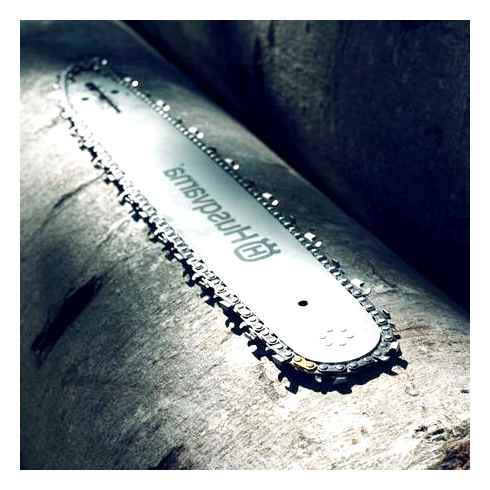

The chain on the chainsaw was stretched out what to do

You can shorten the chain of the chainsaw with your own hands using simple tools. This method is less reliable, but easy to use, does not require special skills in working with cloth equipment. Disadvantage. you cannot control the strength and quality of crushing rivets. This can lead to a breakdown of the tool with serious loads.

What tools will be needed for repair at home?

You can work with the help of the most affordable tools. Depending on the skills and skills, it may be required:

Some masters also use an electric welding machine. It is not recommended to use it, since the seams after welding quickly become unusable under the influence of vibration during intensive work of the chainsaw. This method is suitable only for gearbox chains that transmit efforts to the leading star.

Removing rivets

To disconnect the links, it is necessary to apply physical effort, since high.quality steel is used to manufacture the headset. Before starting work, the circuit is firmly fixed in a vice in order to avoid injuries during the removal. Stack the protruding part. Do.it.yourself rivets itself can be removed in the following ways:

Continue to grind with emery until the jumper. Attach the beards, hide the metal with a hammer. Stream rivet corner grind. Disadvantage of the method. you can damage the chain itself

Work should be carried out carefully, periodically wetting the area with water. After squeezing the chain in the vice for the guides, cut the rivets with a chisel

If you need to increase the number of links or remove one of them, then you need to remove at least two rivets (left and right). When using a corner grinder, the metal can heat up, so after grinding you need to wait for cooling or work in protective gloves.

Connection of links

You can purchase a new link for any chainsaw model in any specialized store, remove it from the old headset. The use of donor spare parts is not recommended, since the quality of the cutting canvas is reduced from this. Installation technology:

- Install the link with new rivets on the chain. Put on the anvil with an open side up.

- Put the top plate on the rivets, stick a hammer for a tight connection several times.

- Attach the beards on the rivet, make 1-2 strong beats with a hammer. Achieve a pronounced thickening, flattening metal. Repeat the operation on both sides of the link.

After work, it should be checked that the chain is mobile, all its elements go freely in different directions. This avoids jamming during sawing.

How to dress and pull the chain correctly?

Before starting work, you should put on gloves to avoid cuts about sharp teeth. Only a cold chain can be pulled. after cooling, it can burst from overvoltage, damaging the mechanism

Remove the protective casing from the chainsaw, carefully put it on the tire

Depending on the configuration of the tool model, the tension is given manually or using a special regulator. In the first case, you need to loosen the bolts on the tire, after installing the circuit, give the voltage using a slotted screwdriver. If there is an adjusting bolt, then turn it all the way until a sufficient tension of the canvas appears. After work, check the absence of sagging, be sure to tighten after the first operation.

Constructive features of tensioners of chainsaw chains

To adjust the degree of tension of the chain on the chainsaw, the design of the tool has appropriate adjusting screws. The first two screws, through which the tire is attached, allow you to carry out a rough setting of the degree of tension.

To set the exact tension of the headset, the tool design has a special screw. This screw is connected to the tire tension mechanism, during the rotation of which a more accurate setting is carried out. To ensure gross adjustment, it is necessary:

- To strengthen the stretch, it is necessary to move the tire away from the asterisk.

- To loosen the tension, you need to move the tire to the side to the leading star.

