Wood grinder types of wood grinder purpose of choice

Despite the fact that these mechanisms are used for the same task, it is possible to distinguish several types of designs, very different in principle.

- The band saw is the ideal choice for fast and high-quality processing of large areas (e.g., floor surfaces, walls). The belt is blocked on the guide rollers and moves at high speed (same pattern as with crawler mowers)

- The eccentric sander. stands out from the others by the fact that the work surface is moving and due to rotation, and at the expense of the work of the eccentric mechanism. Its main advantage is that the surface at the output is perfectly smooth (when working with a belt grinder may remain small risks on the tree);

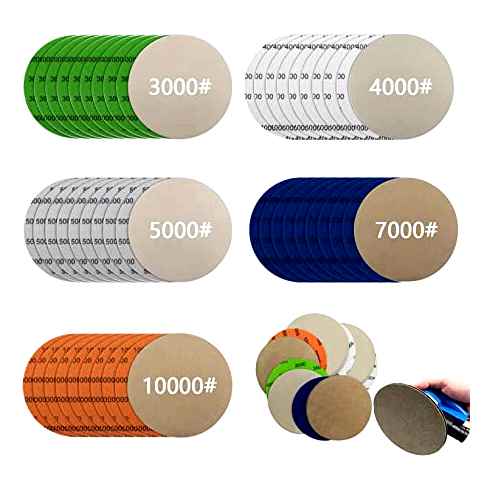

Abrasive grit sizes (sanding/grinding/polishing)

The main units of the eccentric sander

- vibrating mechanisms. in such mechanisms, the work surface performs high-frequency vibrations with small amplitude in the horizontal plane. It uses the rotation of the eccentric. There are no restrictions on their application, have a sufficiently high productivity, so they can be used for both the floor, and for finishing sanding small items;

- often a separate type of vibrating machines with a triangular shape of the working surface (ideal for processing angles in the room). The principle of operation is the same as that of an ordinary wood grinder, and the main differences are in the shape of the soleplate;

- It is also worth highlighting the grinder-sanders. According to the principle of operation. the device is a belt type, but the width of the belt is small, which allows you to work hard-to-reach places;

- In the category of belt sander can be identified and brush sanders. Such a machine for sanding wood is useful in cases where you want to remove a layer of paint or varnish on a wooden product, as well as to give the texture of the wooden surface.

DeWALT DWE6411

Body and ergonomics. The body of this grinder is made of durable black and yellow plastic, so it is difficult to lose even in constant repair and frequent moves. The handle has a comfortable ellipse shape, rubber pads against slipping and is located exactly above the center of gravity of the tool.

Design features. The soleplate is made of aluminum, which provides good heat transfer. It is 108×115 mm in size and is capable of securing the abrasive sheet with Velcro and spring steel clips.

All live parts and bearings reliably protected against dust. There is a small cylindrical dust bag that can be replaced with a hose from a construction vacuum cleaner.

Vacuum bag connection or vacuum cleaner.

The 2.5 meter long cable is reinforced with an additional bend-resistant thickening at the inlet to the enclosure.

Features and functions. The machine is equipped with a reliable American 230 W motor for long hours of work with minimum interruptions. Vibration frequency of 14000 cycles per minute with an amplitude of 1.6 mm is not adjustable, but suitable for grinding of most hard materials.

Accessories. The machine is sold with a dust container and a peorized plate.

- Convenient design.

- Reliability.

- Small size and weight.

- High oscillation frequency.

- Universal abrasive attachment.

- Vibration damping system.

Planogrinding (vibratory) machines

If we take into account the purity of parts processing, flat grinders occupy an intermediate position between belt and orbital. With their help perform finish grinding of flat surfaces, made of a wide variety of materials. plastic, wood, stone, metal Thanks to the relatively large work surface PMM is suitable for work with a serious square. The secret of popularity of vibrating grinders lies in their moderate cost, availability of accessories, as well as in the absence of dead zones of treatment (flat offset soleplate easily processes the corners).

The main working body of the flat sander is the plate, which makes frequent reciprocating movements with small amplitude. Motor in such machines is located vertically, which makes it possible with the tandem “eccentric counterweight” rotational motion of the shaft to translate the translational motion of the platform.

Most of the vibrating grinders traditionally can boast a motor in the range of 150-300 watts, they are quite maneuverable, moderately light and compact. This level of power unit is almost always sufficient. However, such unanimity of producers would be, at least, strange. there are models up to 600 watts (Makita 9046). They are, of course, heavier and larger, but they can run for a long time without overheating at low speeds.

