Lawn Mower What Oil To Pour

The difference between oil for lawn mowers with a 4-stroke engine and the composition used for the manufacture of combustible consistency. Advantages and disadvantages of systems. Oil change procedure in the crankcase.

The internal combustion engines used in lawn mowers are two-stroke and four-stroke. For users, you need to know oil for a lawn mower with a 4-stroke engine is poured separately from gasoline. For a two-stroke engine, a fuel mixture is prepared with the addition of oil. With all this, various formulations are recommended that cannot be replaced and combined.

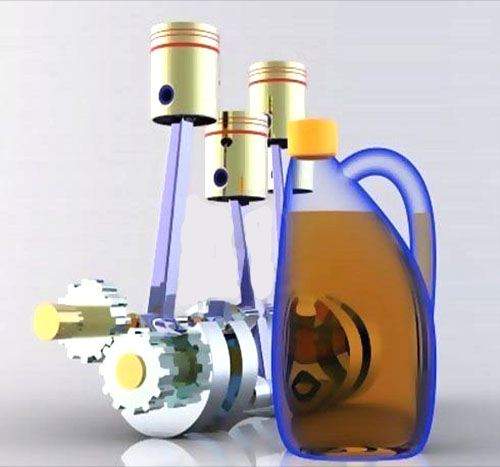

The role of oil in engines internal combustion

The energy transmitted by the motor shaft to the rotating mechanisms comes from the adiabatic expansion of gases at the time of the explosion in the combustion chamber. Due to the movement of the piston in the combustion chamber, gas compression occurs.

This means that the system works with the smallest gaps, abrasion occurs on the mating parts.

The gap between the parts increases, and the compression compression is miniaturized, no suitable pressure is reached for ignition of the fuel-air consistency.

So it would be if the ground parts worked without lubrication. Motor oil for lawn mowers, added to gasoline or falling onto the crankcase assemblies, is applied with a narrow film between the parts, preventing wear and bruising. Because it is unrealistic to completely remove wear, oil washes nanoparticles in the gaps, preventing them from destroying the surface.

The prepared fuel mixture should be consumed within 2 weeks, stored in an iron or polypropylene container. You can not store the composition with gasoline in plastic bottles. Decomposition products will fall into the mixture, soot in the combustion chamber will increase.

The device 2 and 4 of the cycle types is different and therefore the mixture of lubricant and additives in it are different. Each type of conjugated nodes in the mechanisms asks for types of lubricant that correspond to the nature of the movement of this node. Which pour oil in a lawn mower, the manufacturer advises in the annotation for the operation.

You can not fill in oil, guided by the more expensive, the better. The introduction of the ingredients depends on the class of technology on the degree of grinding of the mating units, the criterion of operation.

Composition fuel mixture for two stroke engines It depends on the method of obtaining the base of anti-friction composition. Oil for a lawn mower with a 2-stroke engine has a special composition.

All oils are divided according to the production method:

Their lubricating properties and the ability to remain watery with decreasing temperature depend on this. But 5-15% in each composition is reserved for additives. This they make an effective composition that prevents:

- surface corrosion;

- thermal stability;

- resistance to decomposition;

- increased alkalinity, which prevents oxidation;

- stabilize viscosity.

The lawn mower oil used with the 4-stroke engine has other additives, viscosity. It also serves to wash moving surfaces, but does not mix with gasoline. The oil is oxidized, contaminated with particles of scale and asks for changes every 50 hours of operation.

The difference in the operation of 2 and 4 stroke engines

For two-stroke engines, there are two methods to lubricate the piston system and crank mechanism:

Four-stroke engine mower oil change

Swap Video oils in lawn mower with a four-stroke engine.

Checking the oil and gasoline in a lawn mower

Petrol lawn mowers: Join us on social networks !?

- adding oil to the fuel in the exact ratio;

- pour oil separately, the mixture is formed when the fuel is inlet into the cylinder.

In the photo, the oil supply through the plunger pump dispenser into the inlet pipe of the combustion chamber.

The second scheme has a future, while the first method is used in gardening. the preparation of a combustible mixture. New engines are quiet, economical, but more complex.

To prepare a combustible mixture, you can use the table and the dispenser.

The four-stroke engine has an oil tank, which is used to create protection for the rubbing parts. In this case, the lubrication system consists of a pump, an oil filter and tubes leading the composition to the nodes.

A crankcase or reservoir lubrication method may be used. In the first case, oil is supplied to the system from the crankcase and from there pumped into the supply tubes.

With a "dry sump" drops of oil collected in a sump are again sent to the tank.

In the photo, wet sump grease and dry sump grease.

The difference in oil composition for different types of engines is fundamental. Oil for a lawn mower with a 4-stroke engine should maintain a constant composition for a long time. The composition for two-stroke engines during combustion should have less mineral inclusions in order to prevent the formation of soot.

If you have the recommended oil, you should not experiment with the selection of another composition. If not, select the recommended for 2 or 4 cycle models. Use gasoline above the recommended brand. prematurely go on to replace burned-out valves, other components.

