Making a stand for an angle grinder with your own hands

Angle grinders (angle grinder) are an irreplaceable hand tool. With their help, you can saw, cut, cut almost any material from wood to stone. But often there are tasks that require the use of a machine park.

For example, when cutting pipes, profiles or metal profiles, the task of cutting a long string into segments of a certain length is quite common. In this case, it is important that the ends of the sections are strictly perpendicular to the axial mowing line.

When cutting tiles or bricks, it is even more difficult to keep the cut square by holding the angle grinder by hand. When cutting thin and sticky material, the slightest deviation of the tool from the mowing line of the cut can lead to jamming and tool breakage.

In such situations, it is quite natural to desire NOT to buy a separate machine. this, as a rule, is economically impractical.

Materials and tools

The first question that a home craftsman faces when designing a stand for an angle grinder is what to make it from. The answer to this question is elementary: what is, we will do from that. If you have water pipes on hand, they will come in handy for making hinges and guides. If there is a metal corner, we will assemble a frame from it.

The main and most complex unit of a pendulum cut-off saw is the hinge unit. It carries the greatest loads, while the pendulum arm should NOT be able to freely deflect to the left or right. Consider the design of this node with the greatest care. Roller bearings are ideal. Pick a pair of suitable sizes. and already “around them” build the rest of the structure.

It is best to mount the pendulum arm with ball or roller bearings. This will provide the best precision and rigidity. But if there are no suitable finished products, it is quite possible to spy on the options for homemade designs of this unit.

If ready-made bearings are available, match pairs of metal tubes and steel pins of suitable diameters. This will allow you to make NOT too high quality, but homemade bearings. For a “plywood” machine as a suspension of the pendulum arm, good canopy hinges used for fastening doors and gates will do.

For a secure and tight fixation of the angle grinder in the holder, it is better to glue the stock with a soft and durable material. For example, leatherette. And by pressing the angle grinder to the holder, it is most convenient to use flexible metal ties with a screw assembly. These are widely used in plumbing and car service.

The bed is best made from a thick sheet of metal. Compromises are possible, up to thick plywood fixed to a timber frame. It is good to provide on the desktop the possibility of fixing the abutment corners at some standard angles to the cutting axis. Thus, we get “miter dust”.

Do not forget that you will not be able to control the switching on of the angle grinder on the machine in the usual way. We can replace the operator’s hand on the control keys with screw ties for pipelines. But the keypad control post (which we fix on the bed), a socket for connecting a fixed angle grinder to the circuit and a wire with a plug of sufficient length to connect the entire machine to the network should be saved.

If we have metal blanks at our disposal, it is best to connect them by welding. If you DO NOT have such an opportunity, it is better to contact the familiar masters of this business. Bolted connections loosen over time and nullify There are all the advantages of a metal frame.

Of course, the angle grinder itself will come in handy in the manufacture of the machine. We use it to cut the blanks for the rack, you can feel like Munchausen pulling himself out of the swamp by the pigtail.

Carriage made of pipes and shock absorbers

If there are water pipes, a pair of car shock absorbers and a metal corner or profile in stocks. you can make a wonderful cross-cut (aka “cut-off”) machine with a transverse horizontal carriage feed.

The pendulum unit is still required to bring the tool into the cutting plane. But the carriage, movable along the pendulum arm, allows you to significantly expand the range of material sizes. Now you can cut quickly and accurately not only pipes, profiles and beams.

Complex rail assemblies with spring-loaded bearings are usually designed to ensure smooth yet accurate carriage travel. But you can use car shock absorbers. They have a very robust and precise construction. If you remove gas and liquid, you get excellent guides.

The rear shock absorbers of VAZ cars have a stroke of almost 200 millimeters. This will allow, for example, when attaching an angle grinder-230 to the carriage, to organize a cutting line up to 400 mm long. But even if you have a compact angle grinder with a disc only 150 mm in diameter, you can still cut sheets up to 200 mm wide. This more than covers most of the daily tasks.

When designing the assembly “guides. carriage” on the basis of automobile shock absorbers, be sure to take into account the fact that the bodies of the shock absorbers themselves are rather thin and easily wrinkle. Such “guides” should be attached to the upper arm of the pendulum with semicircular clamping brackets.

Manufacturing options

Honestly, the do-it-yourself rack drawings, which are available in many, should rather serve as food for thought. It is worth taking a closer look at the design, typical dimensions of standard elements and general design principles. Then apply them in our particular case.

