How to do something yourself, with your own hands. home master’s site

EXCELLENT TOOL FOR MASTERS AND HANDICRAFTS AND EVERYTHING FOR THE GARDEN, HOUSE AND COTTAGE LITERALLY A GIFT HAVE REVIEWS.

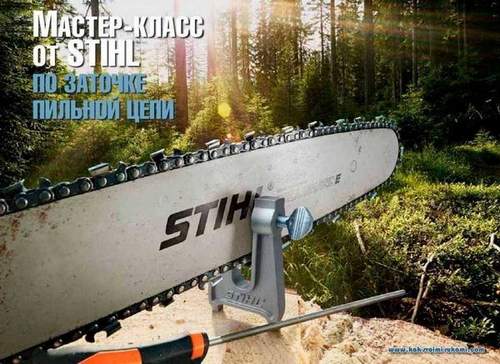

ANY CUTTING INSTRUMENT, WHICH SHARES IT IS NON-ACUTE AND HARD, IS DECKED IN THE WORK. TO SAVE ITS ORIGINAL PERFORMANCE, THE USER HAS TO STRESS THEEST PRESS ON IT DURING WORK, WHICH INCREASES FRICTION. USUALLY, THIS RESULTES IN INTENSIVE HEAT DISCHARGE IN THE CUT ZONE, AND WHEN CUTTING WOOD MAY APPEAR SMOKE AND SMELL. TO EXCLUDE A SIMILAR SITUATION, IT IS NECESSARY TO HELP PERIODICALLY THE CUTTING TOOL TO RESTORE ITS ORIGINAL PROPERTIES. HOW TO INDEPENDENTLY HAND GRINDING A CHAIN SAW? ABOUT THIS TODAY, WE TELL US SERGEY GEKMAN, STIHL AND VIKING PRODUCT TRAINER.

ABOUT THE DESIGN OF THE SAW CHAIN SET

First, a few words about the design of the saw chain. All modern saw chains are three-link and are designed according to the same principle. They consist of leading links, connecting links, as well as left and right cutting teeth (installed alternately).

Over time, it is the cutting links that become dull, even though STIHL only manufactures them from wear-resistant chromium-nickel steel. The chain is put on a tire with a guide groove along which its driving links slide. Note that in STIHL chains, the abutment surface adjacent to the tire is subjected to induction hardening during manufacture to increase wear resistance. Tires have perfect symmetry, so they can be turned over, swapping the bottom and top, which allows you to evenly distribute the load on both sides.

EVERYTHING NECESSARY FOR THIS ARTICLE IS HERE >>>

The chain is driven by a drive sprocket on which the chain is worn. Each chain is necessarily pre-stretched during manufacture, which minimizes elongation during initial use, increases its service life and reduces wear.

CHAIN PARAMETERS

The main geometric parameters of the saw chain are the pitch, the height of the profile and the shape of the cutting tooth, the thickness of the drive link, the number of links. A step is half the distance between the centers of three consecutive rivets.

It is customary to measure it in inches, and each has a symbol (see table 1). Saw chains along the height of the tooth profile are divided into low and high profile. So, for powerful chainsaws, STIHL provides Rapid chains with a higher tooth, and for less powerful chains, Picco chains with a lower tooth. The number of links determines the chain length, depends on the power installed in the engine saw, as well as the type of work performed and corresponds to the size of the tire.

The thickness of the driving link is measured in millimeters (mm) and should correspond to the width of the groove of the used tire (s / i. Table 2). The last digit of this thickness is stamped in the form of a symbol on each leading link of the chain.

Saw chains can also differ in the shape of the cutting tooth. There are two such forms for STIHL chains of production. Micro (M), Super (S). Without going into the subtleties of the design, we note that the saw chain with the shape of a Micro cutting tooth is universal, it combines high cutting performance, ease of use, a long service life and easy maintenance.

Conforms to the requirements of construction, agriculture and forestry. The Super tooth cutting saw chain combines maximum cutting performance, high cutting efficiency and low feed force, meeting the highest requirements for a professional forestry tool. Such chains cut faster and are good for cutting hard or frozen wood. When sharpening the Super chain, there are certain features.

STIHL also has a Duro saw chain with tungsten carbide tipped teeth. It combines the highest durability, ease of use and good performance. It is steady when working with dirty wood or with short contact with the ground, when sawing boards from formwork or scaffolding after completion of work.

Highly effective when used in forested areas damaged by fire. Duro chains last up to 10 times longer than saw chains without carbide brazing. Such chains are much more expensive, and are sharpened by an electric grinding machine with a diamond grinding wheel in specialized service centers.