The mechanism of the chain tensioner has a simple design consisting of a screw with a thread on which a spike and a gear are located. This spike is included in the hook on the tire, and affects it when moving the screw. The gears are designed to transfer the force when rotating the adjusting screw to the screw. The simplicity of the design of the adjusting mechanism affects its reliability. On a chainsaw, this mechanism is extremely rare, but even if this happens, then the part is inexpensive.

The tension mechanism on the chainsaws of different manufacturers can differ in design, only the principle of operation for all devices is the same. The difference in the design of the mechanism affects the location of the adjusting screw, which can be located on the side (the most common option), from the end part or below. over, the screw hat can have a direct shape for a slotted screwdriver or hexagon.

Reasons for the stretching of the chain and why it needs to be shortened

The chain, regardless of whether it went along with the chainsaw in the kit or was bought separately in the store, stretches. This is partially due to its composition, and partially. with the structure of the chainsaw itself. And in this case, the first follows from the second.

The saw chain works together with the leading star and tire. If the chain was made of solid metal, then it would not have reached its stretch. The star would have to be replaced much earlier, in fact, like the tire. Therefore, the chain is made of soft metal.

But still why stretching occurs? The star and chain have a size called step. When the tool is new, these steps coincide in both elements. Working, the star begins to wear out, and the chain. stretch out under, so to speak, its new step. By the way, a driven star is also located on the tire, which has a similar problem over time.

Other reasons that somehow affect the length of the chain:

- When the metal heats up, it stretches. And this, in turn, occurs due to the breakdown of the oil pump, when the oil supply either stops altogether or occurs in insufficient quantities. Therefore, after each filling, it is necessary to check how much oil enters the working surface. To do this, during the operation of the tool, you need to bring a blank sheet of paper on which oil traces should remain.

- Low.quality lubricant, which some owners replace at all, can not only lead to stretching the material through its overheating, but also dull the cutting teeth.

- Earth, dirt, dust-all this directly affects stretching due to wiping the connection place of the links.

Nevertheless, even if all the rules are observed, the lubricants of the highest quality, the stretching of the chain is a natural and inevitable process, with the only difference being that with proper use this will happen later. Therefore, shortening the chain is also a kind of inevitability. And it is necessary to resort to it when it makes no sense to regulate the chainsaw. Shortening helps to increase the operational time of the tool.

How to install a tire with a chain on a chainsaw?

Often the obstacles of the chainsaws appear when the tire is incorrect. This can be found according to the appropriate rattling, vibrations and low sawing of saw in working hours

The tire attachment to the case is between the external plate, fixation is carried out by a special bolt.

The people call this part “engine knot”, it consists of a drive star and stop bolts. It is not difficult to install the tire, coupled with the saw, it is necessary to remove all the protective covers, unscrew the fixing bolts on the third part of the length and put the headset. Then tightly pull all the nuts, twist the tensioner with a special lever.

A step.by.step installation algorithm

Not all modern chainsaws are equipped with a installation wheel, which significantly simplifies the installation procedure of a saw canvas. Systems with a installation wheel among household chainsaws are generally a rarity

Therefore, it is very important to know the technology and sequence of installation of the chain on the chainsaw

The main points should be paid to:

- Prepare a flat surface on which you will put together a chain and a tire. This will minimize the chance of damage to the chainsaw or loss of small details. A tire is laid out on the prepared surface and a chain parallel to the next parallel.

- Remove the protection of the sprocket, on modern chainsaws, it is enough to unscrew the lamb nut, on older models, you may need a unit key of the corresponding size.

- At the base of the guide tire, turn the stretch asterisk to the right to the right. Only in this position is the chain set.

- Then the chain sequentially the link behind the link is placed on the fixing groove on the guide tire. Install the chain from the top of the guide, gradually turn it so that the tire is always on top, and the chain from below, this will always be in a stretched state and go to the guide groove without problems. When you perform this item, be sure to put on thick protective gloves, because your fingers will touch the cutting edge. If you look from above, then the cutter is always located forward by the end of the guide tire.

- And put on the tire and chain on the leading star.