Makita 9046

The most important indicator of the PMS is the amplitude of the sole stroke. It may vary from model to model, although it is invariably a relatively small value. The class-average platform travels 1 to 3 mm, the more mobile models can have 5 to 6 mm (Festool RS 100). A larger amplitude helps you sand the surface faster, but it will also be rougher.

Another nuance. it is the frequency of the sole stroke. At high speed the machine quickly removes a relatively thicker layer, and at a lower frequency it is easier to achieve a fine finish sanding. Some manufacturers make the frequency of movement of the platform variable, exceeding the mark 20000 strokes per minute (Bosch GSS 280 AE L-BOXX), which allows you to adjust to the treatment of different types of materials, the features of specific surfaces.

Bosch GSS 280 AVE

When choosing a vibratory sander special attention should be paid to the platform. With its size, everything is quite simple, there are two options: a kind of “standard” and model “mini”. the area of the plate is about 100 mm 2 (Makita BO4557, Sparky MP 250). The small ones are good for narrow, cramped areas. It is obvious that the sole should be of good quality, perfectly flat and with a clear geometric shape. Budget-priced machines have a steel or high-strength plastic platform, more expensive units have a platform made of aluminium or magnesium alloys (Festool RS 100). A good sole is characterized by accurate balancing, which can be easily determined by a small degree of vibration at work without load (no-load). It is important what is made of the pad, the most suitable option. it is a porous polymer, it is better than rubber, “holds” the plane.

Makita BO4557

In a separate class allocate vibrating grinders with deltoid platform, they are popularly called the “iron” (Hitachi SV12SH, Makita BO4565). Because of their diminutive size and good “passability”, they are used for machining objects with small parts and complex surfaces, such as furniture, joinery, ladder elements, car bodywork. Their triangular platforms can be rotary. you can continue to work with an uneven “eaten away” blade of sandpaper (Festool Deltex DX 93E) or removable (with quick installation of another type of platform. for concave / convex surfaces, for structuring, polishing, rubbing).

Festool Deltex DX 93E

The sledgehammer can be attached to the pad in different ways. It is more convenient when the paper is fixed with Velcro, but the special tooling is relatively expensive. Option with spring clips a bit more complicated, but you can use an inexpensive sandpaper, sliced in-house (it is only worthwhile to make holes in the right places for dust extraction).

Combat with fine dust, which is inevitably formed when working grinder, poses many challenges to the developers. They have to work hard to protect all the mechanisms. In this case a special sealing of the motor, protected bearings and switches, impenetrable housing, channel system with forced dust extraction are used. To remove dust from the work area and not saturate the air, it is directed to the bag-collector or filter, in most cases you can connect a vacuum cleaner to the spigot. this is the most effective method of protection.

How to choose the right sandpaper

What sandpaper to sand the putty under the wallpaper and paint, so that through them did not appear any flaw? Professionals advise the use of sandpaper. But it is also necessary to choose it correctly, depending on the type depends on the final result and the level of sanding. The choice is influenced by the preferences of the finisher, as well as the grit level of the device.

The main difference between the material is the granularity index, the lower it is, the rougher the treatment receive. But also cope, based on this indicator, can sandpaper with different levels of roughness. In the marking this indicator is written with the letter “P”.

What sandpaper to sand the putty decide, taking into account the stage of processing. For the starter fit coarser options, for the finish softer. The process itself is uncomplicated, if the right tool is selected assistant. Having decided on the stage, choose the following types of sandpaper:

- For the primary sanding is suitable variant P120;

- P100 is suitable for working with noticeable irregularities, you should not use types with a lower index, they can break the putty layer;

- P240 is designed for the final alignment of the surface before painting, allows you to remove all the imperfections, so the paint layer will be smooth.

You can also choose to work with an abrasive mesh, it creates less dust, but sandpaper is cheaper and more accessible.

The main difference between the material is the grit size, the lower it is, the rougher the treatment.

Wood sanding machine. Types and features of work

Wood grinder. just the perfect tool to perform finishing work in the country house. It greatly speeds up the process of bringing any wooden surface to perfection. With its help you can clean up the old floor, the wall panelling made of wood and any interior elements damaged over time, including furniture.

