How to properly run-in a single axle tractor

Let’s look at this process on individual brands of power tillers.

Oka with Lifan engine

The model should be run-in for 30 hours. During this time, all elements are lapped at light operating modes and defects are determined. The new machine with a Lifan engine during the tests should work at minimum loads.

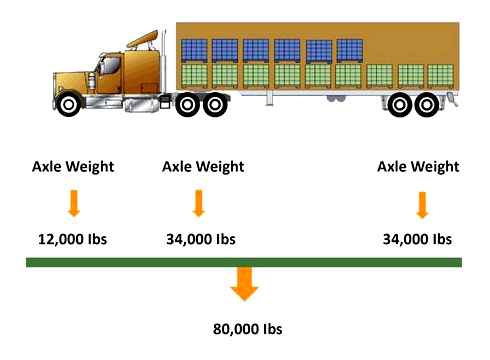

How To Adjust Your Axle Weight On A Tractor Trailer And Correct Overweight Issues

When testing a power tiller on functional operations such requirements are fulfilled:

- The ground is worked to a depth of 10 cm in one pass in one direction;

- the throttle plate should be open to 2/3 of its full stroke;

- On clay soil, the single-axle tractor should work under load for no more than 2 hours.

In addition, you must check the oil level before each start of the engine. In case of shortage refill to the level above the minimum mark on the dipstick.

Neva with Subaru engine

This model, as well as the MB-2 models with other engines, is run-in for 20 hours. This time is quite enough for the parts to run down to the ideal operating condition, as well as to reveal their defects. Do not overload the machine with heavy loads during this period.

The following should be observed during the running-in period:

- Cultivate the soil with a full set of cutters in several stages at a depth of up to 10 cm at a single pass;

- the single-axle tractor should not be loaded with more than 200 kg

- Before starting the engine check oil level and in case of any deficiencies top up above the minimum mark on the dipstick

- fill up the machine with fuel of proper grade and quality.

In another article you can read about the attachments for the Neva MB-2 power tiller.

And on this page it is written about tillage with a power tiller.

You should also regularly check the tension of the drive belt. Do not forget the unlocking element on the left chassis of your power harvester.

Centaur

The machine of this brand should be run in accordance with strict rules. Their fulfillment prolongs the service life of the power tiller as a whole.

Running-in of the new air-cooled Centaur is performed according to the following algorithm:

- Load the engine in stages: it should work on a third of its technical capabilities during the first three hours.

- After the first three hours of the test run, the oil and transmission fluid are drained from the engine.

- For the next 4 hours, run the engine at 2/3 of its rated capacity.

In the process of operation watch the permissible loads. During the allotted time periods by the manufacturer, regularly perform maintenance and routine repairs.

Salute

The Salyut-100 single-axle tractor is run-in at medium rpm. Carry out the first cultivation with 4 tillers. They are gradually lowered with each pass. Cultivate the machine with the coulter.

After every 30 minutes of work take a break of 10 minutes. After the first 4 hours of work change the oil in the engine. Change the oil in the gearbox after the single axle tractor has been run in.

For this model, 25 hours of running-in of parts is sufficient. Do not operate the machine at full load during this period. It is also forbidden to overload it during the tests with weights.

During running-in, such norms are strictly observed:

- When testing the functional modes, you must cultivate the area in 2-3 passes, sinking cutters no more than 10 cm at a time;

- The throttle valve is opened to ¾ of its full stroke;

- engine idle time should not exceed 10 minutes;

- check and top up the oil level in the motor.

In the further process of operation, reliability in the work of the listed models of power tillers is provided by systematic maintenance and routine repair work. This includes obligatory change of oil and transmission fluid.

Getting started

You should never start to use your power tillage machine fully without a running-in period. Those who do otherwise are almost inevitably faced with a host of deformities and breakdowns. The unit may also become unstable if it is not run in first. And what is worse, the premature failure of the machine is likely. This is a sure way to expensive repairs or even to the replacement of the problematic device.

It is important to understand that the preparation for work is no less responsible activity than the operation itself. If one tries to break in a single-axle tractor with violations of the rules, illiterate, it breaks down in almost 100% of cases. Then the necessary repairs turn out to be even more expensive

Commercial Vehicle Weight Limit

It is important to consider that if the overhaul was carried out, the unit and its engine will have to run in again. Without this, there’s nothing to think about the single axle tractor working properly for a long time

Then the necessary repairs are even more expensive

It is important to keep in mind that if a major overhaul is performed, the machine and its engine need to be run in again. Without it, there is no point in thinking that the single-axle tractor will work properly for a long time

How to properly run-in a single axle tractor?