The fact is that the dimensions of the structure and SEPARATE nodes will entirely depend on what you have at hand. For a large angle grinder (for example, the 230 angle grinder), you may need to make a holder larger than indicated on the drawing. This will entail the need to replace bearings, and so on.

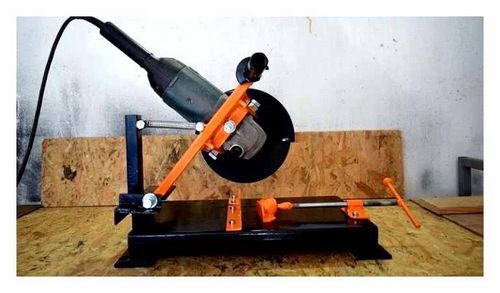

The general principles are clear enough. The simplest and most used machine is the transformation of a hand-held angle grinder into stationary pendulum dust. This design consists of a bed, a stand and a pendulum arm, which is hinged on the stand.

Consider manufacturing options depending on the materials available.

Plywood parts

An interesting solution to the problem of stiffness can be the use of plywood in a wooden structure. The multidirectionality of veneer layers in this material imparts a certain dimensional stability to plywood products. The fact that the product consists of many thin layers, bonded with strong adhesive, provides strength.

Plywood is great for making beds and work tables. When designing, it should be borne in mind that plywood is very strong and stable in the plane of the product. But the plane itself can be deformed. Therefore, plywood products should be mounted on rigid frames.

A good example of construction is a multi-plywood assembly with intermediate bonding and bolting.

Wooden elements

If it is not possible to make the basic elements of a pendulum saw from metal, do not despair. Many structural elements can be made from wood. First of all, this is the bed, swing arm and angle grinder holder.

The frame can be made from any suitable lumber. Very good frames are assembled from bars of hard and heavy wood of significant cross-section. They are both durable and quite heavy. This ensures the stability of the entire machine.

The frame, assembled from 100×100 mm oak timber, is certainly impressive. But it is too expensive. Thick bars of larch or even birch are quite suitable for the base of the desktop.

But for the manufacture of the pendulum arm, you can just use the noble varieties of wood, traditionally used in furniture production. Oak would be quite appropriate here.

When constructing a machine from wood, do not forget about the overall rigidity of the structure. Significant dimensions of the bed allow you to ensure the strength and rigidity of this part when made from NOT the highest quality materials.

The pendulum arm has a long, elongated design. If made of wood, its geometry can be unstable when temperature and humidity change.

Rectangular bed

Very stiff in itself, this profile allows the construction of a rigid and robust bed. importantly, the pendulum arm made of this material will hardly flex during operation.

But the bed frame is only half the battle. The floor of the frame must be placed on a “table top”. a plate on which the processed material will be placed under the angle grinder.

If the frame is made of metal, sheet metal is the best material for the workbench. However, a thick sheet of plywood or chipboard is also quite suitable. Just do not forget that a fairly wide slot must be provided in the tabletop directly under the disc of the angle grinder in the tabletop, which provides a through passage of the disc through the material being cut.

The upright is a very busy pendulum saw unit. The use of a metal profile will allow you to create a strong and rigid structure.

When using metal as the basic element of the machine, preference should be given to welded joints. Of course, metal profile products can also be bolted together.

Safety engineering

As with any electrical tool, electrical safety guidelines must be followed. Do not work in rooms with high humidity. When installing the machine on the street, it is advisable to build at least a temporary shed above the workplace to protect it from precipitation.

Like any cutting tool, an angle grinder, even fixed in the machine, requires strict adherence to safety precautions. It is absolutely unacceptable to work without a protective cover around the disc. And also it is obligatory to use protective glasses or a transparent shield.

Many neglect gloves. and in vain. Sparks flying out from under the gaze only seem small and harmless. Crumbs of abrasive and processed material fly like bullets and can penetrate deep into the skin.

You can learn more about how to make a metal stand for an angle grinder with your own hands.

DIY tools for making a machine tool

To assemble a homemade cutting machine, you need the following tools:

- Angle Grinder;

- Powerful drill;

- Set of dies;

- Keys set;

- Welding machine.

The most important part of a cut-off machine is the angle grinder. It is best not to use a small angle grinder that is designed for low power. It is worth recalling that in order to increase the reliability and versatility of the machine, it is necessary to use an angle grinder with a large cutting disk.

