Self-adjustment of the electric slicer blades

Purchased tool must be checked before working. To start with, you should study the instructions on how to operate the electric planer properly. Then the preparation is carried out, while checking:

- ease of rotation of the shaft;

- The location of the sole;

- positions of the cutting elements;

- The power key can be pressed freely;

- the presence of various defects: integrity of the body, cable, etc.д.

Completeness and working condition of the tool should be checked when buying. The integrity of the tool is determined visually, the rotation of the drum can be checked by moving it with the palm of your hand. The function of the start button. by pressing it. If there are no signs of damage, you get a trial run.

Attention! Before you work with the electric planer, it’s best to first learn on boards that you don’t need. This will help “get accustomed” to getting a quality result if you have no experience.

tool preparation is the key to quality results Source topex.net.ua

Adjusting the plate

Adjustment of the equipment begins with the adjustment of the front part of the soleplate. for which a ruler is required. The work is performed in the following sequence:

- Use the adjustment knob to set the moving part of the sole to the position that provides the lowest depth of planing.

- Place the planer on a level plane upside down.

- Rotate the drum so that one of the knives is on top of its axis.

- A ruler is placed on the plate: both parts must be at the same level.

If the pad on the sole is at an angle, the defect is corrected as follows:

- Remove the adjustment knob and the front piece of the platen;

- Clean the insides of the tool from dirt;

- Lubricate the parts;

- Set the sole plate and the handle in place;

- Determine the position of the plate with a ruler.

Any flat surface can be used instead of a ruler Source ytimg.com

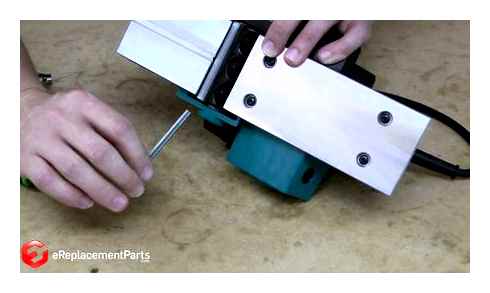

Fixing the blades

Correct installation of blades on the electric slicer is also checked with a ruler. For which it is applied to the edge of the soleplate. Then determine whether the cutting elements touch the surface. When they do not touch the ruler, adjustment is required. The hexagon, which is included with the tool, is used to loosen the blades. Afterwards, the cutting edges are set parallel to the board so that they protrude by about 1 mm.

Knowing how to align the knives on an electric planer, you can use this method for single-blade or multi-blade tools. After adjusting, the edges should be in the desired position.

One must take into account that the protrusion of the blades above the plate will determine the processing depth and the smoothness of the electric planer’s movement. When the blades are mounted correctly, they must not catch the plate when the drum is running.

Attaching the blades is not too difficult Source yandex.net

See also: Directory of companies that specialize in finishing materials and related work

Sharpening the blades

Before adjusting the knives on the electric slicer, it is necessary to sharpen them, if necessary. This can be done thanks to a special block. The actual process is as follows:

- The abrasive stone is prepared first. Put it in water for 2-3 minutes. This will allow the abrasive to absorb it, and, accordingly, in the process of work will not be so much dust. Then the stone is placed on the sharpening machine.

- Then the knife is fixed with nuts in a special block. It will help make the sharpening at the required angle (30 degrees).

- Afterwards the actual sharpening is done. The most important thing in this case, do not disturb the balance of the blade, otherwise the planer will not work properly.

Sharpening of blades of the electric grinder is also carried out with other devices. For example, special sharpeners are sold in stores that allow you to sharpen the blades of tools from any manufacturer.

Grinding electric planer blades is better to trust professionals Source zatochka-ru.ru

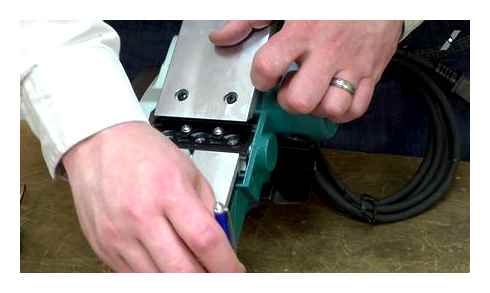

How to install the blades correctly on the planer

Installation of cutting elements on the electric planer. a simple procedure that does not require special knowledge and experience. The step-by-step algorithm is as follows:

- Unplug the tool completely to avoid electric shock.