The power tiller is a very valuable piece of equipment in a personal household. Handle it skilfully and responsibly. But mistakes can be made at the very beginning of operation. Learn how to properly run-in a new single axle tractor in this article.

Block: 1/5 | Number of characters: 337

The strain of running in

Each power block comes with a manual, in which the manufacturer specifies for each individual machine. A 50/50 rule of thumb can be derived.е. If the plough plunges to a depth of 30 cm when ploughing, this depth should be 15 cm when running-in.

The running-in time is measured in engine hours and can vary for each single power block from a few hours to several tens of hours (see “How long does it take to run a power block? instructions). Many manufacturers recommend running-in without load, and this is probably the best way for a more gentle start-up.

Oil

As a rule, the presence and type of oil in the sump, says a special label on the tractor. It could be a special running-in preservative, regular preservative, oil, or nothing filled.

To check the presence of oil, you can also unscrew the dipstick, it should leave traces of oil at the correct level. Make sure that it is oil and not a conventional preservative. The absence of oil on the dipstick does not always mean that the crankcase is dry, you should check the presence of oil in the crankcase, to do this, unscrew the bolt from the oil drain hole.

DO NOT start the single axle tractor when the crankcase is dry! Do not do this even if you decide to quickly see if the engine is running or not and then turn it off. Even a second is enough for the engine to make enough revolutions, at which it is more likely that the piston without lubrication will heat up and will catch the cylinder, resulting in jamming the engine.

Block: 2/3 | Number of characters: 1537

Getting started

Without running in the tractor it is absolutely impossible to start using it in full. Those who do otherwise are almost inevitably faced with a host of distortions and breakdowns. Also, the unit may work unstably if it is not precisely run-in. And worst of all, it may break down prematurely. This is a sure road to expensive repair or even replacement of the problem device.

It is important to understand that the preparation for work is no less responsible activity than the operation itself. If an illiterate person tries to overhaul a single axle tractor, it will break down in almost 100% of cases. Then the necessary repairs are even more expensive. It is important to keep in mind that if a complete overhaul has been made, the machine and its engine will have to run in again. Without this, there’s nothing to think about a single axle tractor running properly for a long time.

Block: 2/5 | Number of characters: 983

How to break in a single axle tractor?

This is very important for a person who has just bought a power tillage implement: it is prohibited to immediately put fuel in it. You can only use the machine when it is running in. This is prescribed in the instruction manual of any model.

The subtleties of running-in of a power tiller:

- At this time, the engine is not running at full throttle, and the gears in the engine and gearbox are lapping. This is called working halfway. That is, if your single–axle tractor is designed to work the ground to a depth of 60 centimeters, then during the running-in you should work the ground at a low speed of 30 centimeters;

- The duration of the running-in will depend on the model of the unit and can be several hours or several hundred hours;

- Pay attention to the sticker on the machine itself, it will indicate what liquid is in the engine crankcase: oil, running-in preservative, simple preservative. It can also be empty. If there is oil or oil preservative in the crankcase, then you can safely start running-in. If it is empty or a simple preservative, then refill or replace the fluid with oil. Never start the engine with an empty crankcase! In just a short period of time, the piston overheats from high revolutions and causes the cylinder to be scraped by the engine.

Run-in phases of your power tiller:

- Check the oil level before you start the engine each time;

- Fill up only the high-quality fuel brand that is right for your model of power tiller;

- After that, you can start the machine. Let it run at medium rpm. After that, alternately work in all gears;

- After that, you should alternately perform all the functions your machine is capable of: cultivate, plow, dig. However, observe the permissible loads specified in the manual!

During the running-in period, you not only extend the service life of the machine, but also get used to it under low loads. You also get to know its capabilities and features. It should be noted that the running-in of a diesel motoblock and the running-in of a gasoline motoblock is practically the same. The important thing is to adhere strictly to the recommendations described in the owner’s manual.

Block: 3/3 | Number of characters: 2148

How to do the running-in

It is absolutely necessary to run the single axle tractor in. This moment is not only important, but also key. The service life of the engine and other equipment depends on this activity. Never fill the tractor with fuel and do not start the engine immediately. it could burn out. The device may only be operated after it has been properly run-in. This action is considered an automotive and engineering term. During the running-in period, all gear couplings in the gearbox are lapped.

