Proudly serving Marlborough Framingham MA for over 75 years

We know that downtime for your mower means you are losing money. That’s why we are committed to turning around your lawn mower repair as soon as possible. You don’t have to wait four weeks when you choose Monnick Supply for commercial repairs.

A lawn mower requires attention now and then. There are a lot of moving parts. It may be gas-related engine starting problems or lawn cutting issues due to natural wear and tear.

You can trust Monnick Supply, your local authorized dealer for lawn mower repair and maintenance. However, here are a few tips and tricks.

Read your entire operator’s manual to understand your machine and the safety warnings. Many of the procedures explained in this article require and understanding of basic procedures that vary between lawn mower models.

Never attempt a repair while the blades are running or the transmission is engaged.

Lawn Cut Quality Problems

For general lawn cut quality issues, clean the underside of the lawn mower’s cutting deck. Use a scraper to remove accumulated grass clippings, which tend to form a solid crust. Clean the top side of the deck, as well.

Uneven Lawn Cut

If your lawn mower is cutting lower on one side, check your tire pressure in all tires. Follow your manual’s inflation recommendation, as this varies based upon mower weight and other factors.

Measure all three blades (height from blade tip to ground) while your lawn mower is on a level surface. If the heights are not equal, adjust the deck shell accordingly.

Inconsistent Quality Lawn Cut

If you are noticing uncut spots, stringers, or discharge problems, this can be due to dull, bent, or broken blades. Inspect the lawn mower blades and sharpen or replace them as needed.

If all the above suggestions check out, bring your commercial mower into Monnick Supply for fast and reliable service and repair.

How to Repair a Gas-Engine Lawn Mower

Pumping new life into an old mower is easier than you think.

By Colin Aylesworth Roy Berendsohn Published: Mar 17, 2023

Jump to:

I’ve restored dozens of gas engine lawn mowers, and it’s been my experience that people put them out in the trash while the machines have plenty of life left in them. The average mower sitting unobtrusively at the curb usually needs nothing more than a thorough cleaning, an oil change, and some minor repairs. Really, in many cases, that’s all it takes to convert a mower from a heap of dried sod to a solid grass cutter.

You don’t need to be a small engine mechanic with a shop full of tools. You need nothing more than a few screwdrivers, a socket set, a putty knife, and some miscellaneous hand tools. Most mowers are fairly simple machines. Even a self-propelled lawn mower is not difficult to repair.

To demonstrate how simple this process is, and how little these mowers really need, we teamed up and plucked two disgusting and badly-neglected mowers from somebody giving them away for free. For both machines, our work was well short of a complete overhaul. Our cost for parts amounted to about 30 per mower. Here, we’ll show you how to transform one of these mowers from junk to gem.

Why Restore a Mower?

There are lots of good reasons to restore a gas engine mower. Even if you’ve bought a battery-powered mower, you may find that cutting conditions sometimes require the power you get out of a gas engine machine, so it makes sense to invest a little time and effort in your gas engine mower as a backup.

There are plenty of reasons you might want to fix up an old gas engine mower:

- Someone donates a tired grass cutter to your volunteer organization because you need it to handle rough-and-tumble cutting on the shoulder of a trail, around gardens, at a park, or even to mow some tough areas at a cemetery.

- Maybe your kid wants to start a lawn mowing business and you want to teach him or her the value of putting in a little sweat equity to stand an old mower on its feet, then put it to work turning a profit.

- Perhaps you just want to keep your faithful grass cutter running longer. That’s reason enough.

- Also, restoring the mower makes sense if you have someone to give you a hand–mowing your yard goes a lot faster with two mowers than it does with one.

- You don’t want to make the switch to a battery mower but aren’t thrilled with the lower build quality of some of the new gas mowers you’ve seen at your local home center.

- You don’t want to send a lawnmower to the landfill if it still has life in it.

Overview of the Restoration

The most common areas of neglect on a mower include a dulled or damaged blade, a grass-clogged deck, a filthy air filter, worn drive wheels, and a dirty grass bag. Believe it or not, most of the time, the spark plug is still good—replacing it will cost you about 6 at a home center.

For a good little tutorial on cleaning and gapping a spark plug, have a look at this video by engine manufacturer Briggs and Stratton.