Video: How to Properly Sharpen a Stihl Chainsaw Chain

Cutting teeth work on the principle of a planer: they cut chips from wood. The depth of cutter cutting into the wood and thus the thickness of the chip is determined by the distance between the depth gauge and the upper part of the cutting tooth. If this distance is not enough, then the saw chain will not pick up chips (that is, saw), but will only glide over the wood. And vice versa, the greater the height difference between the limiter and the top of the cutting tooth, the thicker the chips, but at the same time the greater the vibration produced by the chain, as well as the higher the load on the drive mechanism. Therefore, it is necessary to achieve the optimum ratio of chain vibration to performance, and in all STIHL saw models this ratio is selected.

HOW TO DETERMINE WHAT THE CHAINSAW CHAIN IS TIME TO CHARGE

Frequent work with a chain saw leads to a rapid blunting of the cutting teeth, and when abrasive particles (for example, earth) get in, this process is accelerated. Sometimes it is necessary to restore the cutting ability of the saw several times during one working day: with timely sharpening, less steel will have to be removed each time, which will increase the service life of the entire cutting set in the complex. We list the most characteristic signs of blunting a chain:

- – the saw does not cut into the wood itself, requiring significant pressure on the motor block;

- – instead of large shavings, the saw chain throws out small sawdust;

- – the appearance of smoke and burning odor during sawing, despite the flawless operation of the oil pump and sufficient chain tension;

- – the saw “leads” to the side due to uneven wear of the cutting teeth;

- – when sawing, the chain “beats” and “jumps”, which can be caused by the small distance between the vertices of the depth gauges and the corresponding cutting edges.

In addition, STIHL chains are marked with special lines. these are wear marks. If the chain is worn down to such lines, it is necessary to replace the chain.

PRACTICAL RECOMMENDATIONS FOR SHARPENING CHAINSAW CHAINS Stihl

Sharpening the saw chain with the appropriate knowledge and skills is not difficult, but requires compliance with certain rules. Consider the most useful and necessary.

When working with a saw for a long time, it is necessary to periodically grind its cutting part during the day, since all cutting teeth must first have the same length, sharpening angle and position of the depth gauge.

To do this, first we find the shortest tooth, take it as the reference point, and in the process of sharpening we adjust all the other cutting teeth of the chain to its length. If it is in the right row of teeth, then the guide rail is fixed in a vice with an end sprocket to the left; Then we place this tooth in the grinding zone and turn on the chain brake. Sharpening is carried out with a round file of a certain diameter, depending on the chain pitch. <see table 1), holding it at right angles to the tire plane in the vertical direction and at the sharpening angle. in the horizontal. For the cross cut of wood, the grinding angle is usually 30 °, and for the longitudinal. 10 °.

For this reason, two types of saw chains are produced. transverse and longitudinal, differing in sharpening angle.

When working with a file, 20-25% of its diameter should protrude above the upper face of the cutting tooth. Remember that the file grinds the metal only when moving away from you, and when moving backwards, it should be lifted. In addition, the file should be periodically turned a little around its axis to prevent uneven wear. After two or three forward feeds, check the evenness of steel removal from the grinded tooth. If the removal takes place in places, then either you are using the wrong file, or you are moving the file too high or too deep. You need to grind the cutting edge until the light strip disappears on it.

After receiving a high-quality cutting edge of the sharpened tooth, first turn off the brake, move the chain to the next tooth on the same side of the tire and reinstall the brake before sharpening. Grind the remaining cutting teeth on this side to the same length, then rotate the tool 180 ° and grind all the teeth on the other side in the same way. Recall that all of them need to grind to the length of the initial tooth. If the cutting teeth of one row are longer than the other, then align them by performing one or two additional grinding movements.

Compliance with the above recommendations helps to obtain the correct and the same values of the front cutting angle and sharpening angle at the same height of all cutting links of the chain.

Now we need to adjust the depth limiters, since the height differences between the upper points of the cutting edge and the cutting limiter decreased as the teeth were ground, and it didn’t work the same, because the teeth had to be aligned.

To check this value, it is convenient to use a filing gauge corresponding to the chain pitch and determining the cutting depth (see table 1). It is a template for controlling the position of the depth gauge, it is placed on the cutting tooth, and if the depth gauge protrudes above the upper plane of the caliber, then this surplus must be removed with a flat file. Do not touch the file of the sharpened cutting tooth. Count the number of file feeds when processing the first depth gauge and grind the depth gauges of the remaining cutting teeth about the same number of times, remembering to round the front edge of the limiter to reduce vibrations and reduce the risk of kickback.

In conclusion, we note that the manual sharpening of a chainsaw justifies itself to maintain the productivity of the tool when it is used intensively during the working day. over, STIHL offers a wide range of accessories to facilitate and increase the efficiency of such sharpening. These are special guides, various tool-grinding devices, control calibres, etc. After 3-4 manual sharpenings, we recommend that you carry out professional mechanized sharpening of the saw chain in a specialized service center to guarantee high performance and excellent cut quality.

application

Table 1. Size range of saw chains