Woodworking is a complex process that consists of many stages. Special devices can facilitate the work, so a band saw on wood helps to make a straight cut and is suitable for processing boards of various widths.

What is a band saw?

The tool, which is designed to work both in a carpentry workshop and in a small garage. a band saw for wood for a home workshop, is a metal blade closed in a ring on which teeth are cut, their height, frequency, width of the blade determines the type saws and its ability to work with different materials. A band saw on wood is capable of processing logs and boards of such a width that is not amenable to other types of saws. circular or frame, and can be used to work with other materials:

Wood Band Saw Device

Band sawmills are similar in structure. Professional tools differ in size and weight compared to home saws intended for domestic use in small workshops, and manual units. Structurally, band saws consist of several nodes:

- Frame or bed. the case on which all the main elements are fixed.

- A work surface equipped with a ruler and an emphasis, which helps to regulate the correctness of cut.

- Engine. drives the saw.

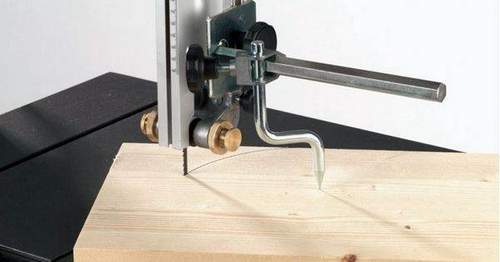

- The band saw blade for wood is mounted on a pulley and rotates at high speed.

- The control panel, lubrication system, protective cover are additional components that make the work of the band saw safe and convenient.

The principle of the work of a band saw on wood

There are many varieties of sawmills working with wood. Understanding how a band saw on wood works is important for it to work properly. The serrated cutting blade rotates thanks to the engine, resulting in the sawing of materials that come into contact with it. The performance of the band saw machine depends on the shape and height of the teeth located on the blade, on the power of the engine. A special sharpening of the teeth is necessary to clean the working blade from sawdust and to prevent jamming of the saw.

What is a band saw for wood?

When choosing a tool for smooth sawing wood, special attention should be paid to household band saws on wood. Adjusting the speed of movement of the cutting blade and direction allows you to use the sawmill for a variety of jobs. The ability to select the size of the teeth for working with a particular type of material expands the range of capabilities of the saw. For soft wood species, a blade with large teeth is suitable, and for hard wood with small teeth. Other features of the band saw make it an indispensable tool for the home master:

- Many band saws for sawing have the ability to fine-tune to the specific needs of the employee.

- Thin blades can cut curly products, a variety of decorative elements.

- A household band saw on wood can work in any direction. both along and across the fibers.

- Using a saw, you can create the same and mirror details for furniture.

- Band saw performance is higher than other types of tools.

- Tape-based sawmills are safe.

Types of bandsaw for wood

In a carpentry workshop you can’t do without a quality band saw from a trusted manufacturer. Choosing a sawmill, you need to understand the differences between the best band saws on wood. By type of sawmills are divided depending on the location of the blade, they are:

Wood Band Saw Vertical

Machines for sawing wood of a vertical type are distinguished by the fact that the blade that is in contact with the cut surface is arranged vertically. This type of table saw for wood can be used in small wood processing workshops, as well as in domestic workshops. Such a tool easily copes with materials of various widths and can work in any trajectory. The sizes of band saws for this type of wood may vary. When choosing a vertical band saw, you must remember the following characteristics:

- moving web speed;

- web length;

- number of speeds;

- the ability to adjust the angle of the table;

- depth cut;

- machine weight.

Video: What You Can Do With A Band Saw

Wood Band Saw Horizontal

Saws in which the cutting blade is located horizontally are widely used by professionals and novice craftsmen to cut a variety of wooden materials. A horizontal bandsaw machine for wood copes well with both transverse and oblique (angled) cuts. Machines for industrial use can work autonomously, electronic control systems in such devices calculate the size of cut surfaces up to a millimeter. A horizontal band saw for wood has the following characteristics:

- the ability to cut at an angle;

- the ability to save programs for reuse (in machines with electronic control);

- engine power;

- web speed;

- desktop size.