The most complex thing that you might encounter is a carburetor that’s been damaged by ethanol gasoline or clogged by the residue that forms when the fuel deteriorates. We treat this topic in a separate section below.

Related Stories

Test Run the Mower

Check the mower’s dip stick to be sure that there’s sufficient oil in the crankcase. Then tip the mower up and look at the blade to check whether it’s bent or severely damaged, such that it would have damaged the engine’s crankshaft. Damage that severe is rare, but when it happens, usually the mower is a candidate for the scrap heap.

On the other hand, I’ve seen blades that were pretty badly chipped from multiple strikes on rocks and roots, and the engine was fine. While you’re checking underneath, it’s a good idea to fit a ratchet and socket to the blade bolt to make sure it’s tight.

Assuming there’s sufficient oil reading on the dip stick, there’s no sign of severe damage underneath, and there is gas in the tank, pull start the mower. If it doesn’t start, there could be several causes, but the most common causes are old or watery fuel, residue from degraded fuel clogging the carburetor, and a dirty spark plug.

LAWNMOWER CUTTING DECK RESTORATION

If you run a fuel check (see steps below) and the mower still doesn’t start or it runs erratically, a simple spark ignition tester will help you see whether there’s an ignition problem. The tool has a small window through which you can view the spark produced by the engine. No spark or an erratic spark indicates an ignition problem. Spark problems are rare, in my experience, but we mention it here out of a sense of completeness.

Assuming that the mower starts and runs, even if poorly, move through the restoration process.

Scrape the Deck

One of the most common ailments of a neglected mower is a grass-clogged deck. Fortunately, a few minutes of scraping and brushing are all that’s necessary to get it clean.

The average donor mower has a deck that’s downright packed with grass clippings. Begin the restoration by removing the spark plug boot from the tip of the plug. This safety measure will ensure the mower won’t start while you work on the machine.

Safety first. To prevent the mower from starting during the cleanup process, pull the spark plug boot from the plug. Tuck the wire and boot out of the way before proceeding.

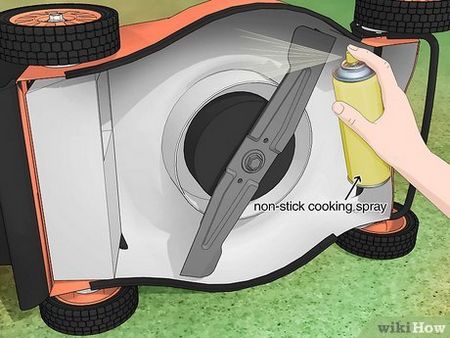

Next, scrape the deck clean with a putty knife. If you find rust flaking off the deck, scrape this, too. If the mower is going to be used often, then regularly cleaning the deck will slow the formation of rust. You can hit the underside of the deck with some spray paint if you want, but it’s not necessary if you keep the deck clean.

Remove accumulated grass clippings with a 1- or 2-inch-wide putty knife. These narrow knives easily follow the deck curvature, resulting in a cleanly-scraped surface.

Remove remaining debris with a stiff brush. Be sure to get the dried material out from around axles and crevices where trapped grass can cause a rust hole to form in the deck.

Replace Bad Wheels

One of the most common deficiencies on an old mower is that the treads have worn off the wheels or the gears inside the drive wheel have worn down. Replacing a wheel requires nothing more than unbolting the wheel and replacing it.

Prop the mower up on a block of wood, then use a flat blade screwdriver to pry off the cover that conceals the wheel bolt.

In most cases with self-propelled mowers, it’s only the drive wheels that need replacement. The procedure is the same for both. Front-wheel drive mowers tend to suffer from worn wheels more than rear-wheel drive units.

While you have the wheel off, clean off grass clippings from the dust cover and lubricate the axle and wheel-height adjustment points with dry lubricant. Avoid using any lubricant here that stays wet and attracts dust, dirt, and grass clippings.

With the necessary cleaning and lubrication out of the way, you’re ready to bolt up the new wheel. Align the drive splines inside the wheel with the drive cog and press the wheel into place.

Align the splines on the inside of the wheel with the gear on the end of the drive axle and push the wheel onto the mower. Before tightening on the wheel bolt, clean its threads with a shot of spray lubricant and apply some spray lubricant to its receiving threads. Tighten the bolt on by hand, and finish tightening it with a socket wrench.

