Construction Husqvarna 365

The advantages of the Swedish brand chainsaws were appreciated by both professional fellers and summer residents, who managed to thin out the garden thickets with the help of the machine and prepare firewood for the winter. Models attract high resource, balance, reliability and simplicity.

Husqvarna 365 saws are distinguished by the following design features:

- a durable aluminum-magnesium alloy was used in the production of the crankcase. This allows you to work at high speeds and withstand maximum long-term loads;

- the model is equipped with centrifugal air purification;

- the oil pump has an oil supply regulator, which saves raw materials;

- convenient adjustment of the chain tension. the controls are located on the side cover;

- reduction of compression in the cylinder is due to the installation of a special valve;

- Smart Start is installed on Husqvarna 365 for easy starting of the saw;

- the convenient location of the handle at an angle facilitates the process;

- with the help of a shield, the operator’s working hand is protected;

- the main parts and mechanisms of the saw are protected from damage by special covers;

- reduction of noise level during operation is provided by the muffler.

The device of the Husqvarna 365 chainsaw is not only convenient to use, but also allows you to repair the tool yourself (although this model does not fail for a long time with proper operation).

In order for the unit to serve for a long period, it is recommended to use AI-92 gasoline and synthetic-based oils for refueling (mineral oils are cheaper, but of lower quality).

Specifications

The model was very popular due to the characteristics of the Husqvarna 365, shown in the table.

The main characteristics of Husqvarna 365 chainsaws:

| Name | Unit rev. | parameters |

| Power | l. s./kw | 4.6 / 3.9 |

| Standard tire parameter | cm | 45 |

| Torque | N / m | 3.9 |

| Chain speed | m / s | 20,7 |

| Fuel mixture tank volume | ml | 770 |

| Fuel consumption | g / kWh | 490 |

| Oil tank volume | ml | 420 |

| Working weight | Kg | 6.5 |

The model is equipped with a two-stroke engine with a cylinder volume of 65.1 cubic meters. cm, which provides enough power to fit the saw bar longer than 18 inches. Includes H42 0.058 ” Pitch Saw Chain.

The Husqvarna 365 chainsaw stands out for its excellent build quality, high reliability and ample work continuity.

The lineup

Chainsaw Husqvarna 365 has in the name and letter designations. SP (that is, special). This is one and the same model, although the presence of letters at the end of the name is often perceived as a variation of the main unit.

In fact, the modification is the Husqvarna 365 h, which even differs externally:

- high handles allow you to work without bending, thanks to the fact that they have a built-in tank and controls;

- the handles are also equipped with a pivoting function, which makes it possible to reach the desired position of the tire in space.

365 h is specially designed for felling in deep snow conditions. Otherwise, the technical features of this option are the same as 365 SP. The downside of the modified version is the cost. it is 2 times higher than that of the base.

Features and characteristics of the Swedish chainsaw Husqvarna 365

The leader in the professional field is the Swedish-made Husqvarna 365 chainsaw. They actively use the tool in logging, but the saw will also be of great help to the owners of garden plots. The mechanism is adapted to the difficult conditions of work. The saw, supplemented with a tacked chain, easily tackles concrete structures and metal parts.

Carburetor adjustment rules

During operation, the Husqvarna 365 saw periodically needs carburetor adjustments, which you can do yourself. If the speed is not satisfied, or the saw does not start, the initial settings may have been violated. They are adjusted using special screws installed on the model:

- H. max. number of revolutions;

- L. low revs and traction;

- T. idle speed adjustment by opening or closing the fuel flap.

In the process of adjustment, you should adhere to the following actions:

- the saw motor is warmed up for 5 minutes;

- all screws are taken out of the state of maximum tightening in one full turn;

- starting the saw, begin to adjust the screw L, trying to achieve the maximum idle speed;

- after that, the screw is turned counterclockwise by a quarter of a turn;

- if it is necessary to further increase or decrease the idle speed, use the T screw for this;

- the maximum speed is adjusted with the screw H, determining by ear the most acceptable option (although it is better to use a tachometer).

The step-by-step steps for adjusting the carburetor (among other items) are detailed in the instructions on the Husqvarna 365 and should always be kept handy.

Chinese counterpart

On the market you can see a cheaper version of the chainsaw with an indexation of 365 XP, but it has nothing to do with the Swedish company. This is an analog fake manufactured in China. It is distinguished not only by its cheapness, but also by its low quality. In order not to make a mistake in choosing when buying, it is recommended to pay attention to the following points:

- there is no metal nameplate indicating the model and its number;

- the fuel filter differs in shape and parameters from the original;

- there are no fastening latches on the filter cover.

When buying a chainsaw, the price should not influence the choice. The focus should be on the quality and originality of the product. Only this will ensure durability and reliability of operation.

