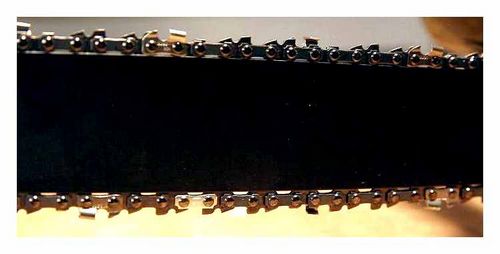

Chain function and correct tension

The correct position and tension of the chain of the chainsaw is very important not only for its normal operation, but also for the safety of the person who works with it, as well as those around. If the chain has the wrong tension, then during operation it can accidentally fly off, which, most likely, will cause damage only to the chain itself, but also to the entire chainsaw. However, it is also undesirable for the chain to be too tight. This can also have negative consequences in the form of an increase in the load on the engine, which in the future will lead to its early failure and a reduction in the overall service life of the chainsaw. The chain has one very important property: it fixes the tire, which prevents its arbitrary movement. Therefore, the care of the chain must be given special attention.

Chain sharpening

Everyone knows that from time to time you need a chain sharpening on a chainsaw. However, not everyone knows how to do it correctly. A sure sign that the saw needs sharpening is the shape of the sawdust. If they look like fine dust, this means that the chainsaw blades are dull and need to be sharpened. If the chain is severely worn, when it is no longer possible to sharpen it, it must be replaced with a new one.

Safety engineering

Personal protective equipment should be worn when using a chainsaw, including eye and hearing protection, leather gloves and a hard hat.

For safety when working with a chainsaw, it is desirable to have one more person nearby, who will be able to provide assistance in case it is needed.

How to shorten the chain yourself on a chainsaw

The chainsaw chain must always be in good technical condition. All defects and malfunctions must be given the necessary attention. It is necessary to follow the general safety rules and recommendations given in the operating instructions. Only in this way can you avoid injuries and other undesirable consequences when working with a chainsaw and extend its service life.

Sometimes due to wear, deformation or other reasons, the chain needs to be replaced or shortened. Please note that chain slack does NOT mean it needs to be replaced. You need to change it if it cannot be completely adjusted.

The chain can sometimes sag during heavy use. This is due to the strong overheating of the metal, its expansion and, as a result, elongation. A way out of this situation can be a periodic stop to allow the circuit to cool down. However, this is not always possible. Another situation may arise when, say, you need to install a chain whose length is somewhat large.

Choosing the right chain

Chain failure is not uncommon, so before you ask yourself how to tighten the chain on a chainsaw correctly, you need to know which chain is suitable for a given model of chainsaw. The main criterion for choosing is its step. It is customary to call a step the distance between its teeth. This distance is chosen between its nearest teeth and is measured in inches. The most common are 0.325, 0.375, and 0.404 inches. Information about the step can be found in the operating instructions for a specific model of chainsaw, and it depends primarily on the purpose of the tool.

Each saw has its own specific step, the only exceptions are professional tools, which are universal. The chain pitch also depends on the engine power. The more powerful the chainsaw, the larger its stride and the more difficult it is to hold it while working. For example, the compact, low-power Patriot chainsaw has a pitch of 0.325. However, there are also more powerful models. One of them is the German STHIL with a step of 0.404. Which, as we can see, is more than a “Patriot” chainsaw.

Pitch is one of the most important characteristics of chain parameters. This means that you should not choose a chain with a large pitch for a low power chainsaw. It may NOT only fail to fit, but also disable the tool.

Required tools

When buying a chainsaw, it often comes with a tool for its maintenance. It is needed to adjust the chain. Looks like this: there is a flat head screwdriver on one end and a flat head screwdriver on the other. A wrench, which fits the blade nuts. To understand how to tension the chain on a chainsaw, you must refer to the operating instructions for this model of the saw.

How to pull the chain on a chainsaw on your own

It is not difficult to do this, the main thing is to remember about your own safety. So how do you put the chain on your chainsaw correctly? Stand in front of the chainsaw with the blade facing you. Grasp the tip of the saw blade with one hand and lift it up slightly. Insert the flat head screwdriver firmly into the adjusting screw where the blade is located when you look at the saw blade. Turn the screw clockwise to increase the chain tension, or counterclockwise to decrease it accordingly. Take the chain in one hand and pull it around the blade. The tension is correct when it is slightly loosened by pulling in the direction of the blade, and at the same time it is firmly against it.

