Materials and tools used by the author:

Material List:

– plumbing pipes;

– brass rods and coupling (for shaft);

– plugs for pipes;

– engine 775 or newer 895;

– mounting bracket for 775 engine;

– engine speed regulator;

– step-up belt drive;

– base board;

– mounting corners;

– sheet metal;

– bearings under an axis of 5 mm;

– paint;

– glue.

Homemade manufacturing process:

Step one. Turbine

First of all, we will make a turbine, we will start with plugs for pipes, which will serve as parts to which the blades are attached. In the plugs, we drill holes for the brass shaft by 5 mm, and we also make markings and cut slots at an angle for the blades. As for the blades, their author cut from the sewer pipe. We install the blades in the grooves and glue with superglue.

Video: What You Can Do From a Burnt Drill

We also need to cut out the part inside which the turbine will rotate, for this we need a piece of pipe of a larger diameter than the turbine. We cut out windows in it through which air will enter and exit. The suction window is located on top, and the blower is located below and the air leaves it through the sleeve. For the sleeve, we also cut parts from plastic or sheet metal. We securely glue the whole structure, after superglue it would be good to use epoxy glue.

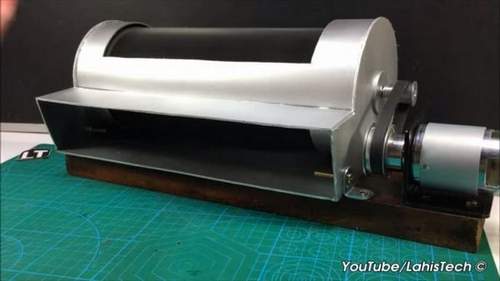

Step Three Assembly

We assemble the car, we attach the fan casing to the base, which is a thick board. We fix everything with screws and fixing angles.

We also install the engine on the base, for this we use fasteners in the form of a corner. We install pulleys and a belt, for the proper operation of the machine, the speed on the turbine should increase, so we put a larger pulley on the axis of the turbine than on the motor shaft.

Receive in the mail a selection of new homemade products. No spam, just good ideas!

By filling out the form you agree to the processing of personal data