Replace the Air Filter

When a mower’s air filter isn’t changed regularly, the dirt and grime on it is obvious. This air filter shows several years of hard use.

A dirty air filter degrades engine performance by blocking air flow. This disrupts the air-fuel ratio that’s necessary for peak power and easy starting. Fortunately, it’s also one of the easiest problems to fix. At most, the only tool you’re likely to need is a screwdriver to take the air filter cover off. Remove the cover, peel the old air filter out, and replace it with a new air filter.

If your air filter cover is cracked or smashed and needs to be replaced, it’s easy to do. Just search online using your mower’s model number, which should be printed somewhere on the deck. This should yield results of parts that are compatible with your mower. An air filter cover should cost somewhere between 9 and 15, depending on size and model. Some even come with the air filter.

Many air filter covers have tool-free access, a few will require a screwdriver.

Some air filter covers are tool free and come off by moving a plastic locking tab out of the way, but others require a screwdriver to open. In the case shown here, remove the single screw holding the cover in place.

Once the cover is off, remove the air filter and replace it with a fresh one.

Few things contribute to mower performance as simply and quickly as replacing a dirty air filter. The filter shown here is a gasketed type (a rubber gasket makes an air-tight seal around the filter’s perimeter). Regardless of whether the filter has a gasket around it or not, peel out the old filter and replace it with a fresh one.

If dust and grass clippings have managed to infiltrate the air filter housing, wipe the surfaces clean before installing the new air filter and replacing the cover.

Sharpen the Blade

Neglected mower. Neglected blade. The two are inseparable. Unlike any other repair on the mower, sharpening a dull blade will contribute directly to lawn health. Grass that’s sheared by a sharp blade loses less moisture and is less disease-prone than grass shredded by a dull one. Begin the processs by spraying the blade bolt with penetrant.

A neglected mower will have a neglected blade. And by neglected, I mean one that’s rusty and dull. Blade maintenance is a multi-step process that we outline in the steps below.

After saturating the blade bolt with penetrant (shown above), place a block of wood behind the blade to keep it from turning and loosen the bolt with a socket wrench. If the bolt refuses to budge, stop and make a second application of penetrant. A badly-neglected mower may require several applications of penetrant before the bolt breaks free.

Sharpen a blade that’s dull (not damaged), using a file. If the blade shows minor damage from hitting small rocks and roots, you can use an angle grinder with a 60-grit flap disk to sharpen it.

Clamp a dull lawn mower blade horizontally in a vise and sharpen the cutting edge with a right angle grinder and a 60-grit flap disk. Work from the center of the blade to the tip. After making several passes on one edge, flip the blade end for end and grind the other side. Try to remove an equal amount of metal from each edge so that the blade will be balanced when spinning in the mower deck.

Once you’ve sharpened your blade, you’ll need to make sure it is balanced, otherwise the mower may not run smoothly. There are several different ways to check a blade for balance. You can clamp a bolt in a vise, and hang the blade on that. You can drive a nail into a stud, and hang the blade on that. You can use a blade balance cone on a work bench and check for balance horizontally. Just make sure your bench is level before using one of these cones.

Clamp a bolt, an awl (shown here), or a large nail in a vise to suspend a mower blade to check its balance. If the blade tips to one side, you know that side is heavier and you must remove metal from it to get the blade to balance. Although this work requires some patience as you oscillate between grinding metal and checking for level, the results are worth it in the form of a sharp blade and a smooth-running mower.

There are a couple of other things to do after the blade is sharp and balanced.

Apply some spray penetrant into the hole that receives the blade bolt. It’s not unusual on a neglected mower to find rust and dirt particles flowing out of the hole as you apply the lubricant. Wipe off the excess lubricant that flows out of the hole.

Place the blade bolt on a drop cloth or a clean piece of shop towel and flush its threads with spray lubricant or penetrant. Wipe the bolt clean before installing the blade.

General Cleaning and Minor Repairs

Not that it will contribute to the mower’s performance, but it doesn’t hurt to spray down the mower deck, engine housing, and plastic parts using spray cleaner and a shop towel.

And while you’re at it, a filthy grass bag isn’t just gross, if its air vents are blocked, the mower won’t bag effectively. Blow out the bag with a leaf blower then wash it down.