Such a careful selection of an angle grinder is due to a huge assortment and different designs. Since they are all different, the cutting machine is made for a specific size and model of the tool. If the machine is manufactured with defects, then in case of breakdowns it will be impossible to install another angle grinder without additional alteration of the pendulum and the necessary fasteners. That is why it is worth purchasing models of grinders from well-known manufacturers.

The second stage of the assembly of the cutting machine

A clamp and a special bar that will fix the pendulum and the body of the angle grinder is made of a metal rod. The bar is a metal plate 25 millimeters longer than the clamp width. The threaded ends of the stepladder will easily fit into the holes made along the edges of the pressure plate, which are fixed with prepared nuts. I carefully try on the clamp to the angle grinder and the bracket, fix them to the rack using welding or bolts.

The selected bearings, which ensure smooth rotation of the pendulum, are reliably pressed into special bearings. They are often used in factory working units or small pieces of metal pipe with a diameter equal to the outer diameter of the bearing. The bearing assemblies are pressed into both sides of the shaft. It is necessary to remember that the connection should be done with an interference fit. This will help eliminate unnecessary offsets. In cases where this connection turned out to be slightly weakened, then it is worth using a reliable method, which consists in applying a small layer of tin to its surface. This is where flux soldering acid comes in handy.

DIY materials for making a machine tool

Before you start making a machine with your own hands, you need to know that the reliability of its operation depends on the stability of the bed. That is why it is worth choosing thick materials.

In further work, you will need the following materials:

- Metal pipe;

- Several ball bearings;

- Steel rod;

- Metal sheet and tire;

- Fixing materials.

The first stage of the assembly of the cutting machine

It is customary to start the assembly of the cutting machine with the design. It is very difficult to find its exact drawings, because the design directly depends on a certain brand of angle grinder. But according to the found drawings, you can simply get the slightest idea of the structure and basic dimensions of the machine. According to the drawing, blanks are made for the manufacture of the machine. Pipes are used for the construction of the pendulum and the rack, and a steel rod, a metal profile and a tire are used to make a cantilever holder. When you need to make a bed for an angle grinder with your own hands, then steel sheets up to 6 millimeters thick are cut to the required dimensions.

Further, to the levers of the pendulum, which is a small pipe, you need a special weld to connect with the hinges. In this process, it is necessary to fasten the pendulum to the shaft at a right angle. A bracket is bent from a metal tire, and holes for bolts are made on its sides, fixing the gearbox housing an angle grinder.

How to make a bed for an angle grinder with your own hands using drawings

In your home, a cutting machine is rarely used, which is why purchasing a professional tool is NOT a rational decision. It is much better to make a homemade angle grinder table, which will increase its versatility and turn it into a small cut-off machine.

The third stage of the assembly of the cutting machine

Stepping back slightly from the edges of the rack, it is necessary to weld the pendulum together with the supporting nodes. In the process of a quarrel, the bearings should not overheat, which is why they should be reversed with a damp cloth or often watered to prevent overheating. The assembled console is welded to the pendulum arm with a fixed angle grinder and a special clamp. The working position of the angle grinder is selected The most convenient for the worker. There is an unequivocal opinion on how best to fix the angle grinder.

Professionals prefer to work with an angle grinder by directing sparks towards themselves. This is argued by the fact that if the angle grinder jumps out of your hands, it will not fly at the employee. Less experienced people often use small angle grinders, which is why they choose the opposite rotation of the disc. This allows for better control of the incision and does NOT damage the work clothes. We attach the angle grinder to the rack, it is worth installing the protective cover correctly. He is obliged to ensure the safety of the worker when the cutting blade breaks.

How does a homemade machine work

It is quite easy to make a machine from an angle grinder with your own hands, because this does not require expensive materials and special knowledge. It has a simple design and is made from the following components:

- Pendulum;

- Bed;

- Special attachment for angle grinder.

The bed is a steel frame made of metal sheets and profiles. A bracket with hinges and an emphasis for the workpiece is attached to it. The pendulum of a homemade machine tool is a product made of a metal profile. It connects with a bracket and attachment for an angle grinder. The latter is done using several brackets, which are movably connected to the pendulum.

The fourth stage of the assembly of the cutting machine

At the end, an angle grinder is installed on the manufactured machine. Looking at the weight of the tool, it is worth choosing and fixing the correct spring for returning the angle grinder. For this purpose, special hinges are attached to the pendulum and the frame or holes are made with a diameter of up to 6 millimeters.