- Remove the wood resin from the working surface of the machine with absorbent cotton soaked in solvent. There is no point in using an ordinary wet rag, because it will not remove, but only smudge contaminants.

- Use an Allen wrench to loosen the bar that holds the knives in the drum of the electric planer, and remove it along with the old blades.

- Use a screwdriver to unscrew the usual bolt connection that holds the cutting edge and remove the latter.

- Screw a new planing element onto the strip.

- The part is inserted into the drum in its original place and according to the rules of installation of blades in the planer only slightly fix it so that it does not fall out.

After that, the blades need to be adjusted. Only after they are adjusted correctly can the bar be finally fastened in the tool. It does not make sense to screw it all the way in once the blades are installed, because you will still have to loosen it later.

Tip! Instead of using a hexahedron, you can replace the blades on your planer with an appropriately sized three-edged file or a flat-blade screwdriver, if necessary.

If the planer is equipped with several blades at once, it is necessary to change the entire set, otherwise imbalance will occur

Characteristics of electric planer blades

To get the right result with a planer without too many problems, you need to sharpen it properly.

The use of the electric planer allows you to process the wooden surface with the highest frequency and preservation of certain dimensions. When choosing this tool it is very important to choose the right blades so that the work does not cause any complications.

it is known from experience that if an electric planer has straight blades, the surface finish is not of high quality. The surface after planing looks wavy. The reason is the small difference in height when making successive passes. In this case the knives are not adjusted correctly in height. This problem disappears when using a tool with a spiral blade.

The electric slicer and shredder has two blades. They have two cutting surfaces and are easily removable. They are made of tungsten, but knives made of steel with high strength and hardening are more commonly used. The blades are sharpened in a blade holder, which sets the desired sharpening angle. This tool allows you to plan with high quality in a limited period.

When buying you need to pay special attention to the protection of the blades. Each tool is usually provided with two types of guards:

The electric slicer has two blades that have two cutting surfaces and are easily removable.

Most of these devices have a special protective plate. It closes the tip of the drum with a spring, making it possible to plan the wooden surface to the required depth and distance.

The blades of the electric planer must be adjusted with the special adjustment mechanism. It is located on the front handle of the tool. Turning the handle to adjust the blade to the desired size, the output can be adjusted to within 2 mm.

The blades of an electric planer are sharpened in the same way as a mechanical planer. The only difference is the number of blades. The electric planer has two blades.

Blades must be changed in pairs. Only one set should be used. This will eliminate the appearance of imbalance. This phenomenon can cause the tool to break and produce a very poor surface quality after planing.

Planing with an electric planer

A separate condition for proper and safe planing with electric planers of any design is a rigid clamping of the workpiece to be processed.

Only when the workpiece is firmly clamped is it possible to plan. You should start with roughing first. For this purpose the electric planer is more commonly used. When using a sherchebet, you should move across the grain, not lengthwise. Otherwise you might plan too much wood.

The finer points of an electric planer

When the surface of small workpieces has been finished with a sherchebet, it should be cleaned first with a single planer and then with a double planer. If you are dealing with long wood, such as timber, it is better to use a joiner or semi-fugue joiner. The surface needs to be traversed lengthways and not against the grain. This is the only way to get the smoothest, smoothest surface.

Planing with an electric planer

Another condition for safe and correct planing with electric planers of any structure is a rigid fixation of the workpiece to be processed.

Only when the workpiece to be processed is firmly clamped can you start planing. Start with the roughing first. This is more often done with a sherchebet. When using a burr scraper, you should not move longitudinally, but across the grain. Otherwise you could plan too much wood.

The finer points of working with an electric planer

After finishing the surface of small workpieces with a hacksaw it should be cleaned first with a single planer, then with a double planer. If you are dealing with long workpieces, for example bars, it is better to use a joiner or semi-fuggan. Do not work against the grain, but lengthways across the surface. This is the only way to get the most even and smooth surface of the wood.