An important characteristic when choosing a protective ingredient is its operating temperature. The additive must be resistant to heat, but not thicken at low temperatures. Therefore, for each mechanism, depending on the operating conditions, there is a brand of oil.

Fundamental differences between internal combustion systems for the user

Which combustion system is more efficient, 2 or 4 stroke? How to understand the user and purchase the best mechanism? There are no gas trimmers and lawn mowers with a 4-stroke engine for sale. The two-stroke is much easier and therefore the trimmer weighs a little and a woman can control it. But there are two-stroke engines on four-wheeled vehicles. Other differences:

- different ways to use grease;

- environmental friendliness is higher with a 4-stroke engine, it is also less noisy;

- easier to repair and maintain 2 stroke engine;

- 4-stroke engine life is longer, but they have more difficult maintenance due to oil change in the lawn mower;

- two-stroke motors are lighter and cheaper.

The 2-stroke engine used in the lawnmower is inferior to the 4-stroke engine in many technological indicators. With a separate supply of gasoline and oil for efficiency and other indicators, it is preferable for light vehicles. In addition, a separate fuel supply saves the expense of an expensive component by 4 times.

In the photo, the condition of the engine that worked without changing the oil for a long time.

The four-stroke engine has a complex lubrication system, and all the more it is necessary to use circulating fluid cleaning methods. A filter is installed in the oil system that prevents clogging of the pipes and pump with scale and other inclusions. As it becomes dirty, this part is replaced.

How to change the oil in a 4-stroke engine

The manufacturer in the operating instructions gives a schedule for the maintenance of the mechanisms and the order of production. Lubrication efficiency decreases after 50 hours of operation. Therefore, an oil change is required.

In domestic use for a season, this time of using the apparatus will not be typed, and the filter must be cleaned, oil must be replaced during conservation.

Before changing oil in a lawnmower, it is necessary to increase fluidity, start the engine and allow the system to warm up.

It is necessary to unscrew the plug to fill the oil in the tank and use the device for taking fluid under vacuum.

To do this, make a nozzle and pump out mining into a prepared container. But at the same time a small part, up to 100 ml still remains in the crankcase and drains from the filter. This residue must be disposed of by draining the liquid for about 5 minutes through the hole.

Change or flush the filter in the system at the same time. After filling in new grease, checking the level with a dipstick. Typically, motor oil is packaged in opaque black plastic so that it does not decompose in the light.

The required volume is 500-600 ml.

What two-stroke engine oil is better to choose: the main properties and composition of different types

There are two-stroke and four-stroke engines. In other words, one cycle is the movement of the piston up and down, but two cycles are performed in one revolution of the crankshaft. It is customary to call a stroke of a piston a stroke at which the piston recovers the energy of gases and fuel combustion to perform useful work.

It is worthwhile to understand the fact that, with similar operating principles, two-stroke and four-stroke engines are still different from each other.

Features of two-stroke engines

The duty cycle of any engine consists of the following stages.

- Inlet. During this period, the cylinder is filled with a fuel-air mixture.

- Compression. The working mixture is pre-compressed in the cylinder.

- Ignition of the fuel charge, as well as the transfer of energy to the piston.

- Exhaust from the cylinder.

In a two-stroke engine, such a work cycle takes place in one crankshaft revolution, and in a four-stroke engine. in two. The working cycle of a two-stroke engine conditionally consists of a combined mixture inlet, compression and working stroke, which do not occur in separate clock cycles (as in a four-stroke cycle).

Under compression the piston rises from the bottom dead center to the top. In the engine, instead of the usual valves, special windows are structurally implemented. When moving the piston up, the purge window first closes, through which the mixture enters the cylinder, and then the outlet window is blocked, through which the exhaust gases leave the cylinder.

Compression of the working mixture occurs when both windows are closed. In the crank chamber, a vacuum is formed in parallel. Due to this, a subsequent portion of the mixture from the carburetor is retracted.

After that, the piston approaches the top dead center, the compressed mixture ignites the spark of the spark plug, and gases are formed that expand and push the piston down.

Energy is transferred from the piston to the crankshaft and its rotation begins.

While the stroke is completed by the piston, in the crank chamber the pressure increases. This leads to compression of the working mixture, which appeared there during the previous measure. After reaching the outlet window area, the piston surface opens and exhaust gases are discharged into the exhaust system.

After that, the piston opens the purge window in a similar way and the mixture, which was in the crank chamber under pressure, enters the cylinder through it, displacing the remaining exhaust gas. After that, the space above the piston is filled with this mixture. After reaching the bottom dead center with the piston, the two-stroke engine cycle is repeated again.

Lubrication system

Two-stroke engines may not have a separate solution for lubrication systems. These motors are lubricated thanks to mixing oil and gasoline in the required proportion (1:25 or 1:50). Such a mixture is not only a combination of gasoline and air, oil particles are also included there.

You just need to remember how the two-stroke engine works, and it will become clear that the circulation of such a mixture in the piston and crank chambers will allow lubrication of the loaded parts of the internal combustion engine (cylinder walls, crankshaft bearings, connecting rod bearings and others). At a time when the fuel mixture burns out, the grease burns out simultaneously with it. After that, the cylinder is blown.