Next, you need to make a test run of the tool. At the same time, the operation of the entire machine at idle speed is checked. Attention is drawn to the backlash of all machine parts and their vibration. If they exist, then it is worth eliminating them immediately. Then a cut-off wheel of the greatest thickness is taken, and a groove is cut in the rack of a home-made machine to fit the size of the cutting disc of an angle grinder. If the need arises, the angle grinder can be removed and the slot widened to the optimal size.

Using an angle grinder

The angle grinder (abbreviated as angle grinder) is used for cutting and grinding various materials. The variability of the use of the tool is provided by replaceable working discs and the power of the device.

Low-power or household angle grinders are used in households. Designed to use discs with a diameter of 115-125 mm. The tool is small in size, low power motor, light weight. NOT designed for continuous operation without interruptions, quickly overheat.

Professional high power angle grinder is used in construction and industrial purposes. The tool is designed to use discs 150-230 mm. Heavy and powerful device designed for continuous operation without risk of engine overheating.

The ability to quickly change working surfaces and the high power of the tool allow you to expand the range of applications of the angle grinder. For example, for the manufacture of homemade machines. Machine use increases safety.

Homemade machine for angle grinder. instructions

For home use, it is irrational to buy expensive machines. Therefore, they are replaced with homemade analogs. Learn how to make a do-it-yourself angle grinder machine using diagrams, drawings and step-by-step instructions with a photo. This information will help you save on the purchase of expensive tools.

Types of machines

Under normal conditions, an angle grinder is used for cutting and grinding parts. But machine tool application expands the capabilities of the device. The machine allows:

- Perform precise cutting of wood and metal parts;

- Makes the wood dusty;

- Use for milling and turning;

- Sharpens tools.

Lathe

To make and process wood products, lathes are used. Such devices cost a lot of money. NOT every master can afford such a purchase. An angle grinder, a welding machine and the ability to handle metal surfaces will help make a functional device.

We make a sledge from an angle grinder according to the following scheme:

- An angle grinder holder is made from metal letters. The side walls are bent in the shape of the gearbox, holes are drilled for the mounting bolts on the body. A ring is cut from the pipe according to the thickness of the protruding parts of the gearbox. The front wall connects all parts.

- A frame is made from a profile pipe or channel. A longitudinal hole is cut in the upper part. It will move the Fixing Stand. An angle grinder holder is welded to the edge of the bed.

- A movable base is made to fix the racks. Cut 2 metal plates and drill holes for the bolts at the same distance. Bolts are threaded and the caps are welded to one of the plates. The part is brought into the hole in the bed with the thread up, closed with the 2nd plate and fastened with nuts.

- The movable mechanism of the rack is made of bearings. They are screwed into a pipe of the appropriate diameter and connected to the cut pins. The other end of the stud is sharpened on an emery wheel. The reverse side of the pipe is connected to the long part of the stud with a screw and nut for adjustment. The mechanism is threaded between the holes of simple racks, which are welded to the moving base.

- A test run is carried out. Install a wooden part, move the mechanism to the desired distance, tighten the nuts. The construction is ready.

Detailed manufacturing instructions are set out on:

Milling machine

For precise work with wooden surfaces, milling machines are used. Such a device costs a lot of money, but an angle grinder is easily replaced. If you have the skills to work with metal and a welding machine, you can acquire a functional device.

The machine is assembled according to Step by step instructions:

- Prepare the metal letter for the base. On one side, markings are applied and a circle with a diameter of 1/3 of the side of the plate is cut out. Clamp the part in a vice and cut off the excess, according to the applied fishing line.

- A hole is made in the 2nd metal plate using a cutting crown. The hole diameter corresponds to the size of the protruding part on the gearbox housing. Here is the resulting mounting blank cut off the extra parts.

- 2 racks are cut from a professional pipe 20×20 mm. The parts are fixed on the base at a right angle using a welding machine. It is important to be careful that the racks do NOT move.

- 2 small elements are cut from the 25×25 mm professional pipe. With their help, the height offset of the angle grinder is adjusted. Sections are welded to the fastening blank, check the smoothness of the movement on the racks. After checking in the sections, larger pipes are drilled for the retainer and the nuts are welded. Screw in bolts that will hold the machine at the desired height.

