Step two: remove the winding drum (spool) with line

The next step in the process is the removal of the winding drum with line from the inside of the head. You need to turn the head open side to see the line and spool. On the side of the head, find two grooves (eyes) through which the line is brought out.

It is necessary to free the line from the holes by turning the drum. then carefully remove the coil from the head area. The winding drum of some models is spring-mounted. This point must be taken into account when performing the extraction operation.

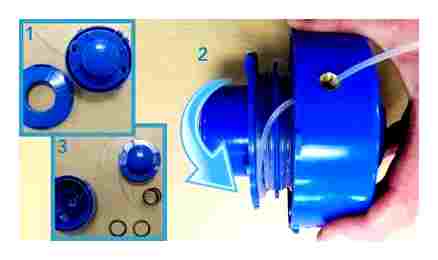

The procedure for removing the trimmer spool with line from the inside of the head: 1 – head assembly with spool; 2 – extraction carefully with a small axial rotation; 3 – extracted parts

The old line is completely removed from the reel. To remove the old trimmer line, you need to remove the wood from the locking loops and pull the free end. This method removes all the old winding. The same process is repeated on the second section of the drum. The master is recommended to use gloves when performing work.

Step three: complete the head assembly

Pull out the ends of the line through a pair of oval spool slots. Replace both washers and the spring (if any) with the supplied new parts. Bend both ends of the line at right angles.

The final technical touch of the process of changing the line on the trimmer is the imposition of the cap on the head, followed by fixation by pressing force and slight twisting..

Pass each end into the hole at the base of the winding drum. Install the coil in the inner area of the head, resting on the spring. Put on the cover, align with the base and lightly press downwards with a small counterclockwise rotation, place the cover on the tabs of the clips. This completes the replacement procedure..

Step one: securing and laying

Fold the end of the line in half. Place a blank over the spool on each side of each half of the winding zone. Wrap both halves completely around the winding drum. Pull the line through the loop.

The procedure for preparing the line engagement in the area of both winding sections of the drum. The loops are placed in specially made cutouts, after which the line is wound in each zone

It is enough to pull the line tightly and plant the knot in the groove made on each side of the winding drum.

How to replace the line on mowers …?

removing the trimmer head cover

At the first stage of disassembly, the trimmer head cover is removed. In the example of Black and Decker trimmer models and others, to remove the cover, it is usually enough to apply some pressure to depress the locking latch that is located on the side of the head body..

On some models of lawn mowers, it is initially provided for the dismantling of the trimmer head, for which the hex key included in the tool kit is used. The head is usually held in place by two to three screws, which are accessed through the side holes of the rear decorative cover..

The head cover, where the line spool is installed, is usually held by a latch-tongue. It is enough to squeeze the latch tab with some effort and turn the lid slightly, after which the lid can be easily removed

How to replace a bad fuel line on a lawnmower

At the moment of squeezing the locking tab, you need to slightly turn and lift the trimmer head cover to remove the winding drum..

Step two: winding the cutting material in sections

The next step is to wrap the line around the reel, being careful. It is necessary that each half is filled with its own winding, evenly, without intersections. Usually, arrows can be seen on the body of the winding reel, indicating the direction of winding. This point should be borne in mind when filling the spool with fishing line..

How to replace the trimmer line?

Replacing the trimmer line with step-by-step instructions will allow even an inexperienced lawn mower owner to perform a rather difficult job.

However, before starting work on changing the line on the trimmer, it is necessary to ensure the safety of the work. In particular, measures should be taken to prevent unintentional or unintentional starting of the mower:

- exclude spontaneous start,

- remove battery (if applicable),

- place the tool on a platform convenient for work.

It is convenient to work on changing the trimmer line when the mower is lying on the table, and the master who replaces the trimmer line has the ability to approach the tool from either side.

Replacing the trimmer line: step-by-step instructions for replacing the trimmer line

Trimmers (they are also lawn mowers) are actively used by modern society for the care of lawns and other similar objects of horticultural farms. The tool is noted for its high efficiency, despite the questionable quality of cutting grass (compared to the usual peasant scythe – earth and sky). The main advantage of trimmers (lawn mowers) is high productivity with low expenditure of physical forces of the operator. However, over time, the trimmer’s cutting element (nylon scaffolding) wears out or gets damaged, making the trimmer a useless tool as a result. Hence, the task becomes urgent – how to replace the trimmer head and how to replace the trimmer head line? Let’s consider this process using the example of lawn mowers manufactured by “Black and Decker” and others.

The line is flying out

The reason that the cord unwinds after starting the unit can also be a weakening of the spring inside the head..