You can easily remove old paint with the belt sander

- The delta grinder is considered a kind of vibratory counterparts. It has a triangular sole and is quite convenient for sanding small recesses, corners, recesses;

- another variety. eccentric grinder allows you to process the surface so well that it becomes almost polished. This is made possible by the oscillatory-rotational motion that the plate performs. For processing small areas and internal angles such a device is not suitable.

Deltashlifmashina convenient for grinding small indentations, corners, recesses

Grinding element in this equipment is represented by a belt, which is attached around two rollers. Their movement allows the belt, which is mounted on the soleplate, to rotate at the required speed. Quite an important characteristic of the wood sander is the speed. It depends entirely on the power of the tool. This can be between 500 and 1200 watts. There are models that are additionally equipped with a speed regulator, allowing you to select the optimal level depending on the surface to be treated.

Grinding element of the belt grinder is represented by a belt, which is attached around two rollers

Belt dimensions can also be different, depending on the model of wood sander. The higher the value, the more powerful the tool. But the greater the number, the greater the weight and the overall dimensions of the machine. When choosing a sanding machine, special attention should be paid to the grit size of the belt used. To make the work qualitative and enjoyable, it is worth buying different types of belts with different grits.

Important! Samples of sanders with a belt mechanism are equipped with a special device for collecting excess debris and dust, which appear in the process of work. Some units are equipped with a nozzle to which you can connect a vacuum cleaner.

To make the work of the belt sander was qualitative and satisfying, it is worth buying belts with different degrees of granularity

The quality of the belt used can be assessed by the following indicators:

Flat-torch belt sander allows you to carry out sanding work in close proximity to the wall

For large amounts of work, such equipment is equipped with a special stationary design. These models monitor the quality and depth of finish and are perfect for beginners who have no experience with this type of equipment. Manufacturers can offer a variant of the wood sander, which has flat ends. This specimen allows for sanding work in close proximity to the wall. A good help will be an interesting feature, in which the belt can automatically filter.

Vibratory grinder: possibilities and application

The principle of operation of the vibrating machine consists in oscillatory motion of the surface on which sheets of abrasive material are mounted. They are held by special clamps or other fasteners. Use of such devices can be for grinding of quite a large range of materials: metal, wood, plastic, and, of course, for the removal of stale paints.

The principle of operation of the vibrating machine consists in the oscillating movements of the surface, on which the sheets of abrasive material are attached

The vibration amplitude can be adjusted. For “axing” work the settings of 4-5 mm are excellent, and for finer work 1,5-3 mm. When choosing such a tool, it is worth paying attention to the speed of rotation and oscillatory movements, its power. The ability to regulate these indicators is an additional advantage of the selected equipment.

Delta grinder: features and advantages

The soleplate of this versatile tool is made in the form of a reduced iron. Ideal for finishing surfaces of almost any hard material. Delta sanders are used for restoring old frames and shabby furniture. Due to the presence of a sharp angle on one side of the tool, it can be used in narrow and hard-to-reach places.

The soleplate of this multi-purpose tool is designed in the shape of a reduced iron

Working speed of such tool is rather high. When buying, you should pay attention to models that have a speed control function, as well as a soleplate that can be rotated at different angles. It is possible to attach additional attachments.

Orbital (eccentric) grinders

The main advantage of orbital wood grinders is considered a finer degree of processing. The abrasive material that comes with them can have different grits, which also affects the quality of work. The form of the grinding element in this case is a circle. In these models there is also a dust outlet through tiny holes in the soleplate.

The advantage of orbital wood sanders is a finer degree of surface finish

Similar options are distinguished by a high speed, the number of oscillations. Speed and numerical settings are an additional and much-needed feature that allows you to find the ideal mode of operation for different surfaces.

Multifunction Grinder

This tool is considered an excellent substitute for a wood sander. It has significantly increased functionality. In addition to standard polishing and sanding surfaces, it can:

The multifunction router comes with many attachments, the use of which greatly helps in the work

It comes with a variety of nozzles, the use of which significantly helps in the work. Among other sanding tools, it stands out for its budget price, very small power consumption.

Belt sander (LSM)

A belt sander (LSM) is an electric tool designed for rough sanding of flat surfaces. Most often they are used for sanding putty surfaces and removing old coatings. There are 2 types of belt sander: household and professional. One of the differences is the size of the sanding belt (in domestic sanders are often used belt width of 6 cm).3 cm, with a belt of 10 cm. in professional sanders, which are used by craftsmen working with large pieces of furniture), as well as the soleplate and the effectiveness of built-in dust extraction.

