What can be sawed with a circular saw

Today we will continue talking about the tools needed in the carpentry workshop. Let’s find out what is the difference between a circular saw and a circular saw.

Some beginners are not well aware of the differences between the two tools and often confuse them. The fact that they both use the same working body. a circular saw blade. It is a steel circle, on the outer edge of which there are teeth, like a saw. The disk is installed on the axis of the electric motor. As it works, it rotates and cuts the material.

The main area of application for these saws is woodworking. With the appropriate saw blade, these tools can be used for aluminum and plastics.

How to cut a scribe/cope internal corner on skirting boards or baseboards

What’s the difference between a mitre saw and a circular saw?

How to use a mitre saw?

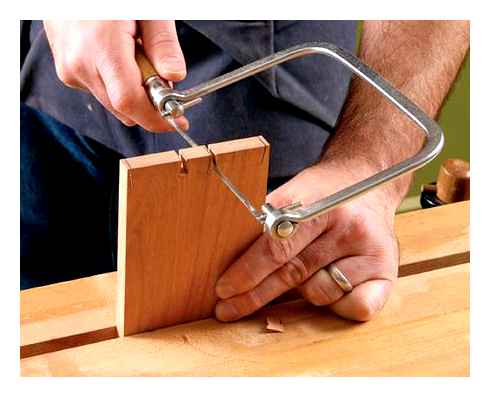

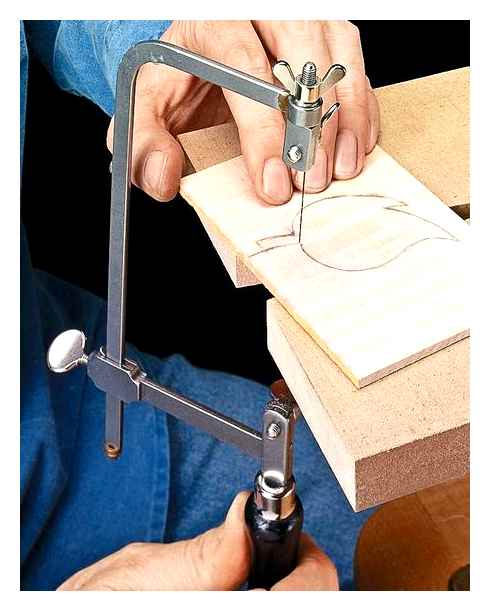

The carpenter frequently has to make square cross-cuts in boards. The cut almost always has to be accurate because it forms the corner joint for a door casing, baseboard, picture frame, or some other structure, and a miscalculation can result in an unsightly gap. The tool for this job is the mitre saw.

A miter saw is the tool you need to make corner cross cuts.

The simplest mitre saw consists of a hand saw and an open box with pre-cut grooves to guide the saw, but the mitre saw is easier, faster and more accurate. This is basically a cutting saw mounted on a vertical spindle that pivots 45 degrees in either direction from dead center. A compound mitre saw, which you should consider when buying if you don’t already have an end saw, also rotates around a horizontal spindle and allows you to cut bevels and sleeves.

Most power tools produce the best results after you’ve developed the skill to use them properly, and the compound mitre saw is no exception. It doesn’t take long to develop this skill, practicing with a few pieces of wood before cutting for real

How to work properly on a crosscut saw

To work properly on a coping saw, you need to follow the basic rules:

- Before starting work make sure the circular saw blade is intact, straight and undamaged. If it is not, it can affect more than just the result of the work. A bent or cracked blade can be detrimental to the tool, up to and including breakage;

- Remove chains, bracelets, rings, and other jewelry to eliminate the risk of an accident. The crosscut saw is a great source of danger and all safety precautions must be strictly observed;

- Do not touch any part of the saw blade while the tool is running. The blade is protected by a blade guard. Keep hands and other body parts away from the tool during cutting to avoid injury. When working with small workpieces, do not use your hands but objects like wood, slats, etc. as pushers;

- Follow the manufacturer’s recommendations regarding the maximum power of the tool in order to avoid damaging the material. Some mitre saws, for example, are not designed to cut ceramic because this material is very hard and strong. It requires a lot of power from the tool, not just a special diamond blade. Study the article on how to cut ceramic tiles;

- For each material, choose the right drive for all parameters. It is better not to use a general-purpose blade to save money. Quality, speed and cut finish of such a blade on any material will be far from perfect. Because each individual job requires a disc with a specific sharpening, tooth frequency, and tooth angle;