- Fasten the cover of the chain star in your place. Make sure that all mounting pins coincide with holes. Incorrect installation with distortions or not to the end may be the cause of extraneous noise, rattling.

- Make sure that the guides “go” into a special mounting gutter.

- After installation, check the fixation of the chain on the chainsaw and on the tire. Everything should be reliably fixed without backlash.

An important point is the degree of tension of the circuit after installing it. Setting the correct tension is very simple and will take no more than three minutes. First you need to loosen the nuts on the protective cover. Using a freely rotating adjusting screw, catch the correct tension so that the chain does not pull from the edge of the guide tire of more than 3-5 mm.

It remains only to tighten the nuts and control the tension. If you need adjustment, to set the tension again.

How to install a tire and a chain on a chainsaw, watch in the next video that presents a clear algorithm of actions:

The order of work

Before talking about how to pull the chain of the chainsaw, it is important to designate several simple rules. Firstly, maintenance must be carried out when the engine is turned off and without the risk of its random launch

Secondly, all work is carried out after cooling the tool. The fact is that the hot saw chain has a large length than cold. If you start a stretch, then there will be a risk of tightening and deformation of the tire after cooling.

Remember security! Put on protective gloves so as not to cut your hands with sharp links in the chain.

If the saw set is installed recently and has slight wear, it makes no sense to change the chain. It is enough to adjust its tension. What are the signs of insufficient tension? In the lower part of the tire, the circuit sags, in the upper. it shifts to the side. This leads to a skew during sawing, which means that it affects the service life of the tire. it wears out unevenly. In addition, insufficient tension of the chain increases the risk of its jumping from the tire and is the cause of increased wear of the saw blade and a drive star

Since it is correct to pull the chain of the chainsaw. does not mean just getting rid of its sagging, it is important not to pull it yet. The difficult course of the canvas in the tire helps to increase the load on the engine and other work nodes of the tool

Try to scroll the chain around the tire with your hand. If this succeeds, it needs to be loosened.

It’s important to know! Most often, the tension requires a new chain, since it has the ability to stretch at the beginning of operation. Constantly check its tension and, if necessary, adjust

So you extend its service life and reduce the wear of other important details of the saw.

To replace the saw canvas, you should release the tire and remove the old chain. To do this, weaken the fasteners of the lid, which holds the saw set, remove the chain from the asterisk and remove the equipment. The new chain should have the same sizes as the old. It is installed on the tire in the longitudinal groove by leading links. The free end of the chain is attached to the asterisk. Be sure to make sure that along the entire length of the headset the links entered the groove. Install the tire on the pin at the mounting site to the tool. Close this knot with a lid and fix the tire. For this, screws or a rotary regulator are used.

Tip: In order for the tire to wear out evenly, it is recommended to turn it over. change the upper and lower part. You can navigate by the inscription on the tire. For example, if the letters were located correctly, when replacing the inscription should be upside down.

The instructions for the tool should describe how to pull the chain of the chainsaw correctly. However, there is no way to use it. Therefore, we will talk about the sequence of actions when servicing saws with different types of chain tension.

Traditional chain tension using a tool. You will need a standard key, which is usually included in the setting set of a chainsaw. On the one hand, he has a working part to unscrew the nuts, and on the other. a slotted screwdriver. First you need to loosen the nuts on the lid, which closes the tire fastening place. Then insert the screwdriver into a special groove and rotate it to stretch the circuit. Do not be zealous. it is better to pull the chain gradually. Make several revolutions. to control the tension with your hands, pulling the chain in the lower part of the tire. After the adjustment is completed, you need to tighten the nuts on the lid.

Non.conductive tension of the chain. This method is simpler and faster. On the side of the cover there is a adjusting screw for tensioning the circuit. Rotating it, you control the decrease in the sagging of the chain.