The main parameters that you should pay attention to when choosing a belt sander:

Automatic belt centering system2. Belt speed3. Power (range can vary from 550 to 1200 W)4. Fixed installation capability5. Nozzle for vacuum cleaner connection6. Soft start7. Limiting depth of sanding8. Switch with lockable on position9. Maximum torque10. Quick belt change system

Leading belt sander manufacturers:

Makita2. Bosch3. SCHMIDTMESSER4. Black Decker5. Dremel6. RYOBI7. Skil8. etc.Once you have bought a belt sander you will also need to pay attention to the consumables. the belt (abrasive). We advise you not to save on this material, t.к. it will help you reduce the amount of time you need to work as well as the amount of material you buy, t.е. tapes. When selecting a belt it is worth paying attention to the following parameters: 1. Dimensions (3 types available: 75×457, 75×533 and 100×610 mm)2. Grit3. Stiffness of the material4. The quality of the seam5. Currently, the of LShMs are varied and can range from 55 u.е. Up to 1540 y.е. All this, of course, depends on the manufacturer and the availability of additional options, such as: a handle for left-handed, stationary use, electronic stabilization system and other. Proceeding from this. you need to be careful in choosing a belt sander.

Sanding uneven surfaces is not an easy task. In the past, sandpaper was widely used as a sanding tool, but in our age of high technology method of sanding with sandpaper is a thing of the past due to its low efficiency and labor intensity. Today, to help in the difficult business of grinding come grinders, both belt and vibrating. A variety of machines for grinding is huge, so it makes sense to consider each type separately, and in this article we will talk about the tape machines. We found the most popular belt sanders and help our readers figure out which belt sander is best for you.

Popular entries

LED lighting between the baseboard and the ceiling: the most reasonable solution Most often, two types of lighting are used

The most fashionable request on the topic of lighting in the apartment. “How to install LED strips for illumination.

Ikea bookcases In the age of high-tech, books are increasingly inferior to other modern sources of knowledge

How to properly insulate the floor with expanded clay? Wanting to perform floor insulation in a private home using insulation.

.1. ABRASIVES FOR SANDING WOOD AND COATINGS

Wood and wood materials are sanded with sandpaper, tools based on it and circles. The main features sanding sandpaper are the type of abrasive material, its grit size, density of grains on the base, the base material, glue-bonding, moisture resistance. Sanding belts are most commonly paper- and cloth-backed, made of aluminium oxide, silicon and glass grains. Abrasive grit on the base is poured rarely or tightly. Binding of grit is chosen taking into account the working conditions of the abrasive. Non-water-resistant mesdr glue and water-resistant resins FM-3, FM-4, etc. are used. The density of the filling depends on the capacity of the abrasive and the quality of the surface finish. Rare filling is recommended for sanding wet or resinous wood. The productivity and quality of grinding affects a combination of groups of factors: grit size of abrasive paper, specific pressure, cutting speed and feed, the contact length of abrasive paper with wood.

The sanding sandpaper in preparation for work in belt sanding machines is selected according to width, length, grit and base. The grain size and grit size of sanding pads are defined in GOST 6456-75 for paper base, GOST 5009-75. for fabric base. Cut skins from the roll to the width and length. Glue the ends of the tape at a butt joint, at an angle of 45° or overlap, at right angles. The butt joint of the tape ends is carried out with the help of a cloth pad. After gluing, the seam is clamped in the press and dried. When overlapping tape ends are joined, abrasive grit on one end is washed off up to 100 mm long, glue is applied, the ends are pressed together and dried. On the discs, the grinding belt is fixed around the perimeter with a ring clamp, checking the tight connection to the working plane of the disc. The method of winding and fastening of the belt ends on grinding cylinders depends on their design. The belt must be fastened to the ends of the cylinders using special clamps. An important condition for proper installation of the tape on the cylinders is to ensure a tight adhesion to the substrate.

The abrasive layer on the sandpaper is solid, denoted by the letter C, and relief, which in This standard applies to cones and tubes, made of sandpaper by.

Drying of abrasive sandpaper is carried out in special furnaces where heating is carried out by steam, gas, infrared lamps, etc.п.

For processing small parts make a “sanding machine”: put sandpaper on Put the sandpaper abrasive down on the board and the nail draw a line on the sandpaper for a trimmer.