Fuel and lubricant are mixed in two ways..

- Lubricant and fuel are in separate tanks, and an oil-gas mixture is formed in the inlet pipe. This pipe is located between the carburetor and the cylinder.

- Together with fuel, engine oil is poured directly into the tank. This is the simplest solution.

The first scheme is more complex. It assumes not only the presence of a tank for oil and the line through which it will be supplied, but also a plunger type pump. It is thanks to this design that the oil will be dosed and take into account the amount of the mixture of air and gasoline.

If you do not go into details, then it can be noted that the pump will produce more output, depending on how much throttle handle is twisted. The more the gas is twisted, the more fuel is supplied.

This means that the lubricant supply will be increased. On a two-stroke engine, a separate lubrication system allows you to more accurately balance the ratio of gasoline to oil.

This leads to the fact that the engine is less coked and smokes, oil consumption is reduced.

In a four-stroke engine, oil flows under pressure to the loaded parts, and through special channels it circulates. The lubricant practically does not enter the combustion chamber. Only the fuel-air mixture burns in the cylinders.

In two-stroke internal combustion engines, not only air and fuel are burned, but also lubricant. From this it is clear that the requirements for oils will differ. The oil after combustion should leave a minimal amount of carbon deposits in the cylinders, maintain its properties for a long time, mix well with fuel.

Types of oil

Push-pull oil is a separate lubricant for internal combustion engines. These lubricants differ from the rest in their properties. As already noted, two-stroke oils have special requirements.

For gasoline 2-stroke engines oils must have the following qualities.

- The minimum amount of ash and coke that are formed in the cylinder during combustion. The grease should ideally burn out completely.

- It should easily and completely dissolve in the fuel.

- The lubricant must have lubricating, anti-wear, protective properties at elevated temperatures. And it should also protect against corrosion.

If the lubrication system is separate, it is necessary that the oil remains fluid and well pumped. If we take into account the scope and specifics of 2-stroke engines, which serve as motors for scooters and mopeds, engines on lawn mowers, boat motors and others, then there are separate requirements for the toxicity of the material.

If the lubricant enters the soil, it must be as safe as possible for the environment, and when it enters water, it must decompose very quickly.

Such oils must comply with TC-W3 and 2 T. standards. Very often they can be distinguished from their counterparts in color, as they are additionally stained. Mostly they are blue. Even when mixed with gasoline, it can be seen well.

According to standard 2 T, similar lubricants are used in air-cooled engines from lawn mowers and chainsaws to motorcycles (light). But for use in outboard motors with water cooling and jet skis, oils of the TC-W3 standard are designed.

There are low viscosity oils for winter use. Lubricants may have the following basis:

- synthetic;

- semi-synthetic;

- mineral.

Recommendations and tips for choosing

You may notice that in the modern market there is a large assortment of oils for boat engines and other 2-stroke ones. You can also find finished products, in which the oil is already diluted and ready for use. For this, it is poured into a fuel canister, mixed well and poured into the equipment tank.

The properties and price of products can vary greatly. Synthetic oil is more expensive than mineral oil. It is because of this that there are difficulties when buying. It is worth noting that, first of all, it is necessary to navigate when choosing the information that the engine manufacturer indicates.

If it is said that oil of the TC-W3 standard should be poured into the equipment, then anyone that meets this standard will do. In this case, it does not matter that it is synthetics or mineral water. Need to choose reputable brands and beware of fakes.

If the instructions for use separately specify recommendations for oils, it is strictly forbidden to pour in other types of lubricants.

The thing is that initially the engine was designed only to work with the specified material, and if you start using other lubricants, then this will quickly lead to the unit coming out of working condition. Simple equipment, especially manufactured in the USSR, can successfully work on the MS-20. But the imported motor can coke and stop working after a few hours.

It is strictly forbidden to inject two-stroke engines into engines diesel or car gasoline oils, and even more so, "working out."

In such lubricants, a large number of additives, during combustion, they form a lot of ash.

It is worth considering that if you ignore all these rules, then not only imported, but also domestic equipment will break down, which is distinguished by its endurance.

Practical application

From all of the above, it is worth noting that it is necessary to choose a two-stroke oil responsibly. The main task before pouring grease into the motor is to study the operating instructions. If the manufacturer allows the use of various oils, then you can fill in mineral water or more expensive synthetics.

Before infusion, make sure that lubricant meets recommended standards. In practice, the difference between synthetics and Al-Koy miner will be insignificant. But still, on synthetics, the engine can start a little better, and wear out less at high speeds. The combustion chamber may contain less carbon and coke.

But if the instructions indicate that it is worth injecting only certain synthetics, then in no case should you use mineral water, even if it is of the same standard. In this situation, for a number of important parameters, mineral oil will still not work. And all due to the fact that the engine lubrication system for the use of oils with a mineral base is not designed.

Composition

A variety of additives are added to the oils, which is why push-pull and four-stroke are different from each other. In addition to the main components, two-stroke oils include a solvent.

