The chainsaws of various companies are based on a two-stroke internal combustion engine, which drives the cutting headset of the tool. To activate the internal combustion engine, the proportions of gasoline and chainsaw oil are used. Combining gasoline with oil is a must, so if you just bought a tool, you need to understand the features of its refueling.

Why gasoline is mixed with oil for refueling chainsaws

Dilute gasoline with oil to avoid failure of the internal combustion engine. The reason for this is the design features of the lubrication system of two-stroke engines. In the design of such engines there is no chamber for filling engine oil, and if fuel is filled without lubricant, the crankshaft, piston, bearings and connecting rods will not receive lubrication. This will significantly reduce the service life of all of these parts, therefore it is forbidden to fill clean fuel.

Gasoline and chainsaw oil must be filled in appropriate proportions, which makes it possible to effectively lubricate rubbing parts. Lack of lubricant or its excess will lead to negative consequences in the form of carbon deposits. In order for the tool to work properly, you need to refuel it not only with high-quality materials from the first day of operation, but also observe the correct proportions.

For the engine to work properly, the main thing is to fill in clean fuel without pollution.

The ratio of gasoline and oil for chainsaws

The proportions of oil and gasoline for refueling two-stroke engines of chainsaws of different brands is 40 to 1 or 50 to 1. This ratio is standard, which is used not only by beginners, but also by experienced filers. It is this ratio for the preparation of the fuel mixture that is close to ideal, and provides lubrication of the rubbing parts of the crank mechanism and piston.

How much oil do you need to pour in gasoline in milliliters? Per ml ratio of oil and gasoline 1 to 50 is 20 ml per 1 liter. In order to prepare the right mixture, pour 1 liter of gasoline into a plastic bottle and dilute it with 20 ml of oil. To correctly measure how much oil to pour, you should take a special measuring container and fill it to the appropriate mark. If it is immediately planned to prepare 2 liters of fuel, then 40 ml of lubricant must be added to this amount of gasoline.

There are other ratios offered by different manufacturers. These values of the ratios differ slightly, but if you subtracted other values in the passport to the tool, then you need to stick to them. Values of 1 to 50 or 40 are standardized. Pour 15 ml of oil per 1 liter of fuel in the summer, and in the winter add at least 20-25 ml. Knowing the recipe for the preparation of the mixture, you should also figure out the question of which gasoline to pour into the chainsaw?

Gasoline and chainsaw oil. which is better

Often, beginners ask, which is better to take gas for your tool? In order not to make a mistake in the selection, it is recommended that you read the instructions for the tool. In the instructions, each manufacturer indicates the corresponding brand of fuel. If the manufacturer indicates that the octane should not be lower than 95, it is not recommended to pour 92 gasoline.

Engine oils for two-stroke engines are produced by such manufacturers:

Usually, the ratio is indicated on the bottle with lubricant, so it will be difficult even for beginners to get confused with the preparation of the fuel mixture. Under no circumstances should you use refining even as chain lubricant. This will lead to the fact that soon it will be necessary to carry out tool repairs.

Instructions for refueling a chainsaw

Knowing the ratio of the preparation of the benzo-oil mixture, you can proceed to refuel it. The fueling instruction is as follows:

- First you need to prepare the mixture. Combining the two main components, mix them thoroughly.

- Place the tool on a clean and even surface. Before unscrewing the gas tank cap, it is necessary to clean or blow off sawdust, dust and dirt

- The neck of the tank should look up

- Install a small watering can in the neck, then pour fuel

- Control the refueling process, as the tank volume is small, so it quickly fills up

- Fill up to a full maximum, as when you close the tank lid, the remaining fuel will splash out

- After the fuel is poured into the tank, immediately add lubricant to the chain

- Fuel consumption and chain lubrication are approximately the same, therefore both tanks must be refilled

- After refueling, you can start to start the engine

It is better to start the engine not at the place where the refueling was carried out, but to move to a distance of 2-3 m. The tool is ready to work, and you can start to start it. How the chainsaw engine starts can be found in this material (link).

What will happen if you pour mining into a chainsaw

If you do not want your chainsaw to fail at the wrong time, use only high-quality fuels and lubricants. It is forbidden to mix mining with gasoline. The reasons for this are the following factors:

- Another viscosity of the material, so mining is not able to provide effective lubrication of rubbing parts and mechanisms

- The mining contains small metal particles and chips, which, falling into the tank, will lead to clogging of the fuel filter and channel. If grease enters the cylinder with small particles, they will leave their mark in the form of accelerated wear on the piston rings

- Emission of a large amount of black smoke, which indicates the burning of oil

Surrogate materials cannot be poured not only into the tank with gasoline, but also into the tank for chain lubrication. What will happen if you use mining in the tank to lubricate the chain, you can see in the video.

Using the instructions, you can independently prepare the correct fuel mixture, on which the chainsaw will work. With improper dilution of the fuel mixture, not only the tool life is reduced, but its performance is also reduced.

Owners of scooters and motorbikes, as well as owners of a gasoline tool with a two-stroke engine, are faced with the need to pour a pre-prepared mixture of gasoline and oil into the fuel tank, maintaining the necessary proportions. Motorists know that it is impossible to refuel equipment with a push-pull type power unit with pure gasoline. This will adversely affect the operation of the motor, its resource and lead to inevitable breakdowns. The oil-gasoline table will help determine the correct ratio of fuel to lubricant.

Let’s get to know the principle of the two-stroke operation more closely, we will deal with the mixing proportions, as well as the rules for preparing the fuel mixture.

Features and operating principle of 2t engine

Any owner of motor vehicles should have an idea of the design of the engine and the principle of its operation. The power unit of the push-pull type is used not only in motor vehicles, but also in other technical devices. lawn mowers, trimmers and others. Despite the completion of many models of modern technology with four-stroke engines, a two-stroke engine is still widely used. It is simple to operate, easy to maintain and repair, and also quite reliable.

Video: Stihl Trimmer Oil Dilution Oil

The duty cycle of such an engine is carried out in a couple of compression strokes and a stroke as a result of energy from fuel ignition. Both cycles are carried out during one revolution of the crankshaft. The two-stroke engine lacks the phase of the fuel mixture intake and the exhaust cycle characteristic of four-stroke engines. The process of fuel inlet and exhaust gas takes place during the compression and expansion phases.

Thanks to this design feature, the torque and power developed by the motor increase with the same cubic capacity as a 4-stroke motor. And although the efficiency of a two-stroke power plant is lower compared to a four-stroke one, due to the two-stroke operation of the piston, the engine elements perform fewer movements. Subject to high-quality lubrication of the mating parts of the motor, it has a sufficiently high service life and is less susceptible to internal wear.

For the two-stroke operation, it is necessary to turn on the ignition, provide fuel supply and crank the engine crankshaft with a starter or kickstarter.

Further work of the two-stroke motor is carried out according to the following algorithm:

- the piston begins to move towards the spark plug from bottom dead center. At this time, the fuel mixture enters the working chamber of the cylinder. The opening of the exhaust window for the exhaust outlet takes place, and the working mixture is compressed;

- in the initial phase of the compression cycle, a pressure drop occurs in the chamber of the crank mechanism, contributing to the flow of a new portion of gasoline. In the upper phase of the piston movement, the working mixture ignites with a spark from a candle;

- The energy resulting from the ignition of gasoline causes the piston to move to a lower point. Thanks to the open channel of the exhaust window, exhaust gases exit through an elbow connected to the silencer;

- subsequent movement of the piston causes the opening of the purge channel and the flow of gasoline into the working area of the cylinder. The phase of displacement of the piston to the lower point completes the duty cycle of the motor and the cycle repeats.

In the process of supplying gasoline mixed with oil, the components of the power unit are lubricated. This distinguishes the lubrication system of a two-stroke engine from the lubrication system of a four-stroke engine, in which there is a gear pump for supplying oil to the area of the mating parts of the motor.

Oil mixed with gasoline is lubricated in a crank mechanism

Why mix gasoline with oil

Not everyone knows how to dilute gasoline for a two-stroke Chinese scooter, and why there is a need to mix gasoline with oil in strictly defined proportions. The fact is that the design features and the principle of the two-stroke engine do not allow for the use of pure gasoline for its operation. Thanks to the oil introduced into the fuel mixture, lubrication is carried out and friction in the crank mechanism is reduced.

Mixing oil with gasoline during the preparation of the fuel mixture is a prerequisite for the normal operation of two-stroke engines.

Diluting gasoline with oil allows you to:

- increase the life of the power plant;

- provide effective lubrication of the rubbing parts;

- avoid jamming of engine parts due to overheating;

- prevent possible breakdowns when the motor is running.

In addition, the use of gasoline mixed with oil in the required percentage ratio avoids the appearance of scoring, which is the cause of the repair. The lack of oil can cause overheating of the elements of the cylinder-piston group and the failure of the two-stroke engine.

Increased oil concentration will cause increased wear of the motor apparatus due to the formation of a thick layer of soot. That is why it is important to determine the proportion, using the table, which indicates the required amount of oil for various volumes of gasoline.

The reason for the formation of soot in the working chamber is the use of low-quality oil

What oil to grow gasoline for a motorcycle

In two-stroke engines, a separate filling of the lubricant into the crankcase is not provided.

Strict requirements are imposed on oil burning with fuel:

- lubricating fluid must provide effective lubrication of all parts;

- the oil should burn easily and should not form soot after burning.

The use of low-quality oil for two-stroke engines is the cause of the formation of soot in the working chamber and a decrease in power.

When determining the type of oil, you should be guided by the recommendations of the manufacturer of the equipment specified in the instruction manual. Brand oils made by reputable manufacturers should be preferred. The preferred grade of oil is API-TB. It is also possible to use oils labeled API-TC.

The choice of type of lubricant is carried out depending on climatic conditions:

- in the warm season gasoline can be diluted with mineral oil;

- in the winter months, synthetic oils should be preferred;

- For all-season use, branded semi-synthetics are suitable.

The manufacturer’s recommendations should be guided by determining the type of oil

For detailed information on the temperature threshold for use, read the information on the oil packaging. Knowing the ratio of fuel and oil, as well as the volume of the gas tank, necessary for stable engine operation, you can easily calculate how much oil is needed for a certain period, given the frequency of trips or the use of gasoline powered tools.

When buying oil to prepare the fuel mixture, you should pay attention to its purpose. This information is indicated on the packaging. Do not use tractor oil or boat lubricant to mix with gasoline to refuel a scooter or motorcycle. Please note that the nameplate of the oil for two-stroke engines necessarily has the designation 2T.

Oil gasoline table. choose the right proportion

Novice owners of motor vehicles do not always have an idea how much oil to add to gasoline. Depending on the manufacturer’s recommendations specified in the instructions, the amount of added lubricant may vary. The most common ratios are 1: 50, as well as 1:40. Slight deviations from these proportions will not affect the operation of the two-stroke engine.

During the break-in period, when intensive grinding of the mating parts of the engine occurs, the amount of oil increases slightly. When the run-in is completed, they switch to a different ratio of the fuel mixture, involving the introduction of a smaller amount of oil.

Dealing with the proportion is easy. For example, a ratio of 1:50 means that a liter of lubricant should be added to 50 liters of gasoline. The use of measuring containers will greatly facilitate the process of preparing the mixture. Depending on the volume of available containers, the amount of added oil changes.

You can quickly prepare the mixture by deciding on the proportions

In particular, for a ratio of 1:50, the table will help determine the amount of oil injected:

- to dilute 5 liters of gasoline, you need 100 ml of lubricant;

- in a ten-liter capacity you will need to pour 200 ml of oil;

- 400 ml of grease should be added to a 20 liter can.

Having determined the proportions, you can quickly prepare the mixture. However, you should not use a gas tank for this, alternately pouring gasoline and oil. Mixing must be carried out in a separate container.

How much oil to pour into gasoline. the rules for preparing the mixture

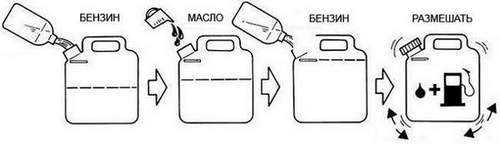

Having figured out how much oil to pour into gasoline, you can start preparing the fuel mixture. This will require a clean metal or plastic canister. First, the required amount of gasoline is poured, and then the lubricant is added in the right amount. After completing the dilution, tilt the canister a couple of times.

As a result of repeated shaking, the liquids are mixed, and the prepared fuel acquires a uniform color. Depending on the color of the added oil, the finished liquid may be greenish, bluish or reddish.

When performing work, safety precautions and fire regulations must be observed. Mixing work must be carried out in a ventilated area, and even better in outdoor conditions. When working with flammable liquids, smoking is not allowed. Mixing must be done with gloves to protect the skin from aggressive liquids.

The prepared mixture fills the fuel tank and the gas tank cap closes tightly. Storage of gasoline mixed with oil can be carried out in tightly closed cans. Gasoline, mixed with oil, retains its properties for a month.

That is why mixing should be done immediately before pouring, given the frequency of use of a scooter or motorcycle.

How to detect a mix out of proportion

There are a number of indirect signs by which it is possible to determine the mismatch of the amount of gasoline and oil when preparing the mixture:

- the formation of contaminants in the float chamber and carburetor channels;

- significant tarry deposits on the elements of the fuel system;

- oxidation of carburetor walls and reduced elasticity of rubber parts.

Any of these signs indicates the need to adjust the mixing process. Observing the proportions recommended by the manufacturer, it is possible to ensure a long service life of the two-stroke engine, as well as to avoid unforeseen and, sometimes, expensive repairs.

Almost always, manufacturers of aircraft model, gasoline engines indicate the ratio of oil to gasoline as a proportion. The calculation formula is simple. We divide gasoline in liters by the proportion and multiply by 1000, we get the amount of oil in ml.

- 28: 1 1l / 281000 = 36ml Per liter of gasoline 36 ml of oil.

- 40: 1 1l / 401000 = 25ml 25 ml of oil per liter of gasoline.

- 50: 1 1l / 501000 = 20ml 20 ml of oil per liter of gasoline.

Calculator for calculating gasoline and oil.

In order not to make a mistake when mixing gasoline with oil. I propose to use an online calculator for calculating. The proportion of gasoline and oil for a chainsaw, trimmer and gasoline model aircraft engines.

The proportion indicated by the engine manufacturer should always be observed; the life of the motor depends on this. Also, do not pour low-quality oil, and even more so, use ordinary automobile oils. The brand of gasoline is indicated in the passport of the engine or tool.