After emptying the bag of all debris, use a heavy-duty spray cleaner such as a degreaser, a scrub brush, hose and nozzle to clean the bag inside and out. Rinse the bag thoroughly and stand it outside in the sun to dry. If you have a pressure washer, you can power wash the bag using the same cleaner that you use on your house. Be careful not to damage the bag by holding the spray nozzle too close to its surface.

Other minor repairs

One of our mowers had its drive belt cover worn through. We patched this area with aluminum foil duct tape that we painted black to match the rest of the housing.

Repair a worn drive belt cover by applying some aluminum foil tape to the inside of the cover then carve off the excess with a sharp utility knife. Then patch the outside of the cover in the same way. You can spray paint the cover with some flat black paint to blend it in. After cleaning grass clippings from around the belt and wiping the area clean, reinstall the drive belt cover.

Use some WD-40 to lubricate cables.

Spray some lubricant in at the cable access point and let it run downhill. While you’re at it, spray any part that pivots or turns, such as wheel height adjustment mechanism, axles, screws and bolts. Basically, if it’s metal on metal, lubricate it. Once you’ve added some lubricant, move these parts to work in the lubricant. You should find that control levers and pivoting or turning parts should start to move easier.

Run the mower for a couple of minutes to warm up the crank case oil, then stop the engine, disconnect the spark plug, remove the oil fill cap, tip the mower over, and drain the oil into an empty pan. After the last bit of dirty oil has poured out, tip the mower upright and refill with an appropriate small-engine oil.

Check and Clean the Plug

While you certainly can replace the spark plug, I’ve found that it isn’t necessary if the engine otherwise runs fine. To keep the spark plug firing optimally, you can simply scub any deposits off with a small brass wire brush. If you have one, you can also check the gap of the spark plug using a gap tool.

If the spark plug appears to be sound (it’s not cracked or its threads are not damaged), then gently scrub off carbon deposits with a small brass wire brush. If the plug shows any type of damage, such as cracked porcelain, replace it with a fresh plug.

Step two of refurbishing the plug is to spray it clean.

Use electrical contact cleaner to remove residue on the spark’s threads or its electrode. Place the plug over a drop cloth or a shop towel and blast it clean with a jet of the cleaner. Let the excess drip off. This cleaner leaves behind no residue.

A refurbished plug should look almost as good as one right out of the box.

A refurbished plug has bright clean threads and a clean (and properly gapped) electrode. This plug is ready to install in the engine.

If you’ve never installed a spark plug before, have a look at this tutorial at the Champion spark plug website. It explains tightening both gasket-base and taper-base plugs.

Thread the cleaned plug into the hole until it’s finger tight and then finish tightening the plug with a ratchet wrench and spark plug socket.

Test Run the Machine in Grass

An hour or two of work should yield a machine that starts easily, runs well, looks good, and cuts grass practically like a new mower. The two most important telltales that you want to look for are a smooth pull start, and lack of vibration when the mower comes up to speed (indicating a mechanically sound engine turning a balanced blade).

Adjust all four wheels so the mower is level, then walk the machine into some grass. A full operational test would include bagging and mulching. Of course, if the mower still has its side discharge chute, walk slowly into into some tall grass; with a properly-sharpened blade and the deck height adjusted for tall grass, you should find the mower produces a steady stream of clippings out of the side chute. We use the same test when evaluating new mowers at Popular Mechanics.

If the mower isn’t performing in some respect, you need to investigate. A bogging engine may indicate a fuel-supply problem or lack of spark under load. Vibration may indicate that the blade isn’t as balanced as you thought. If the machine isn’t bagging, have you pulled the mulch plug out of the back of the deck or forgotten about the hinged mulching door at the back of the mower?

Don’t laugh. I’ve seen more than one mower owner complain about performance while overlooking the obvious.

But as we say above, in most cases, a dirty old mower that has seen some basic mechanical attention will perform surprisingly well.

Carburetor Problems

The float bowl on this carburetor shows the result of today’s ethanol-containing gasoline. The fuel in the bowl is a syrupy mess and the bowl itself is contaminated with varnish and gunk left from the chemically-degraded fuel.

At this point in the story, we’ll switch mowers in order to show you what a fouled carburetor float bowl looks like. The Murray mower shown elsewhere ran perfectly well, indicating there were no carburetor issues. Not so with the Craftsman mower that was the FOCUS of another round of repair efforts.