Do according to the owner’s manual. The permissible loads for a particular machine are indicated. Failure to follow basic rules may lead to premature failure. If the function of the power tiller is to plow soil up to 50 cm deep, then the action is carried out at 30 cm and only on virgin soil. The running-in time depends on the particular unit. Some engines are sold with oil, others are dry. This point must be taken into account

Particular attention is paid to the machine oil

It is important to determine which engine is to be used. The hint is on the labels and stickers for it

When the oil is poured into the crankcase, you can begin the running-in. If it is absent and there are no clues on the engine, you need to pull out the dipstick and check the presence/absence of lubricant by it. If there is oil, it is necessary to start running-in, if not. fill up.

If you have difficulty, it is recommended to unscrew the oil drain bolt and check for oil.

This is a simple action. If the lubricant is present, it will leak immediately. In this case, it is recommended to drain it and pour new oil. Do not accelerate the engine when running-in the tiller. this may have dangerous consequences. It is not advisable to torture the equipment, the procedure is carried out slowly and carefully.

Sequence of operations

The engine is running in and running-in of all components in the engine, transmission and running gear. The action is carried out sparingly for the first 8-10 hours, it is not recommended to rush and work at full power. There are 4 basic rules to follow:

Check the oil level before each start of the engine. If necessary, add oil to the power train components. It is mandatory to fill the fuel tank. In essence, there is nothing complicated about it. However, before carrying out this action, you need to buy the necessary brand of fuel with the proper quality. At this stage the machine is started. It is desirable to let the engine run at medium speed. During the next hour it is necessary to work in all gears alternately. This is to test the function of the engine. During this procedure is not only running-in, but also getting used to the peculiarities of the device. After all gears have been tested all functional features should be checked. At this stage it is advisable to cultivate, plow and carry loads

Important: The permissible load must be observed during these actions.

How to run-in a single-axle tractor, every owner of the device should know. After all, the further work of the machine depends on it. At the end of the running-in period it is required to change the oil in the engine and transmission nodes. Do not run the engine idle for any length of time without movement. This is the most common mistake. It can lead to serious problems in the future.

Carefully read and understand the operating manual before beginning work. All actions are carried out carefully, according to the described rules. In this case, there is no need to worry about further service life.

Model Specifications:

| Engine model | 186F |

| Engine power | 9.0л.с. |

| Oil volume | 0.6л |

| Start-up system | electric starter |

| Tank Capacity | 6.0л |

| Working width | 1350mm |

| Cutter diameter | 300mm |

| Number of gears | 3 forward, 1 reverse |

| Dimensions | 18001350850mm |

| Weight | 135kg |

| Wheel availability | Yes |

Features:

| Engine capacity | 296cm3 |

| Engine power | 4,9kW/6.6л.с |

| Starting | recoil starter |

| Fuel tank | 3.5л |

| Working depth | up to 30cm |

| Processing Width | 120cm |

| Gears front/rear | 2/1 |

| Weight | 125kg |

| Max. speed | 10 km/h |

| Dimensions | 18011085cm |

Approach to different models

It takes 20 hours to put the Neva and the Ploughman through their paces. For an “Oka” power tiller with a Chinese engine this is 30 hours. The most capricious of all blocks “Zirka”. they are run-in for at least 50 hours. During this procedure it is not recommended to plow or cutter installed on the Zirka more than 10 cm into the ground. It is important to remember: lubricate all motoblocs only with immaculately clean oil, carefully making sure that it is not contaminated and while pouring.

When running the single axle tractor with a Briggs Stratton engine in a tractor, you must change the engine oil every 5-8 hours. If a Honda engine is installed, you should not be allowed to idle for long periods of time. Otherwise accumulation of oil in the crankcase will deprive the grease of its useful properties. Subaru requires:

Monitor the condition of the air filters;

Evaluate the quality of the spark plugs and fuel lines;

Avoid heavy soiling of the cylinder ribs.

To learn how to properly run the single axle tractor see the video below.

Peculiarities of the procedure

The first step is to scrupulously check every fastener, every bolt. The tank is 100% filled with gasoline or other necessary fuel, engine oil. You should also make sure that you have enough coolant available. running in does not mean just “lapping” the engine parts against each other, or “working in” between them. Careful inspection of the serviceability of the brakes and steering apparatus is also required.

It is not possible to run the single axle tractor properly if the steering is not correct. After the running-in period, inspect each part immediately. It takes time, so it is worth carefully planning all the work, so that nothing interferes with the process. A technical inspection includes:

- examining the condition of each packing and bearing

- wiping them down with oil;

- Immediate replacement of damaged and deformed parts;

- checking the fork springs and control elements.