How to understand that the chain of the chainsaw is stretched correctly? It should not sag from below, and when it is delayed, the internal teeth should exit the tire groove by no more than 4. 6 mm

It is important to make sure that the chain is not pulled. To do this, scroll it manually along the tire in the direction of rotation, as when sawing

If the move is light, then you did everything right. It is believed that it is better to almost reach the chain than to pull it. In the process of work, this will be quickly discovered and adjusted. But the difficult course of saw equipment is not immediately noticeable and has a pernicious effect on the engine. Performing the maintenance of the tool with your own hands, you will know how to stretch the chain of the chainsaw without the risk of damage to its working nodes. As soon as you achieve optimal tension, you can fix all the fasteners and turn on the tool. Let him work at idle, without load. Then drown out the engine and make sure that the chain has not flown and did not sag. Such a tool can start working.

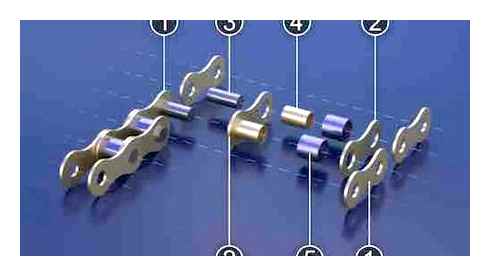

Tools necessary for work

Starting to the rivet, the first thing you need to remove the link from the chain, for this you need to plug the rivets. To rivet, you will need an anvil, a hammer, thin beards, a vice, an angular grinder with a grinding circle or a sandpaper. These tools do not allow you to work efficiently, but they will find them for everyone. A more cultural and careful way to remove rivets using a special punch.

There are several designs of the breakdowns, we will talk about the most popular.

Rubber for rivets

Punch. a machine used to remove rivets.

Your CHAINSAW CHAIN is TOO TIGHT, here’s how to tell

It is mechanical, works on the principle of the press. The kit has a special anvil in which grooves are selected for installing a headset with a different step. There are also interchangeable tips, which are squeezed out of the rivets.

Important: the size of rivets in different types of chains differs, so when buying a breakdown machine, make sure that there are several tips that are used for different types of headset.

We suggest watching a video that shows how to flan out a saw chain using a mechanical punch.

After the chain is flared up, it is necessary to remove the old link, install a new one and stuck. For this, the machine is used to rivet. It is electric, so it costs much more than a breakdown machine.

The rivet-probe machine

A gearbox with a high torque is installed on the machine.

It is used for riveting and rolling the headset in steps from 1/4 ″ to 0.404 ″. The depth of cut chains that can be stuck with this machine from 1.1 mm, to 2 mm (0.043 ″. 0.080 ″). Together with the machine, special rotating inserts and anvils for different types are delivered. Inserts and anvils are marked. Marking “a” means that the inserts are designed for a headset with a 3/8 ″ and 0.404 ″ step. “B”. for 1/4 ″ and 0.325 ″.

The machine works as follows. The saw chain with a new link and rivets is installed in the guide inserts. The repair link with rivets installed in it is pressed by a working roller to the anvil, after which the engine turns on and the roller begins to rotate, gradually crushing the rivet, at this moment, the machine operator slightly increases the force of the roller, tightening the adjusting screw. For clarity, we suggest watching a video about the work of a riveted-rolling machine.

Shortening the chain with your own hands

You can shorten the chain of the chainsaw with your own hands using simple tools. This method is less reliable, but easy to use, does not require special skills in working with cloth equipment. Disadvantage. you cannot control the strength and quality of crushing rivets. This can lead to a breakdown of the tool with serious loads.

What tools will be needed for repair at home?

You can work with the help of the most affordable tools. Depending on the skills and skills, it may be required:

Some masters also use an electric welding machine. It is not recommended to use it, since the seams after welding quickly become unusable under the influence of vibration during intensive work of the chainsaw. This method is suitable only for gearbox chains that transmit efforts to the leading star.

Removing rivets

To disconnect the links, it is necessary to apply physical effort, since high.quality steel is used to manufacture the headset. Before starting work, the circuit is firmly fixed in a vice in order to avoid injuries during the removal. Stack the protruding part. Do.it.yourself rivets itself can be removed in the following ways:

- Continue to grind with emery until the jumper. Attach the beards, hide the metal with a hammer.