Some background is helpful. Today’s standard gasoline contains ethanol, a form of alcohol that’s added to gasoline to reduce air pollution (that’s the theory, anyway). But the alcohol-rich fuel degrades rapidly and leaves behind slimy deposits in the gas tank, in the carburetor bowl, and in fuel lines. If your mower sits for a few weeks or longer without running, the ethanol in the gasoline may begin to degrade and cause engine issues.

If your mower won’t start after winter, you may very well have an easy-to-fix fuel supply issue. To test this out, remove the air filter and spray some carburetor cleaner into the carburetor opening behind where the filter sits, then try starting the mower. If it runs for a second but then dies, that’s a good indication your carburetor is clogged.

Pinch off the fuel line with a pair of locking pliers, place a piece of shop towel under the carburetor to catch spilled fuel, and use a socket wrench and socket to remove the carburetor’s float bowl.

Once the bowl is removed, blast it clean with some spray carburetor cleaner.

Hold the float bowl over a shop rag and using the red nozzle extension, blast the bowl clean with a couple of shots of carburetor cleaner.

A couple of more cleaning steps, and you’re ready to reattach the bowl to the carburetor then test run the mower.

Wipe the bowl clean with a shop rag. There shouldn’t be a trace of residue left in the bowl; it should be bright and clean.

Use the red straw extension again to blast clean the orifices in the float bowl’s screw. After that, put the bowl back in place and fasten it with the newly-cleaned screw.

If this basic cleaning doesn’t work, your best bet is to fully remove the carburetor to clean it or replace it. Have a look at this brief tutorial at the Briggs and Stratton website to give you an idea of what’s involved with these engines. Rebuilding a carburetor is fairly simple, involving disassembly and reassembly with some screws, a few small parts, and gaskets and seals. A rebuild kit will cost anywhere from 8 to 30. If the work seems overly fussy to you, and you don’t want to be bothered with it, replace the carburetor. New carburetors cost anywhere from 20 to 50. In terms of what the old mower is worth, in most cases a rebuild kit is more cost effective, but you’ll have to be the judge of what is effective in terms of your time and trouble.

Roy Berendsohn has worked for more than 25 years at Popular Mechanics, where he has written on carpentry, masonry, painting, plumbing, electrical, woodworking, blacksmithing, welding, lawn care, chainsaw use, and outdoor power equipment. When he’s not working on his own house, he volunteers with Sovereign Grace Church doing home repair for families in rural, suburban and urban locations throughout central and southern New Jersey.

Extend the lifespan of your lawn mower with these minor repair and regular maintenance tips.

By Timothy Dale | Updated Aug 16, 2021 11:14 PM

We may earn revenue from the products available on this page and participate in affiliate programs.

A lawn is a great place for kids to play, pets to run, and adults to host family and friends, but the grass must be regularly cut in order to ensure that it grows healthy and doesn’t become overgrown. Overgrown lawns can often attract harmful pests like ticks, which are known to live in grass that is more than 4 inches in tall. So, it’s important to make sure that you can keep a healthy trimmed lawn by performing minor repairs and ongoing maintenance on your lawn mower.

While some issues are better dealt with by professionals, lawn mower repair and maintenance isn’t necessarily complicated. By establishing and adhering to a maintenance schedule, most issues can be resolved with minor inspections and repairs, including simple tasks like sharpening the blade, using the appropriate fuel, replacing the oil, or changing the air filter. Continue reading for tips on what to do and what not to do in order to properly repair and maintain a lawn mower.

DO sharpen the blade.

This may seem like an obvious task to some, but others may use their lawn mower season after season without paying any attention to the blades. Not only should the blades be regularly inspected for warping, rusting, and other damage, but they also need to be sharpened about twice per season or every 25 hours of use to help extend the life of the blades and the mower.

How to Repair, Rehab, and Renew your Mower Deck. John Deere L, LA, D, E Series & more

Sharp blades don’t just help the mower cut the grass better, they also make clean cuts through the grass, which reduces the likelihood of the lawn developing a disease. Inspect the mower blade for dents or nicks, and take note if the grass height is uneven after cutting, the edges of the grass look brown, or if the grass blades are torn instead of sliced clean through. Each of these signs is a symptom of dull blades that need to be sharpened.