In addition, there are times when the mowing head flies apart when the machine is turned on, and the spring installed in it is lost..

Inexperienced users do not notice the absence of a spring and assemble this unit without it. Therefore, the cord does not hold, and under the influence of centrifugal force flies out.

Trimmer head with two antennae

Head with two flutes

After removing the spool from the spool body, we determine the number of strands for winding the fishing line (1 or 2).

There is no fundamental difference between bobbins with one and two grooves, but if carelessly threading into the twin groove, there will be operational problems..

Due to the likelihood of interlacing adjacent lines of the tool, a situation may arise when, after wear of the working antennae, it is impossible to remove new ones..

Regardless of the number of streams, a fishing line with a length of 1.5 to 3 meters is taken for refueling. Winding must be done in the opposite direction to the rotation of the head, since winding in the direction of travel will lead to the fact that the line will not be removed from the reel.

After the fishing line is tucked into the trimmer coil, thread the free ends (15-30 cm) into special holes. Next, we assemble the head in the reverse order of disassembly and check the operability.

Do not worry if the ends of the two antennae are very different in size, because when you start the trimmer, the knife installed on the protection will cut off the excess.

Cord breaks

If the line breaks frequently, this may be due to the following reasons:

- stones, small branches and other solid obstacles come across in the grass;

- the user mows the grass close to the fence, and if it is mesh, then it breaks off the “antennae” even faster;

- poor quality of the cord (it is recommended to purchase a quality one);

- the outlet holes in the mowing head are worn out, due to which the line is erased on the sharp edges of the bushings and breaks off (a complete replacement of the part is required).

How to properly wind the line in the trimmer, and what to do if the line is quickly consumed, breaks

The trimmer is the most common machine used for cutting grass and small bushes. This device is distinguished by its simplicity in maintenance, uncomplicated operation during operation, and due to its low weight, even women can handle it..

It is no secret that for high-quality performance of work on mowing grass, the correct selection of cutting tools is required. As the latter, special cutting attachments (discs, knives) or trimmer heads with a fishing line inside are used in trimmers.

Nozzles and fishing line are consumable tools, but if the knives can be sharpened, then when the line is used up, it must be replaced. In this article, we will tell you in as much detail as possible how to properly replace the fishing line..

Thickness selection

In addition, you should pay special attention to the thickness of the consumable. For mowing young grass, a thread with a diameter of one and a half millimeters is suitable. The larger the diameter of the thread, the drier and coarser weeds it is capable of overpowering.

When choosing a fishing line by thickness, there is one “but”. It is important not only to assess the capabilities of the material, but also to take into account the features of the trimmer. Be sure to check the user manual that came with your tool for information on cutting element requirements..

Using the wrong thread can damage the tool. Using a thread that is too thick will overload the machine’s motor. And the use of a thread that is too thin will significantly increase the wear of the twisting mechanism..

That is why it is necessary to approach the choice of consumables no less responsibly than to refuel it in the trimmer. When a suitable fishing line is found and purchased, you can begin to consider ways of winding it on a reel..

How to wind the line on the trimmer reel: refuel, which is better, change

No cord feed, coil does not spin

An automatic or semi-automatic head should feed the line without stopping the unit. But if it does not come out, then the reasons may be as follows:

- the fishing line is incorrectly wound in the reel, due to which the latter does not spin;

- the cord is wound unevenly, and the thread can get stuck between the turns (the thread should be wound neatly, turn to turn, without distortions);

- too short ends of the thread come out of the holes, as a result of which there is not enough centrifugal force to extract them, and the fishing line is not fed (it is recommended to always adjust the length of the cord before starting the unit, pulling it slightly);

- the line is stuck together (will be discussed later).

How to change the line on a mower

Many lawn mower owners are confused by the question of replacing the line in the trimmer head. Sometimes this turns into a whole problem that can render not only the tool, but also the mower inoperative. To prevent such a situation, we will analyze step by step the process of replacing the cord (line) in the nozzle..

We remove the nozzle from the gearbox. To do this, it is necessary to combine the side hole of the lower figured washer and the recesses on the axle, insert a screwdriver and fix the shaft from scrolling. Then you can unscrew the nozzle. It should be remembered that the thread on the shaft has a left-hand thread, respectively, the element must be unscrewed by turning it to the right.

The next step is to disassemble the body of this unit. Typically, the cover is attached through the slotted holes using latches. To open it, you need to sink the latches into the case and squeeze the edges of the lid. If the nozzle has an automatic or semi-automatic line feeding mode, it means that there is a spring inside, which may fly out during disassembly. Therefore, we hold all the parts with our free hand and carefully lay them out on the surface..

