How to sharpen a knife from a Bosch lawn mower

Before sharpening the knife, carefully clean it. On steel stripes, plant juice and small particles of grass accumulate. In this case, the juice hardens over time and turns into a hard crust. It is not worth washing the blades, it is better to choose a sharp metal scraper in the garage or use a brush.

No need to polish the cutting element of the machine to shine, the main thing. Remove sticking waste. After that, you need to improve what, straightening it and eliminating all the irregularities. Cones arise from solid fragments and stones falling on the blades. The right option in this case. This is a job with a hammer. With the help of this tool and a flat working surface, on which it is placed, you can fix all local distortions.

Experts advise starting to align the blade from the edge, gradually moving to the middle part. As a result, the steel strip should become as flat as possible. Only in this case he will be able to perform his function by creating an air flow that transports grass to the tank to collect plant residues.

File

In the first case, the work is organized if the blades are in a relatively good condition and only a little dull. Usually this sharpening is used if the owner drags the cutting elements of his garden tool several times per season. If so, then it will be enough to walk around the edges of the file and fix them.

During operation, the curvature of the knife, roughness are removed

It is important to maintain factory angles and descent. Both sides (blades) are based evenly

The grinder is contained in the same position. Disbalance should not be allowed, in which it is impossible to achieve the coordinated operation of the blades. This problem will lead to the operational wear of assembly units (bearings).

After the main sharpening, the edges should be straightened. This is done in order to eliminate the slightest breakdown. It is better to use sandpaper eight hundred gratings. Editing is a small displacement of paper along the sloping plane.

Note! Instead of a file, you can use a grinding stone. Before the procedure, it is soaked in soap and water for a quarter of an hour. During operation, it is also allowed to moisten the tool a little.

Step.by.step process

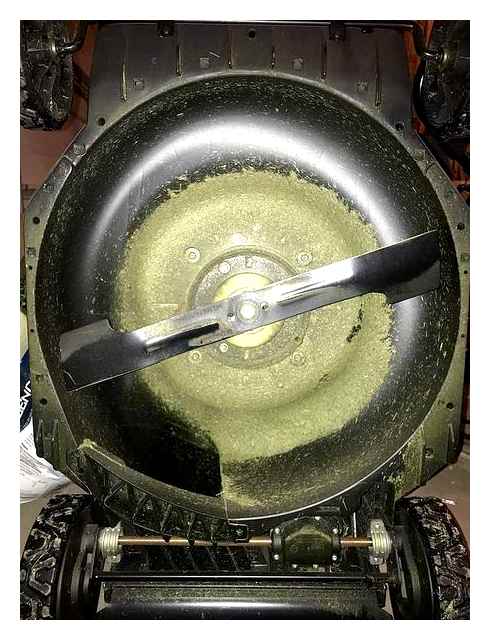

- Before removing with what mowers, fix it with a strong board or log, resting on the ground. It is necessary that the knife does not move when it is removed. However, some neglect this security event and simply hold the liner with their hand.

- Take a wrench or tool in the form of g, is ideal in size. The use of pliers is not recommended. This fitting tool easily spoils the edges of the bolts.

- Usually the cutting block is fixed with one large bolt located in the middle. Modern models have several mounts. As a result, you will have to unscrew them.

- Bolts are more often right.sided. Therefore, to unscrew the bolt, turn the key counterclockwise. In order to screw it back, this is done the opposite, that is, tighten the bolt clockwise.

- It happens that over time, the threaded steam sticks out, rusts, and it becomes problematic to twist the bolt. In this case, special lubricants are used, which are called rare keys.

- If the removal was successful, and all the mounts of the virgin, then bolts, nuts, washers are removed in a box for safety. These compounds may have to be reused.