It is thanks to him that the miscibility of fuel and oil increases, pumping and spraying is facilitated. But at high temperatures, solvents (20%) adversely affect lubricity.

Additives increase the viscosity, so you should choose a product with a high viscosity coefficient. this oil is better.

In addition to the solvent, two-stroke oil contains the following substances:

- Oil base. approximately 60%.

- The remainder is vacuum (the result of the primary distillation of petroleum products). 5−17%.

- Solvent. 20%.

- Additives that are used to reduce smoke and soot from the waste product. the rest.

Basic properties

The functions of the lubricants are:

- prevention of corrosion on parts of the mechanism;

- ideal cooling (heat dissipation, which is created by friction of mechanisms);

- preventing scuffing and improving engine wear resistance;

- reduction between friction engine elements to a minimum.

With the right choice and use of lubricant, the engine will last as long as possible.

2-stroke engine oil

Video: What Oil to Pour into a Viking Lawn Mower

Oils for 2-stroke engines differ from four-stroke engine oils in composition and structure. When choosing engine fluid for a two-stroke engine, it is necessary to familiarize yourself with the principle of operation of this type of power units, generally accepted classifications and approvals of manufacturing plants.

Principle of operation

The 2-stroke engine does not have a crankcase, it is lubricated with a mixture of oil and fuel, which completely burns out in the combustion chamber of the engine cylinder. Four-stroke engine fluids do not come in contact with fuel. Due to differences in operating principles, different requirements are imposed on lubricant manufacturers for the properties of motor fluids for 2-stroke and 4-stroke drives.

A 2-stroke engine requires oil, which will completely burn out in the combustion chamber, without leaving sediment and soot. It is important that unburned oil residues entering the exhaust gas are biodegradable.

For four-stroke power units, the main parameter of motor mixtures is viscosity. the ability of fluids to maintain their structure under various operating conditions to ensure the formation of a strong lubricating film on the drive elements.

Standards and specifications

There are 2 oil standards for push-pull drives:

- 2T. used for power units with air cooling;

- TC-W3. used in water-cooled motors.

According to API classification, two-stroke drive motor oils are divided as follows:

- TA. used for motors of small mopeds, motorcycles, lawn mowers;

- TV. for powerful motorcycle engines;

- TS. applicable to motors on land;

- TD. designed for outboard drives.

Engine mixtures for two-stroke engines of motorcycles and other machines are classified by JASO

- FA. meet the requirements of developing countries;

- FB. meet the operating conditions in Japan;

- FC. smokeless motor mixtures;

- FD. smokeless motor fluids with improved performance.

If the fluid is correctly selected, it will extend the life of the motor, otherwise the operational period of using the vehicle will be reduced.

Watch the video about oils for 2-stroke engines:

Viscosity, base

2 stroke engines have design features, to ensure their normal operation, it is necessary to choose the oil corresponding to the viscosity class specified by the manufacturer of the motorcycle, car and other units. Only the manufacturer can specify the optimum viscosity for a particular type of engine.

If the viscosity is too low, the oil will not protect the engine parts from friction. this will lead to wear of the power unit. Using too thick a lubricant worsens combustion processes, increases friction losses, and leads to increased carbon formation.

When choosing between mineral and synthetic motor mixtures, follow the rules:

- Mineral is used in worn motors due to the presence of a large amount of soot in them.

- Synthetics are used in modern drives equipped with an injection or dosage system. Synthetic fluids are characterized by enhanced properties, so pouring them into power units with high mileage is not recommended.

- Observe the tolerances and recommendations of the vehicle dealer.

There are BIO oils with accelerated biodegradation on the market. Their price is 50% higher than conventional lubricants. This cost is due to the ability of the combustion products to completely decompose in water, the additive BIO, which is part of these liquids, does not affect the operation of the motor.

Conclusion

Try to buy lubricants with characteristics that are consistent with the recommendations of the vehicle manufacturer. Incorrectly selected fluid will lead to coking of the piston rings, cause increased carbon formation, and accelerate engine wear.

Fluids with a competent selection of additives, an excessive amount of which (over 20% of the total volume), can lead to a deterioration in the operation of the motor, can result in poor drive performance. Consider: the correct ratio of chemical elements is contained in certified products that meet international standards.

When choosing an oil-gasoline mixture in a 2-stroke engine, pay attention to the dosage indicated by the manufacturer. If your motor should run on a liquid with a ratio of 1: 100, do not use mixtures of 1:50. From your care envy drive resource.

Replacing Lawn Mower Engine Oil

Lawn mower oil: how to change it correctly and which liquid is better to fill

A lawn mower is a very necessary thing for those who need repeated mowing of grass on lawns and other earthen plots. But with the acquisition of this tool, one should not forget that he, like any other mechanism, asks for repeated service.

Gas mowers and lawn mowers. Oil change in the engine of the Honda lawn mower HRG415C3. Preparation of the fuel mixture. Changing the oil in the engine of a lawn mower. One such point is replacement oils.

How to change the oil in a lawn mower, which liquid is better to fill in? You will learn the answer from the article.

Why is periodicity so important?

