Drill Rules

Electric Drill Safety

When using a power tool, the following recommendations must be followed for safe operation in order to protect against electric shock, fire and personal injury:

When drilling walls, make sure that there is no hidden wiring in this area. Keep order in your workplace.

Consider environmental influences. Do not use the power tool in a humid environment, near flammable liquids or gases, or in low light. Avoid temperature extremes leading to condensation.

Avoid exposing the power drill to direct sunlight of high intensity.

Protect yourself from electric shock. During operation, avoid touching grounded objects, such as piping, radiators, gas stoves, grounded household appliances, etc.

Take the tool only in isolated areas of the housing. Contact with damaged conductive cables leads to voltage in the metal parts of the housing and can cause electric shock.

Protect the cable from heat and oil, from touching sharp and sharp objects. Do not carry the power tool by the cable, do not bend it. Do not remove the plug from the power outlet.

Avoid accidentally turning on the tool. Do not carry it connected to the mains by touching the switch with your finger. Do not leave the power tool connected to the mains unattended.

When working outdoors, use a specially designed industrial extension cord, labeled accordingly (double insulation). The extension cable must be designed for the power consumed by the power tool.

Wear suitable clothing. Wide clothing, long hair, jewelry can be captured by moving parts of the instrument.

Use a dust mask for work involving dust. If the instrument is running at a higher sound level, wear ear muffs.

Before starting work, inspect and visually check the power tool and the power cord for possible damage, the moving parts of the tool for their functioning. Make sure the keys and installation tools are removed from the work area.

Do not grab the rotating parts of the power tool.

Use clamping devices or a vice to secure the workpiece.

Make sure that all replacement parts are inserted correctly. If the power tool requires installation, make sure it is securely attached to the workbench. Check for other conditions that may affect product performance.

Use only sharp, flawless drills. Never use cracked drills or warped drills, or blunt drills.

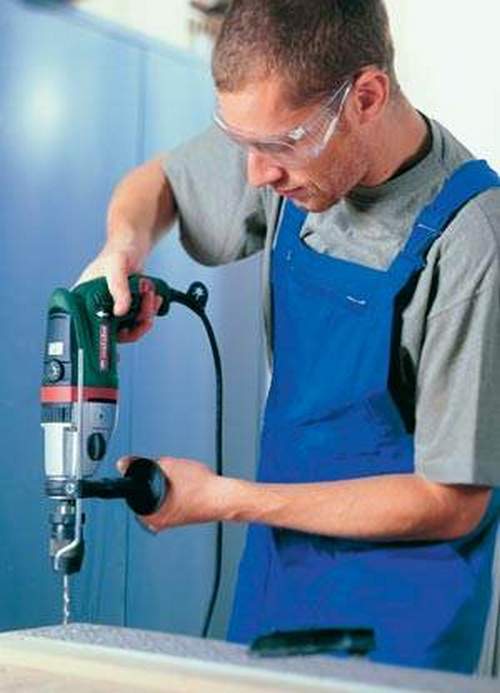

Do not operate with an electric drill without safety glasses and gloves.

Never go with a working drill. Always turn off the drill when moving to another location.

Never use an electric drill for grinding and cutting, even if the interchangeable tool is suitable for the parameters.

Do not brake the chuck (spindle) by laterally pressing on an object.

Repair should be carried out only in specialized service centers using spare parts of the manufacturer.

Adopt a stable body position and always maintain balance. Be careful.

For heavy work, do not use low power machines. Improper use of the power tool can lead to a hazardous situation.

Remove the plug from the power outlet after finishing work when replacing the working part of the tool.

Do not try to modify, improve the power tool in any way. Use of any accessory that is not recommended may result in damage to the instrument and personal injury.

Store the power tool in a safe, dry place out of the reach of children.

Store and transport the power tool in boxes or cases.

Electric drill safety

An electric drill is a tool that is source of increased danger. Therefore, in order to avoid the risk of injury and protection from electric shocks, certain rules must be followed.

Before plugging an electric drill into a power outlet, make sure that the voltage available in the network matches the data indicated in the instructions for the drill (or on the drill itself).

The instrument connection cable must only be connected to the mains when the motor is switched off. It is also forbidden to turn on the tool before contact with the material.

To protect yourself from electric shocks, you need to try not to contact with grounded objects while working with a drill (for example, with metal pipes, heating radiators, stoves, refrigerators).

The electric drill must be protected from rain and moisture, and you can not immerse it in water. Condensation may form on the conductive parts of the device as a result of strong temperature fluctuations. Therefore, before turning on the tool, it is recommended to wait until its temperature is equal to the ambient temperature.

Immediately before working with a drill, it is necessary to ensure the immobility of the workpiece, using a vice or other clamping devices for this. Jewelry and loose clothing can be caught in moving parts of the tool, so don’t wear them. Long hair can be protected with a net or a bandage. Shoes should never be slipping. Protective gloves must be worn on hands.

