How to sharpen a circular saw

Before work commences the tool must be disconnected from the machine, if the part has lost its previous performance. The disk is tightly fixed with special bars, which are placed on both sides of it. Marks are stamped on the saw blade for all the teeth with the same amount of force and movement. This creates a qualitative, even cut on the disc.

The part is put back in place after achieving the desired look and checking the sharpening angles. Then a test cut must be made on the machine and the quality of the work done must be checked

It is important that all the teeth are placed on the same plane, otherwise the movement of the bar will be uneven, and the work of the machine will be accompanied by a characteristic noise. It is also possible if some of the teeth need to be resharpened

If you sharpen circular saw blades by yourself, it is worth remembering about edge setting, when all the teeth are gradually bent in different directions, but the distance between them remains the same. These actions can be performed using a special tool called a deburring, it provides an even bend in the middle of all elements. After this procedure the saw will be freer and the kerf width will be larger.

Since the kerf is not made by the blade itself, but by its edges which gradually remove the wood layers, it is clear that the larger the gap between the teeth, the lower the risk of jamming, and the wider the kerf is. It is worth noting that in this case, for the work of the tool has to apply more force. In the absence of special devices, many people use an adjustable wrench for tooth sharpening, but this technique has many limitations and is not suitable for all saws.

The type of resharpening is first of all influenced by the type of wood that is to be sharpened. For example, a smooth cut without small defects or overhangs in soft wood requires a deeper set. It is advisable that the teeth are bent in the selected direction by 5-10 mm. Wood circular saw blades are not sharpened until the cut is set, as otherwise the teeth would be rendered unusable due to deformation.

General rules for sharpening a circular saw

After the basic sharpening operations, the teeth can be refinished with a fine sandpaper. Check the quality of the tool sharpening in the work environment. If everything is in order, the cut of the material will be clean, smooth, without visible defects and blackening.

Sharpening of circular saw blades

An experienced craftsman usually knows at once when the teeth start to go bad. This can be determined by the following signs:

If the teeth are blunt, it is advisable to sharpen the saw as soon as possible. Many do-it-yourselfers mistakenly think that you can get hurt much faster with a sharp saw than with a blunt one. In fact, it is vice versa. The reason for this paradox is simple: when you use a blunt object saw, you need to use physical force to sharpen it. If you misjudge the force or apply it in the wrong direction, it is very easy to injure your hand. And if the sawyer has well sharpened tools, no effort is needed, the main thing is precise and accurate movements.

Using a special machine

Of course, the easiest way to sharpen a circular saw is to use a special industrial sharpening machine. These machines are quite expensive. It is profitable to buy a sharpening machine for personal use only if a home handyman works daily and cuts a lot of wood. Sharpening service can also be found at many sharpening stores. The machine for sharpening saws somewhat reminiscent of a potter’s wheel, on which the saw blade rotates, placed strictly in the horizontal plane. The sharpening process consists of the following steps:

Sharpening circular saw blades on the sharpening machine is very convenient. The main thing is to observe safety precautions and not to adjust the saw blade while the machine is working. All manipulations with the disk should be done only with the sharpening machine turned off.

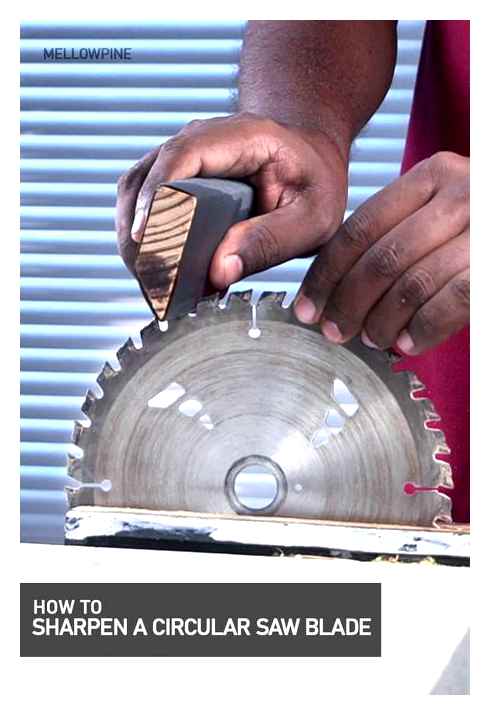

Self-sharpening

Many do-it-yourselfers are perfectly capable of sharpening circular saws without a special machine. Most circular saw owners got used to sharpen circular saw blades by hand with a file or other available sharpening tools. However, this method is very uncomfortable and injurious. over, it is possible to accidentally cut some teeth by hand sharpening. Therefore it is not recommended to use this method.

Proven sawyers usually make a round wooden stand for sharpening saws, on which the saw blade is placed. The principle of operation of such mini-machines is about the same as that of industrial machines.

Masters believe that before sharpening, saw blades should be a little damp. this greatly facilitates sharpening. To do this, sharpeners moisten circular saw blades with water and various chemicals. However, experts say that in fact such a method only brings harm. Any kind of liquid corrodes and corrodes the metal, i.e. rust.