Now we take the fishing line, measure out 5 meters and cut off this piece. It is not recommended to wind a cord with a diameter greater than the value specified in the instructions for the tool. Otherwise, you can get an increase in engine load and increased fuel consumption. Fold the line in half to find the middle and get this “loop”.

On the spool, in its middle part, there are 2 notches located opposite each other (instead of notches there can be holes). We hook the “loop” into one of the grooves and start winding the line counterclockwise. If the reel has two compartments, then the winding goes separately for each branch of the line. Leave the last 15-20 cm of cord free and clamp both ends through the notches at the top of the coil.

We collect the feed elements (spring and washer) in the nozzle and bring the free ends of the line into the holes on the body. We put on the cover, snapping the latches into the corresponding grooves. After that, we pull out the free play of the cord.

It remains to screw the nozzle into place, proceeding in the same way as in the first step. Only now, in order to twist the element, it is necessary to move it counterclockwise.

Here is such a simple instruction will help you quickly replace the trimmer line without spending much effort looking for other solutions..

A trimmer is a necessary and useful tool for a summer cottage and a private house. Many people own and actively use it, but not everyone knows how to replace the line in the trimmer, especially at first.

In this manual, we will walk you through the entire replacement process step by step. Looking ahead, there are two ways to line the trimmer spool. There is no fundamental difference – the difference is that in the first case one line will be refueled, folded in half, and in the second there will be two such lines.

How to wind the line around the trimmer cutter head or lawn mowers

Changing the line in the trimmer: 2 easy ways

Feedback from our readers is very important for us. Leave your rating in the comments with the reasoning for your choice. Your opinion will be useful to other users.

When spring comes, people often spend their free time at their summer cottage. They try to rid their area of problems such as weeds and grass with the onset of warm days. It is difficult to do this manually, especially if the area is very large, so a lawn mower will help. Thanks to this technique, you can trim the grass and remove weeds – it is a suitable device for mowing unnecessary plants near the fence, at home, between rows in the garden on a flower bed, and so on. Read about how to choose the right mower for your needs here. The cutting element in this device is a fishing line (strong polyethylene thread), which is wound on a special element – a spool. But over time, the line wears out and it becomes necessary to replace it. The article will talk about how to fill the line in a lawn mower..

Replacement instructions – how to insert the line

It should be noted that the reels in mowers can be different:

- for functioning with one antenna;

- for functioning with two antennae;

- the line must be threaded through the through hole, which is located inside the element.

And do not confuse this part with an extension cord for a lawn mower on a reel, because despite the similar name, these are two completely different elements.

The mini chainsaw is designed for light work and people who prefer to hold the device with one hand.

This article will tell you about how much the ZIL 130 dump truck weighs and what this transport is capable of..

Read here //machinspec.com/lesozagotovitelnaya/benzopila/stanok-dlya-zatochki.html how to assemble a machine for sharpening chainsaws with your own hands quickly and easily.

In the first option, winding the cutting element is very simple:

- There is a locking tab on the inside of the spool element.

- One tendril of thread is inserted into it.

- It is necessary to thread the nylon thread in the direction opposite to the rotation of the spool element.

- You will need only 2 to 4 meters of fishing line. When the winding process is completed, put the small end of this cutting element outward and fix it in the groove, which is necessary for fixing the fishing line so that it does not unwind during the operation of the mower..

- If there is no special groove, then the end should be held by hand so that the cutting element does not unwind during further assembly of the element..

- At the last stage, it is necessary to thread the outer end of the thread into a special hole located on the outer part of the element. The spool can then be inserted into the mower..

When the roller is working with both ends of the plastic filament, then the following steps must be taken to thread the line into the mower:

- Inside, on the spool, you will see how many slots there are for winding (two or one). If there is one groove, then both ends of the thread will be guided through this groove. If there are two of them, then the antennae are laid out separately – each in its own notch.

- It is necessary to unwind from 2 to 4 meters of polyethylene thread and thread its two ends into the hole.

- Wind both threads in the opposite direction to the rotation of the drum.

- When all the line is wound, the ends should be fixed in the grooves or held by hand.

- Both ends are threaded into the eyelet from the outside of the roller housing.

- The drum is then collected and inserted into the mower..

Tips and steps for changing the line on video.

To insert line into a lawnmower that has two grooves on the spool, you must use the previous threading method for this polyethylene thread. In this case, each of the ends of the line will be wound along its own groove. All other actions are similar to the previous process.

The spool element or roller can have a completely different design from the previous two options. The line can be threaded through the eyelet, which is through and is located inside the reel. In this case, you do not need to disassemble the roller drum and manually wind the polyethylene thread..