Page 29: Fine adjustment, Conditions, Low speed adjusting screw l, Fine idle setting t, Low speed needle screw n, Maintenance, Low speed adjusting screw

Attention! The text in this document was automatically recognized. To view the original page, you can use the “Original” mode.

Operation, pre-adjustment,

ATTENTION! Do not start the saw without the bar, chain, and clutch cover (chain brake) assembled. Failure to do so may cause the clutch to fly off and cause serious injury.

The carburetor controls the engine speed with

throttle valve. An air-fuel mixture is formed in the carburetor, the composition of which can be adjusted. For maximum saw performance

the carburetor must be correctly adjusted.

Carburettor adjustment means tuning the engine to

work in certain conditions, such as climate, height above

sea level, gasoline and oil used in the fuel mixture for two-stroke engines

L = low speed jet H = high speed jet.

T = throttle idle adjustment screw.

heating mixture, depending on the air flow, regulated by the throttle valve, is adjusted by turning the adjusting screws

Fuel supply ports L and H. Turning them clockwise

(tighten), then the quality of the working mixture (air /

fuel) becomes leaner (less fuel), and if you turn them

counterclockwise (unscrew), then the quality of the working mixture

enriched (more fuel). Depletion of the working mixture gives

increase in engine speed, and enrichment. decrease.

The T screw adjusts the idle speed. By adjusting the position

throttle valve, it increases or decreases the flow

air, depleting or enriching the working mixture. Turning screw T clockwise increases idle speed, counterclockwise decreases idle.

HOW TO. husqvarna 372xp 371 365 362 non x torq carburetor replacement

Setting basic parameters and running in

The basic carburetor adjustment is carried out at the factory during the chainsaw test, with the following basic setting: H = 1 revolution, respectively L = 1 revolution.

To ensure proper lubrication of the engine mechanisms (during

break-in time) carburetor during the first 3.4 hours of operation

must be adjusted to a richer working mixture. To ensure this mode, you need to adjust the screw H

maximum speed is 6. 700 rpm lower than recommended at maximum mode (full throttle without load). If you cannot check the revolutions using a tachometer, then the adjustment screw H must be turned towards the enrichment of the working

mixture with respect to the established preliminary position.

The recommended maximum speed must not be exceeded. This leads to overheating and damage to the saw motor.

After “running in” the chainsaw, you need to carry out an accurate

performed by a specialist. First you need to configure

jet L, then idle screw T and then jet H.

Maximum RPM Idling RPM

Before adjusting the carburetor, clean the air

filter and install the cylinder cover. Carburetor adjustment with

a dirty air filter will result in a lean mixture after cleaning. This can cause serious engine damage.

Gently turn the L and H jets clockwise until

refusal. Now turn them counterclockwise one turn. The carburetor is now set to H = 1 and L = 1.

Now start the saw according to the starting instructions

and let it warm up for 10 minutes.

Китайская бензопила.Ремонт карбюратора.Регулировка карбюратора.

the chain rotates at idle, then turn the screw T counterclockwise to achieve its complete stop.

Place the chainsaw on a flat surface with a saw

away from you so that the saw blade and chain do not touch the surface or any objects.

counterclockwise respectively. When will

turn counterclockwise. NOTE! If a

the chain rotates at idle, turn the idle screw

counterclockwise until the saw stops.

Precise setting of idle speed T

Adjust the idle speed with screw T. Then turn it counterclockwise until the chain stops. If a readjustment is necessary, first turn the screw T clockwise

arrow until the saw chain starts rotating. With a properly adjusted idle speed, the engine starts to work

smoothly from any position. In addition, there should be a clear rpm threshold when the chain starts rotating.

If the idle speed is not adjusted until the chain has come to a complete stop, contact your dealer. Do not use your chainsaw until it has been properly set up or repaired.

saw power. Setting the high speed screw H to

mixture too lean (screw H closed too tight)

causes increased revs and disables the engine.

Run the saw at full throttle for about

H 1/4 turn counterclockwise.

Let the saw run again at full speed for about 10

seconds and notice the change in sound

engine. Turning screw H an additional 1/4 turn counterclockwise

arrows, repeat the procedure. So, the saw is tested in the following positions: H = ± 0, H = 1/4, H = 1/2 with respect to

initial position. In each position (on full

rpm), the engine ran with a different sound. The high speed screw H is set correctly if the saw is slightly “quadrupled”. If a

the saw whistles, the mixture is too lean. If you saw hard

Adjusting the carburetor Husqvarna 372 XP, 365

Adjusting the carburetor of a Husqvarna 372 XP chainsaw means adapting the engine to local conditions such as climate, altitude, gasoline quality and oil type.

The carburetor has three control options:

L = low velocity jet. H = high velocity jet. T = Screw for adjusting idle speed.

Likers L and H adjust the amount of fuel that matches the air flow supplied by the throttle valve.