- Stream rivet corner grind. Disadvantage of the method. you can damage the chain itself. Work should be carried out carefully, periodically wetting the area with water.

- After squeezing the chain in the vice for the guides, cut the rivets with a chisel.

Read also: Scheme of the welding machine AC

If you need to increase the number of links or remove one of them, then you need to remove at least two rivets (left and right). When using a corner grinder, the metal can heat up, so after grinding you need to wait for cooling or work in protective gloves.

Connection of links

You can purchase a new link for any chainsaw model in any specialized store, remove it from the old headset. The use of donor spare parts is not recommended, since the quality of the cutting canvas is reduced from this. Installation technology:

- Install the link with new rivets on the chain. Put on the anvil with an open side up.

- Put the top plate on the rivets, stick a hammer for a tight connection several times.

- Attach the beards on the rivet, make 1-2 strong beats with a hammer. Achieve a pronounced thickening, flattening metal. Repeat the operation on both sides of the link.

After work, it should be checked that the chain is mobile, all its elements go freely in different directions. This avoids jamming during sawing.

Important! The headset cannot be installed on a chainsaw if the links cannot move freely. After repair or change in length, check each element.

How to dress and pull the chain correctly?

Before starting work, you should put on gloves to avoid cuts about sharp teeth. Only a cold chain can be pulled. after cooling, it can burst from overvoltage, damaging the mechanism. Remove the protective casing from the chainsaw, carefully put it on the tire.

Depending on the configuration of the tool model, the tension is given manually or using a special regulator. In the first case, you need to loosen the bolts on the tire, after installing the circuit, give the voltage using a slotted screwdriver. If there is an adjusting bolt, then turn it all the way until a sufficient tension of the canvas appears. After work, check the absence of sagging, be sure to tighten after the first operation.

How to choose a chain for a chainsaw

Buying a chain part for a benzo tool is a matter of no less responsible than the purchase of a saw itself. Knowing her purpose and understanding her main technical criteria, the choice of chain will simplify many times and bring only benefits. It should be based on:

mutual compliance with the powerful and technical features of a certain saw and its headset; understanding whether it will be possible to maintain it, its frequency and the volume of required skills; Absolute knowledge of all the nuances of configuration of a specific marking of saw

It is also important to understand here whether it will be possible to understand the working tool with non.original headset or not; overexposure of the position that 3/8 inch is the most optimal step for the chain; selection of angle of sharpening, which can be 10 or 30 0; taking into account the dimension of the guide tire and the cutting canvas itself, which must coincide so that the chain does not sag and is not too long. And how the adjusts of their length can be made at home, we will tell further

And how the adjusts of their length can be made at home, we will tell further.

How the chain of chainsaw is lubricated?

It should be noted that during the operation of the chainsaw, the oil receives not only the tire, but also the tool chain. After the oil enters the tire, a saw element is included in the operation, the links of which are also equipped with grooves or holes. With an increase in the number of engine speeds, the speed of the oil and circuit increases and the speed of oil. Some models of modern chainsaws are equipped with special mechanisms that allow you to increase or decrease the amount of oil necessary for good operation of the chain. Lubrication of a chainsaw with such a function is quite convenient, as it allows you to save oil and eliminates slipping the chain on the tire from an excess of lubricants. Very often, beginners do not know how to lubricate the needle bearing of the chainsaw. This element requires lubrication no less than the tire and chain. Experts advise using special consistent lubricants from STIHL and Husqvarna manufacturers as a lubricant. To add lubrication, use a syringe so that the whole product gets inside the bearing. If we ignore the need to lubricate the needle bearing, then the result will be the replacement of the leading video and a number of other important parts of the chainsaw.

You can delete rivets without the use of specialized devices in several ways:

Rivet removal with a file

- Stiffen. When using this method, it is necessary to control the degree of pressing to the rivet in order to avoid damage to working parts.

- Cut off a cut circle of an angle grinding machine. It should be borne in this case that in this case the metal heats up, which will affect its properties.