How to choose a band saw for wood?

A good woodworking machine is not cheap, the purchase of such a tool must be approached responsibly. Thinking about which band saw to choose from a tree, you need to weigh and correlate the parameters of the tool and your own needs. According to the characteristics of the band sawmills are divided into several types, you should choose a saw for yourself, given the important characteristics:

- Capacity based on estimated production volumes.

- Characteristics of the working canvas.

- Machine manufacturer

Wood Band Hand Saw

Small tools are not inferior in their properties to professional machines for large-scale production. A mini band saw on wood will serve faithfully to a caring master, and will certainly come in handy on the farm, with it you can easily and simply perform different actions:

- cut dry branches on trees;

- get rid of old seedlings in the garden;

- to prepare firewood for the winter period.

Wood Band Saw. Rating

In the carpentry shops such a tool has found wide application. The choice of a band saw for wood is best done based on the rating of the best units that save time, have high performance and reliability are presented below.

- JET JBS-12. The band saw on wood is designed to work with wide boards and timber, copes well with bulky workpieces, powerful and productive, has a stable metal frame that does not vibrate during operation.

- Way Train UE-330 V. The horizontal type machine copes well with wood of any size, works at an angle, is equipped with a powerful engine and a large working table.

- Corvette 35 Encore. The band saw on a tree has high power and speed of the movement of a cloth. A high stand with adjustable legs adjusts to any employee, and a beveled frame allows you to cut curly blanks of any shape.

DIY band saw on wood

It is difficult to make a band saw on your own. The wooden frame for the machine is assembled from improvised materials, any craftsman can find the necessary tools for assembly. The process of working on a homemade band saw on wood can be divided into the main stages:

- The frame for the machine can be assembled from old furniture, a preliminary drawing will facilitate the work, and will allow you to assemble the saw to the required dimensions.

- The simplest home-made tape machine rests on a frame assembled from a bar and two supports. The distance between the supports should be thought out in advance, it should not be less than the size of the processed logs, it is better to make it a little larger.

- For the working surface, you can use the old desk, its cabinets can serve as containers in which sawdust will be collected.

- Depending on the engine parameters, it is necessary to calculate the diameter of the pulleys for the belt drive.

- A massive spring is suitable for the lifting mechanism to which the cutting blade is attached, with which the necessary pressure of the machine will be provided.

- Guides are necessary so that the cut is carried out in a straight line.

- In order to make the machine safe, it is better to close the pulley with a special casing.

- Varnishing for wood or painting the machine will increase its service life.

How to use a band saw on wood?

This device helps to quickly and accurately make any cuts on wooden products. Practice and accuracy are required when working with this type of tool, knowing how to use saws for band saws on wood, the result will be worth the effort.

- Correctly choose the type of band saw, paying attention to power, speed, blade length, parameters of the working surface of the table, electrical characteristics.

- The saw blade must be selected individually for each project, given its width, thickness and take-off of the teeth.

- Before work, you should check the movement of the working blade and adjust the guides.

- The working surface must be adjusted to the desired angle.

- On wooden workpieces, marking must be done before work.

- The saw can be turned on and wait until it picks up speed.

- Directing the workpiece along the guides, make a cut.

Wood Band Saw Setting

Any power tool needs daily maintenance. It is necessary to take a few minutes before setting up and adjusting the band saw on wood. Performing simple manipulations, you can significantly increase the tool life.

- The saw must be disconnected from the power supply and the working blade removed.

- Guides clear of debris.

- Remove the pulleys from dirt, vacuum the inside of the covers.

- Set the canvas in place, adjust the degree of tension.

- Align pulleys; they must be parallel and coplanar.

- Check the working blade, make final adjustments if necessary.

- Check the position of the bearings.

- Make sure that the working surface of the table is set at the right angle to the canvas.