Home Improvement & Maintenance : How to Sharpen Circular Saw Blades

When sharpening yourself, you must be careful not to miss a tooth. Even if only a few blunt teeth are sharp, all other teeth must be sharpened. It will work properly only if all the sawing elements are sharpened equally.

To sharpen circular saws yourself. it is not as difficult as it seems. How exactly to sharpen the saw, on a machine tool of industrial production or on a primitive stand, each home handyman chooses for himself. However, in any case it is necessary to observe elementary safety measures and to sharpen the teeth as sharply as possible. If you are having difficulty sharpening your circular saw at home, you should consult an expert. If a circular saw is sharpened regularly, it can be used for many years to come.

Any cutting tool tends to blunt in the process of operation. This also applies to carbide-tipped circular saw blades that need to be sharpened regularly if wood is to be sawn quickly and with good quality.

The easiest way to sharpen circular saw teeth is with a regular file. But when working with your own hands, over bringing cutting tools into working condition, there are many difficulties, which can be handled only by a good specialist with enough experience. It is much easier, faster and efficient to use a home-made machine for sharpening circular saws or a sharpening machine for circular knives for this operation.

If there is a homemade electric circular saw sharpening machine, regardless of whether it is a factory tool or a homemade one, you should know the basic principles of using such equipment. Especially when there is a need to sharpen the teeth of circular saw blades that have different geometry and sharpening angles.

Preparing

Before starting work it is necessary to de-energize the tool, the part of which has lost its previous characteristics. The saw blade is firmly clamped with special wood shims that are placed on both sides of the saw blade. Marks are placed on the blade for all teeth, and equal amount of force and movement of the tool is applied in the process. This is the way to obtain a good, even sharpening of the disc.

The part is set back after achieving the desired look and checking the sharpening angles. Next you need to make a test cut on the machine and make sure of the quality of the work done

It is important that all the teeth are placed on the same plane, otherwise the movement of the bar will be uneven, and the operation of the machine will be accompanied by a characteristic noise. It is also possible if some of the teeth need to be resharpened

If you sharpening saw blades yourself, it is worth remembering about edge setting, when all the teeth are gradually bent in different directions, but the distance between them remains the same. These actions can be done by means of special tool called setter, it provides even bending in the middle part of all elements. After such adjustment the saw becomes freer and the kerf width is larger.

Considering that the kerf is not made by the blade itself, but by its edges, which gradually remove layers of wood, it is clear that with increasing tooth pitch, the probability of jamming decreases and the kerf becomes wider. It is worth noting that in this case you have to apply more force to make the tool work. If you do not have special tools, many people use an adjustable wrench to sharpen the teeth, but this method has many limitations and is not suitable for all saws.

The type of setting is first of all influenced by the type of wood that is going to be further processed. For example, to obtain an even cut without any flaws or protrusions on soft wood, a large set is required. It is advisable for the teeth to be 5-10 mm on the selected side. Wood saw blades must only be sharpened after setting, otherwise the teeth would be useless because of the resulting deformation.

Methods of sharpening

You can use the sharpening machine for saws or handy tools.

There are three basic methods of sharpening, where a certain fixture is used, and the rules of machining discs are followed. Which one is the right one, it is hard to say. After trying out each technique, you can draw certain conclusions for yourself.

Classic

This sharpening technique has been around for a long time, which is why it gets its name.

- The sharpening begins on the back side of the blade.

- The front end, which runs over the material when cutting, remains in its unchanged position.

- Work directly on the circular saw or remove the circular saw by placing it in a vice.

- If you sharpen with a circular saw, be sure to unplug the machine.

- Use a pair of stones to hold the wheel in place, like wedges. The stones should be pressed against the workpiece so as not to move during sharpening.

- Use a marker pen to mark the first tooth where you will start.

- Perform a specified number of sharpening strokes on the first tooth. Note the number.

- For all subsequent teeth, repeat similar motions in number and intensity.

- After sharpening is finished, be sure to check the functionality of the saw you have refurbished with your own hands. If there is no extraneous noise, no vibrations, and the disc machine behaves steadily, you have managed to get the job done correctly.

Alternative solutions

The two sharpening methods described above are alternatives to the sharpening method described above. They are quite effective, which is why they are often used by craftsmen.

- Full-face saw blade sharpening. Of all the turning methods, this method can be considered the most accurate and highest quality. This is because specialized sharpening machines are used for full profile sharpening. A special wheel is selected according to size and passes over the entire recess between the teeth of the disc in one go, capturing the surface of the adjacent cutting edge in the process. This method of sharpening circular saw blades avoids the possibility of tooth deformation. The only disadvantage of the sharpening method is that different profile saws require different grinding wheels to be used.

- Edge sharpening. The popularity of this method of sharpening circular saw tools is due to the fact that it can be used at the professional level and in normal home conditions. If sharpening is done with a machine, you will need to buy the appropriate abrasive wheels that match the parameters of your saw blades. But the optimal way for most circular saw owners is to use the home work method. This is because it is often not necessary to do a lot of work and all cutting edges are sharpened with a file. To sharpen a product efficiently, 4-5 strokes with a good quality burr are sometimes enough. This way, the teeth are sharpened properly.