If so, further chain adjustment on the chainsaw may NOT be required. If not, then you need to adjust it. Loosen or Tighten the adjusting screw to get the correct fit. Hold the tip of the chainsaw blade with one hand. Tighten both blade retaining nuts on the left side using a saw repair kit or an adjustable wrench. Place the spark plug wire back in place and press firmly.

Chain sharpening methods

There are many ways to do this. Here are the most common examples:

- Sharpening with the introduction of a file. Its convenience lies in its simplicity, because there is a need to use complex equipment and machines. In addition, this sharpening can be carried out directly on site, which saves time.

- Sharpening on the machine. Most often it is used in equipped service centers or workshops, but it also occurs in personal households.

- Sharpening with the introduction of an angle grinder. One of the most difficult sharpening methods, as it requires special skills. Because of this, this method has not been widely used.

The importance of proper circuit setup

Normal operation of the chainsaw causes vibrations, which can significantly loosen the tension on the chain with blades or nuts designed to secure it. The chain stretches during heavy use and does not fit well on the saw teeth, which can create unsafe conditions for the operator. Proper operation of the tool includes checking all nuts and bolts before and during use to ensure safety. If the chain nuts are too loose on the saw teeth, you will most likely need to tighten the chain correctly and then tighten the blade as well.

Before starting work, you should always remember your own safety and use protective leather gloves and glasses. Place the chainsaw on a flat surface such as a workbench or table. The engine must be allowed to cool completely if it has been used before. Further, to prevent accidental starting of the saw, remove the wire from the spark plug connector. Now you can start adjusting the chain.

Chainsaw adjustment

Chainsaw is a hand tool designed for working with wood material. It is equipped with a gasoline internal combustion engine. It is a complex constructive device. During operation, a violation of the factory settings occurs, so periodically it is required to carry out such a procedure as adjusting the chainsaw.

How to tension the chain?

To properly tension the chain on a Husqvarna chainsaw with the engine not started, first loosen the screws securing the cover. After that, the part that corrects the tension is rotated. If the links sag from below (even a little), then you need to tighten them. Before tightening the chain on a chainsaw (Husqvarna, for example), you should read the attached documents. Indeed, the mechanisms of different firms have their own differences.

How should the chain be tensioned on a chainsaw? This can be determined by lifting it up. Normally, the shank should be one third immersed in the groove. If it came out completely, then the chain must be tightened, if it came out less than 2-thirds, it will weaken. When scrolling, the links must pass freely along the bus. After movement by hand, the links pass a little more by inertia at normal tension. If the chain instantly slows down, then this indicates a tug.

To quickly tighten the chain on a Stihl chainsaw, there are special devices that help you do this without keys. To use them, it is enough to release the sprocket cover, and then return the adjusting wheel to the left to loosen, to the right to tighten. All this is only done when the links are cold.

Chain thickness classification

The groove on the saw bar on different units has its own thickness, so for greater efficiency it is better to choose the optimal one. The minimum parameter is 1.1 mm. Such a part can only be installed on household mechanisms with low power. Chain with a link width of 1.3 mm and more is popular. Applies to both cheap and semi-professional Goodluck chainsaws.

The rest of the types are used on powerful tools: 1.5, 1.6 and 2 mm. The last 2 of those listed are only for professional Ural devices. But before choosing a part by thickness, you need to find out which of them can be installed on the track of the tire of a particular tool.

How to lubricate the chain?

- 1.1. the simplest saws;

- 1.3 and 1.5 are semi-professional;

- 1.6 and 2 mm. the most powerful.

Proper maintenance of the chain and correct tensioning is the key to durability. With due attention to the Ural or another brand chainsaw, it is easier for the employee himself to cope with a well-tuned tool. The presented helps to understand the principle of handling the mechanism.

Chain lubrication mechanism

The chain must be lubricated with oil for stable operation. This role is played by a special unit. the lubrication mechanism. During operation, interruptions in its operation may occur:

- Lack of oil in the tank, as a result of which a small amount of lubricant will flow to the chain. it is necessary to replenish the oil level;

- Clogging of the outlet channels. it is required to clean and replace the filter;

- Small diameter of the outlet opening is regulated by special screws.

During normal operation of the chain lubrication system, traces of oil can be seen if the working dust is brought to a light, uncontaminated surface, for example, to a fresh cut of a tree (stump).

The amount of oil supplied to the chain depends on the operating conditions. With dense, sticky or damp wood, the oil consumption should be higher. Dry material will require less lubricating fluid.

How to tension the chain on a Husqvarna chainsaw

All safety rules described for the model above are the same for Husqvarna (Husqvarna) saws. Do not tighten the chain when starting the saw motor. It is allowed to start work only after a complete stop and cooling.

