Grinding frequency

There are no specific intervals in time for the point of the saw chain, it is just advisable to sharpen it before starting work.

Sharpening the chain depends only on the frequency of its use, you need to carefully monitor if there are signs indicating that it is time to sharpen it.

For the process of sharpening the saw chain, special skills are not needed, you just need to be able to work with ordinary locksmith tools. Sharpening chains requires dedicated tools.

Chain selection

Professional chains come in 3/8 “or 0.404” increments. With the use of such a chain, productivity is significantly increased, but the vibration also increases. Such chains are used for work on industrial logging.

For frozen and contaminated trees, use carbide-tipped saw chains.

The chain pitch is calculated by the distance between two adjacent teeth or by the length of the segment between two nearby rivets, divided by two. Component parts from chainsaws of different manufacturers cannot be combined.

The saw part of the chainsaw consists of a sprocket, a bar and a saw chain. Parts from different manufacturers in this kit are incompatible due to incompatibility of technological parameters: the thickness of the drive link and the configuration of the chain. Therefore, you need to very carefully and carefully choose the model of the chainsaw. After all, after purchasing it, you will depend on the supply of sets of spare parts from the manufacturer.

There is an opinion that the performance of a chainsaw is dependent on the shape of the chain, but this is a misconception. In fact, performance directly depends on the power of the engine, since the more powerful the engine, the more torque is transmitted to the chain.

And the power of the engine depends on how much more ability it has to pull the chain through the material being cut. As a result, we can say that the most effective ratio for chainsaws with a powerful motor is a 3/8 inch chain pitch.

Sharpening using a machine

Not all saw chains can be sharpened with a file, this happens when the chain loses the shape of the cutting edges, and using a file in this case leads to a lot of time wasted. Therefore, in such situations, it is justified to use machines for sharpening chainsaws.

There are machines with an electric drive and a manual drive, they use either a sharpening stone or a grinding wheel.

To work on an electric machine, first loosen the screw that holds the chain, insert it into the guide groove. In such a way that the teeth are located in the direction of the grinding wheel. After setting the required angle, you can sharpen.

To work on a manual grinding machine, you need to set the desired sharpening angle, it is determined by the most blunt tooth in the chain.

When sharpening, do not grind the teeth too hard, the chain may become weaker from heat and its operating time will decrease.

To secure the result from sharpening, blow the sharpened links with compressed air and lower them in oil for 2-3 hours.

The advantages of this method are that when sharpening you achieve more accurate results, but also waste a lot of time and effort.

When using an automatic machine for sharpening, you will not only sharpen the chain with high quality and precision, but also speed up the process without wasting your energy.

The machine is made in the form of a small rectangular box with a grinding wheel. You only need to insert the chain, secure it and turn on the machine. And the chain will start spinning and sharpen itself against the stone.

Chainsaw chain sharpening

You can determine that the chain can be sharpened by several criteria:

- Slow chain speed during operation.

- Chain movement in both directions.

- It becomes small chips from sawing.

Chainsaw sharpening

Sharpening with an angle grinder

To use an angle grinder as a grinding unit, you must have some experience with it, otherwise you can easily damage the chain. So, if you have no experience with an angle grinder, then it is better to use other methods. But this method also has some advantages:

- It is not necessary to remove the saw chain from the chainsaw during sharpening.

- For sharpening, a used disc is used for cutting metal with a thickness of 2-2.5 mm.

- When sharpening, the angle is chosen according to your discretion and experience.

- With proper sharpening in this way, the chain can be sharpened up to 10 times.

- The method does not require large financial expenditures and loss of time.

The only drawback is that you need to gain experience and skills by practicing on a broken chain.

Sharpening with files

By using this method, you minimize your cash costs, due to the fact that there is a file in any household. The main thing is to choose the right file diameter for sharpening, which is measured by the dimensions of the saw chain. For chains of 1.3 mm, a round file with a diameter of 4 mm is used, and for chains of 1.6 mm, a file of 5.2 mm is required. Using a flat file, we adjust the edges of the chain, the saw chain is sharpened at a certain angle, to facilitate this process, there is a factory notch on the teeth indicating the sharpening angle.

To sharpen the chain, you also need a clamp, to secure and fix the chain, it is installed on the edge of the workbench and the chain is strengthened in it.

General rules for sharpening chainsaw chains

Do-it-yourself chainsaw sharpening

The tooth of the chain planes the wood like a plane, and the thickness of the chips is adjusted by the height of the stopper.

Intense sawing will quickly dull the chain. Several sharpenings may be required within one day. The problem is aggravated by the fact that the tooth quickly dulls when it meets the ground. It is enough to hook the soil with the tire once or twice, and the work can be stopped. the shavings become fine and the saw stops going deep into the wood.

The sooner dull teeth are sharpened, the less material needs to be removed during sharpening, as a result. the service life of the saw chain is longer. Determining the moment when sharpening is already required is quite simple. An important feature is the feed force. A properly sharpened chain is pulled into the cut with just a little pressure. If, on the contrary, the chainsaw is forced to cut by increased feed force, then the teeth are dull. A dull chain can also be recognized if, instead of large, thick chips, only small chips fly out of the cut.