Pads with sandpaper put on this surface and move them.Sanding pads on a fabric base can withstand longer use.

Buffing sandpaper with different grit sizes is designed for deburring and sanding specific defects on dry gypsum products.

Water-resistant grinding sandpaper according to GOST 10054-75 is used for wet sanding. Sandpaper is a flexible abrasive tool.

angle grinder sanding discs DIY

After deburring or removing of old coatings, it is grinded with fine-grained sandpaper with numbers from 220 to 280.Sanding paper (sandpaper) for.

Tool sharpening on the emery cloth. Sharpening of tools, and not only tools, is feasible on sandpaper. It is glued on a flat surface or attached to, say.

A grinding or polishing wheel is mounted on one end of the rotor shaft, a disc with a sanding sandpaper glued on the opposite end of the shaft.

A rough list of the latter may look like this: nylon scraper; straight and curved scraper; sanding sandpaper; sponge sponge, steel wire sponge.

Sandpaper is a tool on a flexible basis, i.e. on paper or cloth, covered with an appropriate bond (e.g., glue) and sprinkled with abrasive powder.

They are obtained by grinding glass or by “summing” abrasive dust under a working grinding wheel. Soaking non-water resistant sandpaper.

For finishing, it is best to use very fine sandpaper grit 80, 100, 120 or 150. The higher the number, the thinner the sandpaper.

Belt sander ( 16-24) has an endless abrasive belt that is mounted on two circular rollers.Work with sandpaper and polishing paste.

In order to use a belt sander you need, without a doubt, to know how it is built.Sanding belts are a flexible abrasive tool.

On his brush with a metal band clamp is fixed sandpaper on a fabric base. When sanding floors abrasive sandpaper.

Belt grinders. These machines are used for sanding large flat surfaces as well as Sanding sanders flexible abrasive tools.

sand the wheels with sandpaper and varnish them. Put strips of sandpaper on the rims of the wheels. the model will not slip while driving.

5.3. Woodworking. Woodworking includes: sawing, planing, chiselling, drilling, milling, turning, tinning and sanding.

Wood is one of the most versatile materials that people have learned to handle since ancient times. Varied and widely used wood by Russians. Retrieved from: Artistic Woodworking.

§ 40. GENERAL INFORMATION ABOUT WOOD AND ITS PROCESSING. Wood as a building material has been known since ancient times. Historical and geographical conditions of ancient Russia. Found at the link: Woodworking. Wood as a building material.

Basics of woodworking. 5.1. Working tool and its application. Carpentry and carpentry work requires various tools: axe, hammer.

Construction and repair. Carpentry work. in a rural house. А.М. Shepelev. Every year in the countryside is more and more widely developed.

Brushing

Such a device has a roller covered with metal bristles instead of a disc (as on conventional bolsters). The top of the roller is covered by a steel shroud that protects the operator’s eyes from metal and other dust. Also note that the optional handle is not straight, but curved for ease of use of the device. In other respects, it is the usual angle grinder.

Brush sanders are used to remove paint coating and rust. For example, due to the fact that the roller of this device has solid bristles, the device copes better with the cleaning of paint from old iron doors than the same drill with a brush head, which can miss areas of paint. By the way, you can use rollers not only with a metal wire, but also with an abrasive dusting. Abrasive rollers are convenient when working with wood.

What grinder to choose for wood: types, features

Sanders use different types of sandpaper, specifications and output forms. According to the form of release, sandpaper is classified as follows:

- Banding. used in belt-type models, as well as scraping equipment;

- circle. used on “bolsters”, on the back side there is a layer of “velcro”, which facilitates the use;

- triangles and rectangles. used on vibrating type machines;

- roll and sheet. used for a variety of purposes, cut to the required dimensions (platform or pad size) if necessary.

sandpaper varies in shape, base and abrasive material

According to the type of substrate used for manufacture, sandpaper is classified into:

- paper-based. cellulose without chemical additives is used;

- cloth-based. has greater strength than its paper counterparts;

- on a combined basis. cellulose and cloth are used in the manufacture, which allows to reduce the cost and at the same time to increase the strength indicators;

- with the use of Velcro. used in the manufacture of quickly worn discs, used with “bolsters” and vibrating type machines.

The presence of “Velcro” layer makes it easy to replace sanding discs

In addition, for grinding is used abrasive mesh and abrasive wheels, as well as different types of sanding discs for wood, made on the basis of the above-mentioned abrasives.