If the work involves the formation of sawdust, splinters and dust, as well as if work is carried out above the head, you should always wear safety glasses and use a respirator if necessary. If work with a drill is carried out outdoors, then only devices and extension cables specially designed for outdoor work should be used.

During a pause or downtime, as well as when setting up a tool and changing accessories, you always need to disconnect the power drill from the mains.

How to work with a drill

Drill structure

Secrets of working with various materials.

Video: What is Prohibited When Working With an Electric Drill

Crucial in how to work with a drill are drills. There are drills for working on concrete and stone materials, metal and wood. Drills for working on concrete are equipped with an insert made of tungsten carbide (“win”). They are easy to recognize by the tip in the form of a "house" and the designation "NM ST". The diameters of such drills most used in home repairs are from 5 to 10 mm (drills with a diameter of more than 10 mm are already called drills). When drilling a concrete wall, it is best to use the “shock” mode of the drill. There are several rules in working with concrete:

Marking of drill bits for metal is indicated in Latin letters Hss. They are made of hardened steel, and have edges sharpened at an angle. Here are a few rules to help you understand how to use a drill with metal surfaces:

Various types of plastics can also be drilled with a drill for metal, but at the same time it is necessary to use small revolutions, otherwise the plastic will start to burn.

A wood drill has many varieties, but they have one thing in common: the edges are sharpened parallel to the surface, and in the middle of the drill there is a thin awl, allowing the drill to “tilt” the hole on its own. Wood is a softer material and forgives many mistakes, but there are several rules here:

Electric drill safety

What you need to do before you get started.

The entire tool connected to the network must be connected with a flexible, non-removable cable equipped with a power outlet. If the power tool is class 1, this cable must have a separate grounding conductor.

Before starting work, you need to determine the class of the power tool according to its documents, check the reliability of fastening the plug and cable, the strength of the housing, the presence and serviceability of the covers. If necessary, device testing is verified.

For a first-class tool, the reliability of the grounding core is checked. It is forbidden to connect a power tool, such as a cordless drill or screwdriver, to the general network if the working voltage is less than 42 V. Accessories for work can connect personnel with an electrical safety group of at least 3 to the network.

The use of defective equipment or equipment with defects is prohibited.

What you need to remember while working.

During operation, the power drill is turned on only when it is already attached to the marked point on the part to be drilled. If the work is carried out with long drills, the drill is turned off until the part is completely drilled.

Do not remove sawdust or shavings by hand. To remove them, use special brushes or hooks. Wires to the drill must be suspended to avoid contact with metal surfaces, as well as wet or hot surfaces.

It is forbidden in the process of work:

Transfer the power tool to another worker.

Disassemble and repair the tool.

Lift the tool by the wire, touch its rotating parts or remove chips until the rotation stops completely.

It is also prohibited to replace the drills until the rotation stops completely.

Install the cutting tool in the cartridge or remove from it without turning off the electric drill from the network.

Introduce a frequency converter or special transformer inside metal containers or tanks.

Carry out drilling work or others with an electric drill from ladders. To perform work at heights, strong scaffolding or scaffolding must be used.

It is forbidden to work with an electric drill in mittens.

Worker’s clothes should fit the body tightly, the floors are fastened, and the hair is removed and covered with a hat.

Basic rules for drilling with a hand drill;

Manual equipment

Hole Processing Equipment

The following types of equipment for processing holes are distinguished: manual; manual mechanized; stationary.

Manual equipment– this is equipment in which muscular energy of a person is used as a drive; it includes hand drills and ratchets.

Hand drillDesigned for drilling holes manually. When working with a manual drill, the drill is fixed in the chuck, the stationary handle is taken with the left hand and the movable handle with the right. Resting the chest against the bib, with the right hand rotate the handle of the drill. A rotational movement is communicated to the drill through a gear transmission. When working, make sure that the drill is guided exactly along the axis of the hole being machined.

1. It is necessary to firmly fix the workpiece in a vice, and the drill in the drill chuck.

56

2. The handle must be firmly fixed to the drill shaft.

3. Rearranging the handle on different shafts of the drill gear, it is necessary to rationally adjust the frequency of rotation of the drill depending on its diameter. For drill diameters up to 5 mm, rapid rotation is required, and for diameters greater than 5 mm, slow rotation is required.

4. When drilling, do not skew the drill, in addition, you must monitor

perpendicularity of the drill to the drilling plane.

5. When drilling, the drill handle should be rotated evenly, smoothly, without jerking. Pressing the drill stop should be done evenly and continuously throughout the entire drilling process. Deviation from this rule can lead to breakage of the drill.

6. At the end of drilling, when entering the drill from material, it is necessary to loosen the pressure on the drill stop and reduce the rotational speed of the drill.

RatchetIt is used only in those cases when neither a drilling machine nor a drill can be used for hole processing.

Electric drillslight type are used for drilling holes with a diameter of up to 10 mm, medium type. with a diameter of up to 15 mm, heavy type. with a diameter of up to 32 mm. During operation, an electric drill of light and medium type is held in hands.