- To keep the mount tightly on the gearbox housing, make a small cut. A nut with an elongated thread and a ring for free movement of the bolt is welded on the outer fastening ring.

- Parts are made of sheet metal for additional fixation on the surface of the body. In the upper part, holes of the required diameter are drilled, and the lower one is bent at a right angle. They check the correctness of the assembly and weld the corners to the fastening blank.

- Take the old drill chuck and cut the threads from the back. Select the diameter corresponding to the spindle thread of the angle grinder. Install the tool holder, check the functionality.

- Assemble the machine. A mount is installed on the grinder body, the fixing bolt is tightened. Then the cartridge is screwed on. The mount is put on the posts and fixed with bolts at the desired height. The construction is ready.

Will help you understand the step-by-step assembly of the machine:

Circular machine

This tool is used for sawing wood. A simple circular machine with a broach is made from a tabletop. The angle grinder is attached from the bottom of the blade. It is dangerous to use low-power tools due to rapid overheating and small disc size.

Step-by-step instructions for creating an extended sawing machine:

- A sheet of chipboard 1×2 m is used as a tabletop. Legs are attached to the canvas to make a full-fledged table.

- A cut is made in the sheet. Its dimensions should NOT interfere with the disk rotation.

- At the bottom of the table, mounts are installed to fix the angle grinder. For manufacturing, take metal plates with a thickness of 1 mm.

- For the stationary version, the angle grinder is installed on the brackets. Holes are drilled in the plates and bolted to the gearbox housing.

- The mobile version is more difficult to manufacture, but easier to operate. A frame is made from a metal sheet. Holes are drilled in the side plates to fix them on the gearbox housing. The opposite part of the frame is connected to the bracket with a threaded connection.

- To fix the tool in the desired position, another bracket with a long hairpin is screwed to the tabletop. A sleeve with a diameter greater than the thickness of the stud is welded to the movable frame of the angle grinder. Adjustment and fixation of the tool is provided by two nuts.

Cutting machine

This type of device is used for precise cutting of metal parts. The machine makes it easier to work with heavy tools, Transfer the weight to the bed. The most popular and used is the pendulum machine made of an angle grinder.

The procedure for making a cutting machine for an angle grinder:

- Here is a corner of 50×50 mm, 2 pieces are cut according to the size of the tool reducer. Holes with a diameter of 14 mm are drilled in the side parts. Using M14 bolts, parts of the corners are screwed to an angle grinder and fastened together by welding.

- Resistances for the pendulum are made. The swivel mechanism is made of two pipes of different diameters (one tube should fit into the other without effort). The inner part is cut to the thickness of 2 bearings (it plays the role of a spacer).

- The bearings are matched to the diameter of the outer pipe. A thin tube is inserted into a thick one and the bearings are sealed. A pin is threaded into the hole and fixed with nuts. A corner is welded outside.

- Make a rack for the swing mechanism. 2 racks are cut out of a 50×50 mm corner and a hole is drilled into them for a stud. The pivot pin of the turning mechanism is threaded and fixed with a nut. The mechanism is welded to the base.

- A lever is made. It is made from shaped pipes of the same length. The distance is chosen Based on the size and weight of the angle grinder. The lever from the professional pipe is welded with one end to the corner on the swivel mechanism, and the other to the mount for the gearbox.

- The support frame is connected to the metal bed. To increase rigidity, the side parts are cut off and connected to the base at an angle. Fixation is carried out using bolts.

- To prevent the cut-off part from moving during operation, a clamp is installed. For this, a metal corner is welded to the bed. The clamping mechanism is made from a nut that is welded to the bed. A stud is screwed through the nut with an emphasis at the end.

- To facilitate working with the tool, a spring is installed at the lower end of the lever. It will return the device to its original position.

Grinder

A simple homemade product that allows you to sharpen metal products. With the help of such a device, it easily sharpens tools and household items.

The device is made according to the following scheme:

- The base is made from a chipboard sheet. Additional boards are laid on it so that the grinder lies flat. Parts are connected with self-tapping screws.

- The angle grinder is bolted to the gear housing through the board. On the opposite side, the fastening is made with a metal clamp.

- A table is constructed from the remains of chipboard to a height of half the grinding disc.

- The ends of the machine, where sparks will fall, are treated with metal tape.

- Start the angle grinder, check the performance.