- Cut the heads with a file or a file. With this method, the risk of damage to the links is minimized.

- Cut down using a chisel. Before starting work, you will need to reliably fix the chain in the vice.

After the external protrusions are completely cut off, you will need to knock out the rivet from the seat. To do this, you need to choose a punch, the diameter of which will correspond to the diameter of the hole. The punch must be put on a rivet and knit it with a sharp blow of the hammer. After these actions are performed, the chain will be disconnected.

Attention: In order to avoid damage to the links, you need to securely fix them. In addition, the punch should be installed strictly perpendicular to the cut of the rivet

Before and after rummaging the chain

Features of geometry

In order to properly sharpen with your own hands, even if the machine is used, you should know the geometry of the tooth. Its components include:

In this case, the tooth blades consists of the following elements:

It is necessary to sharpen it correctly with your own hands, taking into account the fact that the end and upper blade should be located correctly relative to each other to ensure the best cutting indicators. The back of the tooth forms a certain angle of the upper blade. A similar angle is formed to cut the blades into the material. With your own hands should also be sharpened with the fact that the blade back has a narrowing. this design feature forms the angle of the end blade. It is created to ensure side cutting of chips.

Sliding surface and the end part of the blade forms the front angle. In this case, the angle has a fixed value, it varies from 60 to 85 degrees. If you sharpen the teeth with your own hands, it is worth considering that it is the upper blade that is the main one, and the angle formed by it is the most important angle. Summing up when considering the issue of geometry features, we note that the angle of sharpening may vary depending on the conditions of application. The basic rule that should be observed, if you sharpen the tooth with your own hands, can be attributed to the following: the higher the angle, the greater the performance of the chainsaw, but the reduction in the indicator provides greater smoothness of the stroke of the blades, a decrease in vibration and an increase in the service life. It is worth sharpening taking into account the fact that the indicator should be in the range from 25 to 35 degrees. An exception can be called the option of execution of the blade, which is intended for the longitudinal saw. 10 degrees are maintained by many manufacturers of the cutting element of the chainsaw.

How to remove a link without using a machine

There are several ways to remove rivets.

- Stiffen. Work carefully, trying not to damage the next, whole link.

- With a corner grinder.

- Cut down with a chisel. To do this, the chain must be squeezed in the vice for the guides, so in order to be able to chop rivets on the connective link.

After the heads of the rivets are worn or cut down, the following actions must be carried out to separate the link. Install the beads between the plates of the connecting angle and the sharp movement to hit it with a hammer. The plates should jump off the rivet body, which passes through them.

The Hidden Chainsaw Killer : Chain Stretch. Correct Way To Adjust The Chain Tension On Your Chainsaw

Important: if it is necessary to replace the working tooth, then you will have to rumble connecting links from the left and to the right of it.

Now let’s figure out how to glue back.

How to remove rivets?

The chain of the chainsaw is difficult to disconnect. The rivets are made of high.quality steel and have a geometric shape, which does not just allow you to knock out rivets from the link. The inside of the rivet has a larger radius. The link is rotated on this thickening, and the external parts of the rivets carry only the connecting function, so they simply simply fix them on the outside of the chain. Rivet removal is as follows: the chain is fixed in a vice, and the protruding part is grinded. When stuck, we try not to damage the lateral parts of the links.

It is not recommended to use corner grinder, since the details will heat up very quickly, which will lead to a change in the physical properties of the metal. It is better to use a file or a file for grinding. Survation is carried out on both sides of the link. And now rivets can be knocked out of the chain with a beard, slightly bent down the side parts of the links.

The chain managed to disconnect. Rivet remote from the chain, do not rush. It is possible that you cannot find her suitable replacement. Manufacturers of chainsaws do not suggest that an independent repair of the chain will be carried out, so they do not produce such rivets to the product market.

It is also beneficial for selling organizations to sell chains in their finished version than small parts for repair. For these reasons, a suitable rivet with the desired geometry will be very difficult to find. It will be even harder to make it at home, so you will have to use the old rivet.