Before tensioning the chain on a Husqvarna chainsaw, check if additional tension is required. It should be noted that new saw chains require more frequent tensioning. From time to time, it is stretched in the process of work, so it is necessary to carry out this operation before each of its implementation, if necessary. Otherwise, it will be necessary not only to replace the chain, but also the saw drive mechanisms.

First of all, it is necessary to loosen the fastening nuts located on the clutch cover. The next step is to return the adjusting screw 45 degrees. If the chain on your Husqvarna chainsaw is overtightened, turn to the left (counterclockwise). In the opposite case, the screw turns to the right. If a single tightening is not enough, the operation must be repeated. At the end of the procedure, tighten the nuts on the protective cap using a combination wrench. They can also check the chain tension of the chainsaw by hooking it onto the outer tooth and pulling the chain along the guide in the tire.

Chainsaw tuning work

Chainsaw adjustment work is divided into two groups:

- Setting up SEPARATE nodes;

- Preventive tool maintenance.

Chain selection

The performance of your Husqvarna chainsaw and its service life depend not only on the ability to tension the links, but also on whether it is suitable for a particular brand of machine. This detail differs according to several criteria:

- Step;

- Thickness;

- Cutting depth;

- Chain length and number of teeth.

The pitch value is the main parameter for the chain, based on which this part is selected. Its meaning is determined by the gap between the tails. Common options: 0.325, 0.375, 0.404 inches. You can find out which type is needed for a particular dust by reading the instructions. The smaller the step, the less power should be in the mechanism to which it should be pulled.

A large step affects the “aggressiveness” of the tool, that is, the cutting links penetrate the wood more strongly, and therefore the worker is required to hold the Friendship chainsaw more tightly. The 0.325 chain is very common among household and semi-professional devices. It can be pulled on Druzhba chainsaws with a power of 3 hp. This chain is best for sawing small trees and construction work.

The designation of the number 0.375 is rare, since the marking for the convenience of buyers has been replaced by the value 3/8, because 75 and 25 are easy to confuse if the purchase is made by non-professionals. The power of a Goodluck chainsaw, for example, should be 4 hp. Otherwise, the instrument may deteriorate.

Links with a pitch of 0.404 can only be pulled on professional mechanisms with a power of more than 5 hp.

How to tension the chain?

To properly tension the chain on a Husqvarna chainsaw with the engine not turned on, the screws securing the cover are first released. After such a fact, the part that corrects the tension is turned. If the links sag from below (even slightly), then tighten them. Before tightening the chain on a chainsaw (Husqvarna, for example), you should read the attached documents. Indeed, the devices of various companies have their own differences.

How desirable is the chain tension on the chainsaw? To find this is an option by raising it up. Normally, the shank must be immersed in one third of the groove. If it came out one hundred percent, then the chain must be tightened, if it came out less than 3.5-thirds, it will weaken. When scrolling, the links must be free to pass over the tire. After movement by hand, the links pass even a little automatically under normal tension. If the chain instantly slows down, then this is a tug.

To quickly pull the chain on the Stihl chainsaw, there are special devices that help you do this without keys. To use them, it is enough to release the sprocket cover, and at the end, return the adjusting wheel to the left to loosen it, to the right to tighten it. A complete set is done only when the links are cool.

Chainsaw chain tension. Chainsaw service. Part 5

Learn how to properly tension your chainsaw chain, plus the consequences of incorrect chain tension. Designation.

Chainsaw chain tension adjustment

Any experienced feller who knows his job well, before starting work, be sure to check the chain tension and the degree of sharpening of the chainsaw teeth. If you do not pay attention to the condition of the tool, its performance in the process of work is greatly reduced.

Correct adjustment of the chain tension of the chainsaw will prolong its life and will also prevent it from sliding off the bar during cutting.

Chain tension plays a critical role in the performance of your chainsaw. If not properly tensioned, it can easily be damaged or slipped off the bar during cutting. Conversely, if the chain is very tight, the pressure on the tool motor increases. This significantly shortens the service life of your chainsaw as it starts to wear out much faster. The chainsaw chain has another important function: it holds back the tire, which, when idling, goes in different directions.

How to use a glass cutter correctly.

How to drill a hole in glass. more

Saw chain replacement and adjustment sequence

It is not technically difficult to change the chain of a household and professional chainsaw on your own. The key to the successful implementation of the adjustment work will be strict adherence to the recommendations of the attached instructions.