In this situation, the chainsaw must be sharpened urgently. Do not cut with a dull or defective saw chain. the consequence is high stress in the body, high cyclic load, poor cutting results. In addition, this means a decrease in productivity, high fuel consumption and increased wear of all parts of the chainsaw.

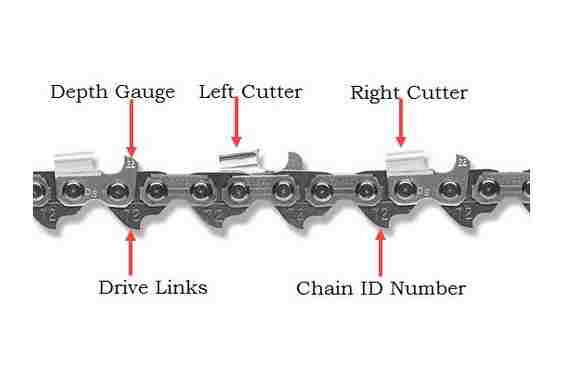

Chain Teeth Parameters

To achieve optimal cutting properties, the tooth blades are given specific angles. The back of the tooth falling back at an angle forms the posterior angle of the upper blade. This angle is needed to cut the upper blade into the wood.

The backward tapering blade of the tooth forms the back angle of the end blade. This angle is needed for side cutting of the chips.

The edge of the end blade forms a rake angle with the sliding surface of the cutting link. Front angles for different types of chains vary from 60 ° to 85 °.

The back angle of the upper blade characterizes the backward tilt of the upper blade.

This angle is measured relative to the sliding plane of the cutting link and, depending on the type of saw chain, ranges from 50 ° to 60 °. The top blade is the main blade and the back corner of the top blade. this is the most important corner. The clearance angle of the upper blade is difficult to measure, the correct value is obtained by observing other prescribed values.

The sharpening angle or entering angle is obtained by measuring from the top cutting edge at right angles to the guide bar.

The sharpening angle can be changed, depending on the application. Rule of thumb: the larger the sharpening angle, the higher the cutting performance when cutting non-frozen softwood. Reducing the angle of sharpening when cutting frozen and / or hard wood contributes to a smoother saw blade and less vibration. However, sharpening angles greater than 35 ° and less than 25 ° should be avoided (except for rip chains where this angle is 10 °).

The rake angle, sharpening angle and upper blade angle change when sharpening. These angles have a decisive influence on the cutting performance of the chain. Be sure to observe the prescribed values.

A depth stop is located on each cutting link in front of the tooth scapula. The difference in height between the top edge of the depth gauge and the front edge of the back of the tooth is defined as the distance of the depth gauge.

The depth of penetration of the upper blade into the wood (chip thickness) and thus productivity depends on the distance of the depth gauge. The distance of the depth gauge is set depending on the chain pitch and the type of execution. Normally, it should be 0.5-0.8 mm, more often 0.6 mm. High values will lead to an increased tendency of the chainsaw to kickback, too much grip and chain vibration. Low values lead to a drop in performance. Since the distance of the depth gauge decreases with each sharpening of the saw due to a decrease in the upper edge of the tooth, the depth gauge also needs to be filed periodically. after 5-10 chain sharpenings.

Chain sharpeners

The round file holder has a mowing line that allows it to be correctly positioned in relation to the chain. The holder fits onto the sharpened tooth in accordance with the line orientation. In this case, the insert itself rests on the upper edge of the tooth and the depth gauge, and the file is located under the cutting edge.

The use of a holder ensures that the file will fit to the tooth at the correct height. There are different tool holders for different pitches of the saw chain. The correct choice of holder, combined with the correct file diameter, ensures that the file protrudes over the back of the tooth by 1/5 of its diameter. Use only special saw chain files.

Before sharpening the chainsaw chain, it is advisable to secure the bar. When sharpening, it is necessary, while maintaining the position of the holder and pressing the file to the sharpened edge, to make several (2-3) turning movements away from you. Do not try to press too hard on the file, the movements should be smooth and measured. Rotate the file regularly to avoid one-sided wear. All other teeth are sharpened in the same way. It is more convenient to first sharpen the teeth in one direction, then change the position and do the same with the teeth in the other direction.

When sharpening all teeth, do the same number of strokes with the file at the same pressure. This will result in the same tooth length. All cutting teeth must be of the same length. Different tooth lengths cause uneven chain running and cracking. If the length of the teeth is not the same, all cutting teeth must be filed to the length of the shortest tooth.

After several sharpening of the cutting teeth, the depth gauge is ground. To do this, a template is superimposed on it so that the stopper falls into the slot, and the tip protruding from the slot is grinded with a flat file.

The principle of using another set for sharpening chainsaw chains does not differ from the first, although its design is different.

A round file is also used to sharpen the cutting tooth, and the depth gauge is used to sharpen the depth gauge. flat. A special template provides parameters for sharpening both cutting teeth and stops. In the first case, it is superimposed on the chain in such a way that it falls into its slots. The file, placed on the template and brought under the cutting edge, rests on the guide rollers. The direction of movement of the file must be parallel to the lateral edges of the template.