DON’T choose a fuel with an octane rating lower than 87.

As with any gas-powered machine, the type of gas that is used can impact the grass-cutting ability of the mower and the longevity of the engine. Gas is rated based on the amount of filler that is included in the gasoline formula, so octane 91 gas, which is often referred to as premium, has less filler than octane 87 gas that is called regular.

The minimum octane level that lawn mower gas should have is 87. This ensures that the gasoline meets the requirements for use in standard motor vehicles, reducing the chance that the engine will be damaged while burning the gas.

Some users may prefer to fill their lawn mowers with premium-grade gasoline, though this isn’t typically required. The best gas for your mower is the type that is suggested by the owner’s manual. However, switching to a premium grade gas during cooler weather, like early spring and late fall, is a good idea to help maintain the health of the engine.

DO check the spark plugs every two months.

Spark plugs in a lawn mower serve the same purpose as they do in a car or truck. These little parts of the engine serve as an ignition source for the gasoline. When they start to fail, it becomes immediately obvious. It’s important to inspect the spark plugs about every 2 months during regular use.

Signs that the spark plug on the mower may be failing include hard starts, poor engine performance, unreasonable fuel consumption, and a worn, cracked, or chipped physical appearance of the spark plug. If the engine is difficult to start up or it tends to die out immediately after the engine finally does start, then the issue may be the spark plug.

DON’T neglect cleaning the deck.

It’s never a bad idea to clean the deck of a lawn mower. Some people say to clean the deck once a month, others insist that it be cleaned after each use. It’s helpful to check the underside of the mower after every use to remove any stuck-on grass, dirt, weeds, or other debris. While keeping the deck clean will reduce the chance that the lawn mower will begin to rust or corrode from the inside, this isn’t the only reason to clean it.

As the deck of the lawn mower slowly fills with grass clippings, weeds, and dirt, the accumulation creates a barrier that prevents the grass from standing up straight while underneath the mower. This results in a poorly cut lawn and this build-up can even start to hinder the rotation of the blades, putting undue stress on the engine, blades, and component parts of the mower. So, after mowing the lawn, just take 5 minutes to flip the machine over and clean out the deck, saving the hassle of future lawn mower repairs.

DO inspect the flywheel.

A flywheel is a part within the engine of the lawn mower that stores the momentum from the combustion process in order to keep the crankshaft turning between the power strokes of the engine. It also helps cool the engine by blowing air around the engine block. Without a functional flywheel, the engine could quickly become overheated or it may not even start.

Some signs that a flywheel is damaged or failing include the inability to start the engine, the engine constantly stalling, and a burning odor from the engine. It’s advised to inspect the flywheel at the beginning and end of every lawn maintenance season to check for cracks, broken fins, slight burrs, shearing, and crankshaft damage. Just make sure to disconnect the spark plug lead before opening the engine to check the flywheel.

DON’T neglect oil changes.

Similar to sharpening the lawn mower blades, changing the oil in the lawn mower is a task that can either be almost entirely ignored or regularly performed with strict adherence to a maintenance schedule, depending on the user. If you don’t know exactly how it benefits the lawn mower, then it may seem like changing the oil does a lot. However, without this lubrication on the moving parts of the mower, the engine begins to seize and break down prematurely. Many people think of oil as the lifeblood of the engine, so it makes sense that the engine cannot function without it.

Check the oil level with the lawn mower dipstick before each use and change the oil when it becomes murky. For regular maintenance throughout the year, it’s advised to change the oil about once every 25 hours of use or at least twice per mowing season to ensure that the lawn mower engine is properly lubricated with clean oil.

DO change the air filter.

The air filter in the lawn mower is designed to protect the engine by trapping dust, dirt, and other debris, but the filter can only hold so much dirt and debris before it becomes dirty and clogged. Some lawn mowers have reusable air filters that can be removed and washed, but this is a rare feature. Generally, a lawn mower filter should be replaced about once every year to help maintain a healthy engine.

Symptoms of a dirty or clogged air filter include a dirty physical appearance, engine misfires, a reduction in the horsepower or power output of the engine, concerning engine noises, strong fuel smells, and in serious situations, flames or black smoke can be produced by the engine. If you detect any of these signs, stop mowing and go get a replacement air filter. They are inexpensive and relatively easy to replace if you follow the lawn mower manufacturer’s guidelines for air filter replacement.