Planing, be it a board or a beam

When planing the ends of a beam or plank, make several movements with the electric planer from the edge of the end to the center, and the same from the opposite edge. This helps to avoid chipping and splintering. It is not necessary to apply much effort in the process. The planer should move smoothly along the wood fibers.

Make a few movements on the surface to be treated with the electric planer. For the second and third passes over the surface, each time turn off the electric planer, come back and turn it off again.

The electric planer can be used for beveling. Based on the width of the required bevel, run the planer along the edge of the workpiece the required number of times.

electric slicers and principle of work

An electric planer is a device that operates using an installed electric motor. The latter drives the blade head, which provides planing. The body of the device is equipped with one or two handles for ease of operation. Russian market offers a rather large range of electric planers. They differ from each other by many parameters: power, maximum planing depth, width of the passage, size and shaft rotation speed. To adjust the planing depth it is necessary to use a special mechanism. It shifts part of the soleplate higher or lower, depending on the need. This element is one of the most important components of an electric planer. I would like to say that the smaller the step of this adjustment, the cleaner and better surface finish can be obtained. Like most other power tools, electric planers are divided into:

- household. designed for home use;

- Industrial. more expensive electric slicers, applicable to the production of enterprises.

I would like to say that the power rating of the electric motor 700 watts in electric planers for home use is quite possible to use the device for household needs. In most cases, the width of the planing area of such devices is 100 mm.

Planing the surface of lumber

Before you start planing the surface with an electric jigsaw. The workpiece should be securely clamped to the workbench without play or warping. Otherwise the part can fly out while working and injure the carpenter.

The cutting part of the planer should not touch the surface before you start!

When switched on, the machine should be carefully guided against the wood without tilting to different sides. Hand pressure should be more concentrated on the front of the tool at first, and then slightly transferred to the back of the tool when you are finished.

The speed of the planing operation should not be too fast. Material about two meters long should be processed for one minute per run. If you rush too much, you will be left with bumps and notches on the surface.

Grinding electric planer blades with their own hands

Use of blunt-edged tools increases stress on the motor, resulting in premature tool wear. In addition, the quality of work is impaired.

Sharpening the blades of power tools at home is not that difficult if you are careful.

Materials required

- sharpening stone: coarse-grained for primary sharpening, fine-grained for final sharpening;

- two boards of laminate, a wooden bar. if you want to make a sharpener yourself.

Know: How to choose an eccentric sander: 5 tips and tricks

Tools

- hacksaw;

- sharpening machine;

- knife clamp;

- ruler;

- screwdriver;

- pencil;

- wood knife;

- chisel;

- hammer;

- fixing screws and studs;

- electric drill;

- a knife from a planer;

- two identical bearings.

How to properly perform the sharpening with your own hands:

Carefully screw them to the clamp so that the edges lie in one plane.

Smoothly, pressing lightly, lead the knives on the abrasive. it is important to make sure that the blades are sharpened at the same time. In this way the original sharpening angle will be preserved.

Tip: To prevent grinding dust from flying in the face, it is better to wet the stone beforehand.

Check the work: inspect the blades for defects, make sure the cutting part is sharp enough.

Fit the plates to the electric planer and adjust them.

This method is suitable if you need to sharpen the accessory slightly. For knives that are too dull, you need a special tool. But this can also be made with our own hands.

How to make a tool for sharpening

Making a sharpening cart yourself is not an easy task, but it is doable.

| Creating the body | Creating the blanks for the fasteners: |

| 1. Draw an axis on the laminate with a pencil. | |

| 2. Mark a couple of points on it, which are slightly larger than the width of the electric slicer blade. | |

| 3. Use an electric drill to make holes for the studs. | |

| 4. Now do the same with another piece of laminate. The first one can be used as a template. | |

| Transfer the size to the body of the future fixture: | |

| Place the wooden block vertically. | |

| Make a through hole at the edge, with a distance slightly wider than the wheel. | |

| Make another similar hole on the other side. | |

| Final Stage: | |

| 1. Insert the pin into the drilled hole. | |

| 2. Place the workpiece on top of the chisel. | |

| 3. Use a screwdriver to tighten the nuts on the studs. | |

| 4. Use screws to fix the bottom part of the laminate to the joist. It can be drilled and countersinked directly on it. | |