When sewing the stopper, the template is applied so that the stopper falls into the cut, next to which is written SOFT (for soft wood) or HARD (for hard wood). As in the case of the first device, the file is seamed with smooth, even movements of the flat file away from you.

Chainsaw chain sharpening machines

Stihl produces two modifications of hand-held machine tools. stationary FG 2 and mobile FG 1, mounted directly on the tire. There are analogues of less well-known companies, comparable in price with the simpler devices described above.

The working part of these devices structurally resembles a bow saw, into which a round long file is inserted instead of a saw blade. FG 1 and FG 2 not only sharpen the chains, but also straighten them, adjusting the length of the top edge of all teeth to the same size. on the smallest tooth, which is taken as the control one. A rather complex configuration mechanism allows you to set all the necessary parameters. Sharpening is carried out in 2-3 movements, after which they proceed to the next tooth, keeping for it all the settings that were made for the control tooth. This ensures the same sharpening parameters for all teeth. When sewing the stopper, the round file changes to a flat file.

An electric chain sharpener for chainsaws is simple and convenient to use. It has an adjustment system that allows you to set the chain at the desired angle and bring the disc exactly to the sharpened edge. There are machines that automatically clamp the vice when lowering the disc onto the chain.

Guide for toolholders

Despite the risks applied to the holder, it is sometimes difficult to accurately maintain the angle, especially for an inexperienced user. Therefore, Stihl offers a special guide FF1, which on the saw bar and allows you to precisely maintain the required sharpening angle.

Clamping holder 2 in 1

With the correct sharpening of the chain, two operations must be performed: sharpening the cutting teeth and sharpening the depth gauge. Stihl offers a universal solution. a clamping holder for two files, with which you can simultaneously perform both operations.

Stihl FG 2 chain sharpener

When using this tool, the chain must be removed from the chainsaw. This is one of the most accurate tools you can use to sharpen a chain saw for a gasoline saw.

File parameters for sharpening the chain

The most important parameter of a chain file is its diameter. It is important because, depending on the pitch of the chain, a file of a certain diameter is used. Below is a table that indicates which file is suitable for a chain with one step or another.

| 1/4″(6.35mm) | 1.1-1.3 | four | thirty | 0.65 mm |

| 3/8″ Picco / Micro (9.3mm) | 1.1 | four | thirty | 0.65 mm |

| 3/8″ Picco / Micro (9.3mm) | 1,3 | four | thirty | 0.65 mm |

| 3/8″ Picco / Micro (9.3mm) | 1.3 (for rip sawing) | four | ten | 0.65 mm |

| 0.325″ (8.25 mm) | 1.3 | 4.8 | thirty | 0.65 mm |

| 0.325″ (8.25 mm) | 1.5 | 4.8 | thirty | 0.65 mm |

| 0.325″ (8.25 mm) | 1.6 | 4.8 | thirty | 0.65 mm |

| 0.325″ (8.25 mm) | 1.3-1.6 (for rip sawing) | 4.8 | ten | 0.75 mm |

| 3/8″ (9.3 mm) | 1.3 | 5.5 | thirty | 0.65 mm |

| 3/8″ (9.3 mm) | 1.5 | 5.5 | thirty | 0.65 mm |

| 3/8″ (9.3 mm) | 1.6 | 5.5 | thirty | 0.65 mm |

| 3/8″ (9.3 mm) | 1.3-1.6 (for rip sawing) | 5.5 | ten | 0.75 mm |

| 0.404″ (10.26 mm) | 1.6 | 5.5 | thirty | 0.75 mm |

| 0.404″ (10.26 mm) | 1.6 1.3-1.6 (for rip sawing) | 5.5 | ten | 0.75 mm |

In addition, it should be borne in mind that most files are sold without a handle. It should be purchased separately. This, of course, does not apply to file sets in which most of the files are equipped with handles.

Sharpening roller device Stihl FG4

This sharpening device is installed on the bar, keeping the required angle exactly, and also allows you to check and correct the depth stops on the chain.

What Size File Do I Need for My Chain Saw?

Clamp

In the field, the clamp allows you to firmly secure the tire for precise sharpening.

Sharpening template

In addition to combined templates, Husqvarna also produces regular templates that allow you to maintain the correct angle when sharpening the teeth of chainsaw chains.

Combo pattern

Unlike the combined gauge produced by Stihl, the Husqvarna gauge allows not only measuring, but also sharpening directly. Templates must also be selected according to the chain pitch.

Recommendations for the use of the working chain set

The practice of working with one chain is fundamentally wrong. Experienced sawers are advised to keep several copies in the kit and periodically operate them in working mode.

In this version, uniform wear of the tire and the drive sprocket occurs, the service life of these expensive elements will be equal to the total resource of 3 or even 4 saw chains.

Composition of sharpening kits

The selection of the required round file for the diameter is determined by the chain pitch of the saw attachment. A standard chain sharpening kit consists of several parts. In addition to cylindrical and flat files, the list includes several templates and a headset cleaner.

Both files are used for each cutting link. In particular, cylindrical. the cutting edge of the tooth, the upper and end blades are formed.

