. All actions to manage the motor.cultivator to carry out in accordance with the operating manual for the MROT motor.cultivator.

7.eight. Periodically clean the starter grid from the seeds of grassy plants.

- in areas with thick and high grass, use not the entire width of the capture of the cutting apparatus;

- In uneven areas (slopes, recesses), use a motor.cultivator without transport wheels.

7.ten. In the first 40 50 hours of operation of the mowing, an intense hood of drive belts occurs, and therefore it is necessary to carefully monitor their tension, especially during the first 5 hours of operation. Further, the tension control is carried out periodically.

Rotor mower for a walk.behind tractor

Devices of this type are also called disk. Judging by the name, it becomes clear that specialized discs participate in the process of cutting grass. If you distribute these mowers according to the connection method, they are divided into those that are connected to the pulley by means of the belt and those that are directly to the UM. The principle of operation of the unit is as follows: the discs spin on each other, which allows not only to competently download grass, but also carefully put it in a row for further cleaning and transportation. As a result of such work, you can easily and quickly collect vegetation and put it in a specially prepared place.

As for the structural features, the rotary braid to the walk.behind tractor is based on a metal frame, where a supporting wheel with a cutting element is installed. During movement, the support wheel promotes the movement of knives, which carry out cutting of grass. The visual display of the machine device is displayed in the following drawings:

As you know, different modifications of mowers can be equipped with three blades. Often, such hinges are accompanied by “skis” that contribute to the operation even on an uneven surface. Positive features include a special drum that pushes the grass, allowing you to work even with dense and thick plants. But such devices are not designed for the processing of large territories. As for the features of choosing a model of a rotary braid, it is necessary to pay attention to the power, height of the cut, the speed of rotation of the cutting element and other points. The main thing is to understand the need to follow all the rules described in the operating instructions, since the indifference to elementary caution is fraught not only in the breakdown of the device, but also to obtain injuries.

How to set up a mowing before work?

After buying rotary equipment, you must correctly configure and adjust the mower. You can set up in several main stages:

- All settings are carried out after aggregation of the mower to the walk.behind tractor.

- Put a protective casing on the raised device and secure it with son.in.law bolts.

- Rotors should be strictly parallel to the surface of the field.

- Adjust the height of the mowing. To do this, there are a special bolt on the salaes that will help to set the desired height. When adjusting the height, it is necessary to take into account the irregularities of the landscape, working discs should not capture the soil.

- Check all the connections. The bolts should be tightly tightened. Knives move freely. If necessary, they need to be sharpened.

- Run the mower and go through one row. If the height is suitable, then you can perform work.

- People and animals should not be on the field. The operator needs to wear protective clothes and a mask. They will protect from branches and small pebbles.

Chips on the choice

Choosing a hinged unit for hay harvesting using the Neva MB 2 walk.behind tractor, you need to consider:

- Type and relief of the terrain;

- The composition of the grass and its changes;

- Their financial capabilities;

- The capabilities of the walk.behind tractor in terms of installation of attachment equipment;

- The required power of the motor.

Modernization or refinement

The main disadvantages of any braid that can be bought at the store are:

- insufficient strength of the structure;

- insufficiently rigid fixation to the walk.behind tractor;

- ineffective sharpening of knives;

- ineffective lubrication of rubbing parts;

- insufficient ski length;

- lack of defense of the operator;

- the impossibility of comfortable movement.

To increase the rigidity of the structure, pipe and other elements are welded to the braids on the bolts that remove excessive mobility of the frame. If the standard mount does not provide enough rigid fixation of the attachment equipment to the chassis, then it is redone, eliminating all the backlash. The method of alteration and refinement depends on the design of both devices.

The standard knives have no notes, so instead of them are used by homemade dampers, sliced from old sickles or knives of various agricultural machines, and then balanced so that vibration does not appear after installing them.

Reducers are often supplied with gearboxes without sufficient lubrication, especially often this happens with Chinese and devices.

In order not to disassemble the gearbox each time, a tawnnik is cut into its side or upper wall from a car, for example, gas 2410, then once a month or season through it is served a suitable lubricant.

Facial devices equipped with standard skiing are well suited for even areas, however, where there are pits of various sizes, their lengths are not enough, so the braid can fail, which will lead to a damage to the knife and possible breakdown of the shaft. Therefore, those who are forced to mow grass in uneven areas welcome extension cords to standard skis, so that the mowing passes without incident.

Almost all braids are deprived of the operator’s protection, so a stick or stone that came under a knife can injure you.

To avoid this, stretch behind the plates under the engine of a target from a tarpaulin or durable linoleum.

