DIY engine engine repair with your own hands

Consider the typical malfunctions of the motor.cultivator, their causes and ways to eliminate.

There may be several reasons why the engine does not start:

- We check the presence and amount of fuel in the tank, if necessary, add it;

- We examine the spark plug, if it is faulty. replace it;

- If the candle is working, but there is a case, we remove it;

- check and, if necessary, adjust the gap of the spark plug.

- We examine the fuel supply hoses to the carburetor, when a breakthrough, we replace them.

Manual

It is important for a few days after the purchase not to use the unit at full power. you must remember that the first 24 hours the device must be passed with the operating room. Therefore, the same bed is better processed in several stages, while every time increase the depth of processing

Before starting, it is worth checking the oil level, the serviceability of the engine, whether the power unit with another unit is reliably fixed, which performs an additional function.

The engine is launched when the control lever is clamped (the position of the engine speed regulator is “fast”) because the clutch at the device works automatically, when the engine is reached the desired speed indicator, which is more idle than the turnover at idle.

Soil treatment

You need to stand near the steering wheel and hold the handle tightly. Do not press the lever much, slightly increase the number of engine speeds.

At this time, the device will begin to move. The soil processing deeper into cutters is determined by the position of the deep regulator, which can change when it is rearranged in the bracket along the holes, which are available in the regulator.

Turn off the device

To do this, lower the control lever. He himself will return to the initial position of the idle fast as a result of the operation of the return spring. Then pull it down all the way and the motor will stop working.

Characteristics of the cultivator

The advantages of the brand of cultivators under consideration include:

- The speed of the cultivator Tarpan is quite high. Usually in 5 hours you can process 10 acres with it.

- This device does not require special service. Its operation, in accordance with the instructions, as a rule, does not cause difficulties.

- This unit is characterized by a relatively small weight.

- For him it is easy to buy spare parts.

- The cutters used are reliable in operation, while they have an acute sharpening.

- If necessary, the motor can easily be removed from the frame.

- Cultivator Tarpan can use a variety of hinged inventory when working.

Along with the above features, you can also indicate some disadvantages of this device:

- This design of the cultivator does not provide for the possibility of reverse. This makes it difficult to work on a small bed or those that have a complex configuration.

- When working, you constantly need to press the gas button with a thumb of hand. With prolonged work, this can be tedious.

- When rotating the milling mills often it turns out that weeds are wound on them. At the same time, you have to stop the work and with your hands clean them.

- In this walk.behind tractor, the oil change procedure is inconveniently organized. In order to do this, it is necessary to remove the clutch and unscrew several nuts.

Here are a few more features of the device in question:

- The width of the working strip in various cases can be from 25 to 100 cm.

- The depth of land cultivation is from 16 to 25 cm.

- The transmission used in the design allows you to move at several speeds.

How to start a cultivator. methods of repair of malfunctions

If the motor.cultivator does not start, then the cause of this may be the malfunctions of several main units of the unit. Below we consider the typical breakdown of the main mechanisms of the household cultivator and the methods of their independent elimination in more detail.

Malfunctions in the ignition system

Elements such as magneto, a candle, a pre.installed cap and a high.voltage wire are most often oxidized, as a result of which they inevitably fail. If dirt and moisture are found on a high.voltage wire, then they are the cause of its breakdown.

A weak spark or its complete absence most often indicates a lack of efficiency in the spark plug, which is why the motor-cultivator refuses to start. In this case, you should check the condition of the gaps and the distance between them. It is best to do this with a special probe. a normal value for work should be 0.8 mm. If there is such a necessity, then you need to completely remove the resulting carpet from the outer surface of the insulator and the metal parts available in the candle.

The readiness of the engine before launch is affected by the serviceability of the elements of the piston group. Since they constantly work in difficult operating conditions, their surfaces are severely heated, which leads to a breakdown of the ICE cylinder, pistons and rings. If the unit does not start, you will need to check it with the exhaust and inlet valve. It often happens that they do not fit the saddles loosely, and in this case it will be necessary to eliminate the malfunction as soon as possible, and then try to start the cultivator again.

Another detail that often lends itself to breakdowns is a full.time muffler of the cultivator. On the walls of the element inevitably accumulate combustion products and the remnants of the exhaust gases, which leads to the lack of the opportunity to start a cultivator. With a large number of these substances, the engine will stop starting sooner or later. To eliminate this malfunction, you will need to completely remove the muffler and clean it with compressed air from the cylinder.

All of the listed malfunctions and methods of elimination are suitable if motor cultivators of the production of SUNGARDEN, TEXAS and Neva brands are not started. Models from these manufacturers have a simple design, so even a beginner can easily cope with their repair.

Breakage of the carburetor and ways to repair it

Often, the motor-cultivator does not start due to clogging inside the nozzles or a carburetor filter. A sign of this will be an absolutely dry and pure unit sparkling candle. Repair is carried out in the following order:

- First remove the carburetor of the unit;

- Disconnect the fuel fitting and blow it with compressed air from the cylinder;

- After that, blow the combustion chamber and fuel tubes;

- Install the carburetor in place and try to start a cultivator.

There is no spark on the walk.behind tractor: options for eliminating the problem

The most common cause of motoblock malfunctions is malfunctions in the ignition system. The problem can be associated with a cap, magneto, a candle of ignition or a high.voltage wire of technology.

If a spark is gone, you need to perform the following actions:

- Check the ignition system for the presence of blockages. Often there is no spark, since water or dirt hit;

- Control the presence of contact between the main electrode and the cap of the candle;

- Make sure of the integrity of all electrodes, the presence of a gap between them. You can use a special probe. The optimal gap is 0.8 millimeters;

- Feeling from the insulator and metal parts of the ignition node is removed;

- Unscrewed and the candle is checked for the presence of oil spots. The existing oil spots and a thick feld must be thoroughly cleaned and the candle is dried. You need to dry the unit cylinder, by pulling the starter cable by pulling out;

- If after diagnosis the cause of the malfunction is not detected, the spark plug is required to replace the sparkling. This detail has a low price, but it is advisable to give preference to more expensive options. They are distinguished by reliability and durability.

All described methods of elimination of malfunctions are suitable for motoblocks of the following brands: mole, MB-1 and MB-2, Neva, cascade, agro, bison, salute.

The ignition is a mechanism responsible for the formation of an electric pulse required by a walk.behind tractor to ignite the refueling fuel. The first launch and the subsequent operation of the agricultural load engine depends on the serviceability of the ignition system. Like the rest, this mechanism needs regular maintenance and timely repair. this will become the key to stable operation of the internal combustion engine under any weather and operational conditions.

Trimmer does not start for grass. Why?

A gasoline trimmer for grass is an amazingly useful thing, with the help of which you can, without unnecessary troubles, put in order not only a miniature lawn in the backyard of the house, but also to dig a considerable size of the lawn. But, like all things in this world, it has the ability to break. In this article, we will try to figure out what to do in cases where a trimmer for grass refuses to work.

The gasoline trimmer for the grass is poorly started

So, what to do if the gasoline trimmer for the grass is poorly started or not started at all? The most common reason for such a breakdown.This is poor.quality fuel. Remember that, for example, trimmers for the grass of brands “STIHL” and “Husqvarna” are unlikely to start the quality below AI-92. Do not save on fuel, t.to. Repair of cylinder parts.the piston group can be a third of the entire cost of a braid for grass, and sometimes even half. Also, when preparing the fuel mixture, it is necessary to correctly observe the proportions of fuel and oil, which are always indicated in the instructions for the trimmer.

What to do if high.quality fuel is flooded in the gas tank, there is a spark, but the tool still refuses to start up? It is necessary to check the condition of the candle. It is located in the center of the gas mowing housing. It needs to be carefully twisted and make sure if there is a raid on it. If it is, then carefully clean the candle from the carbon and dry it.

If the lawn mower does not start even after the methods proposed above, then you need to try to remove the air filter and start the device without it. If the trimmer for the grass has not earned, clean the old filter well from dust or buy a new one.

It also happens that the lawn mower works as a maximum of 5 minutes, and then stalls and does not start until it cools down. In this case, try to open the pouring cover of a benzogornin. a suction sound should appear. After that, tighten the lid back. If you do this manipulation during the time when the trimmer for the grass has just begun to stall, then the turns will recover, and it will be possible to continue to work. If the lawn mower stalled until the cover is opened, then you just need to start it as it should be according to the instructions.

Trimmer for grass does not start after winter

How to be in such a situation? Do not worry and panic. This is a very common problem that is solved in just 3-4 minutes. Firstly, if the fuel is left in the gas tank last year, then it must be drained. Gasoline loses its octave properties after 2 weeks of downtime. Secondly, start a lawn mower after a long stagnation in a slightly different way. First you need to open the damper and pump up a little fuel mixture into the carburetor, then stretch the handle until a small resistance is sensed. After that, you can start a trimmer for the grass.

Modifications of the cultivator Tarpan

Interesting. After the cultivator of Tarpan was released, work on it was not stopped. The manufacturer constantly studies the practical experience of using, collects reviews and suggestions. Gradually, he modifies the device and releases new modifications of the cultivator.

Tarpan-03

This option is able to work effectively on almost any soils. In particular, it is effective when working on virgin or hard clay soils.

This option is used:

- American engine Briggsstratton Quantum 650, the power of which is 6 liters. With.

- According to the attached leadership, a worm gear, which usually demonstrates higher efficiency compared to a common cuneiform transmission.

- During the control process, a movable steering rack is used. One of the advantages that it gives is the opportunity to be on the side of the cultivator during work and not walk on the already plowed ground.

Tarpan-031

This modification has lower power compared to the previous option. In this case, it is 3.5 liters. With.

Read the same how to make a house from branches

The model is characterized by a small weight (it is 28 kg). The width of the working strip is 36 cm.

Tarpan-04

- Briggsstratton engine is used, with a capacity of 6.05 liters. With.

- The width of the capture strip is 58 cm.

- Soil processing depth. up to 20 cm.

- Weight is 48 kg.

When selling, two sets of milling.

Tarpan Ec-03

The peculiarity of this variety is that it works from an electric engine.

- The power of the device is 2200 watts.

- The cultivator of this modification is able to perform soil processing at a depth of up to 30 cm.

- This motor is easily installed or removed. It has a universal application. For example, if you remove it from Tarpan and install it on a lawn mower (for example, a string is suitable for this), then it will be possible to work on it.

- When working, a very low noise level is shown.

- A comfortable handle is used in the cultivator (you can adjust the height, turn or reject to the sides).

Popular models

The first motor cultivator from the TARPAN series with a two.stroke engine with a capacity of 6.2 liters.FROM. He was released from the assembly line in 93. He immediately established himself in the market from the positive side, but because of some production defects, he was not so popular among farmers.

Thanks to the work of engineers, a few years later on the domestic market introduced the Tarpan-03 model. Today he does not lose his leading position in the market. Up to thousands of such cultivators are bought by consumers every day.

The plant engineers complemented the model with various nozzles, which can be used regardless of a year: for winter, you can use a rotary snowman, while its width will be 75 cm. He throws snow to 5 meters, you can also buy an ice ax to clean the track.

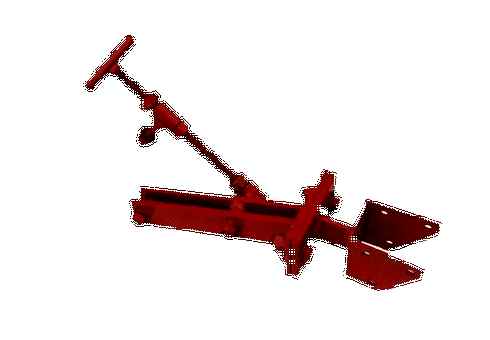

Regardless of the season, with the cultivators of TARPAN, Mantis, Cayman, Viking, Texas, Swift, Champion, Patriot, Loplosh, you can do all the work in the garden with a plow, rotation cutter (included), mills, rubbish, chopper and rakes. Soil alignment, weeding and other investments.

Read trimmer for STIHL FS 38 grass starts and stalls

The cultivator can be used as a lawn mower, and in the fall you can dig the roots and prepare the soil for winter.

The operating time of the engine. 1000 hours. The centrifugal clutch machine allows you to disassemble the model to several devices that can be easily transported and stored.

Thanks to the improved steering wheel design, the steering wheel can be rotated both in the lying position and in the standing plane, so that the operator will move to the unit until the loose soil is pulled out.

- Engine: Briggs and Stratton I / C 6.0 liters. With.

- Engine power: 6.0 liters.FROM. At 3600 rpm

- Cylinder volume: 190 cm3.

- Constant air cooling.

- Starts with manual launch.

- There is only one transfer.

- Fuel tank: 3.8 liters

- Motor oil volume: 0.6 liters

- Fuel consumption: 1.5 l / year.

- Power: 0.06 ha / h.

- Carzac at maximum speed: 100-120 rpm

- Growing width: 350-700 mm and depth 200 mm.

- Parameters (length / width / height): 130 (76) / 70/106 (75) cm.

- Weight: 45 thousand. Gram.

Understanding that it is necessary to produce high.quality, competitive, reliable and affordable equipment in order to confidently conduct and develop business in the modern market, which is constantly changing, the manufacturer annually updates its fishing line for a trimmer consisting of conveyors.

031, 04, 07

In recent years, in addition to basic models, models of cultivators 031, 04, 07 have been released.

- Motor: Briggs Stratton (USA).

- Engine power: 5 l.FROM.

- Engine type: one-cylinder 4-stroke, upper shaft.

- Clutch type: automatic, centrifugal, dry.

- This Tarpan cultivator is a worm and single.stage type gearbox.

- Transmission: 1, forward.

- Hot mixture: gasoline.

- Clutch: centrifugal clutch.

- Width and depth of processing: 360 x 200 mm.

- Weight 28 thousand grams.

Malfunction of engine systems when starting

In the event that when checking the candles, they turned out to be wet, t.e. The fuel comes normally, but the motor does not start, the problem may be as follows:

- Failure of ignition system:

- Air sunset through the seals of the carburetor, spark plugs, heads of candles and cylinders, as well as carburetor joints and engine cylinders.

If depressurization of the compounds is detected, it is necessary to carry out tightening fasteners, tighten the candles and check the integrity of the gaskets between the heads of candles and cylinders.

To eliminate this problem, it is necessary to ensure the free course of the damper, checking the quality of the drive work. If you find seizures, they need to be eliminated.

Violation of compression and malfunction in the carburetor

It happens that the launch is carried out, but its process is significantly difficult. At the same time it works extremely unstable and cannot develop sufficient power for normal operation.

The reason for this may be the loss of compression, which can be detected by:

In order to restore compression, you need:

If in the process of operating the engine a black smoke comes out of the muffler, and an excess of oil is revealed on the electrodes of the candles or they themselves are covered with soot, this means that:

- An oversaturated fuel mixture is supplied to the carburetor;

- The sealing of the fuel valve of the carburetor is impaired;

- the oil.scrubbing ring of the piston was worn out;

- Breeding.

To eliminate this problem follows:

- adjust the carburetor;

- replace the leaky valve;

- replace worn piston rings;

- Clean or replace the failed air filter.

In the event that when the engine is operating, light smoke comes out of the muffler, and the electrodes of the candles are dry and covered with white coating, this means that a lunch fuel mixture gets into the carburetor. This problem is eliminated by adjusting the operation of the carburetor.

The same.based tractor starts and dies: the causes of malfunctions and mechanisms for their elimination

From the situation where the uniform tractor starts, but immediately stops at idle, the owners of neither new nor used walk.behinds are not safe.

This can be caused by a number of factors:

- Problems in the ignition system:

- Deviation or rupture of electrical contacts;

- Faulty spark plugs. They can be installed only after unscrewing and external inspection. If a candle:

Мотокультиватор Тарпан. Топливный фильтр (двигатель “B&S”)

- Dry. The cause of the malfunction lies in the carburetor, where gasoline is not supplied. This can happen due to clogging of its filter or separate nozzles;

- Wet. The engine does not develop speed due to excess fuel;

- Covered with soot. The fact of its failure, due to which inflammatory sparks may not form. The final check of this will help to check the electrodes;

- After replacing or cleaning the fork, electronic components are checked. The integrity of the connections and the wires themselves, which, due to strong vibration, may require repair;

- Disadvantage or poor fuel quality. Often the engine does not gain speed due to improperly prepared fuel mixture or clogging of the carburetor. In this case, the repair begins with its removal from the body of an off.road tractor and cleaning of dirt particles. At the same time, the fuel changes, first draining the old one and washing the fuel tank and the feed hoses.

- Another reason why the unoic tractor starts and stops immediately related to gasoline. Very often this is observed after a long period of inaction (for example, after the winter), when the unoic tractor was not used for a long time and was stored with gross violations. After repairing or replacing the entire fuel tank, the device is usually restored;

- Cool weather, due to which diesel equipment is often forgotten. Therefore, in the early spring, experts advise turning on the unoic tractor only after pouring hot water into the radiator;

- Boxing gear malfunction. The fact that the cultivator does not develop speed and does not work at idle, as evidenced by the characteristic knock of a gearbox that occurs against the background of a shortage of oil.

Read adjustment of the Champion 241 chainsaw carburetor

The main causes of breakdown of “Lifan” engines

Lifan is a popular Chinese brand, which combines lines for the production of small.blood.cubatic motor vehicles and large buses. But engines for motoblocks, agricultural machinery and small motor vehicles are of the main popularity.

Diesel and gasoline engines are distinguished by motorized resources. The former are capable of providing 4,000 m/h, the latter. 1,500 m/h. But, despite this advantage, diesel when buying and in operation is much more expensive than gasoline (carburetic). Therefore, owners of motoblocks make a choice in favor of Lifan carburetor engines.

Timely maintenance and repair of engines of specialized devices significantly extend the service life of a large tool.

Breakdown and repair instructions

The malfunctions of the engine and its nodes include:

does not develop speed or works with jerks;

improper work of the gearbox and clutch;

problems in cooling, lubrication systems, etc.D.

With these problems, it is necessary to eliminate the main reason, through proper diagnosis and repair work.

Important! You have found a motoblock malfunction? Instantly turn off the unit to cool, and only after a while proceed to the commissioning!

Consider the main causes of frequent malfunctions and methods for their elimination

The engine of the walk.behind tractor works with interruptions, does not develop momentum, or vice versa is “different”. rapidly gaining them.

Weak fixation of the levers of the regulator and traction.

It is necessary to adjust and tighten the control drive.

Fleet cleaning on the inner walls of the muffler.

It is necessary to remove the knot, disassemble and clean, assemble and correctly adjust.

Elimination of felted products on a candle.

When turning on. power loss and engine stop.

Turn off the one.axle tractor and wait for its cooling. Check the oil level in the crankcase, the cleanliness of the surfaces of the blocks and cylinder heads.

Nadir’s formation on the lower head of the connecting rod.

The motor block engine is disassembled and the condition of each node and component for serviceability, deformation, melting is checked and checked.

Rifle or sprayer oil is faulty.

The Lifan engine smokes, white smoke turns from the walk.behind tractor and works “in a zabukhanka”.

The same.based tractor stands under the slope (crankcase oil forms thick smoke, getting onto the valve).

You need to check the spark plugs. If the candles are dry, then there is no fuel in the engine cylinders.

Small garbage in the hole of the gas tank plug.

Clean drainage, rinse the tank and pour pure gasoline.

If gasoline enters the carburetor, but does not reach the cylinder, it is necessary to adjust the Lifan engine carburetor. To eliminate the malfunction, the entire node is removed, disassembling and cleaning are performed. After that, it is necessary to collect the details and install them back in the unit.

If when checking the candle is wet, this means that the fuel comes without problems and it is necessary to identify one of the following problems:

The size of the gap between the electrodes is disturbed.

Damaged candle insulators or wiring.

Cleaning candles with emery, washing gasoline and drying.

Violation of sealing of connective elements and seals.

Lining of fasteners, checking gaskets.

Lifan engine service

To prevent the main breakdowns of the motor, ensuring its durable operation, regular maintenance must be performed.

Checking the oil level, replacement or topping new.

Checking, adjusting and replacing spark plugs.

Checking and adjusting the idle move of the engine.

Regulation of optimal size between valves.

Each Lifan gasoline engine is made of high quality materials according to all standards. Since the manufacturer is the main priority of the manufacturer, with timely diagnosis of the engine, agricultural machinery will delight the owner of a light and effective work with a low level of noise and vibration!

ᐈ Repair of the walk.behind tractor Tarpan Kyiv. 2021

Repair of the Tarpan motorlock in Kyiv: engines and mechanical part

Owners of garden equipment are periodically interested in the repair of motoblocks in Kyiv. features of operation leave their mark, and repair work needs all models without exception. The technique of this level requires professional service: its further reliability in operation depends on this. Online service Kabanchik.UA will help to find a specialist who inexpensively and reliably perform repair work.

When you need a motor block repair?

Contact the master periodically for the purpose of preventive maintenance. But there are factors indicating that the help of a professional is needed immediately. Among them:

- decrease in the power of the equipment;

- unjustified increase in fuel consumption;

- the exit from the pipe of the smoke of black or blue;

- quick and excessive heating of the motor;

- knocks and other extraneous noises during work;

- enhanced vibration in the process of work;

- lubrication.

All these factors can be prevented by observing the rules of operation of the walk.behind tractor: using high.quality fuel, regularly change the air filter and oil, use the lubricant that the manufacturer recommends, properly store the equipment. Complex and expensive repairs will not be needed if you do not overload the one.axle tractor, do not jerk it at high speeds, not allow strong tilt to the side.

Types of malfunctions and repair of motoblocks

Most often, domestic owners of technology are interested in repairing the bison of the bison or repair of the motor block of the centaur. these models are most widespread, differing in high power and reliability. But, like any technique, they periodically fail. All arising malfunctions can be divided into two groups: engine breakdowns and the mechanical part:

- In case of malfunctions of the engines, the master will be able to eliminate the breakdown of the fuel system of the gasoline or diesel engine, breakdowns of the speed control, ignition system, launch system, or mechanical damage to the cylinder-piston group.

- In the process of repairing mechanical damage, the master most often has to deal with the wear of the transmission bearings, parts of the gearbox (gears, shafts), on.board gearboxes or differential, power shaft parts, adhesion system.

The price of the repair of the motor block or the mechanical part of the equipment depends on the large number of factors: such as equipment, countries of production, accessibility of spare parts, complexity of repair work, type of breakdown, and so on. Part of the faults can eliminate the specialist directly on the spot. For some work, you will have to take care of transporting a walk.behind tractor to the workshop.

Who to order a motoblock repair?

Inexpensive, fast, guaranteed high.quality repair of motor blocks is available to everyone, provided that the specialist is searching through our site. We have a base of registered and trusted specialists: private masters and specialized companies. You can verify their professionalism according to reviews, portfolio, quality ratings. All data is objective and verified.

Price: Repair of the Tarpan motornote in Kyiv 2021

| Carburetor cleaning | from 150 UAH. |

| Replacing piston rings | from 300 UAH. |

| Technical diagnosis of a walk.behind tractor | from 150 UAH. |

| Replacing the spark plug | from 100 UAH. |

You can arrange the task directly by selecting the performer yourself. You can also indicate the conditions, price and terms, wait for several applications from the masters and choose the best among them. Payment of services is carried out in fact, therefore, possible risks are excluded. Use our service: get a high.quality and fast service with the optimal cost without spending time and nerves.

There is no spark on the walk.behind tractor. we understand the problem

Another common reason that the unoic tractor does not start is lies in the malfunctions of the ignition system of the unit. Faults can be hidden in a cap, magneto, spark plug or in a high.voltage agricultural wire.

When examining the ignition system, first of all, you need to carefully check each part for clogging. If a spark is gone, then the reason for this is often the ingress of moisture or dirt on the elements of the ignition system. Also, the agricultural machine often does not start due to the lack of the ability to form a spark-the reason for this is poor contact between the central electrode and the candle cap.

If you did not find dirt and moisture in the ignition system, and the uno.ears of the tractor is not started, then be sure to check the integrity of the electrodes and the gap between them. As a rule, a special probe is used for this. Ideally, the gap should be 0.8 mm. If necessary, remove the carbon from the insulator and metal elements of the ignition system.

If the unit does not start, and not one of the above procedures helped, then it will be necessary to replace the light of the he ignition of the walk.behind tract. The cost of the parts for replacement is low, however, when buying, we advise you to give preference to more expensive candles. they will last many times longer than cheaper analogues. All of the listed methods are suitable for the repair of MOT-blocks MROT, Neva MB-1 and MB-2, as well as cascade, bison, agro and fireworks.

Cultivator. a technique that rural residents, summer residents, farmers often use. Despite its high quality, there are times when the equipment fails. What to do if it happened to your technique? Today we will analyze one of these situations, namely, we will figure out what needs to be done if the cultivator does not start.

Reasons and their decision

It is worth noting that for a long service life of your equipment, you first need to learn how to take care of it. After all, cultivators require constant attention, namely, they need regular diagnosis and timely oil replacement. If these key rules are not observed, your unit can often fail and upset you with its malfunctions.

So why the motor.cultivator does not start:

- At the end of work on the site, many owners leave the equipment without work with the old fuel inside. Since after several days the fuel emits condensate and precipitate falls, all this negatively affects the fuel system. The carburetor is even more subjected to this, which will then need to be cleaned. To avoid such problems, always pour the remaining fuel from the tank, or work as a cultivator until the gasoline is over.

- If you left gasoline winter in the unit, then first of all you will need to pour it out of the fuel tank. Next, pour new clean gasoline and leave the unit for a couple of hours. After a combination of time, supplement the tank with a small amount of fuel. If after the operation the motor.cultivator does not start, then it is worth looking for a problem in electrical firing. And this is already very difficult, so we advise you to contact specialists here.

- The engine of any garden equipment will in no case function in the absence of oil. So check the presence of lubrication in your cultivator.

This we provided the basic recommendations on how to make a cultivator in case of its malfunction. DIY Cultivator repair instructions can be found in the unit maintenance manual. If you do not have technical skills and are poorly versed in the design of motor cultivators, then you should seek help from professionals. Experts in a short time will be able to find out and eliminate the reason why the motor cultivator is not started.

When operating complex equipment, sooner or later breakdown occurs. It’s good if your one.time tractor is under warranty, and the service center has no reason to refuse you free repairs.

And such a situation may arise when you do not know what to fill in a motor.cultivator, and incorrect operational fluids led to a malfunction.

If you do not violate the operating conditions, and carry out maintenance in time, breakdown occurs only due to the wear of the rubbing parts, or factory defects.

In order not to rack your head, why the cultivator stalls, or how to disassemble the gearbox. we will consider the main malfunctions of this garden assistant. Knowing the device of the unit. you can understand how to repair any of its nodes.

Важно! Самостоятельный ремонт возможен только после окончания гарантийного срока эксплуатации. Если в сервисной мастерской обнаружат следы вашего вмешательства – аппарат немедленно будет снят с гарантии.

All breakdowns can be divided into the following groups:

- A malfunction of the fuel system of the engine (cliff or clogging of the fuel, clogging of the carburetor, failure of the fuel pump);

- Electrical equipment malfunction (failure of the components of the ignition system);

- Mechanical malfunctions (gearbox, piston engine system, leading axis or power selection shaft);

- Clogging of filters. air, fuel;

- Lack of fuel or its low quality (as it doesn’t sound banal).

Malfunction of engine systems when starting

In the event that when checking the candles, they turned out to be wet, t.e. The fuel comes normally, but the motor does not start, the problem may be as follows:

- Failure of ignition system:

- Air sunset through the seals of the carburetor, spark plugs, heads of candles and cylinders, as well as carburetor joints and engine cylinders.

If depressurization of the compounds is detected, it is necessary to carry out tightening fasteners, tighten the candles and check the integrity of the gaskets between the heads of candles and cylinders.

To eliminate this problem, it is necessary to ensure the free course of the damper, checking the quality of the drive work. If you find seizures, they need to be eliminated.

Violation of compression and malfunction in the carburetor

It happens that the launch is carried out, but its process is significantly difficult. At the same time it works extremely unstable and cannot develop sufficient power for normal operation.

The reason for this may be the loss of compression, which can be detected by:

In order to restore compression, you need:

If in the process of operating the engine a black smoke comes out of the muffler, and an excess of oil is revealed on the electrodes of the candles or they themselves are covered with soot, this means that:

- An oversaturated fuel mixture is supplied to the carburetor;

- The sealing of the fuel valve of the carburetor is impaired;

- the oil.scrubbing ring of the piston was worn out;

- Breeding.

To eliminate this problem follows:

- adjust the carburetor;

- replace the leaky valve;

- replace worn piston rings;

- Clean or replace the failed air filter.

In the event that when the engine is operating, light smoke comes out of the muffler, and the electrodes of the candles are dry and covered with white coating, this means that a lunch fuel mixture gets into the carburetor. This problem is eliminated by adjusting the operation of the carburetor.

Motobobe engine malfunctions during operation

The nodes and components of the engines that are installed on agricultural mini-equipment are subjected to significant loads. They can fail in the process of operation of the unit, which will very quickly lead to serious failures.

If suspicious noise, jerks and violations in the operation of the walk.behind tractor are found, it is very important to immediately turn off the engine, and then let it cool. only after that it will be possible to eliminate the problem.

If during operation the motor begins to independently gain momentum, t.e. There is a “different”, most likely this means that the attachment of the levers of the regulator and traction weakened. In this case, the user will have to re.adjust the engine.

Sometimes, with a completely open throttle, the engine does not accelerate when pressing the handle of gas, but on the contrary begins to lose power until a complete stop. This is a clear sign of overheating, so the unoic tractor needs to be turned off and wait until its nodes are completely cooled. After that, you should check the oil level in the crankcase, as well as to control the cleanliness of the walnut surfaces of the blocks and cylinder heads.

With increased loads on the engine, it can jam it. There may be several reasons for this:

If the engine of the walk.behind tractor jammed, it will have to disassemble and check the condition of the main components and components: faulty, deformed, melted, etc.D. subject to replacement.

Do.it.yourself motoblock repair

Unfortunately, any technique sometimes fails, so its owner needs to be able to eliminate the malfunctions on his own. Of course, if the car is under warranty, it is better to take it to the service center, where specialists will conduct warranty repairs for free.

Often damage to the cultivator, motoblock occurs due to its incorrect operation-when poor fuel is poured, large loads are allowed or the loss of lubricating fluid is not replenished during the time. Then the car begins to stall, “burst out”, it is bad to gain momentum (especially if it has an electric motor), or even stops starting up. But, knowing the device of the unit and the principle of operation of its mechanisms, you can identify the cause of the damage and carry out the repairs efficiently.

Repair of the fuel system

The breakdown of the fuel system can be argued if the engine:

To eliminate the malfunction, first check the condition of all filters, including air and oil. If they are clogged slightly. they make purge with compressed air or flushing, if there are strong contaminants on them, they are replaced with new ones. Then the carburetor is disassembled, the details are washed with a special cleaner, clean the fuel tap tap, tank and a piston system with gasoline. After drying, the reverse installation is carefully performed.

After the motor is completely assembled, the crankshaft is manually scrollful. it is important that the piston goes freely, and the valves work impeccably. Then pour fresh grease, start the motor and leave it to work on the “idle”. Be sure to check the flow of fuel into the cylinder. Perhaps, after such a repair, the cause of the malfunction will be eliminated, and the unoic tractor will begin to function without interruptions.

Repair of the ignition system

You can judge the breakdown of devices for inflammation of the TVS by signs when the engine:

- Starts, but stalls at idle;

- Does not start even with good fuel supply;

- Works on “idle”, but with some interruptions.

To clarify the reason, first check the condition of the candles: if there is damage to the insulator, they replace them. Next, inspect the electrodes and, if necessary, regulate the gap between them. Check the state of high.voltage wires for the oxidation of the tips and insulation disorders. damaged wires must be replaced with new. Without such a repair, a spark can be completely abyss or will leave for isolation, breaking through the engine housing, and will not be able to ensure the ignition of the TVS.

If there is no defect with a spark at this stage, then the reason is that the technique does not start or stalls, lies in the generator or coil (for models such as Neva, the cascade it serves for the formation of a spark). To check the generator to its conclusions, the measuring device is connected. Scroll through the pulp of the starter of the motor unit and fix the testimony of the device-they should be in the range of 12-16 watts. If the indicators are normal, then the reason is contained in the ignition coil and after replacing it can be given a load on the engine. Most likely, after such a repair, its performance will resume completely.

Мотокультиватор Тарпан. Регулировка холостого хода.(двигатель “B&S”)

Transmission repair

The following factors indicate the transmission malfunction:

- The working shaft is motionless, and the output shaft rotates;

- Engine speeds do not correspond to the revolutions of the working shaft;

- The engine seems to be “choked” from the load.

If at least one of the listed reasons is manifested, they immediately check the presence of lubrication in the gearbox. The lubricant in it should be normal, since the lubricant prevents the “dry” friction of moving parts and does not allow them to overheat.

Then the gearbox is disassembled, the gears are examined, the chain tension is checked. Entire details are washed in kerosene, and damaged ones are replaced with new. After that, the design is assembled and monitored to prevent the skew of the gear.

Before installing the assembled gearbox on a single tractor, they make shaft scrolling to make sure that they rotate evenly and without the slightest rattle. The gearbox is filled with fresh lubricant fluid, and the motor cultivator is launched. In the absence of leaks under the body, simple actions with soilofrease or a hinged loader are performed and the functionality of the motor block is checked. If his performance is restored, then all efforts were not in vain, and repair and maintenance were carried out correctly.

The block does not work or works unstable

It is logical to start the analysis of possible breakdowns with this situation: the cascade unoic tractor starts and immediately stalls. Or completely stopped starting. The following reasons are most likely:

- excess gasoline (the moisture of the candle speaks of it);

- In models with an electric starter, the problem often lies in the discharge of the battery;

- The total power of the motor is insufficient;

- a failure arose in a silencer.

The solution of each of these problems is quite simple. So, if there is a lot of gasoline in the gas tank, they must dry the cylinder. After that, they start a single tractor with a hand starter. Important: before that, the candle should be twisted and also dried. If the manual starter works and there is no electric, then you should charge or replace the battery.

If the engine does not have enough power for normal operation, it must be repaired. To reduce the likelihood of such a breakdown, it is necessary to use only gasoline of impeccable quality. Sometimes a carburetor filter is clogged due to poor fuel. You can clean it, but better. we will repeat it again. to perceive such an event correctly and stop saving on a fuel.

Sometimes it is required to adjust the carburetor KMB-5. Such devices are placed on lightweight motoblocks. But therefore, the importance of their work is not reduced. After the repair of the failed carburetor, only suitable gasoline brands should be used for washing individual parts. Attempts to remove pollution using a solvent will turn into deformation of the rubber parts and washers.

You need to assemble the device as accurately as possible. Then bends and damage to the parts will be excluded. The smallest parts of the carburetors are cleaned with a thin wire or steel needle. Be sure to check after assembly whether the connection of the float chamber and the main case is tight. And also should evaluate if there are problems with air filters, are there any fuel leaks.

Actually, the adjustment of the carburetors is carried out either in the spring, when the one.axine tractor is first rolled out after the “winter vacation”, or in the fall, when the device has already worked for a very long time. But sometimes they resort to this procedure at another time, trying to eliminate the shortcomings that have appeared. A typical sequence of steps is as follows:

- heating of the motor in 5 minutes;

- wrapping to the limit of adjusting bolts of the smallest and largest gas;

- twisting them for one and a half turns;

- installation of gear levers on the smallest move;

- task of small revolutions using a throttle;

- The gasping of the gas screw for setting the idle speed. with a continuously working motor,;

- jetting of the engine;

- Assessment of the quality of adjustment by new launch.

To exclude errors in the process of setting up the carburetor, you need to check each step with instructions for operation. When the work is done normally, extraneous noises in the motor will not appear. over, malfunctions will be excluded in any of the working modes. Then it will be necessary to observe the sounds that the one.based tractor makes. If they differ from the norm, you need a new adjustment.