Angle grinder bed a real carpentry workshop in your garage or shed

Despite the fact that the angle grinder belongs to the category of hand-held power tools, its capabilities allow you to create a full-fledged stationary machine. The most widespread are cutters based on an angle grinder.

In THESE devices, the angle grinder is mounted on an oscillating arm, and allows you to cut and cut any material with high precision and safety. There are both industrial and handicraft fixtures.

However, it is impossible to use the rest of the capabilities of this universal tool with cutting machines. The following tools can be made from an angle grinder (with the appropriate attachment):

This is detailed here.

Shown is a homemade wood lathe from an angle grinder.

On this, the master demonstrates sharpening a chain for a chainsaw by making a simple sharpening device from an angle grinder

Many of the listed works can be performed while holding the tool in hand. But to improve safety and efficiency, it is more correct to fix the angle grinder to a rigid, stable base. A so-called bed is needed, where the angle grinder will play the role of a power plant with replaceable nozzles.

How to correctly and inexpensively make a bed for an angle grinder?

For work, it is necessary to make a stable base on which the tool will be rigidly fixed. The fastening must be made quick-release in order to easily use the angle grinder in manual mode.

The photo shows a universal bed that can be used as a sharpener, cutter, or end grinder.

It is not necessary to make a separate structure with support legs. If you have a solid workbench, just make a bracket for an angle grinder and fix it on the worktop. Regular clamps will do. This design is reliable, versatile, and most importantly. safe.

In any version, the minimum set is a stable mount and a guide stop for the workpiece being processed.

The proposed types of drawing show the main components of the structure. The angle grinder is attached to the base of the bed with clamps. To fix the vertical deflection of the working disk (or other nozzle), an adjusting gasket is used.

The worktop can completely cover the tool, in which case it is enough to cut the blade. The drawing shows a variant of using an angle grinder as a circular saw or cutting machine for metal, plastic and other flat workpieces of a large area. For the second tasks, it is enough to set the workpiece stop opposite the working disc.

If the angle grinder is used as a cutter, but the discs are NOT moving, but the workpiece, the design can be even simpler. A homemade bed is made from an old board to which an angle grinder is attached.

This option uses a Power Tool Handle Seat into which a bolt or threaded rod of the appropriate size is screwed in.

The result is a reliable design that can be assembled and disassembled in half an hour. When using an angle grinder of low power, it is NOT necessary to reinforce the fastening with clamps. This makes the bed practically free.

An impromptu emphasis is installed along the disc. It can be mounted on self-tapping screws, if necessary, adjust the length of the workpiece to be cut. Using such a device, you can quickly cut a large number of identical products.

If you need a grinding machine, the design will be different, but just as simple and inexpensive to manufacture. An old wooden box can be used as a table, on which an angle grinder is attached with clamps. I installed a grinding attachment, we get a stationary machine for processing and finishing the edges of any workpieces, from wood to plastic and metal.

Again, the frame is made by hand, literally from the trash, which is in the shed of any home craftsman.

sophisticated angle grinder attachment options

Some “kulibins” adapt the angle grinder for completely unusual tasks. For example. from it you can make a full-fledged milling machine for wood.

If you need to perform a large number of carpentry work during the repair or construction of a house, you cannot do without small mechanization.

In curly carving, we are NOT talking, but for processing the ends of long workpieces, this design is just right. Since the work is coming one-time. the purchase of an electric planer or router is not economically feasible. Therefore, we take our favorite angle grinder, crepe it on the workbench, assemble guides from wooden scraps. and the machine is ready.

The only difficulty is to find an adapter for attaching the milling nozzles to the working shaft of an angle grinder. But such devices are produced industrially, so the problem is quite solvable.

Considering the mobility of the angle grinder, it is possible to make movable devices for processing wood from it. This is a mechanical copying machine. Of course, this is NOT a CNC. but the quality of work is not worse than industrial analogues.

The bed for an angle grinder is a movable farm with two degrees of freedom. The template rotates synchronously with the workpiece being processed, and the angle grinder with a milling attachment copies its shape. over, the movement of the tool is carried out manually in two directions, which provides full control over the process.

This photo is not a guide to action, but clearly illustrates the capabilities of an angle grinder with a suitable bed. over, this machine is also made from scrap materials at home.

If you approach the use of a familiar power tool creatively, you can not only expand its capabilities, but also save significant money.

See how you can make a simple homemade machine from an angle grinder and improvised tools.

How to correctly and inexpensively make a bed for an angle grinder?