- Before working, make sure that your mitre saw has enough power to work with this or that material. Whichever maximum rpm is stated on the saw blade, the tool must also pull those rpm. For the correct choice of mitre saw. Check out the latest Crosscut saw ranking for the home;

- The arbor hole diameter of the circular saw blade must fit exactly in your mitre saw. The standard saw blade fitting size is most often 3 cm, but other blade sizes are available. This parameter must be strictly adhered to, otherwise you risk damaging both the disc and the tool itself in the process of work;

- Clamp both the tool and the workpieces well before starting work. The mitre saw must be securely fastened to the work table without backlash. Make sure it is secure and not unstable, making sure you work safely and without hesitation.

How to secure a crosscut saw

Before you start, you need to secure the mitre saw to the work surface. To do this you must:

- Make sure that the tool is unplugged;

- Choose a comfortable working surface;

- Set the crosscut saw on it;

- Fix the tool in vertical position relative to the surface of the table, using the clamps;

- Make one or several stop adjustments depending on the saw model, make sure it is properly secured and has no play.

How to cut a board straight

How clever and smart our people are!

Sergei Burkov: How to dissolve a 3 m board how to dissolve both halves of the resulting board were for example 10 mm thick

How Pros Cut Molding Inside Corners

BANDIT #: You explain as schoolchildren, with a countersunk head, etc

COMPUTER: And if the board is long 2 meters? How to put it on the butt?

Nikolay Sitkov: Ha, here before a hacksaw I did not have enough intelligence, although more than once faced with such a problem.nice.

KAK TAK?: Christmas trees, watch out for your fingers, bro. I wouldn’t do that)))

Workshop on the balcony: Simple, cheap and easy:))). LIKE

Mike VIZ: Hello, you have already had this circular saw in the frame a few times. This is AEG or another company? Maybe shoot a review, I choose a saw, I would like to hear the advice of an experienced person, what you should pay attention to.

Is it possible to cut long pieces of wood lengthwise with a crosscut saw?

Sawing wood. this is the main purpose of the sabre saw. If for cutting metal or ceramic, there are certain requirements to the technical characteristics of the tool, such as: its power, maximum torque and the size of the tool, allowing the installation of large-sized saw blades. Any crosscut saw is good for cutting wood. After all, wood is a soft enough material that any crosscut saw can handle it. Learn how to cut metal with a mitre saw and how to cut tiles with a mitre saw.

For longitudinal sawing there are somewhat different requirements, not related to power, motor type and dimensions. Here it is the facing mechanism which will allow you to make the cut in the horizontal plane that is more important.

If setting the disk in the horizontal position allows the selected model of the tool, the crosscut saw is quite suitable for a longitudinal cut. It cannot be used for long boards only. If you often need to make a longitudinal cut of long logs, it is better to buy a circular saw for that purpose, which can do such work quickly and qualitatively.

If we talk about the trimmer, it can be used for longitudinal sawing of wooden parts of small lengths. It can do this job quite successfully, providing a smooth seam and high precision work.

Can the mitre saw cut metal?

- What are its features.

- How is it classified.

- What points to pay attention to before buying.

General information

Along with circular and circular saws, as well as jigsaws, trimmer can cut metal profiles, sheets, different types of pipes.

The structure of the device is very simple. key elements are: gearbox, saw blade, frame (base), handle with “start” button, motor. The latter is divided into two varieties:

The advantages of the panel saw are its simple operation, while the advantages of the asynchronous saw are its longevity and the noise it makes during operation.

The motor with the saw blade is connected by means of a toothed or belt drive. They have their disadvantages and advantages. The belt saw, for example, is virtually silent.

It eliminates disk vibration, but is capable of slipping off the base during prolonged work, forcing the owner to stop the work process. The toothed saw is exempt from this kind of disadvantage, but instead it makes noise during operation and gives a slight vibration.

The working tool in the circular saw is the blade. It is made of strong metals, because it carries all the main and quite serious load.

There are cuts or wavy lines on the planes of some of the removable components of this type of saw. This is designed to reduce the noise level during work, as well as to compensate for deformation caused by high temperatures.

According to the appointment, you can allocate household equipment, professional and machine tools. The first are characterized by low power (no more than 1500 watts), compactness and For example, Bosch GKM 18 (cordless, cost. 15 thousand. р.).