Additional Information. Before taking out the knife, remember its position. Most often, the knives put counterclockwise the tip, and the rotation of the element is as follows. However, this advice does not concern all models

Therefore, you should pay attention to the position of the element. It is in the same position after sharpening that you will have to put a new knife or fasten the old

How to sharpen a knife

The easiest and most effective method of how to sharpen knives for a lawn mower is to use a drill with an adapter for grinding wheels. It is not worth counting on “factory sharpening”, since it is performed using a diamond disk, but you can restore the cutting edge with this method in 5-10 minutes.

The disk is selected with fine granularity, in the range of 800-1500 Grit. To sharpen a traditional knife, 4-5 such skins will be required. During the grinding of the edge, it is necessary to monitor the balancing. To do this, just hang the knife on the rope, passing the one through the central hole for fastening. If he will not deviate in any of the sides, everything is in order. Otherwise, you need to slightly walk again with a skin on the opposite side to level weight.

After sharpening with the help of the disk, it remains only to perform the final eyeliner of the cutting side of the blade. Experts recommend using sharpeners with very fine grainness for this, from 1.5 to 4 thousand Grit.

You will have to spend at least 15 minutes on each side of the knife, clearly withstanding the angle of 30 °. To achieve the best results, the upper part of the blade is made rounded. It must be borne in mind that with a final eyeliner, the angle changes to larger 2-3 times. First, the transition is made from 30 to 35 °, then. up to 40 °. Literally 2 passes after the shift will be more than enough. This form of the blade is made for greater resistance to the appearance of burrs.

A knife for a trimmer for grass (meaning a model of a lawn mower with an electric drive) is sharpened in a slightly different way. There you have to use only a file or diamond sharpener. The ideal option is a sharpener. where the disk with diamond spray is wearing. But as a rule, the sharpening of a knife for an electric lawn mower with your own hands is not performed. This is done by qualified masters when using special equipment (laser sipping the edge is performed).

Community rules

The rule of good tone is the indication of the place where the trophy and elementary politeness was caught.

It would not be very bad if the video is indicated to the video and the actions taking place in it. The Picabu is most often read and watched pictures, so if you have a video and a swording of this video, then your post will have higher chances to get into the hot

The posts that are advertising are extremely approved, in cases of which you can always call @moderator. They will definitely help to figure it out.

The rest of the rules are no different from the rules of the Picabu can read here https: // pikabu.ru/html.PHP?ID = WTF

The knife should be kept at the same angle when sharpening

From the experience of communication with the population I state, no one can sharpen the knives. The knife is sharpened on the “emery” removing a significant part of the metal. And in everyday life I often see the blades staged to the base.

I was taught by the knives and any cutting instrument Father, a carpenter from God. over, he sharpened to razor, axes, and shirts and shamings, not to mention knives. Taught to check the severity of the blade, the knife should cut the hairs on the arm just above the wrist.

Soft Japanese steel and hard European? 🙂 It’s already funny.

And if there are 3000, 6000 and 8000 grits in the free sale of stones, grinding goy paste. This is already masturbation. Some like it, but by and large it is pointless.

I will reduce even more: you need to get a crap like in the second picture.

If you are not a knife.handed, and do not masturbate on knives from special craft steels of manual forging. then you have enough classic stones based on silicon carbide, they are also ordinary cheap.

The price of the issue ≈1600-1800 with a set of pebbles. The machine can be assembled by yourself who has a workshop in the garage, the rest is easier to find according to ads, it is really made artisanly in the country, and therefore there is something to choose from. You can look at YouTube how it works. For some reason, the author poured thousands of beech instead of 1 vidosik.

Useless text. Generally. But, people, how the angle is calculated? Here on the device is like in the 2nd picture. Angle of 40 degrees. How to put up? It will be the angle between the bar and the plane of the blade?T.E was 40 degrees on one side, turned the knife, 40 degrees on the other side? The RK itself will turn out 80. Or an angle for sharpening a knife at an angle of 40 degrees, you need to set the angle between the bar and a knife of 20 degrees? That after the coup of the blade, it gave 40?

And fucking, when there is this ? Harps anything. Reliably, quickly, neatly.