For work, it is necessary to make a stable base on which the tool will be rigidly fixed. The fastening must be made quick-release in order to easily use the angle grinder in manual mode.

The photo shows a universal bed that can be used as a sharpener, cutter, or end grinder.

It is not necessary to make a separate structure with support legs. If you have a solid workbench, just make a bracket for an angle grinder and fix it on the worktop. Regular clamps will do. This design is reliable, versatile, and most importantly. safe.

In any version, the minimum set is a stable mount and a guide stop for the workpiece being processed.

The proposed types of drawing show the main components of the structure. The angle grinder is attached to the base of the bed with clamps. To fix the vertical deflection of the working disk (or other nozzle), an adjusting gasket is used.

The worktop can completely cover the tool, in which case it is enough to cut the blade. The drawing shows a variant of using an angle grinder as a circular saw or cutting machine for metal, plastic and other flat workpieces of a large area. For the second tasks, it is enough to set the workpiece stop opposite the working disc.

If the angle grinder is used as a cutter, but the discs are NOT moving, but the workpiece, the design can be even simpler. A homemade bed is made from an old board to which an angle grinder is attached.

This option uses a Power Tool Handle Seat into which a bolt or threaded rod of the appropriate size is screwed in.

The result is a reliable design that can be assembled and disassembled in half an hour. When using an angle grinder of low power, it is NOT necessary to reinforce the fastening with clamps. This makes the bed practically free.

An impromptu emphasis is installed along the disc. It can be mounted on self-tapping screws, if necessary, adjust the length of the workpiece to be cut. Using such a device, you can quickly cut a large number of identical products.

If you need a grinding machine, the design will be different, but just as simple and inexpensive to manufacture. An old wooden box can be used as a table, on which an angle grinder is attached with clamps. I installed a grinding attachment, we get a stationary machine for processing and finishing the edges of any workpieces, from wood to plastic and metal.

Again, the frame is made by hand, literally from the trash, which is in the shed of any home craftsman.

Angle grinder bed. a real carpentry workshop in your garage or shed

Despite the fact that the angle grinder belongs to the category of hand-held power tools, its capabilities allow you to create a full-fledged stationary machine. The most widespread are cutters based on an angle grinder.

In THESE devices, the angle grinder is mounted on an oscillating arm, and allows you to cut and cut any material with high precision and safety. There are both industrial and handicraft fixtures.

However, it is impossible to use the rest of the capabilities of this universal tool with cutting machines. The following tools can be made from an angle grinder (with the appropriate attachment):

- Circular saw;

- Lathe;

- Grinder;

On this, the master demonstrates sharpening a chain for a chainsaw by making a simple sharpening device from an angle grinder

- End grinder.

Many of the listed works can be performed while holding the tool in hand. But to improve safety and efficiency, it is more correct to fix the angle grinder to a rigid, stable base. A so-called bed is needed, where the angle grinder will play the role of a power plant with replaceable nozzles.

sophisticated angle grinder attachment options

Some “kulibins” adapt the angle grinder for completely unusual tasks. For example. from it you can make a full-fledged milling machine for wood.

If you need to perform a large number of carpentry work during the repair or construction of a house, you cannot do without small mechanization.

In curly carving, we are NOT talking, but for processing the ends of long workpieces, this design is just right. Since the work is coming one-time. the purchase of an electric planer or router is not economically feasible. Therefore, we take our favorite angle grinder, crepe it on the workbench, assemble guides from wooden scraps. and the machine is ready.

The only difficulty is to find an adapter for attaching the milling nozzles to the working shaft of an angle grinder. But such devices are produced industrially, so the problem is quite solvable.

Considering the mobility of the angle grinder, it is possible to make movable devices for processing wood from it. This is a mechanical copying machine. Of course, this is NOT a CNC. but the quality of work is not worse than industrial analogues.

The bed for an angle grinder is a movable farm with two degrees of freedom. The template rotates synchronously with the workpiece being processed, and the angle grinder with a milling attachment copies its shape. over, the movement of the tool is carried out manually in two directions, which provides full control over the process.

This photo is not a guide to action, but clearly illustrates the capabilities of an angle grinder with a suitable bed. over, this machine is also made from scrap materials at home.

If you approach the use of a familiar power tool creatively, you can not only expand its capabilities, but also save significant money.

See how you can make a simple homemade machine from an angle grinder and improvised tools.