A flat file is used to cut the cutting depth gauge. As a result of straightening the cutting teeth, the productivity of sawing wood of different species is significantly increased.

Chainsaw chain sharpening file. features of choice and application

Chainsaw operation with blunt edges of the cutting links of the saw chain reduces the efficiency of the tool by almost half. In the simplest version, the problem is solved by a file for sharpening chainsaws, complete with a guide device.

A simple attachment is inferior in performance to sharpening devices with an electric or mechanical drive, but provides a significant cost benefit. The correct sharpening of the chain with the proper quality can be performed by the operator directly on the working site.

The list of advantages of manual sharpening:

- compactness and low weight of sharpening kits;

- autonomy of work, which allows the circuit to be brought into working condition at a distance from power sources;

- less intensive consumption of the service life of the saw chain.

Wear-resistant chains with carbide cutting elements are recommended to be sharpened only with special equipment.

Alternative options

On the Russian market, there is a wide range of auxiliary equipment that allows you to choose a file or a chain sharpening device of various configurations and price levels. The best quality is distinguished by the products of the leading manufacturers of chainsaw equipment.

A significant part of the proposals is made up of branded accessories for different models of sharpening machines. These files do not have shanks and handles, therefore they are not suitable for manual sharpening. Piece products can be sold separately or complete with templates, mandrels, holders or other optional equipment.

how to sharpen a chainsaw chain with a file

Criteria for choosing a file, taking into account the parameters of the chain

The need to straighten the edges of the cutting links is manifested by a noticeable decrease in sawing performance, increased vibration, output of small chips, the need for additional efforts to enter the headset into the cut.

Files and guides are matched to the chain pitch. The rail mounted attachment ensures the optimum sharpening angle. In the proprietary range of many manufacturers there are simple holders and more advanced roller-type sharpeners.

Storage rules

Files are made from hard but brittle tool steel. The storage and transport of several copies in one box may affect their performance.

As part of the factory sets, the files are provided with optimal storage conditions. It is recommended to keep a set of several separate instruments in a sectional case like a cartridge belt.

Files with a dirty or oily cut can be restored to function by scrubbing with a stiff brush and rinsing in a solution of dish grease remover, acetone or unleaded gasoline.

Advantages of machine and manual sharpening of saw chains

Despite the efficiency, autonomy and other advantages of manual sharpening, experts recommend periodically sharpening chains on special machine equipment. Even a single operation has a positive effect on the calibration of the cutting links.

On the other hand, mechanized sharpening significantly affects the resource of the saw chain, since all cutting links are subjected to standard processing, regardless of their condition.

- In order to sharpen the chain yourself in the field, you need to have strong skills in working with the existing tool. The best option is to keep several chains in stock, which can be changed with minimal loss of working time.

- To properly sharpen the cutting edges of the headset, in addition to a good eye and a firm hand, you need a special sharpening kit, which includes a flat and round file.

Benefits of a branded assortment

In any case, the best result can be obtained using a proprietary chain sharpening tool, the capabilities of which are an order of magnitude higher than cheap counterparts.

The practice of working with the brand tools shows that the products of the leading manufacturers Stihl, Husqvarna, Oregon and a number of others do not differ in quality characteristics.

How to choose a file for sharpening a chainsaw chain

Most users are wondering: how to choose a file for sharpening a chainsaw chain. The answer to it is complex, since implies a lot of options. But the most correct way is to pay attention to the chain pitch. The size (diameter) of the cylindrical file depends on it. But in addition to it, a second is also required. flat.

Two files are used to sharpen different parts of the same link. If we consider the process in more detail, the saw tooth of the link, namely the end and upper blades, is sharpened with a cylindrical file. Cut the depth gauge with a flat file. It is important that both files can be purchased as a set with a set of templates and a hook for cleaning the saw and bar from the saw set. Some manufacturers of chainsaws and their electric chain counterparts even produce similar kits themselves.

Different types of files for sharpening the saw chain

Chainsaw chain sharpening file

- How to choose a file for sharpening a chainsaw chain

- Chainsaw chain file diameter

- Stihl chainsaw sharpening files Stihl

- Correct sharpening of the chainsaw chain with a file

The most inexpensive way to sharpen a saw is to purchase a chain sharpening file and do it yourself without assistance. However, this scenario implies a lot of nuances. You need to know how to choose a file, what characteristics are worth focusing on, learn the sawing technique, and, in the end, have patience, sharp eyesight and firm hands. The last three factors are indispensable, because without them it is impossible to sharpen the correct file with a file.

Chainsaw chain sharpening files

Chainsaw chain file diameter

The diameter of the chain saw file is very important in the selection process. The wrong file will damage the chain and cause problems during the sawing process. The saw can get stuck inside a tree, break off and break expensive tools.

The diameter directly depends on the pitch of the chain. When sharpening, 4 main sizes of diameters are used, corresponding to their step:

Step ¼ “- diameter 4.0 mm;

Pitch 0.325 ″. 4.8 mm;

Pitch 3/8 ″. 5.2 mm;

Pitch 0.404 ″. 5.5 mm.

For some types of chains, files with a diameter of 3.2 mm are also used.