| 5. Now the screws need to be screwed in. | |

| Positioning the bearings | Create a projection: |

| Mark on the joist the lines where the wheels will go. | |

| Use a hacksaw to cut it where the bearings are attached. | |

| Remove the excess wood. A chisel and hammer come in handy. | |

| Securing the bearings: | |

| 1. Draw the wheel centers. | |

| 2. Use a knife to shape the cylindrical projections. | |

| 3. Slide the bearings into the prepared slots. | |

| Tip: You can smear the surface where the wheels are attached with glue for a better hold. | |

| Final part | Install the second laminate board. |

| Insert the electric planer blade between the top and bottom board and fasten it with nuts. |

Figure it out: Which of the 2 types of cutters is better. vertical or horizontal??

Reusable head

This tool differs from disposable blades by its size and shape. High-quality steel is used for production. After surface treatment with these blades the surface is smooth and does not require further grinding. Machine tools are marked with the letters HSS (High Speed Stil or High Speed Steel). The equipment is of the professional type.

You need a special adjustment to set the blade, as well as a high-precision balancing. The angle of sharpening of the planer blade should have exact parameters.

The basics at a glance

To work effectively with an electric planer, you need to remember a number of rules:

- Before you buy a planer, run the tool several times at idle speed. You can check for smooth, vibration-free running, and see some of the advantages and disadvantages of the machine.

- Work your boards in fibre direction.

- If the planer jams or gives “shaggy” shavings, it is necessary to sharpen the blades on the blades. This should preferably be done by a professional.

- Do not apply pressure to the planer when working.

- The flatter the heel is relative to the drum, the better the cut will be.

- When working with a side stop, you must take into account that it moves along the edge of the board, and, of course, if the end is curved, then the notch will be “ribbed”.

- To make the depth of cut approximately the same throughout the board, apply more force to the front of the planer when you start, and to the back of the planer when you finish.

- If you work with a long log, you should move smoothly along it while processing parallel to the tool. This way you can avoid steps.

An electric planer is a complicated tool. Both when selecting and operating it. Anyway, due to certain advantages it’s almost the only device for carpentry work at home. If you decided to save money on planing boards, buying a planer will be the right decision.

When to change blades?

The drum rotates while processing wood. In the progressive motion of the tool the cutting edge of the knife cuts off particles of material as it rotates. Gradually the sharpness of the blade wanes.

Foreign particles (nails, dirt, pieces of set mortar, if boards were previously used for shuttering or plastering) can be found in the boards being worked on, leading to rapid wear and tear.

Reduce the sharpness of sharpening and knots found in the array. Planing will be perpendicular to the fibers.

What tools can be used

The easiest and most affordable way to do such work with their own hands. is to use the device in the form of a wooden bar. The planer blade itself is fixed in its upper part. By setting the bar at one angle, you tilt it toward the abrasive. The result is another fulcrum, the knife edge itself, which will be sharpened.

A simple device in the form of a bar for sharpening planer blades

It is worth remembering that the work should take place so that the blade is sharpened at an angle of 30 degrees. Only then will your planer work properly.

To obtain such an angle, it is necessary to choose the height of a wooden bar and the position of the blade itself on it correctly.

In addition to this simple and homemade method, there are other, no less effective. To sharpen the knives for the planer with your own hands, a special block is enough. The process itself should be performed in several stages:

- the first thing to do is to prepare the abrasive stone. Place it in water for a few minutes. Such a procedure allows the stone to collect more water, which means that there will be less dust and sparks when working. After such “bathing” the abrasive wheel is installed on the sharpening machine;

- It is now necessary to fix the planer knife in a special block. Such a device allows you to do the sharpening at the right angle. Special sharpening blocks are made by many manufacturers, so you can easily find a suitable option. The knife is installed at the place allotted to it and fixed with nuts;

- Next, the sharpening is performed. Here you should not have much difficulty. The most important thing is that the knife is not out of balance during this process. If this happens, the electric planer won’t work properly.