“The final chord is the sharpening of the” goi “paste.”Pasta g. O. And. (State Optical Institute)

To hell. My wife is constantly cut and swells me for sharp knives.

For knives with a blade that is wider than a handle. Ribbon grinder

For smaller and narrow setting sets that cost relatively pennies

WREDOG answer to the “Call is accepted”

There was, they say, an exhibition in some side. All peoples showed their work and weapons, including. Our Zlatoust Bulat did not pass such a place. And the Germans put their crafts next to our craft, and they boast: “Ours are better”. I see, the dispute has risen. The people from the whole exhibition came across the people. Then ours rolled through the machine, at which they tried flexibility, put the saber up with the point, grabbed the handle in the clamp and say:

The Germans began to evade, and they hold their nose up:

Here, thanks, other peoples got involved, especially from the military layer.

They chose from all the peoples that they were here, by a person in a judge, and a volunteer was found on the wheelhouse. Some kind of military man like a master came out, with gray hair already. not great, but the ridge.

Submit a German saber to this stranger. He grabbed the ends to experience the ends. Look, but the German saber has no end.

Submitted another. This time I got an adequate to try the middle, and again from the first time the German saber has half at all.

Submitted the third. This was directed so that the sabers close the handles close, and the end is the same: from the German saber in his hand one handle remained and remained.

Ours still insisted, so that they would be brought to the end. Strengthened the German saber in the machine, and the same man began to chop on it on it. I scared once. there was no tip, two. half, three. one handle in the machine, and there are no signs on our saber. Here everyone is noisy, clap their hands, they seem to shout in different languages, and this shirt pulled out a dagger of ancient work, with a gold notch, strengthened in the machine and asks:

He grabbed his shoulder. And what do you think? On the dagger of Zazubin to the very interception, and our saber was, so it remained. There were still weapons, and one thing was one thing: either completely our bulat will chop the weapon, or so. Then the shirt looked around the saber, kissed her, twisted it over his head and began to say something in his own way. Our quails: he, they say, on his side, the most famous person in arms and he has accumulated a lot of everyone, but there was no such bulat. Is it possible to buy this saber? He will not regret the money. Ours, of course, did not stir up.

What knives to put on an electric and a lawn mower

Before buying and putting a knife on a motorcycle, find out what they are and in what cases are used. Today, manufacturers offer the consumer a large number of types of these supplies. In general, the entire cutting tool designed for mowing grass can be classified:

The main material for the manufacture of trimmer knives can be plastic or metal. The use of such consumables largely depends on two parameters:

For safety reasons, manufacturers do not recommend putting steel knives on electric trimmers for grass. Almost all motokos operating from the electric network and battery are equipped with plastic blades. Depending on the manufacturer, they can be a solid disk design, with several blades or in the form of a special mowing head, which provides for the installation of removable plastic blades.

Direct rod in a gasoline trimmer for grass and curved in electric

Putting a metal knife on an electric trimmer for grass does not allow its design features.

- The curved rod of the unit reduces the distance from its working part to the legs of the Kosar. In the case of a collision of blades with a stone or other hard object of a braid for grass, it is discarded to the legs.

- The high torque, which we mentioned above, in the event of a collision of a metal knife with a solid object, transfers a large load to the flexible shaft of a trimmer for grass and its engine. What causes their premature failure.

- Handle Electric Knules most often does not have a restrictive bar playing the role of the stop. Which does not exclude leg injury.

It is these features that allow the use of exclusively plastic knives on trimmers with electric engines. In a collision with an obstacle, the blades are destroyed, thereby protecting the legs of the mower from obtaining possible injuries.

Plastic knives cope well with outgrown and dry grass. They can mow the nettles and stems of burdocks.

The use of metal knives only on gasoline trimmers is also due to constructive features.

- The direct design of the rod increases the distance to the legs, which provides the Cossacks with complete safety.

- Comfortable U-shaped and J-shaped handles allow you to keep the tool firmly. D-shaped handles Motokos are equipped with a limiter resting in the leg of the Costsa, which does not allow to let the head to the legs when meeting a cutting disk with a solid obstacle.

- The clutch of the gasoline engine allows you to smoothly gain speed to the optimal level. And when the blade collides against a hard surface, it can extinguish part of the blow.

Thus, gasoline trimmers for grass with an installed metal knife are best used in large areas. They will successfully cope not only with high coarse grass, weeds, burdocks and nettles, but also with shrubs, as well as young trees.

The shape of the blades of the disk set to the trimmer for the grass does not affect the quality of the work performed. The speed does not depend on them. Triangular, trapezoid, rectangular forms are all marketing course of manufacturers.

If you plan to prepare hay, then it is best to put knives on a motorcycle with a large number of blades. Pay attention to the wheels with eight teeth or discs with four large blades and four additional. Two and three lobed knives will greatly grind the grass.

How to choose?

When choosing a knife for a mower, you should pay attention to many points. For example, discs with metal teeth are often made in the form of a circle. Teeth can differ in shape, appearance, size. For small trees, as well as for thick herbs, it is better to use discs with a large number of teeth.

It is worth noting the advantage of milling circles for motorcycle, as a fast speed. Nevertheless, a high moment of inertia is not best affected by the block drive. For tight mowing, for high, as well as for small coarse herbs and shrubs, it is better to choose circles with 40 or more teeth and peoration. They are not able to destroy vegetation, and it will practically not wrap around the circle. If the number of teeth exceeds 60, then you can safely mow grass and trees with a barrel thickness of 7 cm.

Read how to lubricate the upper gearbox trimmer for grass

Disks with a solid blade and without holes have a large weight, so they should be chosen for powerful trimmers (more than 40 cm3). It is also convenient to mow rare grass and dry; They are also suitable for mowing with different density.

Victory discs should be selected for mowing plants near obstacles. If you need to mow grass on the hay, prefer steel knives with a lot of softly sharpened teeth. Solid discs with the number of teeth from 16 to 32, well.cut plants with thick stems.

For low.power trimmers, blades with a minimum torque are better suited. The smaller the blade, the stronger the tool will grind the grass. Yes, discs with two blades are most often used to cut homogeneous grass. The main advantage of this species is that it discards cut plants to the side.

When cleaning hay, it is recommended to choose blades with four blades so that the grass does not cut.

How to choose?

When choosing a knife for a mower, you should pay attention to many points. For example, discs with metal teeth are often made in the form of a circle. Teeth can differ in shape, appearance, size. For small trees, as well as for thick herbs, it is better to use discs with a large number of teeth.

It is worth noting the advantage of milling circles for motorcycle, as a fast speed. Nevertheless, a high moment of inertia is not best affected by the block drive. For tight mowing, for high, as well as for small coarse herbs and shrubs, it is better to choose circles with 40 or more teeth and peoration. They are not able to destroy vegetation, and it will practically not wrap around the circle. If the number of teeth exceeds 60, then you can safely mow grass and trees with a barrel thickness of 7 cm.

Read how to lubricate the upper gearbox trimmer for grass

Disks with a solid blade and without holes have a large weight, so they should be chosen for powerful trimmers (more than 40 cm3). It is also convenient to mow rare grass and dry; They are also suitable for mowing with different density.

Victory discs should be selected for mowing plants near obstacles. If you need to mow grass on the hay, prefer steel knives with a lot of softly sharpened teeth. Solid discs with the number of teeth from 16 to 32, well.cut plants with thick stems.

For low.power trimmers, blades with a minimum torque are better suited. The smaller the blade, the stronger the tool will grind the grass. Yes, discs with two blades are most often used to cut homogeneous grass. The main advantage of this species is that it discards cut plants to the side.

Bosch DIY Manual Garden Lawn Mower AHM 38G

When cleaning hay, it is recommended to choose blades with four blades so that the grass does not cut.

How to put a knife on a trimmer for grass correctly

Putting a knife on a trimmer for grass is not so difficult. The manufacturer equips his tools with a special pin that allows you to block the gearbox and the key, with which the spool is unscrewed with the fishing line. The most important thing is to observe when changing the cutting elements safety precautions and the assembly sequence of disassembly.

The algorithm for installing a knife on a trimmer for the grass is as follows:

- Remove the protective casing;

- We block the drive. To do this, it is necessary to combine two holes. in the hub of the shaft and in the gearbox cup. After combining them, insert the pin into the holes;

- We unscrew clockwise a spool with a fishing rod with a fishing line or a mounting nut that holds the boot (if the trimmer for the grass has not yet been used);

- Next, we install the cutting knife, so that the slots on the puck of the hub coincide with the notchs in the hole of the cutting disk;

- Install the boot;

- We twist the mounting nut (counterclockwise) holding the stopped pin;

- We tighten it using a tubular key;

- Return the protective casing in place.

Disk selection criteria

You need to choose a plastic or metal knife, given the area of the site that is planned to be processed, as well as the type of trimmer for grass is electric or gasoline. The number of blades will depend on which shoots must be removed using the tool. Choose the desired disk shape, the number of blades and manufacturing material can be using the instructions for the operation of the device. It usually prescribes which mills are recommended to use to solve certain problems.

Material

It is not recommended to put metal knives on electrocos, since the design features make their use dangerous for the user. This is due to the curved shape of the bar, the absence of stops on the handles, as well as a high speed of rotation.

Important! Direct rod provides the safe use of a trimmer for grass at such moments when the disk, rotating, pushes into the obstacle. In this situation, he bounces back. towards a person, so a curved design can cause an injury.

On trimmers with a flexible bar in terms of safety, plastic knives should be used. Their purpose is a mowing of soft grasses, dry. Whereas metal disks do a great job with high, thick, hard shoots, shrubs, as well as shoots of trees.

Blades

The number of blades is important in solving diverse problems. So, two to three pieces are enough to grind the grass. For hay harvesting, it is necessary that there are four to eight blades on the disk. To destroy small shoots of trees and shrubs, instead of blades on the discs, there should be a large number of small teeth.

Cleaning and editing

When the knife is removed, it needs to be cleaned the first thing from adhering dirt and hardened herbal juice. The easiest way to do this is to use a metal kraitsy. The knife strip should be clean from all sides: not to a metallic shine, but without the smallest sticky fragments.

Often, due to the entering the working area of solid items, such as stones and chips, the blade is very noticeably deformed. Most of the blades themselves are not straight, but the cutting edge and strip 10-15 cm from it should be examined for the presence of local tubercles and curvatures. This is done using a short even line.

You can straighten the blade with an ordinary hammer, in which the edges of the box are slightly rounded. The knife is laid on an even massive support (anvil), then the correct shape is given with weak blows of the metal. You need to rule the knife, starting from the edges of the curved area, gradually moving to the center. The curved body of the blades is a small problem, but it is very important that the cutting parts are straightened into one straight line for a trimmer. You also need to check the casting blades that often extend from the blow. If the blades are bent at different corners on different shoulders of the knife, this will worsen the air flow and the mowed grass will not be mulched properly.

Editing edges

When the blades are sharpened, they need to be corrected. This is done using a segment with moisture.resistant sandpaper with a grain of about 600-800 grit. The paper must be moistened with water and turned into a cylinder with a diane of 100-150 mm.

Edit is aimed at removing small burrs and blocks, because of which the narrowest edge of the blade may be wrapped in. The sandpaper touched into the cylinder must be pressed little to the descent plane and stretched out with smooth movement from the grain. In this case, it is also recommended to make a smooth displacement from the center to the edges.

When the descents and sharpening, what remains to make our client manipulations, were carried out only with one side of the blade. During the editing, the knife is also processed on the back. Here the paper is pressed almost close to the body of the knife, but with a slight slope towards the edge. The force of the paper compressed when editing is very small, but the movements need to be made a lot, seeking to eliminate huge crooks on the brilliant descent, which remained after sharpening.

For reference: to sharpen the lawn mowing can be sharpened and a response similarly with a conventional manual scythe. This, however, asks for a special adaptation. grandmas, in addition of a specific skill. But with this method of pointing, you do not need to balance the knife.

The knife turned off

Signs: poorly cuts grass. After the mowing the ends of the grass, the sung, filamentary ends turn yellow.

Elimination of the malfunction: turn the mower and sharpen the knife. If there are nozzle on the knife, or it is very dull, it is necessary to unscrew the nut, remove the knife. So it is more convenient and faster to sharpen it. Often the nut acidifies and unscrews it is not easy. In this case, drip a little WD-40 or a solvent of rust and wait 15-20 minutes. Try again. For the convenience of unscrewing, you can create an emphasis for a knife: in the plastic bottom there are holes into which you can insert a screwdriver, it will serve as an emphasis.

How to sharpen a knife. Enough for the house.

Knife. One of the most ancient tools. What is the most amazing. The culture of handling knives is quite mediocre. Despite the fact that everyone has a knife, and not in a single copy, use the knife correctly, monitor it and keep the knife sharply. Even at the school in labor classes, girls are taught to cook, sew, something else there, and boys are taught to make poisonings, stools, birdhouses and pull out bolts. and many different things of dubious need in real life. Our education somehow misses such an important and necessary thing like sharpening knives and a culture of using knives. I am not saying that the knife should cut transparent rounds from the lying tomato, but it should cut products, and not to give or cut it. Here is an example of a very sharp knife:

Really at home such sharpening fucking is not needed, since it does not last long, the sea requires effort to maintain, it requires accuracy even more. On the gif is rather a demonstration of the sharpener skills than really functional sharpness.

Speaking about the culture of using the knife, I mean that the knife should be used correctly and for its characteristic tasks. Reality is as follows, then the usual layman considers it quite normal to cut something directly in the plate with a knife, directly in a pan, putting on some pebbles or using completely unbearable surfaces as a cutting board, for example different pieces of iron (I honestly do not know why use iron tables for cutting and cutting on a production scale, maybe someone competent will enlighten me in Комментарии и мнения владельцев) or glass boards that for some reason use for cutting, although they are intended for serving. With such use options, the cutting edge shines and the knife stops cutting. You can take your knife, go to the light source, take the knife so that the blade looks at you and look at the cutting edge. Here is a picture of parts of a knife.

If the edge shines, then there are nozzles on it. So it will not be cut or will be, but extremely fig. Here is a gif where this moment is clearly shown.

The second option of unusual use of the knife. This is a different penny, a flinging of unscrewing and opening canned foods that are not intended for this and gets something like this:

I am not saying that this cannot be done, but in our country the people open the banks with kitchens, which are intended for completely different. If you have some severe chopped-crowned-pierced, such as Coldsteel Recon Tanto, Mora Robust, Mr.Blade Frat or Kershaw Thermite (in the same order in the pictures), then it’s okay.

Oh, they will throw me with slippers of the habitat for such examples, but I think the essence is clear: the knife should be used in the tasks for which they are intended. Well, or soberly evaluate, is capable of a knife for it without harm or not.

1) Cut with a knife only on cutting boards made of wood, plastic or other soft materials. But not on a iron tray or glass/ceramic/faor plates. But how to cut meat, you ask? And here are 2 options. You either use special table knives (they have a specially cutting edge made to transmit/cutting), or use wooden planks on which you either spread and cut it, or give them right away: there are round bamboo with a groove of the groove. just atmospheric from such steaks eat. and any other meat. And the process itself is very differently perceived for some reason.

2) perform work with the knife that is intended for this or will be able to do this work without much harm for itself. Strict boots or break/pick a coconut with a kitchenette. A bad idea for this is better than knives above. At the same time, the knives presented above tire/cut products of course, but this is a dubious pleasure. Yes, damn it, pleasure. We devote a bunch of time in our life to cook food, and it may be worth learning to enjoy the process? And for this you need a normal suitable tool in good technical condition.

Let’s go directly to sharpening. I will not go into history and give just a lot of disparate information, but I will offer several really working decisions that are suitable for home and warn against errors. I do not claim the truth in the last instance, ways and approaches to the sharpening and maintenance of the sharpness of the knife slightly less than the dohren. it’s like buildings in RPG characters. I will just tell you about something and I will give a completely working solution.

We all saw such sharpeners. Most have such sharpeners. Only the result of sharpening with such sharpeners is extremely doubtful without understanding the process and sound approach.

Comrade Livsi has a very good overview of such sharpeners here, it’s better to follow read, because I just don’t see the meaning stupidly, but the material is good there and in the case. Here’s the same, but in the form of a video.

How to sharpen lawn mower blades THE CORRECT WAY ( Angle grinders will destroy your mower blades)

Briefly. You can use them, but only with the chehmic thin (or rather, with a subtle information, and a certain angle of the cutting edge) knives. The result is dubious and extremely not long. If you still use such a thing. then use the one that two.sided with ceramic rods from the second side (blue in this case). Not much, but the result will improve.

How to sharpen a lawn mower to sharpen yourself

The blades of the knives of various lawn mowers are almost always made of high.quality steel, however, despite this, they are still periodically necessary to tighten them. And most importantly. to do it so as not to worsen the quality of the metal. However, no special tools and skills are required for this, and any summer resident will easily be able to cope with such a task!

Why do you need to hide the knives of the lawn mowers?

Of course, cutting off excess juicy green grass from your favorite lawn is quite real and a knife with blunt edges. But the grass, as a result of such manipulations, will begin to be relaxed (this stratification will go mainly in the longitudinal direction), gradually turning into an inaccurate fringe. And after a few days, it will even dry and can even get sick for several weeks. That is why the cuts should always be neat and even-in this case, they are delayed in only a few hours and allow you to maintain a spectacular juicy green lawn. And in order for them to be such, it is necessary to periodically drag the knives of the used lawn mowers used!

Before proceeding to such an important event, it is important to try to secure yourself and the garden gadget to the maximum. This is especially true for gasoline lawn mowers (models with electric drive are easily neutralized by elementary disconnection from the network): first it is necessary to free the spark plug from the cap, and then you need to completely exclude the probability of fuel leakage. This can be done in two ways. both by draining the tank, and by laying under the lid of rubber hermetic membranes and overlapping the fuel crane. If there are no other instructions in the instructions, then the lawn mower is turned exclusively towards the handle. And before you do this, the hose intended for exhaust gases should be suppressed. this will help to avoid oil leakage.

Knives in various models of lawn mowers can have the most diverse configuration, but the thread on the bolts is always unscrewed the same way. counterclockwise. And to prevent the possible rotation of the shaft, you can place a bar firmly stolen in the ground under the knife. And, of course, in order not to confuse anything, setting the knife back, it is important to try to remember or even draw the position of the blades.

The removed knife must be cleaned from hardened herbal juices, as well as from the mud that has sticks on it. The easiest way to do this is using metal stains. Then the surface of the knife is examined for the presence of any curvature or tubercles. If there are such, they are straightened with a regular hammer with slightly rounded edges of the box. As a rule, the knife begins to rule from the edges of the curved area, gradually moving to its center. It also does not hurt to check and often extending from the blows casting blades, because if they bend at unequal angles, this will inevitably entail a deterioration in the air flow, as a result of which the cut grass will simply not properly mulch.

The next step is to remove the descent. First, get rid of excellent chips, taking the edge of the blade at the same angle along the entire length of the cutting part. And the descent at the required angle will help a small file or an electric sharpener equipped with a carburond stone. At the same time, it is important to try to remove metal from the knife as uniformly as possible. But the corner grinder for these purposes is strictly not recommended, since it can significantly worsen the quality of the pulled blade.