To begin, let’s figure out how to fundamentally change the oil in a lawn mower periodically. Firstly, this fluid provides air cooling of the mechanism, thereby allowing the engine to operate at maximum speed. Secondly, lawn mower oil protects its parts during storage in the winter.

How often do I need to change the fluid?

It should be noted that the frequency of substitution oils It is directly dependent on the technical condition of the motor. For example, if the engine on a lawn mower is new, then the fluid needs to be changed immediately after break-in.

In time, this is approximately 5-6 hours of operation of the mechanism. So that in the coming different garbage does not penetrate inside and does not accumulate in engine, you need to change the water a couple of times with a frequency of 5-10 hours.

Replacement four-stroke engine oil mower

Video about oil change in a four-stroke lawn mower engine.

. CHANGE OF OIL Husqvarna Lawnmower 4-stroke ??

I have the first 500 subscribers! This video is tied to this number! It is time to serve the gas lawn mowing machine.

If the motor is not new, the lawnmower oil can be changed approximately once every 25-50 hours of operation of the tool. This is an average of 2-3 months of work. Using the mower for any other purpose; Changing the engine oil.

Also condition oils can be found without measuring the number of hours worked. Just make sure that it does not start to get a dark color.

When this happens, be sure to change the fluid, otherwise soon the engine may just jam.

Replacement oils

And now about how to change the oil in a lawn mower. The whole process can be divided into several steps:

- Initially, an ancient fluid is combined.

- Further, the mower turns to its side (to the side where the drain hole is located) for a couple of minutes, until the waste fluid drains one hundred percent. How to change the oil in a 4-stroke engine; Oil change in lawn mowers Oil change c. Then the tool is put back in a horizontal position. With all this, you need to prepare a small container for an old oil in advance.

- Then a new one is poured through the mouth into the lawn mower.

Everything, at this step, the oil change can be considered complete. When you fill the neck with the latest fluid, remember that you need to pour it strictly to the indicated mark in the crankcase.

What kind of oil for lawn mowers worth choosing?

It is necessary to emphasize that a certain type of water and its viscosity are directly dependent on the temperature criteria in which this tool is used. So, if the weather is warm (temperature from plus 5 to plus 30 degrees Celsius), it is recommended to use a liquid of the SAE-30 series.

In the off-season season, experts advise pouring oil for lawn mowers with a viscosity of 10W-30. Changing the oil in the engine of a Stihl lawnmower (Viking. In winter, 5W-30 series fluid can be used.

It is also worth paying attention to Synthetic 5W-30, which by its properties ensures reliable operation of parts lawn mowers at a relatively low temperature.

Run-in and operation of a 4-stroke engine

Before operating the tiller engine (a cultivator, a snowmobile, an electric generator, a motor pump, a lawn mower, etc.), you must read the instruction manual. Many buyers, unfortunately, do not. And starting from the first day of the engine, problems begin.

First: which gasoline to use

We recommend filling gasoline with an octane rating of 92. Air-cooled engines are not designed for use with AI95 and AI98 fuels. The 95th and 98th gasoline contains additives that have a detrimental effect on the piston group of the engine and the valve system, leading to its breakdown.

Use fresh gasoline with a shelf life of no more than 30 days.

Secondly: what kind of oil is poured into the crankcase

Many people consider automobile oil of well-known brands to be the best for use in tiller engines (motor cultivator, snowmobile, electric generator, motor pump, etc.). This is completely wrong.

Car oils are designed to work in water-cooled engines, not air-cooled ones. The boiling point of automobile oils is lower than that of oils that contain special additives for air-cooled engines.

Engine manufacturers recommend filling SAE-30 API SG / CD (for summer) and SAE 5W30 API SL (for winter) oil.

Always keep an eye on the level. The oil level should be at the last thread of the filler hole in the horizontal position of the engine. There are two filler and drain holes on the engine. on each side of the engine. Do not pay attention to the dipstick. It will not provide accurate oil level information.

Engine Oil Fill Level

Different engines have different crankcase volumes. If you have an engine of 4, 5.5, 6.5 or 7 hp. then you need to pour 600 ml. oils. In engines of 7.5 hp poured 900 ml. In engines with a capacity of 8, 9, 11, 13 and 15 hp respectively 1.1 liters.

Third: engine start

At the first or cold start of the engine, an increased load on the piston system occurs. High revs can damage the motor. Therefore, it is necessary to start the engine at 1/3 of the gas position. And run in. at medium speeds.

Fourth: how the engine breaks in

Air-cooled engines don’t like idling. We start the engine, let it warm up for 1-2 minutes. and to work.

During the break-in, do not give a heavy load and take mandatory breaks in work after 20-25 minutes. After a break, when the engine has cooled down (15-20 minutes), you can continue to work again.

In this mode, the engine should run for the first 4-5 hours, after which the oil must be replaced. Break-in is over.

REMEMBER. Engine failures occur mainly from improper operation.

The first cause of failure: an unopened fuel cock

When the engine does not work, and the fuel valve is open, carburetor overfill and spark plugs occur.