Different diameters of files for sharpening chainsaw chains

Stihl chainsaw sharpening files Stihl

There are various files for sharpening Stihl Stihl chainsaws on the market. Despite the external differences, they are all proprietary. Some of them are accessories for sharpening machines and are sold in packs of several. They do not have handles, so they are inconvenient to use without a base. Individually packaged files may be included in the kit or sold individually. There are 2 options for them. with and without a sharpening template.

In addition to files, Stihl also produces a range of accessories:

filing gauges;

sharpening mandrels;

templates (holders) of different types;

clamps.

The filing gauges are designed to check the depth of sharpening, clean grooves and check corners by hand.

The mandrel is a plate with guides applied on it, indicating the angle of sharpening of the link. By moving in accordance with the guides, it is easier to maintain the correct degree of the angle. It is attached with magnets to a metal rail.

The clamp works on the principle of a holder and allows you to sharpen the cutting and limiting teeth of the link in one step.

Stihl chainsaw files

Correct sharpening of the chainsaw chain with a file

It is easiest to start sharpening directly on the bar, but some manufacturers oppose this, citing various arguments, and recommend removing the chain from the device and securing it in a vice. But this is extremely inconvenient, because the ambassador of sharpening each link has to dismantle the chain and reinstall it.

If, nevertheless, the sharpening of the chain takes place directly on the saw, the tire can move on the weight under the pressure of the hand with the file, therefore it is necessary to install a stop for the tire from the opposite edge, for example, a block of wood. It is important to clean the chain from sawdust, grease and debris before sharpening. This will make the job easier.

Sharpening the saw chain correctly with a file

Begin sharpening with the sharpened tooth itself. It is on it that all the others will be aligned. If the tooth is broken, it must be replaced by riveting the chain with a special machine and installing a new element of the appropriate size and type. After the element is selected, start sharpening. The file is moved straight away from you along the semicircular edge of the saw tooth, resting with the template against the edge of the adjacent chain link. In this case, it is necessary to observe the parallelism between the file and the plane of the surface on which the saw or vise is installed, as well as the angle of the guide indicated on the plate template.

Thus, all chain links are processed in turn through one, i.e. only those that are on one side of it. At the end, they go to the other half of the links and do the same operation, but at the opposite angle, also indicated on the guide in the template. After completion, the file for sharpening the chainsaw chain is set aside, and the chain is swept with a brush, eliminating metal shavings.

Chainsaw chain sharpening angle. How to choose the right one?

Even the popular Stihl does not last forever: once the teeth of a chainsaw wear out, which is easy to determine by the nature of the chips formed. With a blunt cutting edge, the chips are small, because the working edge does not cut, but crumples the wood. Naturally, the effort expended by the operator increases dramatically. It’s time to sharpen the saw. How to do this correctly. choose the optimal technology, establish what angle of sharpening the tooth should be and how to check it?

Chainsaw sharpening angles and tooth configuration

The cutting edge of a tooth is characterized by the following parameters:

- Width;

- Thick;

- Sharpening angle.

In addition, each tool model has its own tooth pitch, the value of which for household and semi-professional models is associated with the power of the chainsaw, and the torque that the drive develops. For example, for rip sawing, the pitch is taken less (for example, 0.325 inches). In this case, the productivity of work will decrease, but the required effort will be significantly lower. The upper values of the steps for household chainsaws are extremely rare, mainly when felling trees with a large trunk diameter. In this case, the motor power should not exceed 2500 W.

The thickness of the cutting edge for most manufacturers of chainsaws is set the same, and equal to 1.3 mm (there are also edges with a thickness of 1.1 mm, but, firstly, they are extremely difficult to sharpen at home, and, secondly, such links are extremely not very functional: they can only be used for cutting thin branches).

The height of the chain profile can be either 0.625 mm or 0.762 mm, and in most cases it is a low profile that is used for household gasoline-powered tools. When sharpening the limiters, this parameter is very important, because with a decrease in the height of the above-permissible values, the vibration of the tool during operation increases, although the quality of the cut remains satisfactory. Therefore, you should not get carried away with lowering the height of the limiter when sharpening a tooth.

The sharpening angle of the chainsaw chain depends on the main purpose of the tool. for crosscut or rip sawing. Since the resistance of the wood is always noticeably higher when ripping, the edge of the tooth must also be very sharp. It is recommended to do it in the range of 6. 12 ° (for comparison. with the prevalence of cross-cut. up to 25. 30 °). Naturally, in the first case, sharpening should be done more often, and especially carefully, since an unacceptably small angle of inclination of the tooth contributes to its rapid chipping during the operation of the chainsaw. This is especially important for links that are made of structural alloy steels containing silicon and manganese, for example, 40KhGS or 35KhGSA.

Chainsaw chain sharpening template

When purchasing a chainsaw, it is advisable to acquire a special template (see Fig. 3), with which you can easily set the optimal values of the tooth angles. With its help, the values of the rear angles of the upper and end blades are controlled, as well as the leading edge angle (it is indicated in the manufacturer’s instructions, and can vary within 65. 80 °).