The polyethylene thread is threaded through the hole and rotated by pressing a special button. This button is located on the body and is intended for the operation of the equipment so that it is possible to release the line as it wears out..

Do not worry that the polyethylene thread will wind in the wrong direction, since in this design it can only rotate in one direction..

Which line to choose to refuel the lawn mower

The thickness of the polyethylene thread depends on the model of equipment and varies from 1.2 to 4 mm. She may be:

- with a round cross section – this is the most durable material for mowing grassy plants;

- with a curly section – used for mowing soft plants;

- twisted – used for thin grass;

- professional type, not suitable for all models of equipment.

To change the line on a lawn mower, you need to purchase a cutting thread that will be ideal for the type of mower..

You can soak the thread in a bowl of water for a few minutes to increase elasticity and strength..

Preparing for replacement

We disassemble the trimmer spool

For clarity, the mowing head (spool) was removed from the lawn mower. To replace the fishing line, you do not need to remove it, everything is done locally. It doesn’t take long.

We disassemble the trimmer spool – it rests on the latches. Remove the cover by pressing on the latches. If you do not have enough effort to do this with your hands, then use a screwdriver.

The spool consists of the following:

- Spring case

- Cover with locking latches

- Button coil

The principle of operation is as follows. By pressing the button, the spool presses on the spring and comes out of the locking grooves in the spool cap. Holding in this state, the reel can be twisted, thereby adjusting the length of the line. When the button is released, the body spring returns the coil to its original fixed state.

Disassembled trimmer spool

On the bottom of the reel there are several holes for different diameters of the lines. They may differ from trimmer manufacturer. In some cases (like here) they are signed, in others they are not..

These holes are needed to fix the line when changing it. After winding the fishing line on the bobbin, the ends of the latter are inserted into them. This is necessary so that the scaffold does not unwind when the coil is installed in the trimmer body. In other words, it makes it easier to change the line..

Holes for fixing the line

There are models without specifying the diameter of the consumable. Then, in order to find out what the maximum diameter of the scaffold can be used, it is tried on along the holes for the outlet of the fishing line from the trimmer spool body (see the figure below).

Fitting on the holes of the line output

The reel has two line sections separated by a baffle. They may not exist. They are needed only to delimit and facilitate the winding of the consumable.

Two sections for line

First, they are determined with the required length of the loess. The latter is wound into one of the sections of the coil so that it does not go beyond its limits. In this case, 3 mm was wound, the length turned out to be about 2 meters. Those. for two sections you need a 4-meter segment – this is for the 1st method. For the second method, you need two segments of 2 meters each.

Determining the required line length

Now you need to figure out which way you need to wind it. To do this, many trimmer manufacturers apply special designations to the spools, such as in the figure below..

Special designation on the reel

If no such designations were found, then you need to pay attention to the spool body. There is necessarily an arrow that indicates the movement of the mowing head. The line is wound in the opposite direction.

Bobbin case designation

The first way

Line bent in half

The prepared segment (in this case, it is 4 meters) is bent approximately in half, – one segment should be 15-20 cm longer, and inserted into a special slot located on the dividing partition.

The line is inserted into the slot

The line is wound in the direction determined earlier. This is done in an interference fit, the line is neatly distributed. In this case, you need to wind a segment that is longer in the section that is closer to the button.

There are designs that do not provide for dividing the coil into two sections. This does not change anything, the line is wound in a similar way. You just need to make sure that the segments do not overlap with each other..

The first should end that section, which is located at the bottom of the coil, i.e. the one closest to the fixing holes.

This tip fits into the corresponding hole in diameter. The line is securely fixed.

The line is securely fixed

A long segment is wound half a turn. There he is similarly fixed. In this case, the segment crosses another section of the coil..

A long segment is wound another half turn

The fixed ends of the coiled line are inserted into the holes in the trimmer spool body.

The fixed ends of the coiled line are inserted into the holes of the trimmer spool body

The coil is attached to the body. The ends of the fishing line are pulled with effort so that the fishing lines previously fixed in the holes of the reel jump out from there. It is easily identified by the characteristic sound (click).

The ends of the line pull up with effort

Button spool snaps into trimmer spool housing.

Button spool snaps into trimmer spool housing

The line was changed successfully. In this case, you need to put it back on the trimmer and you can start mowing the grass.

It should be repeated, there is no need to remove the spool from the trimmer – this was done for clarity of the process of replacing the fishing line. You can disassemble the spool in place, wind it on the spool and put it back.

Line replacement completed successfully

Tips so that they do not hit the trimmer cover can and should be trimmed.