The second reason for the breakdown: the engine was turned over during transportation or storage

Since the engine is 4-stroke. gasoline is poured into the tank, oil in the crankcase. and they should not mix. After the coup, these components may mix, the engine will need to be disassembled and cleaned.

And the third reason for the breakdown: improper start by manual starter

Many tiller users think that the more you pull the starter handle, the better the engine will start. This is not true. The starter handle must be pulled until the cams engage, and then gently, but with a large amplitude, pull up. And the engine (if it is working of course) will certainly start.

Good luck to you.

Call 7 (963) 723-00-43. We will be happy to answer questions related to the operation of air-cooled engines Honda, Briggs&Stratton, Mitsubishi, Subaru-Robin, Lifan, GreenField, Champion.

05/14/2013 How to choose an engine for a tiller

The heart of gardening and construction equipment is the engine. And if the engine fails or fails, then it’s time to change it to a new one. This article will help you choose a new engine for your “assistant”.

4-stroke engine oils

The choice of oil for four-stroke engines with air cooling is a separate issue that interests not only motorists, but also all owners of light equipment. It includes motor boats and motorcycles, as well as many options for modern gardening equipment.

Features of 4-stroke engines

First, let’s talk about the differences between water-cooled and air-cooled motors. The temperature of the load on the piston group of the engine in four-stroke air-cooled engines is much higher than their water counterparts, so the requirements for oil quality for "air" grows significantly.

First of all, oils are considered that have the ability to form a protective film immediately upon start-up, even if the engine has already passed the correct run-in and has been put into operation according to all technical standards.

For the ignorant, we dare to remind you that it is not worth using oil for two-stroke engines in four-stroke ones.

In the first case, it is mixed with gasoline before work, in the second, on the contrary, the initial mixing with fuel is not permissible, since the technique has a separate lubrication and protection system for elements that are especially subject to friction.

Four-stroke engine oil graduation

The choice of oil for 4-stroke air-cooled engines is akin to choosing a motor lubricant for a car. The GOST classification has long been adapted to SAE global indicators, so all manufacturers of such lubricants on the packaging write this particular characteristic of climatic and temperature use.

Despite the fact that in winter, four-stroke units are used less, oils for them are produced in a fairly wide range. The following are the unified parameters for choosing oil for four-cycle air-cooled engines, on the basis of which you can easily choose your own, guided by the recommendations of the manufacturer of the equipment noted in the service book.

- 4TD Series Engine Oil. A special development for four-cycle air-cooled engines with diesel or gasoline fuel.

The base is based on polyalphaolefin oils of deep refining of a mineral or fully synthetic nature.

Additive packages are applied to a high-quality base complex, which provide increased protection of the engine against deposits on the piston system and the crankcase, resist coking of the rings and tend to reduce the power consumption of the units.

A feature of this group of oils is its high resistance to thermal oxidation, coupled with increased protection against wear, thanks to extreme pressure additives.

.

Hurry up to take advantage of the advantageous offer!

Mineral oil 4TD

- 4TD Series Engine Oil SAE 30 STANDARD. All-natural mineral lubricant for four-stroke air-cooled engines.

It is indicated for use by equipment at high working and temperature loads in the summer season. It has prolonged protective properties in the temperature range from 10 to 40 degrees Celsius.

Semi-synthetic oil 4TD

- Engine Oil Series 4TD PREMIUM SAE 10W-30. high-quality semi-synthetic oil for four-cycle air-cooled engines with all-weather use.

Extreme climatic working temperatures are in the range from 25 to 40 degrees, which allows to expand the scope of application. The main difference from mineral oils is the instant formation of a protective oil film between all rubbing parts of the engine immediately upon start-up.

The good structure of the base allows it to withstand high temperature deposits and oxidations.

Synthetic 4TD Oil

- Engine Oil 4TD Series ULTRA SAE 5W-30. fully synthetic lubricant for four-stroke air-cooled engines, made on the basis of special oils with a frost-resistant formula.

Refers to multigrade oils with operating temperatures from 38 to 50 degrees.

A distinctive feature of synthetic lubricants of this class is an easy start and quick warm-up of the engine with increased protection (completely eliminates overheating in any weather) in the on / off active mode.

In addition, they have excellent anti-seize performance even when operating in an aggressive environment and constant overload. Reducing wear and protection against deposits of various nature, allows you to use light equipment for a long time, however, oils significantly reduce the power consumption of the power unit, which is beneficial for the owner.

We tell you how to prepare a gas generator for winter. AvtoDela edition, September 2014 | Press about us

Most electric gas generators are bought as a backup power source for a country house and homestead. As a consequence of this, the technique is used for the most part occasionally, only at times of power outages. It often happens that the generator turns on only a couple of times a year and for five years the factory oil does not change at all.

At the same time, many users store generators and other gardening equipment in the far corner of a damp garage, often filled with fuel. Or they store gasoline, especially for the generator, for many years, without spending it, in cans. Because of this, mainly problems arise in operation.

And when you have to get the gas generator for use, it is often not possible to start it or start-up can be much more difficult.

Typical malfunctions of this method of operating a gas generator: carburetor corrosion, valve freezing, spark plug contamination, etc.