It is especially important to use a template to estimate the value of the clearance angle of the upper blade. This angle of sharpening of the chainsaw chain is very difficult to determine otherwise, but meanwhile it must be maintained within rather limited limits. from 50 to 60 °.

Measurement of the sharpening angle is performed by determining the angle between the upper cutting edge and a line perpendicular to the chain guide.

The angle of sharpening of the chainsaw chain can be changed, depending on what kind of work will be done. As the hardness of the wood increases, its value should be lower. In general, it is considered the optimal value of the angle 10. 12 °. with a longitudinal cut, and 25. 30 °. with a cross cut.

Figure 3. Appearance of the template for sharpening the teeth of a chainsaw

Sharpening can be done manually using a round file with a working diameter of 4. 5.5 mm, or on a machine. In the first case, it is extremely important to correctly position the tool in relation to the sharpened tooth. The upper edge of the working part of the file is approximately one fifth higher than the upper edge of the tooth. The tool is positioned perpendicular to the chain axis, and at an angle of 25. 30 ° to the upper edge of the tooth

One round file is not enough. You will need a flat file to sharpen the stopper, and a hook that removes the resulting sawdust to clean the work area. There are also special holders on sale, on which the mowing line is graduated with the direction of movement of the file relative to the axis of the chain. As seen from Fig. 4, the holder can be mounted on top of the tooth and rest on its upper edge. Since the height of the holder is adapted to a certain chain pitch, it should be selected in relation to chainsaws of specific models and brands.

The minimum required set in order to obtain the correct sharpening angle of the chain by hand is shown in fig. five.

Figure 5. Set of sharpening tools and accessories

First, the teeth are sharpened in one direction, and then in the other. Start with light pressing of the tool away from you, gradually increasing the load. During sharpening, the round file is periodically rotated along its axis.

External signs of a blunt cutting edge of a chainsaw tooth

Recall that the chainsaw tooth has a complex configuration (see Fig. 1), which also depends on the direction of chain movement. It has two working edges: the lateral one, which is located perpendicular to the axis of movement of the links, and the upper one, located at a certain angle to the direction of movement of the chain. In addition, a limiter is provided on each tooth, the parameters of which determine the height of the removed chips. Since the main cutting force falls precisely on the working angle, then all subsequent work with the tool will depend on which angle to sharpen the tooth.

Figure 1. Functional parts of a chainsaw tooth and their appearance

Before starting long-term work with a chainsaw, she needs to inspect and perform test sawing, as a result of which:

- Visually establish the presence (or absence) of a tapered section adjacent to the corner of the tooth, as well as radius curvature on it. the main signs of bluntness (see Fig. 2).

- Check the feed force at which the tool runs stably, with a fast cut. For sharp teeth, the initial moment of penetration of the tooth into the wood occurs quickly, and without significant material resistance.

- Find out the presence of chain vibrations during a steady cut. if they are noticeable, then the teeth must be sharpened.

- Inspect the appearance of the just cut end (especially if the tool is used for ripping). In the presence of rough chips and dents, the chainsaw chain must be sharpened.

Mechanized sharpening on the machine

Sharpening on the machine is much more convenient and does not require high qualifications of the performer. Such machines are electrically driven and equipped with special grinding wheels.

For a household workshop, it is worth purchasing compact units that do not take up much space during storage, and are suitable for quick and high-quality sharpening of chainsaw chains from different manufacturers. Such units must operate from a stationary power supply with a voltage of 220 V, have low power consumption (up to 100 W) and be easy to install on a circuit.

When choosing a machine, you need to pay attention to its following technological characteristics:

- Possibility of processing teeth with different thickness of the upper edge and different chain pitch;

- The ability to adjust the sharpening angle, within the limits specified earlier;

- Availability of replaceable grinding discs;

- Constant value of the cutting width.

The design of the machine is simple, and includes a drive motor, a shaft with a seat for a sharpening disk, a handle with controls, a device for attaching the machine to a chain. The adjustment of the pressing force on the sharpened element is provided by a spring clamp. Modern models of sharpening machines are equipped with a differentiated clamp, which provides for the self-centering of the product on the machine. For the convenience of working on the clamp body there is a measuring scale.

Optionally, the machines can also be equipped with a miniature electric lamp that illuminates the working area, as well as a hydraulic booster that makes sharpening easier.

Safety of work is ensured by a folding safety guard.

Tooth parameters

The cutting link of the chain of a gasoline saw consists of: a tooth blade, a link base and a depth gauge. The chisel blade has an end blade that is positioned vertically and a falling top blade that is positioned horizontally.

To achieve optimal cutting properties, it is necessary to give the tooth blades certain angles. The back of the tooth, which falls at an angle backward, forms the angle of the upper blade, which is required to cut into the wood of the upper blade. The blade of the tooth, which tapers back, forms the angle of the end blade necessary for side cutting of the chips flying from the chainsaw.

The edge of the end blade with the sliding surface of the links forms a rake angle that varies from 60 to 85 degrees for different chains. The backward tilt of the upper blade is measured in accordance with the sliding plane of the link and depending on the type of saw chain, and reaches 50. 60 degrees. Upper blade. the main blade, and the upper blade angle is the most important angle. The angle of the upper blade is difficult to measure, its correct value is possible if all the values indicated above are observed.