Due to the thermal expansion of the metal, the chain is installed on the chainsaw and the subsequent adjustment is made only on a cold tire.

- In the classic solution, the technology provides for the inclusion of a blocking from accidental engine start, unscrewing of threaded fasteners, dismantling of the tire and cleaning the guide groove from sawdust.

- Next, you should make sure that the dimensions of the shanks are aligned with the width of the groove, determine which side of the chain is placed on the chainsaw, fasten the tire and adjust the chain in the sequence indicated by the instructions.

- Before putting the chain on the chainsaw, you should make sure that the direction of the chain on the chainsaw meets the stated requirements, and the chain tensioning mechanism has sufficient free play.

After adjusting the new chain, it is recommended to run the saw at medium speed for 2-3 minutes, then check the chain tension again. This moment can be combined with visual inspection of the lubrication system.

How to tension the chain on a chainsaw: installation and correct operation

Regardless of the class and purpose of the chainsaw, the cutting device includes a guide bar and a saw chain with a tensioner. The instructions contain information on how to properly tension the chain on the chainsaw in order to exclude additional loads on the engine and accelerated wear of the headset.

This element of the intent mechanism is used in conditions of high variable loads, therefore, it requires constant monitoring during operation. A characteristic feature of the used saw chains is the increase in size due to the formation of gaps in the joints of the links.

Advantages of making a chain set

The chain and bar are included in the list of interchangeable equipment, so the sawfly, depending on the peculiarities of the work, can use several sets of different lengths and productivity. Average service life of wear-resistant branded tires allows the service life of three saw chains.

The cutting edges of the saw chain links need to be sharpened periodically. The indisputable advantages of using a set of several chains are uniform wear of the drive sprocket and good compatibility with the chains included in the optional set.

Reasons for premature failure of saw chains

Accelerated elongation of the part occurs during the running-in phase and in the last quarter of the service life. Throughout THESE time slots, your headset needs special attention and care.

- The reason for the rapid stretching of the saw chain can be the poor quality of the material of the budget model, the mismatch of the configuration of the crown and excessive wear of the drive sprocket, a malfunction or ineffective operation of the lubrication system.

- The full operation of the chainsaw chain also largely depends on the condition of the tire and the drive sprocket, the quality of the chain oil and the performance of the lubrication system, the timely and competent sharpening of the edges of the cutting links.

According to professional Sawers, the operating style of the operator and the level of operational loads affect the durability of the headset. The chains of the budgetary group are more susceptible to stretching, the more expensive branded assortment has no comments on technical and operational properties.

Tensioning the Husqvarna chainsaw chain. Chainsaw chain tensioner broke

A cool guy is a cool guy and the chain is NOT tensioned and with all this clamps the clutch. Noteworthy CHANNELS: Radiosx.

Tools needed for work

Before you start setting up the Husqvarna carburetor, you need to take care of the presence of all the tools, which may come in handy. To carry out this type of work yourself, you will need:

The structure and principle of operation of the Husqvarna carburetor

To successfully tune your Husqvarna chainsaw carburetor, you need to know its design and understand how it works. In fact, everything is not as difficult as it seems at first glance.

The saw carburetor has a built-in fuel pump, which is responsible for transporting a mixture of gasoline and oil, as well as a diaphragm, a needle valve from the rocker arm. Their joint work allows metering the fuel supply to the main chamber and two dampers.

One of the valves is designed to adjust the fuel supply to the cylinder when the gas is pressed, it is called the throttle, the second is responsible for restricting the air supply from the air filter to facilitate starting a cold Husqvarna chainsaw. At the moment when the operator cuts off the air supply to the carburetor with the help of the air damper, the fuel mixture becomes leaner and its supply to the cylinder increases, due to which the chainsaw starts much easier than in the case when a cold start is carried out in normal mode.

In the operation of the Husqvarna carburetor, a nozzle valve is involved, which atomizes the fuel and prevents air from entering the main chamber. Often, problems with saw operation can be caused by defects in this particular element. For example, the valve, if the chainsaw is not stored properly, may stick, the fuel supply will stop, which will make the engine impossible to operate. Also, irregularities in the operation of the injector can become a prerequisite for air leakage into the main fuel chamber of the carburetor. In such cases, correcting the position of the adjusting screws will NOT correct the situation, it will be necessary to repair or replace the unit.

By setting the quality and quantity of the mixture, as well as the number of revolutions of the crankshaft in idle mode, there are three adjusting screws installed in the carburetor body:

- Screw (L). adjusts the amount of fuel in the low and medium speed modes;

- (H). is responsible for traction at high speeds and their number;

- (T). changes the position of the throttle valve, thereby regulating the amount of fuel mixture entering the cylinder and the operation of the engine of the tool in idle mode.