Experience is a useful thing, thanks to which you can avoid a number of mistakes typical of beginners

For this reason it is very useful to pay attention to expert advice if you want to achieve a positive result for yourself when sharpening a circular saw

- Always wear safety glasses. Many people ignore this rule for some reason, and then the sharpeners themselves suffer. Therefore, be sure to wear all necessary protective equipment before sharpening;

- Do not try to remove more metal than necessary. Remove just enough to remove all existing cracks, burrs and irregularities;

- Be sure to hold the disc in an unchanged position while sharpening;

- If the disk has not been sharpened for a long time, you will have to remove a greater layer of metal;

- Keep all teeth identical in shape and height.

Circular Saw Blade Sharpener Jig. DIY. How to make

Sharpening initially seems to be a technologically complex process. But with a little experience, you can easily sharpen circular saw blades.

Sharpening of circular saw blades is necessary for any tool used for woodworking. It is made in case of reduction of cutting quality and requires observance of basic rules, because the period of operation of the saw is also affected by the correct execution of sharpening.

Teeth geometry of circular saw blades

Circular saws are made from high-temperature brazed solid steel, with carbide plates attached to the body. The alloys used to make these tips can vary. Domestic manufacturers mainly use tungsten and cobalt alloys. Foreign manufacturers use their technological compositions. Characteristics of one or another composition will depend not only on its chemical characteristics, but also on the size of carbide grain used. Small granularity will provide the greatest parameters of hardness and strength, which the material will possess.

Circular saw teeth can have different geometric shapes. There are several basic shapes among them:

Saws that have straight shaped teeth are used to make fast, longitudinal cuts. In this case the quality of such a cut will be quite low.

Tooth oblique shape can have right or left angle of inclination. Circular saws can often be made with alternate beveled teeth, i.e.е. where the left and right angle teeth will alternate. Such saws are used for cutting longitudinally and crosswise particleboard. This design shape allows to avoid different chips on the surface of the material to be cut.Saws with tooth in trapezoid shape can be used for cutting fiberboard. Low wear of tooth material and relatively low cutting speed are the special features of such saws. Very often the trapezoidal teeth alternate with the straight ones, which are used for cleaner cuts.

Saws with tapered teeth are used for auxiliary work in top or bottom laminate trimming. This saw protects against chipping and preserves the surface of the material being worked on.

How to know when it is time to sharpen a blade

Regardless of how a circular saw blade is used, the cutting edge of the blade will wear out. In this case it does not matter what material is used for the element and what kind of fillings are on its teeth.

The following signs are indicators that sharpening is necessary:

- more effort must be applied during cutting so that the blade can make the cut;

- cuts are made with jagged, jagged edges;

- when working with wood or other material, the cutting points have a pronounced charred appearance;

- a burning odor when working, the smoke from under the blade guard and the rapid heating of the blade or the drive

- when sawing with a blunt blade, the sawdust is very fine and looks more like dust.

Experts consider blunted discs irrational. as not only the load on the tool increases, but also the time it takes to cut the workpieces.

When to sharpen circular saw

There are very definite signs by which you can judge the condition of a tool. Sharpening of saws is necessary when the following is evident:

- Smoke and a peculiar smell of burned wood is produced during operation, the guard that covers the saw’s teeth gets hot quickly.

- When moving the tool along the workpiece, considerable force must be applied, as if pressing the saw forward.

- After cutting the material and visual inspection of the saw’s edge you can see black tarnish or many chips, fiber burrs, scraped areas.

- If you look carefully through a magnifying glass you can see that cutting tips of the saw have rounded edges and not sharp edges.

All these facts should be stopped immediately, otherwise there is a great risk of material deterioration and saw blade wear to the point where sharpening will not help it anymore.

Working without a machine and the quality of the work done

Circular saws can be sharpened not only with a special machine, but also with auxiliary tools. This method can be used if you have no money and no desire to buy a sharpening machine. Most people do not use such a hand tool very often, so there is no need to buy additional devices.

If you have a regular sanding machine, you can do all the required procedures with it. For ease of operation, you need to make a device that will produce a clamping saw in the required position relative to the abrasive element. For this purpose, an ordinary metal stand, the surface of which will be located at the same level with the axis of the abrasive wheel is suitable.

On this stand you need to put a circular saw blade so that it lies in the required plane relative to the surface. It can be fastened with bolts, which will also help you make adjustments to the angle of inclination.

To be sure in the quality of the work done will help in the absence of chips and various cracks on the surface of the saw. the rounding radii of all cutting edges should be within the following limits: 0.012-0.015 mm. When visually inspecting them, their surfaces should be free of glare.

safely and securely operate the circular saw without frequently changing circular saw blades. And their cutting part will perform a quality cut of the desired products and materials, without spoiling their surface.