Gasoline trimmer is a useful tool for cleaning unnecessary grass of adjoining territories and lawns of a large area. The design of this technique is quite complicated, therefore, if the device breaks down, there can be several reasons. The most likely factors causing the breakdown are usually described in the user manual. Knowing why the trimmer stalls, you can try to fix the defect yourself. The most common malfunctions that cause the lawn mowers to stop, and the possibility of their repairing with their own hands are in the material below.

Causes of malfunction and their elimination

To most accurately determine the cause of a malfunction of a trimmer of any brand (for example, Echo) and find out the possibility of its elimination, it is necessary to establish during which action the device stalls. The engine can turn off both at idle and at high speeds, heating up under load or immediately after starting, etc.

If stalled after gas supply

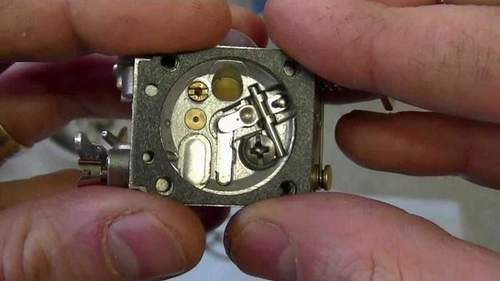

Owners of gasoline braids often mention that the lawn mower stalls when you press the gas. Typically, such a breakdown occurs due to carburetor problems. Failure in its operation can occur due to prolonged storage, use in difficult conditions, significant overload of the motor. The symptom of such a breakdown will be the vibrating movement of the device during operation.

On a note! Users familiar with car carburetor repair can try to repair this important trimmer assembly on their own using the instruction manual. Otherwise, the right decision would be to contact the service center for help.

Sometimes the trimmer stalls when you give the gas because fuel valve clogged. This interferes with the supply of gasoline. To fix the problem, just loosen the valve. In this way, the normal carburetor fuel supply will be restored.

Another possible reason why the brushcutter stalls when gas is supplied is breather pollution (check valve). This part prevents the appearance of vacuum in the gas tank. If it is clogged, air does not enter, which means that fuel does not go to the carburetor. To resolve the problem, you must clean this item.

If stalled at high speed

If the carburetor stalls at high speeds, this means that at idle and small it has enough incoming fuel, and to work at high is no longer enough. Then it is necessary to check the serviceability of the following trimmer nodes.

- Fuel hose. its integrity could be compromised by cracking. In this case, a replacement part is needed. Or maybe you just need to tighten the clamps.

- Strainer between carburetor and hose for supplying a gasoline mixture. it could become clogged. In this situation, it is necessary to clean the part.

- Valve, located on the lid of the gas tank. it could stick or clog up with garbage. Cleaning is also required.

- Carburetor. perhaps as a result of constant vibration, its deregulation occurred. This is usually typical of cheap Chinese parts. To fix the problem, you must configure according to the instructions. In some cases, just loosening the carburetor body is enough. If the adjustment fails, you must install a new element.

- Additionally, check air filter. It may need to be washed and cleaned or replaced with a new one, as it could become clogged with dirt and grass particles when tilting the equipment when the user mowed in hard-to-reach places.

If stalled while idling

If the lawn mower stalls while idling, there may be several factors.

- First you need to check the cooked fuel solution, when it comes to a four-stroke trimmer running on a gasoline-oil mixture. There is a possibility that it is made incorrectly. the proportions are not maintained. Because of this, the gearbox heats up, and the speed on the drum decreases.

- Another likely cause is clogged elements such as throttle, air filter or carburetor. It is necessary to clean the specified parts.

- Another possible factor is misregistration or incorrect carburetor adjustment. You need to re-configure according to the instructions.

- Observe this problem mono and when opening the air damper. In this situation, the lack of fuel for the trimmer occurs due to the flow of air.

Video: Idler Trimmer Works Give Gas Stalls

If the device does not have enough fuel, it works properly at high speeds or when they increase, but stalls at idle. If the root of the problem lies in the carburetor, the lawn mowing will be turned off and during cold start, and on hot.

If stalled after starting

If the equipment starts and stalls immediately after start-up, this indicates incorrect setting or misalignment devices. As a result of this, the fuel enters the engine unevenly, which leads to significant vibration and disconnection of the trimmer. To fix the malfunction, it is necessary to reconfigure the device according to the user manual.