Mf-610 Mower Deck Restoration

This is an older restoration from last year, but it was never posted here. I figured I would do so and attach a link to the sticky with the parts info.

This mower deck was in need of a ground up restoration, the bearings were shot, and the deck rough. To start, I needed to remove the spindles, but the pulleys were stuck. I tired to sneak them off with electrolysis, but in the end I had to just cut them off with my grinder.

With those removed, I now had the deck stripped bare. I was able to find the missing top shield on e-bay and armed with these, it was time to sandblast the deck. Once blasted, any dents and heavy rust pitting that would show was filled with body filler and primed.

Attachments

May your crops be green, and your tractors red. :smilewink:

1971 Massey Ferguson 12-H 1974 Massey Ferguson 12-G 1974 Massey Ferguson 8-G

Now, once the deck was primed, it was entrusted to a friend who sprays in truck bed liners. By luck, he just happened to be doing a red truck liner and sprayed the liner where I had outlined with a sharpie.

But, while this was out, I took the time to restore the spindles. They were torn down, sandblasted and powder-coated. I took this time to install grease fittings as well. The spindles received all new bearings and seals, and the needle bearing was upgraded to a 1 wide bearing for better contact. Throughout this restoration, all new stainless steel hardware was used.

The bearings seals were bought at Accurate Bearing Supply:

With those finished, the mower deck was picked up with it’s fresh bed liner. This was done to keep the rust away where the wet grass sits under the shield. The underside was not coated, more on that later. You can see the liner perfectly matches the shield, right down to the bolt tabs. This keeps the shield from rubbing and creating rust too. (Plus, when I need to re-paint, I can just mask off the liner and paint only the outer edge. This way all the belts and pulleys do not need to be removed.

Attachments

May your crops be green, and your tractors red. :smilewink:

1971 Massey Ferguson 12-H 1974 Massey Ferguson 12-G 1974 Massey Ferguson 8-G

Now before painting, I wanted to brush a coat of semi-gloss black Rustoilzum rusty metal paint. This has held up well in the past, so it at least helps keep the rust at bay.

Then it was time to mask the liner and give it a coat of paint. I used the Tractor Supply paint, as I do plan to repaint this pretty much every year or two to keep it looking nice. I mean, it IS my main mower!

All the other little parts and brackets were also restored and painted at this time. One dry, it was time to bolt it up and give it a try!

And there we have it! It’s due to be painted again to fix up the scratches on the sides, but it mows great and leaves a very good lawn cut and the roller does a good job stripping too. Thanks all! :wave:

Attachments

May your crops be green, and your tractors red. :smilewink:

1971 Massey Ferguson 12-H 1974 Massey Ferguson 12-G 1974 Massey Ferguson 8-G

Thanks guys! I must say, it mows wonderful too! I find that the flat discharge shape will toss the cut grass further and not show as windrows if the grass gets heavy.

May your crops be green, and your tractors red. :smilewink:

1971 Massey Ferguson 12-H 1974 Massey Ferguson 12-G 1974 Massey Ferguson 8-G

I love the way the MF610 mower deck mows. Especially with the roller all the way across the back. It stripes the grass just like the new fancy zero turns, granted maybe not at 9 mph. I got my bearings yesterday and got them installed. Gotta paint the spindles yet, mower deck was mostly stripped down and then primed and painted.

awesome idea with the bed liner. i think im going to do my mf12 like that, but bed liner the underdeck and back roller. real nice machine you have.

Just my opinion here, but I would not do the underside myself. A yearly coat of some rustoilzum rusty metal black will be a better choice. The rough texture of the liner will make the grass stick to the deck even more than it does now. The roller should not be a problem, but with normal use, the light rust is worn off and it keeps a somewhat clean metal look. The main reason I did the top side was to keep the grass that will sit under the cover, from rusting the deck out. If you look at my deck in the photos early on, you will see just how deep the rust pitting was, mostly under that cover. After sandblasting to remove the rust, and a rusty metal primer converter, the liner should prevent it from rotting. I do know it’s always packed with grass when I remove the cover!

May your crops be green, and your tractors red. :smilewink:

1971 Massey Ferguson 12-H 1974 Massey Ferguson 12-G 1974 Massey Ferguson 8-G