Adjusting the carburetor of your Husqvarna chainsaw

Modern chainsaws have a complex system and consist of several main units, which periodically require maintenance and adjustment. In this article, we’ll talk about how to adjust the carburetor on a Husqvarna chainsaw.

Nuances of adjustment

After adjustment, the chainsaw should easily pick up and drop speed, work stably at low and high speeds. If the saw chain rotates at idle after adjusting the carburetor control screws, this is a sign that the adjustment has been made incorrectly and the position of the screw (T) must be corrected.

Also, when adjusting the Husqvarna carburetor, it is worth considering the response time of the chainsaw to the rotation of the screws. The settings do not change immediately, but within five, ten seconds.

One of the indicators of an incorrect adjustment is a strong smoke during the operation of the saw, which indicates a large amount of fuel entering the combustion chamber. If such a situation occurs, you need to correct the position of the screw (L).

Factory settings

The factory default setting for the Husqvarna carburettor is the position of the screws (H) and (L), in which a working chain saw is guaranteed to start. For Husqvarna tools, this is one and a half turns from fully tightened screws (H) and (L). In the process of adjustment, you must first set the screws to the standard position, then start the chainsaw and make precise adjustments to power, the number of maximum revolutions and idling.

When does the carburetor of a Husqvarna chainsaw need adjustment?

There are a lot of problems that can be solved by adjusting the carburetor. Adjusting the carburetor of a Husqvarna chainsaw is necessary if such faults occur as:

- Increased idle speed;

- Strong smoke during tool operation;

- Difficulty starting a cold or hot engine;

- Lack of traction and reduced maximum speed.

This is by no means a complete list of problems that can be solved by tuning the Husqvarna carburetor. In some cases, adjusting the quality and quantity of the fuel mixture is carried out after an engine overhaul or in the process of scheduled maintenance of the chainsaw.

DIY carburetor repair

If in the course of carrying out a complete diagnosis of a Husqvarna chainsaw, carburetor defects were found, then some of them can be repaired without contacting a Husqvarna AB service center. For example, you can independently:

- Change the gaskets under the covers of the main chamber and the fuel pump;

- Clean or replace the strainer;

- Replace the diaphragm or needle valve of the main chamber;

- Troubleshoot the fuel pump diaphragm.

Gaskets, diaphragms and rocker needle valve can be found in the repair kit, which is available for every Husqvarna chainsaw carburetor.

Also, if you have some experience, you can try to restore a faulty injector valve, but you cannot guarantee a positive result when trying to restore an injector, if it is faulty, manufacturers recommend changing the carburetor completely.

The first thing to do before removing the carburetor from Husqvarna is to clean the dust with a compressor, since Dirt can interfere with a quality repair. Next, you need to open the top cover of the chainsaw, remove the air filter, disconnect the rods from the control levers of the air and throttle valves. Then Unscrew the carburetor fixing screws.

It is quite easy to disassemble the carburetor body for repair. The main chamber cover is held in place by four screws, which can be dismantled with the usual open, the fuel pump cover is fixed with one wide screw.

Below is presented. Seeing which it will become clear how exactly you can repair the carburetor without contacting a Husqvarna service center.

Husqvarna carburetor adjustment algorithm and description

Husqvarna carburetor, adjustable in the same way as the carburetor settings on second-hand chainsaws.

The order of work is as follows:

- Husqvarna carburetor is factory set on muted dust.

- The engine starts and the saw warms up for a few minutes.

- By turning the screw (L) clockwise, the position is found at which the engine develops maximum rpm, after which the screw must be turned back 1/4. If at the same time the chainsaw chain rotates, then it is necessary to reduce the idle speed by correcting the position of the screw (T).

- The next stage is adjusting the power of Husqvarna at maximum speed and adjusting their number. To do this, the tachometer is connected to a running chainsaw, the throttle stick is squeezed out to full, after which the tachometer readings are checked. If the value of the maximum revolutions differs from the maximum number recommended by the manufacturer, then by changing the position of the screw (H), the tachometer readings are returned to normal.

Conclusion

Carburettor adjustment or repair work on Husqvarna chainsaws can be done WITHOUT some experience. In order to do everything right, you must follow the algorithm and have a minimum set of tools. It is also worth assessing your strengths in advance and NOT taking risks if you do not understand anything at all in the technique. Believe me, sometimes it is better to pay a small amount to the master than ruin the instrument by self-adjustment.