Another likely problem is gas valve clogging. It must be cleaned.

On a note! If the trimmer starts, but immediately stalls, it may also mean that the fuel is moving with difficulty to the carburetor. The weakening of the valve will help to fix the problem. this will ensure uniform and free circulation of fuel in the device.

Another possible reason is damaged fuel intake hose. Through cracks and holes, air can enter the system. To solve the problem, you need to increase the engine speed in order to get rid of air bubbles that have penetrated into the device.

If stalled when opening the shutter

If the equipment works properly at idle, but stalls when the air damper is opened, this indicates air entering the system through cracks in the fuel supply hose or damaged seals. To fix the breakdown and to set up the tool without sucking air from the atmosphere, it is necessary to replace damaged parts.

Another possible cause of the breakdown is carburetor dosing system malfunction. To resolve this problem, it is better to contact professionals.

If stalled during heating

Benzokosa often stalls when heated. It looks like this. the tool starts, works “jerkily” (not smoothly) and quickly stalls. This situation is due to boiling fuel in the carburetor or improperly selected damper, which should not be disk, but rotary. In the latter case, if an error is detected, the part must be replaced.

Damage to the trimmer may be caused by damaged ignition circuit wiring or a defective coil.. The broken node will need to be replaced with a new one.

If stalled under load

Sometimes the trimmer stalls under load, as it cannot gain momentum. It means that the cable tensioned in the carburetor is loose and sagging. If you have experience in repairing this unit, the cable should be tightened.

Another cause of the malfunction is the fuel intake hose is taut. Under load, it stretches even more, resulting in cracks, as a result, the part deteriorates. To eliminate the breakdown, you will need to replace this element.

If stalled without gaining momentum

If the trimmer does not gain momentum and turns off, there may be several reasons. The most common culprit is clogged air filter. It must be removed and cleaned, if necessary, replaced.

On a note! The trimmer could stall without gaining speed due to a carburetor malfunction. The unit for repair or replacement must be taken to a service center.

Another possible malfunction is related to engine drive mechanics. This part of the trimmer needs to be thoroughly cleaned, as well as the cables located inside.

You also need to make sure that the cable in the carburetor did not sleep. Before starting the trimmer for the first time, you should check this structural element and make sure that it is firmly tensioned, but not extremely tight. Otherwise, the cable may crack, resulting in costly repairs.

Preventive measures and rules of operation

In order for the brushcutter to work properly and not to stall at startup, it must be properly stored and operated. Following these simple guidelines will help you forget about the problems.

- When mowing grass, you need to monitor the condition of the cooling system. It is also necessary to regularly clean the channels in the housing and the ribs of the starter.

- To clean the tool, use kerosene, thinner or other detergents.

- Do not clean a hot tool. it must be cool before washing.

- It is important to comply with the recommended operating mode. this will avoid overheating of the engine.

- If the braid is not used within the next thirty days, the fuel must be drained, otherwise it will disintegrate into heavy components that can clog the carburetor channels.

- After the fuel is drained, the trimmer should work at idle for a while until it turns off. This will completely get rid of the remaining inside the working mixture.

To store the tool in cold weather:

- completely drain the fuel;

- disassemble the mower, wash and clean out all available components;

- inspect the condition of parts, eliminate all defects that can be fixed;

- pour the required amount of oil into the gearbox;

- clean the air filter;

- partially disassemble the engine, wash, move and lubricate all moving parts;

- To lubricate the piston, unscrew the spark plug, then raise the piston to the top dead center with a starter, pour a small amount of oil into the spark plug hole and rotate the crankshaft several times.

Important! If it is not possible to store the trimmer in a warm, dry room, you must first wrap the motor with an oiled cloth.

Only observing these rules, you can be sure that the brushcutter will work properly and will not stall for a number of seasons.

As you can see, the shutdown of the trimmer can be caused by many reasons. Most of them can be fixed on their own using user instructions. In cases where there is no self-confidence, it is recommended that the equipment be referred for repair. It is worth remembering that improper actions can do more harm to the trimmer. As a result, repairing the lawn mowers will cost a significantly larger amount than it would have been initially, and in the worst case, you may need to purchase a new unit.

The best petrol scythes

Husqvarna 128R trimmer on Yandex Market

Makita EBH341U trimmer on Yandex Market