For sharpening the blade, a flat sandpaper is usually used, the granularity of which is in the range from 400 to 600 grit. Before proceeding to the grinding of the blade, it is recommended to soak the bar for ten to fifteen minutes in soapy water. Periodically during the sharpening process, this manipulation must be repeated. And the knife should be hidden by pulling the bar in the direction from the center of the sharpened area to its edge. At the same time, it is desirable that the stone be in the same position. this will contribute to maintaining a constant angle. And, of course, the same amount of metal should ideally grind from the knife blades!

The sharpened blades must also be “corrected”. To do this, you need a small piece of moisture.resistant sandpaper, the grain of which has a range from 600 to 800 grit. The paper is moistened with water and folded into the cylinder, the diameter of which reaches about 100. 150 millimeters, and only after that proceed to “edit”. And before installing the knife, it is important to make sure that the weight of his shoulders remains the same, otherwise (in case of unbalance), extremely undesirable vibration may occur. To check the balancing, at first a smooth bar is horizontally clamped horizontally, and then, through the hole located in the middle, the blade is put on it and also try to install it horizontally, observing its behavior. one shoulder should not noticeably pull the other. If the balance is not observed, then a little more metal is grinded from one of the shoulders. And only after that you can again install the sharpened knife on the lawn mower!

You will need to sharpen the cutting nozzle:

- Two stools.

- The key is 19 (or another to the size of your nut).

- File, sandpaper with a grain of 600 and a wooden block of 5 x 10 cm.

- Grinding disk for a drill.

- Sharpened.

Stages

Removing a knife

First we put the handle of the lawn mower, and put rubber gaskets on the neck of the gas tank and the oil crankcase (or can be covered with cellophane) so that when we turn the device, combustible materials do not flow to the floor. We turn the lawn mower and put it on two stools or to one side. We take the key to 19 or another size, and unscrew the nut on the knife. If the nut does not go, then splees a little WD-40 or ordinary water on it and wait 5 minutes-the nut should unscrew.

The choice of angle of sharpening

When sharpening the knife, the edge of the edge is allowed from 30 to 50º. If there is an angle of less than 30º, then the blade will become sharp as a razor, but it will be quickly stupid, and with a lot of angle it will tear the grass.

Rough sharpening

Clean the nozzle of grass and dirt and clamp in a vice. Then, with the help of a flat or trihedral file at an angle of 30. 50º, begin to sharpen the knife with progressive movements from the base (from the fastener) to the edges, and relative to the edge from top to bottom. Try to count “friction” from top to bottom, so that from the other side of the knife, make the same amount and remove the same amount of metal. So after sharpening there will definitely not be an imbalance of the nozzle. For this work, the VIRA 820003 file with three faces of 20 cm long is suitable.

Some prefer to repulse the knife on the anvil, as is done with the usual hand-headed scum, but we noticed that because of this, the metal on highly bent knives can crack and the nozzle has to be thrown away.

Rough sharpening can also be performed using a conventional sharpener on an engine or grinding nozzle on a drill. With proper skill, you can sharpen much faster than a file, but there is a possibility of “rewind” one of the faces, removing more metal. If you sharpen the knives, then there will be no particular difficulty. the main thing is to observe the right angle. Grinding nozzles are suitable for both a drill and an electric screwdriver.

Editing edges or “tender” sharpening

On a wooden bar we put on sandpaper pre.moistened with soap water. Now from the base (as in the case of a file) to the edge we draw a bar with an emery. Evenly on each side we bring the blade to the working condition.

Balancing check

Click a metal hairpin or thick screwdriver in a vice. Put a knife on the stiletress and spin it. If you feel an imbalance, it means that somewhere they removed more and you need to correct. If the knife rotates evenly, then everything is in order and you can put the nozzle in place.