Pendulum saws: varieties

Trimmer tool lends itself to classification, much easier than, for example, jigsaws, which can be either electric or mechanical. The mechanisms under consideration can be divided according to criteria:

Examples can be such products as:

- Saw Bosch GKM 18 (cordless modification, the cost of about 15000 p.);

- saw Kolner KMS 210 ;

- Domestic facing machine “Kalibr PTE-900” capacity of 900 W at a cost of 4500 p.

Trimmer is not a piece of equipment for household purposes, which is used only at the plants that produce rolled metal products, and every day are engaged in their cutting or processing. Such devices are sold for tens and sometimes hundreds of thousands of dollars, their power exceeds 1000 W and weighs several centners.

- machines of domestic producers;

- DH 10-4 (3 kW, weight 360 kg, price 105 thsd. );

- DKB-40K (power 200 kW). 5,5 kW, weight approx. 700 kg, price 340 thsd. ).

Professional metal end saws for profiles, sheets and pipes according to the mentioned parameters occupy an intermediate state. For example:

Makita LF 1000 (power 1650 W, price from 60 thousand. ), DeWALT d27111 (power 1500 W, price from 50 ths. ).

The broaching function gives the user a big advantage when working with long slabs or pipes.

The models have two parallel slats on which a cutting disk is mounted and moves freely on them.

The fixture with the broach has the advantageous feature of a thorough cutting width of the workpiece and additionally very fine teeth on the disc. In addition, the tool in some cases has a laser pointer to control the process and make marking easier.

Metal facing saw equipped with a broach has a higher weight than usual, and the presence of the option increases the cost by 25-30%.

Cutting blade size is the central criterion for classification

Teeth size determines the width and depth of cut, and the material is determined by the possibility of using the unit on a particular metal.

Manufacturers you can trust

Here are the recommendations for your crosscut saw brand of preference. Based on customer reviews and forum information.

The optimal crosscut saw in terms of comfort, manufacturability and safety at work is considered to be the products of one of the following companies: “Corvette”; DeWALT; Metabo; Makita; “Interskol”. Hitachi; Bosch.

Most of these manufacturers provide an extension of the special table under the workpiece, however, for cutting large parts in some cases additional supports are required.

Such can be found, for example, at the manufacturer “Makita” in the model of crosscutting saw LF 1000. This addition greatly simplifies the work of the user.

In addition, the moving part of the metal saw is included in the stable frame, which has a place for assembling the angle of cut.

The best crosscutters, in terms of stability and reliability, are those whose frame is made of magnesium or aluminum alloy. They are stable, strong and have an acceptable weight. An example is the Bosch GCM 10. the most popular modification among professional models. For all other advantages, it weighs only 15 kg.

Fixtures

There are different attachments that are used in metal mitre saws. Depending on the machine type, they are designed to facilitate and guarantee the quality of the operator’s work as well as safety. For example, in addition to the rotary table design that allows you to achieve a given degree, models can have a table with two sides of the cutting angle.

Dust collectors can be bagged or fitted with hoses, similar to an industrial vacuum cleaner. They reliably protect the operator from metal dust, which can enter the respiratory tract. In addition, the product may have a protective hood and work area illumination. Those who are particularly careful in choosing a metal facing saw can choose a variant with a depth of cut limitation.

Additionally, the unit may have a variable speed option. Also the number of revolutions can be characterized by a smooth increase when turning on. It is convenient and will not allow the disk to jam at the beginning of cutting. Other units may be equipped with an automatic switch-off in the event of jamming.

Cutting aluminum with a mitre saw

It is possible to cut aluminum properly by following the following simple algorithm of actions:

- place the special non-abrasive disc in the respective slot of the mitre saw (this ensures a clean and geometrically correct future cut);

- Position the pendulum saw on the work surface;

- press the aluminum workpiece firmly against the stop in the position required for cutting;

- set the cutting angle (loosen the locking screw, set the angle on the scale, tighten the locking screw);

- Adjust the bevel angle to the left and right (loosen the handle, turn the tool arm to the desired angle, tighten the handle, do the same to set the bevel angle to the right);

- Make sure the saw is in good condition and the electrical cord is intact (if you have a cordless saw, check the charge of the rechargeable batteries);

- Take all necessary safety precautions. wear a face mask or goggles and gloves;

- check that the aluminum workpiece is securely clamped;

- press the trigger and the safety lever;

- smoothly point the arm of the tool downward while making the cut (remember that you should always align the saw blade on the side where the waste of the aluminum piece to be machined will be removed).