But after spending only half an hour a year (!) You can get rid of problems and have a mechanism always ready for operation.

To service the generator independently is within the power of everyone; special knowledge and a professional tool will not be needed for this. All 4-stroke engines of garden equipment are similar in design, and once you service one generator, you can also work with a lawn mower or snow blower without problems.

The first thing to do at least once a year is an oil change. If the oil has not been changed for several years even once (and this is not uncommon!), Then flush the oil system. To do this, it is quite possible to use a car wash, for example: Liqui Moly Oilsystem Spulung Effektiv.

Rinsing with this will require very little 30-40 grams, because the oil capacity in the generator on average is only 600 ml. The rest of the flushing can be used in your favorite car. The sequence of actions is as follows: start and fully warm up the generator, open the filler neck and fill in the flushing.

Next, start the generator again and let it run without load for another 10 minutes. Drain and pour fresh.

The choice of oil must be approached carefully and read the instructions for the unit. However, it often happens that the instruction is lost at the time of unpacking the freshly purchased generator.

What to do, because we read the instructions when nothing else helps. And the generator is not a car, pounding on wheels and wiping headlights with it does not work.

Then decide for yourself whether you intend to operate the equipment only in the summer or all-weather.

Liqui Moly Rasenmaher-Oil SAE 30, a summer mineral motor oil specially for air-cooled engines, is suitable for summer operation.

This oil is characterized by outstanding stability at high temperature and the correct viscosity, specially selected for engines of power equipment.

After all, such engines do not have an oil pump, and the lubricant is supplied to rubbing surfaces with a special scoop on the connecting rod bearing cover and spraying onto the cylinder walls.

For all-weather operation of the generator, Liqui Moly Universal 4-Takt Gartengerat 10W-30 oil is not only for all-weather use, but also universal, that is, for generators, lawn mowers, and snow blowers. over, both for gasoline engines and for diesel engines, although they are few. By the way, the canisters are equipped with a filling tube and an additional funnel is not needed.

Corrosion protection of moving parts

After changing the oil, lubricate and protect the moving parts of the generator, fasteners and ignition contacts from corrosion. Best for this is Liqui Moly LM-40 Spray, a penetrating multifunctional lubricant.

The preserving and protective effect from the use of the product is up to a year, and you can operate the equipment in normal mode. The spray displaces moisture, lubricates, eliminates jams and creaks, cleans and protects rubber and plastic. The composition is ideal for the protective treatment of electrical contacts.

The spray can purchased to service the generator will come in handy more than once in everyday life, in the household.

Rodent protection

It is necessary to pay attention to protection against rodents, in nature they are abundant, they can run into the garage and into the house.

Inexplicable but the fact! Mice and rats are very fond of gnawing insulation on wires, and the fact that they can die from electric shock does not stop them at all! Liqui Moly Marder –Schutz-Spray is an aromatic compound that suppresses appetite in rats and mice to protect wires and scare away rodents. It protects guaranteed for two weeks, for the extension of the effect will need additional processing. This drug is also useful for protecting electrical wiring.

You can complete the list of necessary chemistry with a gasoline stabilizer. Since the fuel is stored in the generator tank and is not consumed immediately, gasoline, especially the modern EURO 4-5, oxidizes and loses its octane number.

After six months, gasoline in general may lose the ability to ignite from a spark of a candle and will be suitable only for igniting a barbecue. And the generator’s power system, the carburetor, is not good for a long time and without protection is simple.

To stabilize gasoline and protect the entire power supply system from corrosion, Liqui Moly Benzin Stabilisator, which, incidentally, is approved by leading manufacturers of power equipment, will help.

Before you remove the generator on a “combat duty”, fill the tank with gasoline and pour 5 lm of additives for every 5 liters of fuel there. Then, we start the engine for a couple of minutes to spread the “potion” through the system and turn it off.

Now the generator can again be pushed into the far corner of the garage in anticipation of another public accident.

P.S. And if the generator service cannot be started because it simply does not start, then use the aerosol to quickly launch Liqui Moly Start Fix. A couple of seconds of spraying, five seconds of pause and pull the cord. The engine will work even with a filled candle or in severe frost, it is important not to overdo it and not pour half a bottle into the filter at a time.

About how to prepare a gas generator for the winter, says a technical specialist at Liqui Moly, Dmitry Rudakov.

The following auto chemical compositions and oils were used to process the gas generator:

Fast flushing of the engine LIQUI MOLY Oilsystem Spulung Effektiv is used to effectively clean the engine when operating in private traffic jams, with aggressive driving styles and exceeding the standard oil change interval. It does not require special training.

A 300 ml flushing bottle is used per 5 l of oil.

LIQUI MOLY Oilsystem Spulung Effektiv allows you to clean the engine even of complex contaminants in the conditions of tough operation and exceeding the oil change intervals, which prevents a whole range of possible problems, the elimination of which can be very expensive.