You can change the angle of sharpening of the chainsaw chain depending on the application. The main rule: the greater the value of the sharpening angle, the higher the cutting performance when cutting soft non-frozen wood. When cutting hard and frozen wood, reducing the sharpening angle helps to reduce vibration and a smoother saw blade. But remember that the sharpening angle should not be more than 35 and less than 25 degrees. The exception is chains intended for longitudinal cutting, this angle is 10 °.

Upper blade angle, sharpening angle and rake angle change when sharpening. These criteria have a decisive influence on the cutting performance of the chain. A depth gauge is located in front of the scapula on each link. Differences in height between the edge of the back of the tooth and the edge of the depth gauge are determined as the distance of the depth gauge.

The level of penetration into the wood of the upper blade (chip thickness) depends on this indicator and therefore on productivity. The distance of the depth gauge is set depending on the type of execution and the chain pitch. It should be in the norm 0.5-0.8 millimeters, most often 0.6 millimeters.

High values cause the chain saw to be more prone to kickback, chain vibration and too much grip. Low values provoke a drop in performance. Since with each sharpening of the chainsaw, the distance of the depth gauge decreases due to a decrease in the upper edge of the tooth, the depth gauge also requires periodic filing. after ten sharpenings.

The need to sharpen the saw

Chainsaw chain sharpening procedure. no more difficult than the process of sharpening any cutting tool with special tools. The saw tooth has a complex geometry. Side and top cutting edges, the second of which is beveled in the direction of the mowing line, the movement of the chain at a certain angle makes this operation difficult.

To a large extent, the high performance of a chainsaw is influenced by the correct use of its chain, which must be sharp and sharpened without fail. This is the only way to ensure efficient and safe operation when using it. After all, a properly sharpened chainsaw chain is more important than a powerful engine. The saw must be sharpened after its bluntness, which consists in slow work, and the device also drives to the sides.

Intensive work of the chainsaw provokes a quick dullness of the chain. Sometimes several sharpenings may be required throughout the day. The problem is exacerbated by the fact that the teeth quickly dull when they hit the ground. Even if you hit the ground with a tire once or twice, you can stop working. the shavings will become fine and the saw will stop digging into the wood. The sooner dull teeth are sharpened, the less material needs to be removed during sharpening, as a result, the useful life of the saw chain becomes longer.

General rules for sharpening

Correct sharpening of the chainsaw chain requires following several recommendations. It is strongly recommended to pay attention to them before sharpening the chain. The sharpness of the cutter angle and the height of the cut stop must meet the criteria specified by the manufacturers. In addition, it is important that all links in the same chain are identical in size. Doing so may decrease performance and increase vibration and engine load. Uneven loads increase the likelihood of circuit breakage.

Since the inner contour of the tooth is close in shape to a circle, and the material of the chain is quite soft, it is customary to sharpen the chain with a round file, which has a small diameter. Chainsaw sharpening requires precise positioning of the file relative to the tooth being sharpened.

The top edge of the file should protrude about 1/5 of the file diameter above the top edge of the bit. Immediately before sharpening the chain of a gasoline saw, it is recommended to find out its parameters; it is recommended to choose the file diameter depending on the chain pitch. It usually fluctuates in the range of 4-5.5 millimeters.

When you need to sharpen your saw

Unfortunately, the sharpening of the chainsaw chain in many cases is not carried out in time. users simply do not notice the signs that indicate that the chain has become blunt. Do not cut with a defective saw or a dull chain, which will result in poor cutting results, high cyclic loading, high fuel consumption, drive sprocket and tire destruction. This, in turn, leads to a decrease in productivity, increased wear of all parts of the chainsaw and a drop in the useful life of the chainsaw.

To avoid such problems, pay attention to the type of chips while working. Based on the condition of the chips, it will be possible to determine when you need to sharpen the chain. If it gets darker than before, this is a clear sign that the chain needs sharpening. You can recognize a dull chain if only small chips fly out of the cut instead of a large thick one. At the same time, a lot of dust appears in the shavings, and it looks like needles.

It is enough just to determine the moment when sharpening is needed. An important feature is the feed effort. The target, sharpened correctly, is retracted into the cut even with small presses. If, on the contrary, the chainsaw is forced to cut by increasing the feed force, then the teeth are dull.

Take a closer look at the chain teeth. bluntness in many cases can be seen with the naked eye. You can determine the need for sharpening the Stihl chainsaw chain by the reduced level of productivity. it is more difficult to saw, and the work takes more time from the user.

Electrical equipment, light, lighting

Absolutely all owners of chainsaws will sooner or later face the need to sharpen a chain. This problem can be solved in two ways. to give the chain to the workshop, or to sharpen the chain for a chainsaw with your own hands. With the first solution, everything is clear, but sometimes contacting a service center is impossible. for example, the chain is dull when working in a country house, from which there are hundreds of kilometers to the nearest workshop. In this case, you will have to cope on your own. Let’s talk how to properly sharpen a chain of a gasoline saw.