Cultivation Tips For A First Time Walk Behind Tractor User

Parts of the owners of such devices do not like to walk for a long time, so in addition to the hitch, the mowing is attached to the walk.behind tractor, turning the device into a self.propelled machine. After such an alteration, even the mowing of huge areas is not difficult, because the operator does not have to follow the mower on foot, because he controls her while in the cart’s seat.

“Zarya-1

The disadvantages of this model include high labor costs when installing a single tractor. Structurally provided for connecting the mowing to the rear of the motor equipment. To do this, you will need to expand the handle of 180 degrees, install the gearbox and connect the rotary mower to it. Motoboglok moves at the rear speed.

Additionally, you will need to provide the possibility of activating increased gears when moving forward. This is necessary in order to exclude the possibility of hitting the operator at high speed. The complexity of such operations directly depends on the design features of the walk.behind tract and may require some manipulations for switching control drives, gearboxes and other elements responsible for managing the equipment.

How to configure the cs: go 2 1 video

KSF-2.1 is intended for hanging on a mini-tractor and motoblocks. This device is created to mechanize the processes of hay harvesting, having received its own skill title due to a special type of grass cutting. in the appearance of large sharp triangles. Also called “segment-paltsevo”.

Segmented type KSF-2 braids.1 are produced by Lyubertsy (our homeland, this enterprise is the successor of the Ukhtomsky factory and the successor of his longevity business. the creation of haying equipment of various types and structures.

KSF-2.1 They are well controlled with mowing work to a greater extent in the flat territories. they mow different.type herbal crops with laying plant mass to mowing:

The braid is applicable for planning mowing in the territories of actually all weather zones. it provides unlimited work with the exception of only semi.desert and desert sections. Photo of the KSF-2 mower.one

Apart from the ability to use in any weather, segmented KSF-2 mowers.1 have many other advantages during which they are appreciated by many business executives:

- The highest performance, achieved by the relatively highest speed and a large width of the simultaneous capture-more than 2 meters.

- The light weight of this suspended mowing equipment allows you to work with the child even on small types of transport devices.

- The small energy intensity of the apparatus will help save the means does not affect the increase in the cost of hay with a decrease in the volume of the workpiece.

- Conventional control without connecting hydraulics does not ask for additional maintenance personnel, not counting the operator of the draft tractor.

- The economy of acquiring the device itself and spare parts for it, available everywhere.

- High.quality work at high speed and a long service life. by the expiration of the operation period, you can change the cutting canvas, and Kosilkaopyat will be ready for the daliy season.

Read Fishing line in trimmer Patriot Video

KSF-2 brand mower.1 consists of subsequent main structural nodes and parts:

- Frames on which other working tools are required and which has a mount for installation to a tractor hitch.

- Traction bar created for the connection of a working cutting tool with the device frame.

- Cutting canvas with sharpened sectors (fingers).

In the works of the mowing, a canvas with knives is brought into the progressive-dressing movement parallel to the surface of the earth. With all this, the trunks found on his way fall on the motionless segments of the canvas and immediately tightly pressed into the apartment with moving blades. The slice of herbs occurs like the work of ordinary scissors, leaving a strip of ready.made mowing. Scheme of the KSF-2 mower.1 1. a knife head; 2.4. guide heads of the knife; 3. knife head cover; 4. inner boot; 5. a divert rod; 6. external boot; 7. field board; 8. finger; 9. finger liner; 10. a sector of a knife; 11. clip of a knife; 12. the back of the knife; 13. friction plate.

The mower is mounted to the tractor with fixation of the longitudinal rods of the tractor of the hitch, setting the distance from the ground to their rear ends about 40 cm and up to less than 65 cm. This is done for the impossibility of the side shift of the braid frame relative to the central axis of the drain unit.

Read how to check the ignition coil motorcosa

When working with the device, the rules that promote long and non.hazardous operation should be followed:

- The cutting apparatus of the braid should be covered by a protective casing.

- The tractor stopped with simultaneously putting the power shaft of capacities.

- What remains to make our client tuning and treatment work with the mowing itself and in particular cutting inventory are carried out during the working stop and plug of the tractor.

- Transportation of the device is carried out with a protective shield mounted on its teeth.

Technical properties of the segmented mower of the KSF-2.one:

Before buying a particular mower, read the most popular and common options. Compare their and main characteristics. Take into account the existing pros and cons of. Only then make a specific choice. and more. Top manufacturers include:

Ghepard

Professional segment mower for the GHEPARD (MBK0012013) walkover has 92 cm width, which is quite suitable for personal use on a suburban area. The design uses a transmission (included in the kit) with a large work resource. Durable teeth and made of high.quality steel with a special coating. The model is good for both decorative mowing and hay harvesting. Detailed parameters: