How To Troubleshoot a Cub Cadet PTO That Will Not Engage

Have you ever encountered a situation where you pull the switch of your Cub Cadet several times, but PTO will not engage or works for only a few seconds at a time? If yes, you might have wondered whether it is possible to troubleshoot this PTO failure and if possible, then how to troubleshoot a Cub Cadet PTO that will not engage?

First, gather all the required tools and materials. Then, check the PTO switch and do a continuity test of your Cub Cadet PTO switch. Next, mount and remove the PTO. Lastly, if required, replace the PTO switch with a new one.

Continue reading this following article to learn how to troubleshoot a cub cadet PTO will not engage.

What Causes the Problem?

If you own a Cub Cadet mower and the PTO is not engaging, it most commonly occurs due to either the clutch not getting enough power, a worn-out clutch, or the clutch solenoid being defective.

Similar PTO malfunctioning or complete failure issues can also arise due to improper installation or user misuse.

In any circumstances, as soon you notice that your Cub Cadet PTO is failing to engage, make sure to perform a continuity test to ensure whether it’s the switch that requires to be replaced or a simple adjustment will do the job just right.

Steps to troubleshoot a cub cadet PTO will not engage:

Imagine you are about to start mowing or middle of mowing your lawn on a perfect sunny day.

Suddenly, you notice that your Cub Cadet stopped working. When you investigate further, you noticed that the PTO won’t engage even after several tries, and you have no idea what went wrong cause last time, it worked perfectly.

Isn’t it one of the most frustrating and discouraging moments to encounter?

Undoubtedly, it is, and when the PTO failure or malfunctioning occurs, it can cause the blades to either not engage, or fails to disengage properly after finishing the cutting job.

That’s why I am going to explain a quick, easy, and cost-effective way of troubleshooting your cub cadet PTO that fails or will not engage:

Things required to troubleshoot the cub cadet PTO will not engage:

Look at the checklist of the required tools and materials for this troubleshooting task:

| Tools | Materials |

| Decent Digital Multi Meter | Cub Cadet PTO Switch |

| Standard Mechanical Tool Box | |

| 2 Ton Chain Hoist | |

| Safety Goggles Gloves |

Step 1- Checking the PTO Switch:

First, pull the switch out of your Cub Cadet dash.

Then, turn on the key, and you will hear a click of the fuel solenoid on the carburetor bottom.

Now, pull up your Cub Cadet PTO and see if it is responding or not.

Step 2- Testing Continuity of the Cub Cadet PTO Switch:

If the PTO on your Cub Cadet is not responding, the next thing you should do is, test the switch with a Digital multimeter or voltmeter.

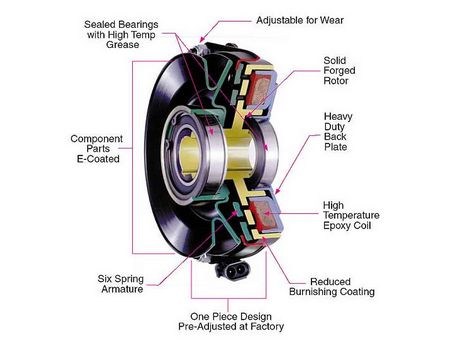

The Cub Cadet PTO switch will look as shown in the above image.

There should be continuity through the pins right through these two. And through these in some way as indicated in the picture.

Now, turn the multi or voltmeter on first and set it to continuity.

Next, connect the switch with the meter and check whether it has continuity or not.

If it has continuity, open the switch and test again, it should not have now. If those two prongs are in good shape, try testing the middle two.

Check while keeping the switch open, and then, check again while keeping the switch close. When you close the switch, the continuity should stop.

Now, check the last ones and repeat the same testing method once again.

Step 3- Mounting Removing the Cub Cadet PTO:

If you see no continuity through any of the particular rows, see closely towards the switch.

If you find that the switch has started to burn or melted a little bit as shown in the image, you can try to mount the PTO.

But make sure the PTO is good because you can have a PTO going bad, which can cause your Cub Cadet PTO switch to fail.

So, tilt your Cub Cadet mower upward with the help of a 2 Ton Chain Hoist to access the underneath of your mower more comfortably.

Now, go underneath your Cub Cadet and disconnect the PTO switch. Sometimes these switches can be pretty tight.

So, be careful while you try to remove them.

Now, clean out the terminals.

You can also see that there are two wires in there to check the amount of resistance.

First, look at your Cub cadet’s owner’s manual to know what the resistance should be like 2 to 4 Ohms.

Now see this one is coming in 3.3, so it’s right in the middle of spec, and that means your Cub Cadet PTO is in good term.

Step 4- Changing the PTO Switch:

First, buy or bring a new PTO switch to replace the older one.

Then, plug this in by pulling one of these tabs, and they snap in on the plastic.

You can put a screwdriver under these and usually pop them up from the top side as long as you are careful enough.

When you have successfully inserted the switch in place securely, do not forget to check whether it works or not.

Tips: Sometimes, the PTO switch can be from different configurations or different manufacturers, but they test straight across. So, make sure you first test the continuity before installing the new PTO switch.

To troubleshoot your Cub Cadet Mower or tractor, follow this article: How to Troubleshoot a Cub Cadet PTO. You can also watch this detailed video.

Performing such troubleshooting tasks can be hazardous if you do not have enough expertise. Also, always read your tractor or lawn mower’s instructions manual before operating, servicing, or troubleshooting it.

Frequently Asked Questions

What causes a cub cadet PTO to not engage?

Your Cub Cadet PTO might fail to engage due to two typical reasons. One of the reasons can be incorrect installation or adjustments, and another one is aggressive use or owner’s misuse.

It can also occur due to a lack of continuity or no continuity issue of the PTO switch. So before confirming, investigate thoroughly.

Where is the PTO switch located on a Cub Cadet?

To locate the Cub Cadet PTO, first, open its engine cover. Then, remove the ignition wire from the engine assembly side’s the spark plug. Now, find the small bell housing located on the underside of your Cub Cadet’s engine and this housing is for its PTO.

How to engage PTO on Cub Cadet?

To engage your Cub Cadet mower, thrust the blade or PTO lever forward into the On position. If your mower’s PTO is in good condition, it will engage immediately with a click sound.

John Deere PTO Clutch Removal and Replacement Video LA145, 3 MINUTES!

How tight should a Cub Cadet slip clutch be?

On average, your Cub Cadet slip clutch should be 14 thousand an inch tight.

Why won’t my Cub Cadet blades not engage?

The main reason your Cub Cadet blades won’t engage is either a weakly charged battery or a dead internal battery.

Final Verdict

Cub Cadet lawn mower or tractor users often complain that their Cub Cadet’s PTO will not engage even after several tries, and if the PTO engages, it won’t last for long.

This is not a rare or particular issue that only occurs while using Cub Cadet mowers and can arise with any other brand’s mower or lawn tractor. But there’s an easy-to-do technique to get rid of this problem, and I have already explained it in today’s article.

Remember, you can only get the best result if you thoroughly follow all the instructions to troubleshoot a Cub Cadet PTO will not engage.

s:

How to Adjust a PTO Clutch on a Lawn Tractor

Many lawn tractors, particularly John Deere riding mowers, use a PTO clutch. The PTO function is what engages the mower blades of the lawn tractor. The mower’s battery sparks the PTO clutch, which then guides the shaft and rotates the blades of the mower. However, if your lawn mower is not working at its best capacity, it may need to be adjusted or replaced. There are two main ways to tell if your PTO needs adjusting. By adjusting the PTO clutch, you can ensure the best quality, most efficient and safest lawn mowing.

What Is a PTO Clutch on a Lawn Tractor?

A PTO clutch is a switch or lever found in tractor engines and stands for power take off. It can be run by a belt or shaft. Typically in larger lawn mower engines, the PTO clutch is shaft-driven. The operator of the lawn tractor engages the mower blades using the PTO clutch.

- Many lawn tractors, particularly John Deere riding mowers, use a PTO clutch.

- The PTO function is what engages the mower blades of the lawn tractor.

How Will You Know Your PTO Clutch Needs Adjustment?

As the lawn tractor engine ages, the PTO clutch can start to slip. This causes the mower deck to cut less efficiently and at a lower quality. If you notice a Rapid decline in the standard of your mowing, it could very well mean your PTO clutch needs adjustment.

Another sign your PTO may need checking out is if the mower in your lawn tractor is unresponsive. This could be a sign that the PTO clutch has stopped engaging the mower blades.

How to Adjust Your Lawn Tractor’s PTO Clutch

Firstly, you’ll need to ensure your lawn mower is parked on a flat, even surface. The parking brake must be on and the ignition must be off. For safety, you must also ensure that the PTO switch is in the off position.

- As the lawn tractor engine ages, the PTO clutch can start to slip.

- This could be a sign that the PTO clutch has stopped engaging the mower blades.

To find the PTO clutch, check the crankshaft under the engine. On the clutch plate will be a sticker, informing you if the clutch is Warner or Ogura. If the sticker says Warner, you’ll want the feeler gauge at 0.51mm. If it says Ogura, the feeler gauge should be at 0.41mm.

In the brake plate directly above the pulley, there should be a slot. Insert your feeler gauge through this slot so the gauge is between the armature and the clutch rotor. Keeping the feeler gauge under the bold directly, tighten the three lock nuts, one at a time.

- To find the PTO clutch, check the crankshaft under the engine.

- If the sticker says Warner, you’ll want the feeler gauge at 0.51mm.

Using a sweeping motion with your feeler gauge, tighten the first nut until you can feel adequate friction between the clutch rotor and armature. Then, repeat this step with the second and third nut.

Finally, start up the engine again and check the PTO’s engagement of the rotor blades. You may need to tighten or loosen the nuts again in order to get the exact engagement you need.

What is a PTO Switch on a Lawnmower?

A PTO, or Power Take Off switch, is an integral part of any ride-on lawnmower. The switch controls the power from the engine to its drive system, as well as other accessories attached to it. Without this switch, the lawnmower would not be able to start up and begin mowing. This article will discuss the PTO switch on a lawnmower in more detail.

What is a PTO switch?

The PTO can be found on the dashboard of most electric ride-on lawnmowers. It is a large red switch, which needs to be turned on each time you mow your lawn. The main job of the PTO is to act as a safety feature so that the lawnmower blades won’t go around unexpectedly.

When the PTO switch is in the “on” position, it sends power from the engine to the lawnmower blades, which allows the grass to be cut. The PTO has metal prongs that conduct the current and pass power from the engine to the blades.

The PTO acts as a clutch on an electric ride-on mowers and is commonly found on lawnmower makes, including John Deere and Ferris. It is commonly referred to as a PTO clutch or switch.

If the PTO is in the “off” position, it won’t send any power. This is because it will deactivate the clutch and won’t send any power to the blades. The operator can turn the PTO switch off and then work safely on the lawn mower mechanics without worrying about accidentally activating the mower blades. Properly using a PTO switch is essential for safety.

The PTO switch is also an excellent addition for those who want to use their riding lawnmower as a tractor. It allows you to disengage the blades, meaning that the grass won’t be cut, and the mower will also be safer if it’s running around children or pets.

How to maintain a PTO switch

To maintain a lawnmower’s longevity and performance, it is essential to remember to turn off the PTO switch after each use. This will prevent unnecessary wear or damage to its components and ensure that it works as intended every time you need it.

To ensure the PTO switch is working correctly, it is crucial to inspect the switch periodically. This can be done by turning off the engine and using a multimeter to test the power source from the battery to the switch. If there is no current flowing through, then it’s likely that the PTO switch needs to be replaced. Additionally, it’s essential to check the safety features on the switch for proper operation.

Finally, it is important to regularly clean and lubricate the PTO switch to ensure it works properly and safely. Cleaning should be done with an air hose or a soft brush, while lubricating should be done with a light lubricant suitable for the switch.

Following these steps will help ensure that your lawnmower is working safely and efficiently. If the PTO switch has gone bad, it may need to be replaced. PTO switches can be affected by the following problems:

Corrosion

Corrosion can occur when moisture accumulates and creates a thin film that weakens the PTO switch. This weakening can lead to difficulty starting your mower, or it may stop working altogether.

Frayed Wires

Frayed wires are one of the most common problems people face with their lawnmowers. If the wiring around the PTO switch gets worn or damaged, it can cause the mower to not start or become difficult to operate.

Dirt and Debris

If dirt and debris get into the PTO, it can lead to a faulty connection that won’t power up your lawnmower. Cleaning out the area around the switch is often the first step in solving this problem.

John Deere Ztrack PTO Clutch Wire Fix

Loose Connections

Loose connections can cause a false connection with the PTO switch, leading to difficulty starting up your mower or other problems. Tightening the screws and connectors around the switch can help resolve this issue.

Blown fuse

A blown fuse can be caused by a faulty connection or other problems. If the PTO is not receiving enough power, it could cause the mower to fail to start or become difficult to use. Replacing the fuse should resolve this problem.

Bypassed connection

If the connection to the PTO is bypassed, it can lead to a faulty connection that prevents the mower from starting up. Correcting this issue requires identifying and fixing the bypassed connection.

Conclusion

To summarize, the PTO is an essential part of any lawnmower. It controls the power from the engine to its drive system and other accessories. Without this switch, it would be impossible to start and use a lawnmower. To maintain your lawnmower’s performance, make sure to turn off the PTO switch after each use.

What is a PTO Switch?

An electric lawnmower clutch, or a PTO switch, is a safety feature that turns the mower’s blades on and off. Manufacturers like John Deere, Cub Cadet, Ferris, and other riding mowers all have the same basic feature on their models. When this essential part of the mower machinery isn’t working, you’ll want to inspect it immediately to see what the problem might be so you can get it fixed and get back to your lawn care routine.

From wear to damage, a few things may be disrupting your connection between the switch and the blades, resulting in the blades shutting off or not connecting in the first place. Knowing what to look out for will help you be prepared in case your PTO switch stops working.

What Does P.T.O Stand For?

PTO stands for ‘Power Takeoff,’ referring to the clutch that engages the rider mower’s blades.

How Do You Use A PTO Switch?

When you engage the PTO switch, it actives the clutch (the mechanism that connects and disconnects engine power to a part of the machinery) for the mower blades. When you disengage the PTO switch, it disconnects the power to the blades, and the mower stops cutting.

The PTO switch is a connector, having metal prongs that provide the medium for the current to flow to the mower blades. As a safety feature, not having the mower blades on at all times, especially at homes with children and/or pets, decreases risks associated with blades that run whenever the mower is running. This feature allows users to disengage the blades if they want to drive their riding lawn mower as a tractor to pull other equipment.

What Happens When A PTO Clutch Goes Bad?

After a while, the PTO connection may start to wear down. When the PTO clutch goes bad, the blades will either shut off during use or not start at all. If you’re trying to mow your lawn, you’ll want to inspect the connection immediately to diagnose the problem.

Generally, the problem will be that power isn’t flowing between the switch and the clutch due to an interruption at one point or another along the connection between the engine, the clutch, and the PTO knob. Taking a look under the hood, you’ll be able to check the various nodes for a sign of damage or disconnection.

Why Does The PTO Not Engage?

There are several reasons that the power may be interrupted along the PTO connection:

- Corrosion or debris in switching mechanism – The PTO switch is a pull-knob usually made of plastic, and the internal switching connections are made of metal prongs and brackets. Over time, the plastic will wear down and may build-up, and the metal may get wet and begin to rust or otherwise corrode.

- Blown fuse – If there is a failure along the connection, the associated fuse on the operational panel will be blown out, and the connection interrupted for safety. This may be caused by too high of voltage being received due to frayed wires, exposure to moisture, or another connection short.

- Frayed or exposed wires – Over time, the plastic insulator coating on the copper wires will wear down and may expose the wire. When that wire comes in contact with a conductor like moisture or an organic material, it will short the connection and may blow a fuse or heat up the switch, becoming a fire hazard.

- Burnt out switch – A switch can get damaged by a short in the connection. The plastic connector may melt or heat the metal excessively, damaging the switch and disrupting the flow of power.

- Connection was bypassed – Some skilled riding mower owners interrupt the PTO switch connection intentionally and at their discretion. A bypass of the safety feature may be done by users who don’t have children or pets around, don’t drive their mower as a tractor, want the blades on always, or have other reasons particular to them. If you purchased a used model and your PTO switch isn’t engaging, the connection may have been intentionally bypass

How Do I Know If My Pto Switch Is Bad?

If the engine is running, but the blades won’t engage when you’re pulling the knob, then you know the interruption isn’t due to a dead battery. You can remove the switch from the dashboard panel to inspect the controller itself and check the connected wires and the clutch at the base of the mower to see which node in the system may be the dead end.

How To Test A Pto Switch

Your PTO switch can be tested for connectivity using a multimeter, a tool that measures electric currents and conductivity. Below the knob on the switch, there are 3 rows of prongs that are the electrical connectors for the on/off settings. When the switch is off, it won’t allow electricity to flow, but when it’s on, the switch opens the connection, and the blades can receive energy from the engine.

You can use the multimeter to test the on-position and see if the middle and bottom row of prongs permit an energy flow. If not, the switch needs to be replaced. This can easily be done by purchasing a new switch and connecting it. Using dielectric grease on the metal prongs will help insulate it from moisture and corrosion and can extend the life of the switch.

If the switch is functional, the problem is a disruption in the connection elsewhere along the line. In this case, follow the wires connected to the switch down to its connection to the engine and clutch. Gently testing the wire connectors with the multimeter to see if voltage is flowing through it will identify where the disruption or damage is.

Even if the switch seems to be damaged and the point of disruption, you should check the connections along the line for any voltage amplification or damage that may have shorted the switch, fuse, or other node in the connection.

What To Do If Your PTO Won’t Engage (Answered)

Modern lawnmowers and garden tractors are chockful of technological features that make them safer and more efficient than ever. Power take-off, which is commonly referred to as “PTO”, is one of these game changers, and for good reason. But what if your PTO won’t engage?

For a PTO that won’t engage on your mower or tractor, testing and or replacing one of the three parts of the system could fix the issue. Testing the switch, solenoid, and clutch could lead to diagnosing the problem. Replacement is the most common fix for each issue.

In today’s article, we take a look at some of the problems that can affect your mower’s PTO system, with a particular FOCUS on the switch mechanism. What causes a PTO to fail and, more importantly, what can you do to remedy (or prevent) such issues?

What Is A PTO On Lawn Tractors?

Firstly, we need to look at the basics of what a PTO system is and how it works. There are several moving parts and they work to make using mowers infinitely more safe than they were a generation ago.

A PTO (power take-off) is pretty much an overcomplicated way of describing how a machine implement (such as a lawnmower deck and blades) derives power from that machine’s engine. In the case of a lawnmower, PTO is what enables you to engage or disengage the mower blades while the engine is running.

Before this technology came on the scene, blades on rotary mowers would keep spinning for as long as the engine was running…something which is as dangerous as it sounds.

A quick glance at current lawnmower accident statistics (at a time when PTO is now the norm) hints that the pre-PTO era must have witnessed more than its fair share of landscaping carnage.

According to the National Institutes of Health (NIH) and the U.S. Consumer Product Safety Commission’s National Electronic Injury Surveillance System (NEISS) there were 934,394 lawn mower related injuries between 2005 and 2015. This equates to an average of 84,944 each year.

In a study done by researchers from the University of Chicago and the University of Virginia, the numbers were not significantly decreasing over this period. Yet, without a PTO system installed, these injuries would be much higher and admittance to hospitals would far exceed the 8.5% of incidents currently.

How Do PTO Systems Work On Lawn Mowers?

A PTO system is comprised of a PTO implement, a clutch, and a switch. All three of these parts work together to control the functionality of the blade spin.

A PTO system on a lawn mower works to control the ability of the blade under the mowing deck to spin. It is essentially a switch that turns on a magnetic pull from the solenoid via the clutch. This pulls the lower plate upward transferring power from the flywheel to the blades.

The clutch itself is comprised of upper and lower plates. The upper plate houses an electromagnet known as a solenoid. The lower plate is attached to the mower deck pulley and, ultimately, the blades themselves. Between the two plates is a flywheel that is attached to a shaft that is driven by the engine’s drive system.

When the machine operator engages the switch, signals are sent to the clutch via electrical cables. This activates the solenoid’s magnetic pull, which attracts the lower plate towards the upper plate. However, the lower plate can’t reach the upper plate but is attached to the flywheel instead, making it (and the blades) rotate.

When the switch is disengaged, the signals are cut-off. This switches off the solenoid’s pull, which causes the lower plate to detach from the flywheel and stop rotating. Naturally, the blades will also stop spinning.

Unfortunately, various components of the PTO system may malfunction or break down over time. As one of the moving pieces in this equation, the switch is especially prone to this.

How Do I Know If My PTO Switch Is Bad?

If you suspect a wonky PTO switch, the only way to be certain is to remove it and test it. There are tools that can help you get an accurate reading on your switches operation.

To find out if your PTO switch is bad, you will need a multimeter that is set to the Ohms setting. The aim is to assess resistance levels between the switch’s pins. PTO switches feature pins that are plugged into a socket that is hooked up to the electrical cables linking to the clutch.

There are usually eight pins arranged in three rows. One end of the rows is known as the “normally closed” (NC) side and the other end is the “normally open” (NO) side. These sides are often labeled.

In simple terms, NO means the circuit is open by default, allowing the current to pass as long as the switch is set to on. The circuit is cut off when the switch is set to off.

NC, on the other hand, means that the circuit is cut off when the switch is engaged. Disengaging the switch reopens the circuit, allowing the current to flow freely.

How Do You Test A PTO Switch?

Since testing a PTO switch is the main way to diagnose the problem, how exactly is this done? Most issues revolve around the switch and it should be the first thing tested.

Step 1: Check Resistance With Switch Off

The first step of a PTO switch test involves placing one of the multimeters leads on an NO pin. The other lead must be placed on the corresponding NC pin in that row. Note that the PTO switch must be in the “off” position. If there is continuity between the two pins, the multimeter will beep and display a resistance reading.

After this, repeat the process for all corresponding outer pins. Again, if you get beeps and readings, you’re good…so far.

I recommend this inexpensive and popular multimeter from Amazon to accurately check your PTO switch.

Step 2: Resistance Check With PTO Switch On

The next phase of the test requires you to set the switch to the “on” position.

Now, you will be testing your NC pins against their corresponding middle pins. The NO pins are irrelevant for this part. Again, you will be looking for beeps and readings on the multimeter display.

Ultimately, if you get readings all the way through, it means there is continuity between pins, which is what a functional switch should have.

Step 3: Diagnose A Faulty PTO Switch

If at any point, you do not get beeps or readings, you can repeat the test (using different multimeters if you can). If it’s still no dice, then that’s a sure sign of a faulty switch.

You might be able to fix a PTO switch but these components are so cheap that replacement is usually less of a hassle.

Then there is the solenoid that creates the magnetic pull to bring the power to the flywheel. There are times this can be faulty.

How Do You Test A PTO Solenoid?

The solenoid in a PTO system is essentially an electromagnet that pulls the lower plate hooked to the blades upward toward the flywheel providing kinetic energy from the engine. There are several things that can cause it to stop working.

Step 1: Check Solenoid With Multimeter

The first thing that needs to be determined is if this electronic portion of the PTO assembly is working properly. To do this a multimeter is again your tool. Yet, there is another simple trick to test your mower’s selenoid.

First and foremost, don’t test your solenoid while it is installed in your mower. Take it out to protect other parts from power surges.

This next part is a great tip for any who have or have not tried this before. You don’t need special equipment, only a battery charger that can be hooked up to the proper poles on the solenoid. Then you can check the functionality in a few simple steps.

Step 2: Check For Debris

Though these magnets are fairly strong and can be relied upon to work through some harsh conditions, as they age debris can have more and more of an adverse affect on their functionality. This can even come in the form of metal shavings or objects along with built up debris from normal usage.

Clearing out objects and buildup can restore much of the functionality of the solenoid. Though on a newer mower this is less likely, on mowers with many hours of use this could be an issue.

If you have already checked the switch, this should be the next step.

Step 3: Look For Bent Parts

The spacing for the proper operation of a solenoid is crucial. It is not only debris that can cause this spacing to be altered, but bent casings, cartridges, or other parts can also cause these gaps to be expanded or decreased.

The issue here is the ability of the average owner to be able to fix this issue themselves. Though it can be done, most manufacturers suggest replacing the solenoid assembly.

How Much Does A PTO Clutch Cost?

With the clutch handling much of the operation of a PTO system, it is put to use quite a bit. This can cause it to be one of the needed replacements over the years of use for many mowers.

The cost of a mower PTO clutch ranges from 100 to 300 for the assembly alone. Most residential PTO clutch assemblies cost from 100 to 170. This is not including the installation charges that could take the replacement from a couple hundred dollars to closer to 1000.

To reduce the cost of installation, those comfortable with repairing and replacing parts on their own equipment can save quite a bit. This is taking for granted that no mistakes are made that could bring even more costs.

What Else Would Cause A PTO Not To Engage?

Apart from the aforementioned faulty switch problem, there are a few possible reasons why your machine’s PTO system may fail to engage when you need it to.

Electrical Connections

The first reason is a disruption in the electrical connection. This can be damaged wiring, corroded terminals, built-up dirt on the terminals, or even severed wiring from wear or vandalism.

No Voltage To The Clutch

Another common problem with electric PTO systems is a lack of voltage at the clutch end. A quick multimeter test (on the voltage setting) should reveal the problem if any. The clutch solenoid required 12 volts to work correctly, so that’s the value you should get when you hook the leads up to the PTO cable end that connects to it.

Electromagnet Issues

If the voltage is there, but you’re still not getting any engagement, you might want to test the electromagnet itself.

This test is a resistance test using a multimeter on the Ohms setting. Place a lead on both poles of the electromagnet and observe the device display. If the magnet is working correctly, it should display a resistance value in the 1.5-3.0 range. Any lower or higher, and you’ve got problems.

Hand Levers

For mechanical PTO systems, we highly recommend that you inspect the linkage between your hand lever and the clutch. Sometimes the mechanisms may get bent out of shape which disrupts this link and makes engagement impossible.

The Final Touches On When A PTO Won’t Engage…

Problems with a PTO system can be frustrating, but like anything when we know how to go about solving the problem the stress melts away. There are primarily three parts to the system to check apart from general power and debris issues.

The simple fix for any one of these parts is to replace it. Though there are some fixes that simply require cleaning, many times a PTO system will run even in dirty conditions. Replacement parts are usually the way to go.

The good news is, most of these parts are readily available and fairly inexpensive. If you are not experienced in small engine repair, it is best to find a qualified expert you trust. They can do the job in a fraction of the time and make sure it is done right.

Mathew has worked in landscaping professionally for over 10 years. He is a grandpa and frequently interviews other experienced landscapers and lawn care experts who are also grandpas for these articles.

Recent Posts

Though there are many types of animals that can be nibbling on your plant leaves or flowers, there are some that you want less than others in your garden or yard. We know bunnies, deer, and other.

No one likes a clogged gutter and all the problems that come with it, from water damage to pest infestations. So now and then, we have to get our hands dirty. But what do you do when you have gutter.

About Us

We are Jerry McMillan and Mathew Booe (Father-In-Law/Great-Grandpa and Son-In-Law/Grandpa). Jerry has been in the landscaping business professionally for over 45 years and 10 of those years Mathew worked with him and helped him run his business. Together they answer landscaping, lawn care, and gardening questions of all types from hard work, first hand knowledge, and experience.

About The Grandpas report this ad

Legal Information

This site is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. We are compensated for referring traffic and business to Amazon and other companies linked to on this site.