This is interesting: Characteristics and attachments for power tillers Oka MB-1D1M10 and MB-1D2M16. learn in detail

The single axle tractor should always be run in. This is not only important, but also of critical importance. The long service life of the engine and other equipment depends on this measure. Pour fuel and immediately start the engine under no circumstances. this can cause it to burn out. The unit may only be operated after it has been properly run-in. This action is considered an automotive and mechanical engineering term. During the running-in period, all gear pairs in the gearbox are lapped.

Do this in accordance with the owner’s manual. The permissible loads for a particular gearbox are indicated. Failure to follow basic rules may lead to premature failure. If your power tool is designed to work on bare soil down to a depth of 50 cm, you should only work at 30 cm. The running-in time depends on the specific machine. Some engines are sold filled with oil, others are sold dry. This is a point to keep in mind. Particular attention is paid to machine oil.

It is important to determine which engine you want to work with. The hint is on the labels and stickers to it. When the oil is in the crankcase, you can start running in. If it is not, and there are no hints on the engine, pull out the dipstick and check for the presence/absence of lubricant. If oil is present, it is necessary to start running-in, if not. pour in.

If there are difficulties, it is advisable to unscrew the oil drain plug and check for oil.

This is a simple step. If the lubricant is present, it will immediately leak. In this case, it is recommended to drain it and pour in new oil. It is important to determine which engine is to be used. When working on the tiller, do not accelerate. this may lead to serious consequences. It is not advisable to torture the machine, the procedure is carried out slowly and carefully.

Sequence of operations

Running-in is the lapping and running-in of all the parts in the engine, transmission and running gear. The action is performed sparingly for the first 8-10 hours, it is not recommended to rush and work at full power. There are 4 basic rules to follow:

- Check the oil level before each start of the engine. If necessary, it must be refilled in the transmission units of the power tiller.

- The fuel tank must be filled. In essence, there is nothing complicated about it. But before you do this, you must buy the fuel of the appropriate grade and quality.

- At this stage the rotary cultivator is started. Let the engine run at a medium speed. During the next hour it is necessary to drive in all gears one after the other. This will allow you to test the functional features of the engine. During this procedure is not only running in, but also getting used to the peculiarities of the device.

- After testing all the gears it is necessary to check all the functional features of the device. At this stage it is desirable to cultivate, plough and transport loads. The tractor and implement must not be used for extended periods of time.

How to run-in a single-axle tractor, every owner of the device should know. the more durable it is, the more difficult it is to sharpen by hand, but the longer the result will be. You should replace the oil in the engine and transmission at the end of the running-in period. In no case you can not run the engine at idle speed without movement. This is the most common mistake. This can lead to serious problems in the future.

Carefully read the manual before operating the machine. All actions are carried out carefully, according to the described rules. In this case, you can not worry about further service life.

Getting your power tool started for the first time

When buying a new motoblock before the first test start and check it for performance, it is imperative to check the presence of engine oil in the crankcase of the motoblock. To do this, you can inspect the oil dipstick or unscrew the plug of the engine oil drain hole.

The engine oil is usually filled in at the factory and a sticker is attached to the single axle tractor with relevant information, but this is not always the case. It is better to make sure yourself, because starting the engine without engine oil will lead to its jamming or failure in just a few revolutions. That’s why you should always remember about it when starting a new tractor for the first time.

Neva motoblocks with a Subaru engine

This single-axle tractor is run-in for 20 hours (like other Neva models with different engines). During this period the load on the single axle tractor must not be exceeded. Cultivate no more than 10 cm and transport loads weighing no more than 200 kg.

Centaur motoblocs

Running-in of the air-cooled Kentavr engine should be carried out according to a clear algorithm:

- For the first three hours, the engine must run at a third of its capacity;

- Drain the oil from the engine and transmission units, replace it with new;

- further 4 hours let the power tiller work at 2/3 of the engine’s capacity.

Also keep in mind the load limits and after completing the run-in. Carry out regular inspections and repairs.

Oka with Lifan engine

This model is run-in for about 30 hours, performing simple work with minimal loads. When running in with an attachment, remember the following rules:

- Do not work more than 2 hours on difficult soils (e.g. clay soils);

- Throttle opening should be 2/3 open;

- Ploughing should be carried out to a depth of 10 cm in a single pass.

Number of blocks: 14 | Total number of characters: 17118Number of donors used: 5Information on each donor: