It is difficult to imagine the world of modern construction without affordable, durable and environmentally friendly material, which are MDF panels.

over, their installation can be carried out even by unprofessional specialists; at the same time, the master, in his work, should be as accurate and accurate as possible. Do it yourself with your own hands to finish the walls of MDF panels, enough skills of an ordinary joiner.

Required Inventory

In addition to the classic home tools that almost everyone has available, you should buy plumb bob (you can do it yourself without problems using nuts, fishing line or thread).

Also make sure that you have at hand a tape measure, a tool for determining surface deviations from the vertical or horizontal, and a special nozzle on the drill with which self-tapping screws are wrapped, a locksmith will also be needed.

It is desirable that it be metal, with different thicknesses of legs. You can cut the material for slopes without problems with a square, a more massive leg is used as an emphasis. A special screwdriver also does not hurt, but you should not buy it specially.

It stands out for its compact size, as well as ease of use. in its dimensions and shape, the saw is similar to a machine for men’s haircuts. over, such a device is universal.

Complete circles change without problems, so the device can process a wooden, metal or stone base.

But, the saws differ with the processing of the material, so evaluate which one will be cheaper for you to purchase.

Installation technology

If the surface on which the MDF is to be mounted on the walls was once covered with mold or fungus, the room has a damp smell, and wet traces are noticeable, if the lime mortar is covered with tubercles and deformed, while its layer is more than 1.2 cm, it necessarily cleared.

Such simple manipulations will not only ensure the durability of the future design, but also significantly reduce the cost of fasteners. Also, this will determine if there are hidden flaws on the surface. Naturally, decorative elements that separate the floor from the wall should also be dismantled.

Do-it-yourself MDF wall sheathing is carried out by two technologies:

- using a lattice structure of wooden blocks;

- using the basis of professional profiles made of galvanized material.

To design a crate from a tree will be easy. To do this, use a small amount of metal fasteners.

Reiki made of real wood, or even the side of the log, having one sawn and the other not sawn side, will cost more than a metal base.

Do not forget that the lath made of natural wood is recommended to be pre-treated with a professional anti-fungal agent, antiseptic, which will also eliminate possible rotting and staining.

If you live in a house made of bricks, or in your room an increased percentage of humidity, installing a crate made of natural wood is not worth it.

Moisture and fungal spores will certainly penetrate through brick voids, in addition, the space between the lining and the wall is considered the optimal environment for the reproduction and vital activity of microorganisms.

In rooms with high humidity, such as a bathroom, a kitchen, it is recommended to use laminated panels and install furniture made of moisture-proof MDF.

For an internal load-bearing structure consisting of a combination of linear elements, purchase profiles yd and sd. The two options considered in their form resemble the letter P and stand out only by configuration dimensions.

Fasteners (“ears”) and connectors are produced for the cd profile of the company, which are rational to use for large volumes of work, the installation time is strictly limited.

If the MDF paneling for the walls will be carried out by the master with his own hands, a video of the work that can be found in the vastness of the world wide network, it will be inappropriate to acquire them specially.

For more information on wall decoration with MDF panels, see the video:

Thermal insulation

If you design your own walls from MDF panels, think about their insulation, in which voids are filled with polystyrene foam, construction foam or silicone.

The second considered insulation can be applied unevenly, and this will entail the presence of protrusions, which are easily removed with a special construction knife.

It is a humid environment that is most optimal for the development of various pests. Here about the bathroom furniture. In addition to an additional insulating layer, foam, foam or silicone will additionally protect the room from the formation of possible condensate, which most often appears in voids.

MDF, what is this material? Do not forget that MDF is a panel of sawdust, so it is recommended to monitor them, along with a real tree.

Video: Than Sawing MDF Panels At Home

Thermal insulation of the room will additionally help cool it on hot summer days. When the room warms up, the influx of heat from the street will decrease significantly.

Just the mdf on the frame acts as a heat shield that can reflect elements. If a ball of material, which is a foam plastic mass, is still added to the MDF, together they create a double protection.

over, the reflection coefficient of the material exceeds 0.7 units of heat. Having made insignificant corresponding calculations, we can understand that no more than a few units of heat will enter the room. How will their outflow through the surface change in the winter months?

Considering that the process of heat exchange through the walls is about 0.15 percent of the total heat flux, we can confidently expect a significant reduction in all spent funds for heating, as well as air conditioning. by no less than ten percent.

At high tariffs, this fact will significantly affect the budget savings.

Lattice structure

If you are interested in: “How to sheathe MDF panels with your own hands?”, First take care of the design in question. A variation of wood is attached to the supporting structures with curly nails or professional dowels.

The latter are similar to self-tapping screws, only with a smooth and asymmetric profile for threading. It is driven into a special plastic hole with an ordinary hammer. On the dowel head there is a recess under the tool for screwing in and out screws. The metal crate is mounted exclusively with curly nails.