Using an enhanced package of engine oil additives, it effectively dissolves deposits and complex contaminants without clogging the oil receiver, channels and ducts of the oil system. Significantly reduces non-leaking residue and extends the life of new oil

Thanks to a package of protective motor additives, it safely cleans the engine and forms a protective layer that reduces friction

The composition contains a complex to care for the rubber parts of the system and completely leaves the system with old oil. Unlimited suitable for both gasoline and diesel engines

HOW TO USE THE COMPOSITION

The LIQUI MOLY Oilsystem Spulung Effektiv cleaner must be added to the heated oil before changing at the rate of 300 ml of additive for 5 l of motor oil. Then start the engine and let it idle for exactly 10 minutes. MOVE TO THE FILLING OF NEW OIL YOU CAN’T! Next, drain the oil, replace the oil filter. Pour fresh high-quality oil.

Means for stabilizing the properties (preservation) of LIQUI MOLY Benzin-Stabilisator gasoline for lawnmowers, garden motor vehicles and other equipment on 2- and 4-stroke engines allows you to save fuel properties and protect parts of the equipment from corrosion and deposits during storage. The latest developments in the field of fuel additives have been used.

Convenient packaging with a LIQUI MOLY Benzin-Stabilisator dispenser allows you to accurately measure the required amount of additive for the available volume of gasoline.

The complex of antioxidants and anticorrosive additives included in LIQUI MOLY Benzin-Stabilisator preserves gasoline from tarring and falling octane number. Corrosion inhibitors create a layer of polar molecules on metal surfaces, which prevents the attraction of water molecules to surfaces.

The drug: prevents oxidation, tarring and aging of the fuel, prevents the octane rating of gasoline from falling, has a long-lasting effect, increases the reliability of operation of the equipment.

The use of LIQUI MOLY Benzin-Stabilisator gasoline preservation agent avoids problems with the oxidation of oil and the fuel system of the garden and other 2- and 4-stroke equipment during storage.

HOW TO USE THE COMPOSITION

LIQUI MOLY Benzin-Stabilisator add 25 ml of the product per 5 l of fuel to the tank and start the engine. Allow it to idle for approximately 10 minutes. The additive mixes with fuel on its own. After that, you can turn off the engine and put the equipment in storage.

LIQUI MOLY Start Fix is designed to easily and quickly start all types of 4- and 2-stroke gasoline and diesel engines, as well as rotary piston engines in case of problems with starting due to batteries, wet candles, cold and wet weather, etc. d.

HOW TO USE THE COMPOSITION

To start gasoline engines, spray LIQUI MOLY Start Fix directly into the air filter or into the intake manifold and immediately start the engine. To start diesel engines, it is necessary to turn off the glow plugs and heated flanges, open the throttle fully, spray the agent into the intake manifold and start the engine.

LIQUI MOLY Marder-Schutz-Spray. protects against rodent damage to wires, rubber and plastic products in the car, preventing expensive repairs. A mixture of odorous substances repels rodents, but is absolutely harmless to the environment and animals. Process all plastic and rubber parts from all sides. Repeat treatment every 14 days.

In the event of a risk of damage to car parts by rodents, it is necessary to treat LIQUI MOLY Marder-Schutz-Spray with all available rubber and plastic parts of the engine compartment and wheels. Spray on all plastic and rubber parts. After 14 days, repeat the treatment.

In addition to good results, LIQUI MOLY LM-40 was remembered for a very pleasant vanilla smell, and if you are going to use a similar product at home, it is better to use LM 40 than to “taste” incense of a mixture of solvent with kerosene and other chemicals. As for the tests, here the drug showed good results, which allowed staking a place in the middle of the tournament table. The average turning moment was 8.96 kgf / m, which is almost 2 kgf / m below the initial moment.

ADVANTAGES: pleasant smell, good performance in the test.

DISADVANTAGES: with this attachment of the nozzle of the atomizer, the latter is very easy to lose.

OVERALL ASSESSMENT: the habitat of LIQUI MOLY LM-40 is not only the trunk of a car, but also a shelf in the house.

LIQUI MOLY Rasenmaher-Oil 30. summer engine oil for 4-stroke lawn mowers, power plants, motor cultivators and other equipment.

Provides excellent engine cleanliness and excellent anti-wear properties. The high content of additives provides excellent lubrication and prolongs engine life.

Protects against corrosion even under severe conditions. Tested for compatibility with the catalyst.

HOW TO USE THE COMPOSITION

LIQUI MOLY Rasenmaher-Oil 30. specially designed for 4-stroke engines of lawn mowers and engines for which the use of oil with viscosity SAE 30 HD is prescribed. Should be taken into account when applying the prescription to automobile manufacturers and motor manufacturers.

COMPLIANCE AND TOLERANCES

API SG; MIL-L-46 152 E

LIQUI MOLY Universal 4-Takt Gartengerate-Oil 10W-30 is a multigrade 4-stroke engine oil for agricultural machinery. created based on the latest technology. Exceeds the requirements of motor manufacturers like Briggs & Stratton, Honda, Tecumseh, etc.

HOW TO USE THE COMPOSITION

When using LIQUI MOLY Universal 4-Takt Gartengerate-Oil 10W-30, the recommendations of engine manufacturers and manufacturers must be observed.