As you have already guessed, the chain of the chainsaw will have to be disconnected twice. Do not forget to calculate that the number of guide protrusions from the inside of the chain and the distance between these protrusions are combined with the leading star of the chainsaw. If you shorten the original chain, then this is not necessary. And if this is a chain from another model of a chainsaw, then everything needs to be very well trotted and calculated. The deviation in the chain step (even small) from the parameters set by the design will lead to the fact that the chain will stretch again (at best) in the shortest possible time or break the chainsaw star. The end and tire will come, since the driven star will quickly overheat.

How to pull: installing the cutting element of the chainsaw

The main reasons for the sagging chain we dismantled. How to install a chain on a chainsaw is described above. Now you need to correctly pull the grades, and check if it is pulled.

The chain stretch

You can pull the chains in two ways: fast and frontal. It is best to stretch the front way.

If you carry out a front stretch, you need to unscrew the nuts that hold the tire and raise it over the edge. A special bolt that is on the right must be pulled by the grades until an acceptable stretch is obtained, and then raise the tire even higher and squeeze it.

If you use the fast stretch method, then you first need to raise the handle of the lamb nut and loosen it. Then tighten the chain tension screw to the stop clockwise. Then tighten the lamb nut and lower the handle again.

Checking the stretch

To check the stretch of the circuit, you need to turn off the brake system of the saw. Then manually draw grades along the tire, if he walks smoothly and does not sag, then everything is fine. If the chains walk very tight, then it needs to be a little weaken, because there is a risk of gap during operation.

Causes of early failure of saw chains

Accelerated extension of the part occurs at the stage of the running.in and in the last quarter of the operational resource. Throughout these time intervals, the headset needs special attention and careful maintenance.

- The reason for the rapid stretching of the saw chain may be the poor quality of the material of the budget model, the discrepancy between the configuration of the crown and the excessive wear of the leading star, the malfunction or inefficient operation of the lubricant system.

- The full.fledged operation of the chain of the chainsaw also largely depends on the state of the tire and the leading star, the quality of chain oil and the performance of the lubricant system, timely and competent sharpening of the edges of the cutting links.

According to professional sawmills, the durability of the headset reflects the style of the operator and the level of operational loads. The chains of a budget group are more susceptible to stretching, a more expensive company assortment in the technical and working properties of Комментарии и мнения владельцев does not have.

Good evening.Puzzled by the question of how to shorten the chain? Is there any meaning? Whether there will be increased wear in the process of using the stretched chain of the leading stars and tire? I thank everyone in advance.

Take into the service and shorten. There are specialists there and appropriate equipment. If you are thrown out one link in such a way that the chain still fits on the tire, there will be no increased wear. If the chain is stretched, you have a sprocket. And how many chains do you have.

I will not bear the service definitely, it’s easier to buy a new one and not bother. At home is not real? The stretched resource has 50-60% on the tooth, and in the amount of 5 chains from Stiel. It will be pleasant for the soul to restore it yourself, but how?

Krot. wrote: I will not bear the service definitely, it’s easier to buy a new one and not bother. At home is not real?

Really, probably. But is the game worth the candle? I mean, is the result of such hemorrhoids worthy? »In the service, to shorten the chain, it is worthwhile pennies.

The stretched resource has 50-60% on the tooth, and in the amount of 5 chains from Stiel. It will be pleasant for the soul to restore it yourself, but how?

It seems to me, you have something with the lubrication of the tire, if the tooth resource is 50-60 percent, and the chain is already stretched out by the most do not indulge.

I do not see the point. By the way, he shortened his friendship, but there were no turnover like that of modern saws. I would not.

Newzubok wrote: take it to the service and shorten. There are specialists there and appropriate equipment. If you are thrown out one link in such a way that the chain still fits on the tire, there will be no increased wear. If the chain is stretched, you have a sprocket.

Valerich wrote: Exactly what will not go on the stars.

And with what fright? The chain step from shortening to one tooth will not change, and the chain has already stretched and has been operating on this star. The game costs a candle when three chains work, and one for some reason stretched ahead of time. I had this once when something was clogged in the tire lubrication system. Washed with gasoline and solarium, restored grease and threw one link in the service. Then he hopped all 3 chains “to zero”, changed them and changed the asterisk, as usual.