To attach it, use special fasteners with a diameter of 0.4-0.6 cm. The stronger the base, the lower the rate. You will get each curly nail or the expansion bolt shield at the same time with a plastic fixing element.

The holes in the surface under it should be drilled accordingly to the diameter of the body of the socket. The body of the fastener, whether it is a nail or a self-tapping screw, must be driven into the wall by at least 4 cm.

For example, if a ball of plaster is 1.2 cm and a lattice structure is constructed with rails or a profile 4 cm thick and the panel is 1.6 cm thick, then the length of the metal product will be equal to the sum of all the described indicators: 6.8 cm.

That is, when purchasing, pay attention to details with a length of 7-8 cm. The distance from the surface to the bottom should be identical with the length of the socket. Please allow 1.2-2cm error. When buying a longer drill, it must be equipped with a restrictor tube.

It is not recommended to make a hole too deep: the thickness of the bearing walls between the rooms can be insignificant, even less than 20 cm.

Lathing with wood blocks

If you are interested in the visual question described, find on the Internet a video: “Do-it-yourself mdf paneling of walls”. Lattice construction made of wood always installed starting with uprights, which are placed in all corners in pairs.

Visually, it should look so that as a result a right angle is formed, which is visually visible from the edge of the window opening, the door and the base to the top cover. A stand is applied to the surface, the borders of which are drawn on the surface.

Then, a mounting hole is drilled on the material with a pitch of 70 cm, elements for fasteners are driven into it. On the rack, their border is marked, then a hole is drilled into two third of the diameter of the fastener.

professional repairmen can drill holes in advance, while their marking on the surface can be carried out directly through them. Then, horizontal wooden beams are installed using the same step.

Beams must be installed on the upper part of the opening, under the board or stone slab of the window. Opening slopes are formed on two edges with slats, the use of crossbars is not allowed.

When finishing the ceiling, MDF panels should be placed along a vertical or inclined structure and across the beams. Here is the mdf for the ceiling.

Lath made of metal elements

This type of lattice structure is carried out in a similar way: beams in the corners and openings, then crossbars. Lattice pitch. used similar to wood. Beams should be constructed from the profile profiles, they are mounted and installed up to the place profiles sd.

After checking horizontally with a device for determining deviations of the surface are attached to the first, then to the surface, in a previously created for this zone.

Details must be attached to each other. For this, small self-tapping screws are used.

They are mounted on a wall with a curly pointed rod. It is irrational to use a plug-in spike for this purpose: you either will not achieve the element you need or deform the profile. Profile Elements SD in advance you need to fasten with each other to the selected length.

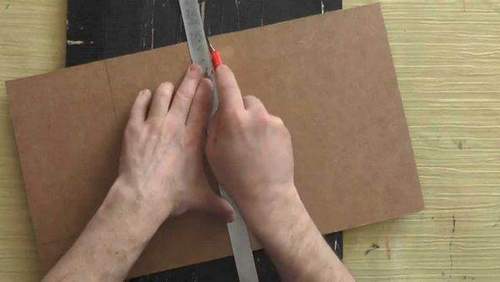

Work on the crate with metal elements should be carried out with the smallest in size and functional features angle grinder.

You can also purchase a hand saw. An electric jigsaw, even if it is equipped with a metal saw, the installation will be significantly delayed and many defective panels will be obtained.

DIY wall cladding

You can always find a video of the described material in the article on the worldwide network. The process of installing mdf panels on a lattice structure or continuous flooring is much easier than all the work at the preparation stage, described earlier.

- start from the corners. Cut into dimensions the specified amount of mdf material to sheathe the required plane to the nearest beam. Corner sections must be treated with a sandpaper;

- take the first panel on which you need to cut off the crest of the longitudinal protrusion. The panel is attached to the corner with a fastener or small cumulus rod. Here’s how to fix mdf to the wall. Important is the groove of the castle. Its sides are fastened with nails or a metal perforated plate (clip);

- superimposed another panel. The comb slides into the groove, where it is attached and so on, until you see a couple of the last panels;

- the last element is cut to length according to the specified dimensions. Just take into account a gripping of 0.2-0.5 cm;

- the crest of the last part should be cut in half and rounded off;

- two penultimate fasteners are mounted in place by a "house". Press down on the fasteners to hear a special “snap” sound;

- the last fastener is pushed to the end on the one that was installed earlier; secure the free edge with a curly nail.

conclusions

Finishing slopes should be carried out in a similar way. In this case, the wizard can install MDF panels along or across. If wide slopes are used, choose any covering method. The plane between the wall and the window itself will look harmonious if it is sheathed with elements of dark and light colors.

In general, everything as the master and other residents of the house wish. Install the MDF panel, if you understand in detail all the steps described, it will not be difficult. Remember that you can always call a specialist, and for a moderate fee, he will do all the work for you.