Sharpeners

A common set designed for sharpening a chain of a gasoline saw consists of a round file, which is installed in a special holder, a flat file, which is necessary for grinding the depth gauge, which provides the last operation of the template for sharpening the chainsaw chain, and a special hook for cleaning the chainsaw from sawdust.

The round file holder has a mowing line that allows it to be positioned correctly in relation to the chain. The holder is installed on the sharpened tooth according to the orientation lines. The insert is supported by the depth gauge and the upper edge of the cutter, and the file is placed under the cutting edge.

The use of the holder ensures that the file will fit to the tooth at the correct height. There are different holders for different chain pitches. The correct choice of the holder according to the correct file diameter ensures that the file protrudes 1/5 of its diameter above the back of the tooth. Only use special files.

How to Sharpen a Chainsaw?

Before hand sharpening the chainsaw chain, you must secure the bar. Select files in accordance with the type of chain, the main selection criterion in this case is its pitch. Round files have a diameter of 3.6 millimeters and are intended for sharpening the cutting bit. For flat files, the width ranges from 4.12 millimeters, they are used to remove the control tooth.

Pay attention to these recommendations that help to sharpen the chain of a gasoline saw correctly:

- sharpening should be done in such a way that 1/5 of the file for sharpening the chainsaw chain protrudes above the cutting edge;

- the tool must be moved not back and forth, but in one direction;

- every 2-3 sharpening of a tooth it is worth sharpening the cut limiter.

Sharpening is carried out in this way:

- pre-set the chain brake, tightly clamping the chainsaw between your knees;

- then place the template in such a way that the “arrows” point to the “nose” of the tire. Do not forget to mark with chalk the tooth from which sharpening began;

- move the file to the side indicated by the arrows, moving away from you and sharpen;

- the control tooth must be removed using a flat file and an onlay. In this case, the direction of movement can be any.

It should be noted that working with a chain sharpening kit for a chainsaw requires certain skills, which is why it is not advisable to sharpen an expensive chain without experience.

Do not try to press too hard on the file, make measured and smooth movements. Rotate the file regularly to avoid one-sided wear. Sharpen all other teeth in the same way. It is more convenient to sharpen the teeth in one direction first, and then do the same with the teeth in the other direction, changing the position.

When sharpening, do the same number of file strokes on each tooth at the same pressure. This results in the same tooth length. All cutting teeth must be the same length. The different length of the teeth causes the chain to run unevenly and cause cracks in it. In the case of unequal tooth lengths, file all cutting teeth to the length of the shortest tooth.

Sharpening machines

Not every chain can be sharpened with a file. If, during operation, the saw has thoroughly plowed gravel or sandy soil, or it has not been sharpened for too long, that the cutting edge has completely lost its shape, sharpening with a file will require too much time and effort. It is reasonable in such cases to use a machine for sharpening the chainsaw chain. Such machines are divided into electric ones, which are equipped with grinding wheels, and manual devices.

The working part of such devices for sharpening a chainsaw chain structurally resembles a bow saw, in which a round long file is inserted instead of the saw blade. The machines sharpen and straighten the chains, adjusting the length of the upper edge of all teeth to the same size along the smallest tooth, which is taken as the control one. A sophisticated configuration mechanism will help you set all the necessary parameters.

Sharpening should be done with 2-3 strokes, then taking on the next tooth and leaving all the settings made for the control tooth. This can provide the same parameters for the sharpening procedure for absolutely all teeth. Change the round file to a flat file when you grind the stopper.

Electric tool for sharpening chainsaw chains. simple and convenient to use. It is equipped with an adjustment system that helps to set the chain at the desired angle and accurately drive the disc to the sharpened edge. There are machines that automatically clamp the vise when lowering the disc onto the chain.

The machine, in fact, performs the same role as chainsaw grinding wheels and gauge, but with higher accuracy. Sharpening is performed as follows:

- Loosen the screw a little to begin with, which adjusts the chain clamp.

- Install the chain in the guide groove in such a way that the links point towards the sharpening stone.

- Then set the desired sharpening angle. The standard value is an acute angle of 300, but other options are possible depending on the use of the chain. Choose polarity depending on the sharpening of the cutter. left-handed or right-handed.

- Sharpen. There are two possibilities. The first of them is sequential sharpening, processing the cutters one after another, but each time in this case you will have to change the polarity. The other consists in sharpening every second cutter: first processing the left-handed and then right-handed incisors, or as it is more convenient for you. By reducing the number of operations, since there is no need to change the polarity every time, the speed of work increases.

In the process of work, it is important to follow some rules. First, the optimal level of sharpening is determined based on the length of the most blunt tooth, which serves as a reference point. Secondly, it is not advisable to sharpen too deeply, because this leads to a decrease in the strength of the link. After completing the work, it is recommended to blow out the chain with compressed air and leave it in clean oil for a certain time.

Now you know what a procedure such as sharpening a chainsaw chain with your own hands is, and what is the price of sharpening a chainsaw chain. The work is not easy, it has its own characteristics and nuances, it requires minimal basic skills, but it is quite solvable at home. It remains only to choose one of the options for the development of events. the use of a file or a hand-held machine.