Krot. wrote: I will not bear the service definitely, it’s easier to buy a new one and not bother. At home is not real? The stretched resource has 50-60% on the tooth, and in the amount of 5 chains from Stiel. It will be pleasant for the soul to restore it yourself, but how?

Newzubok wrote: Threw one link in the service.

You haven’t been counted anything? I have been with a chainsaw of the year so since 1982. Give a chance to improve?

Read also: What do files make from

Not wait. It’s time for me to sleep. Tomorrow to work by 9 00. In general, one link cannot be thrown out. Just not to glue it. Spare links went to the friendship chains and I riveted myself. That’s why I know. We give modern to the service, so we know little. But the principle is the same. Goodnight!

To shorten the chain is easier. The connector is sold | 3 hryvnias with rivets of 3 hryvnias apiece to all chains of the same company | E, the Stilev but are suitable for Oregon, the main thing is the same step (we have such a price in the court, maybe where it is otherwise). The rivet head is neatly cut on the chain with a corner grinder, the tooth is thrown and the chain is rumble I do this often, work | about 5 minutes.

Valerich wrote: You haven’t been counted anything? I have been with a chainsaw of the year so since 1982. Give a chance to improve?

I didn’t confuse anything. I just thought that I was talking with a technically competent people who understand what is meant by “one link”. Just like that of a bicycle chain and a motorcycle.

You need to go to the service specifically and the question is not in money, but in time. Yes, and I like it yourself. And the chain stretched due to oil work without oil, friends tried (for the last time with this saw)

By the way, stupid chains are also very stretching. Generally stretched chains to saw. The stars wear out quickly, then when you put a new chain on the old stars, too, is not a gut. If the stars are not worn out, then it is better to buy another chain, I understand that the toad is pressing, but it is better a chain than then a tire with a star.

Dimon 35 wrote: by the way, dumb chains are also very stretching. Generally stretched chains to saw. The stars wear out quickly, then when you put a new chain on the old stars, too, is not a gut. If the stars are not worn out, then it is better to buy another chain, I understand that the toad is pressing, but it is better a chain than then a tire with a star.

Dim, and what a fright of the tire? About the asterisk. I agree. I agree that if the asterisk is almost new. (Damn, why should she be almost new. Tooth resource 50%, if three chains evenly worked on the asterisk racing, the asterisk is already worn enough). I had a similar situation, I shortened the chain and finished off all three chains on the old star, and then I bought new three chains and a new asterisk.

How do you think the developed star should look like? I’ll compare with my own.

Krot. Wrote: How do you think the developed star should look like? I’ll compare with my own.

From such a fright that there is also an asterisk on the tire, and it also works as well as on the saw. And about when to change. When the chain cannot be pulled normally when working with the saw, then it is pulled, then sags or when a haste on a leading star is more than 0.5 mm.

Krot. Wrote: How do you think the developed star should look like? I’ll compare with my own.

She has such grooves on her rays. The question is not even in their depths. Sometimes there are a couple of pieces on the ray. There is simply a practice when 3 chains are bought, which are used on the asterisk, in a circle. That’s when the chains are exuded “to zero”, change the chain and asterisk. If you put a new chain, teeth that pull the star on a worn asterisk, will be quickly worn out, and the saw teeth will remain almost whole. Therefore, they do not recommend buying one new chain instead of the old extended for some reason (lack of lubrication, for example, like yours). Then it is better to finalize the two remaining, if there is no way to shorten the third. And then change the chains and an asterisk. As I understand it, you have 5 chains? Work three before their full wear. Then change the chains and an asterisk. Когда три новые износятся до состояния оставшейся в запасе четвертой, вводите ее в работу и работайте четырьмя по кругу. And so again until their complete wear. And then again change the chains and an asterisk. And during this time you look. and shorten the fifth chain. Well, then. according to the same scheme. Personally, I would do this.