A clamping device for sharpening planer knives

Some manufacturers of planers and other carpentry tools make special devices for sharpening them. For example, you can find a special sharpener on the market. Such a device is capable of sharpening blades from planers and planers from almost any manufacturer.

To sharpen the knife, it is necessary to install it in a special fixture. Next, with the help of templates to set the necessary angle. The fixture itself is equipped with a roller, with its help one can easily perform translational movements, thereby sharpening the blade.

But when using such a device, as well as with any other method of sharpening, special attention should be paid to the reliability of the fixation of the knife. Its flatness should remain in its place (at a certain angle to the sharpening surface) during the whole procedure. If this requirement is not met, the knife will be sharpened unevenly. This means that when working, high quality is not worth talking about.

After sharpening, it is advisable to readjust the blade. Even with modern devices, small defects can still occur. To keep them out of the way, it is advisable to run the blade through the barrel roller. Such a device allows to get rid of all small “paths” and other defects in two or three passes.

Determining the need for sharpening

This question is relevant first of all for joinery tools, because working with wood does not tolerate inaccuracies. If something is cut unnecessarily or the cut is oblique and does not meet the specified parameters, the entire job will have to be redone. That is why characteristics such as serviceability and quality are fundamental and need to be determined in good time. It also concerns all kinds of planers, to be more exact, their knives, which should always be sharpened and ready for use.

To identify the need for sharpening, it is necessary to pay attention to the following subtleties:

- The blade of the knife is in constant contact with different materials, which leads to its gradual blunting. It must be remembered that it is positioned at a certain angle, and its sharpness ensures a precise and correct cut.

- electric planer has blades directly on the rotating drum and two cutting edges. When at least one of them gets blunt, the knife starts to turn over. In spite of the fact that such knives are made of high-strength steel (tungsten carbide), they also successfully become blunt over time.

Different shapes are known to be inherent in all kinds of planer models. They can be straight, rounded, and wavy. Some amateurs believe that blunt most of all straight-shaped knives, but this is wrong, this process can affect any design, so to monitor the state is necessary.

People who by virtue of their professional duties work almost constantly with woodworking, face this phenomenon more often. The changes are usually reflected in the quality and speed of the work performed and are accompanied by such signs:

- Difficulty in making movements;

- surfaces that are worked on for a long time do not change their shape;

- The appearance of a shiny thread-like stripe on the bevel (cutting edge).

The main points in a nutshell

To work effectively with an electric planer, you need to remember a number of rules:

- Turn the planer on several times at idle speed before you buy it. So you can check the smoothness of movement, the presence of vibration, to determine some of the advantages and disadvantages of the device.

- Work the boards in the direction of the fibers.

- If your planer gets stuck or gives “shaggy” chips, sharpen the blades on the blades. It is desirable to entrust it to professionals.

- Don’t force the electric planer while working.

- The flatter the heel is against the drum, the better the cut.

- When working with the side stop to take into account that it moves along the edge of the board, and, of course, if the end is crooked, then the notch will be “ribbed”.

- To ensure an approximately equal working depth across the board, apply more force to the front of the planer at the beginning of the pass, and to the back of the planer when it is finished.

- If you are working with a long log, you need to move smoothly along it parallel to the tool during processing. This avoids stepping stones.

The electric planer is a sophisticated tool. Both when selecting and when operating. Anyway, due to certain advantages. this is almost the only device for carpentry work at home. If you decide to save money on planing boards, buying a planer is the right decision.

The planing process: nuances

To planing in complete safety, the main prerequisite is that the workpiece must be firmly supported. Planing can only be started when the workpiece is securely in place. Roughing is done first. The sherchebet is used for this purpose. The tool with the sherchebet must be driven transverse to the grain. Otherwise, too much wood will be used for planing.

After you have finished small workpieces with a Sherchebet, use a double planer to deburr the surface.

The movement should be along the fibers. The result is a smooth, rough surface

The electric planer is often used to bevel a workpiece. Depending on the width of the required chamfer, the planer works the edge of the workpiece. angled movement allows you to get the right bevel angle.

If you attach a special side stop, usually supplied with the electric planer, it is possible to perform folding. At the same time the stop should touch the workpiece being machined.