If the nozzles are screwed in clockwise, the mixture will be poor (less fuel in relation to the amount of air), and if the nozzles are screwed counterclockwise, the mixture will be richer.

A bad mixture gives higher rpm, but richer mixture. lower turns. The T screw adjusts the idle position of the throttle.

If the T screw is turned clockwise, the idle speed will increase, and if you turn the screw counterclockwise, the idle speed will decrease.

Pre-configuring and running XP

The carburettor has been pre-adjusted during the performance check at the factory. Pre-adjustment: H = 1 turn, respectively L = 1 turn.

To ensure that the parts of the Husqvarna saw engine are sufficiently lubricated (pumped in), the carburetor is set with a slightly higher fuel mixture for the first 3-4 hours of operation.

For such an installation, the maximum speed is set at 6-700 rpm below the recommended speed.

If it is impossible to check the maximum number of revolutions using a tachometer, then the H jet should not be set on the fuel mixture below the presetting.

Do not exceed the maximum number of revolutions. If the chain rotates at idle speed, turn the screw T counterclockwise to stop it completely.

Fine carburetor adjustment Husqvarna 365, 372 XP

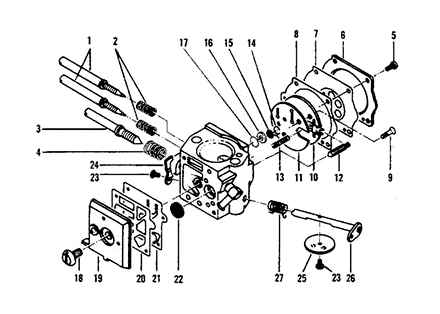

Dismantling the chainsaw carburetor in the photo

After disassembly, you need to troubleshoot and replace damaged or worn parts. Next, the entire set should be rinsed with a special product, dried and wiped with a dry, lint-free cloth. The jets and tubes of the assembly must be blown out with compressed air, or, in order to more thoroughly remove the formations on their inner surfaces, they must be treated with ultrasound before that.

DIY disassembly: nothing complicated

First of all, you need to prepare a place for disassembly. This can be a workbench or a regular table. In addition, you need a rectangular piece of cloth or cardboard. on it you will neatly fold the carburetor parts. And, finally, a tool: for disassembly, you need a set of open-end wrenches and screwdrivers, a special cleaning compound and an ultrasonic cavitation bath.

Chainsaw carburetor repair tool

First, you will have to dismantle the chainsaw carburetor. This is done in this order:

-

To get to the carburetor, you need to remove the top cover of the chainsaw, fixed with three bolts.

Removing the fuel hose and drive rod

After removing the petrol hose, the carburetor is ready for disassembly.

Disassembly of the carburetor must be carried out in the manner prescribed by the design and functional solutions of its elements. Chainsaw carburetor parts do not differ in size, so they need to be folded carefully and in order, trying not to lose anything.

Too weak mixture on the high speed saw blade and risk of engine damage.

Let the saw run at full throttle for 10 seconds. H = 1.

Then turn screw H 1/4 turn counterclockwise. H = 1 1/4.

Give the motor another 10 seconds and listen for the difference in sound at maximum speed. Repeat the procedure with adjusting screw H turned 1/4 turn counterclockwise. H = 1 1/2.

The saw now runs at H ± 0, H = 1/4 and H = 1/2 based on the presetting. At full throttle, the engine sound will be different for each setting.

Jet H is properly seated when the chain saw runs with little noise at full throttle and no load.

If a lot of smoke comes out of the muffler and the saw is noisy, then the mixture is too rich.

Rotate the H nozzle clockwise until you reach the setting with the correct sound.

Correctly adjusted carburetor chainsaw Husqvarna 365, 372 XP

The carburetor adjusts correctly when the saw is revving up and when it is running with a little noise at full throttle and no load.

The chain must not rotate at idle speed.

With an excessively lean mixture on the L jet, it can be difficult to start the engine and the engine will not receive enough pulses.

Setting the H nozzle with too bad a mixture will reduce the saw power, it will not pick up enough RPM and / or may damage the engine.

An overly rich mixture on the L and H jets creates problems in gaining momentum or at too low operating speed.

Husqvarna

Specifications Husqvarna 372 XP

Engine’s type. Gasoline Working volume of the cylinder, cc, cm. 70.7 cm3 Maximum power, kW. 3.9 kW (9600 rpm) Rated power at operating speeds, h.p. 5.3 h.p. (9600 rpm) Frequency at idle speed. 2700 rpm Spark plug. Champion RCJ7Y 5776166-02 (61141), Husqvarna HQT-1 5774840-01 (63893), NGK BPMR7A Electrode gap. 0.5 mm Fuel tank capacity 0.77 l Torque, max. 4.3 Nm / 6600 rpm Capacity of the chain lubricator. 0.4 L Pump type for the lubrication circuit. Adjustable flow chain pitch. 3/8 “Chain Thickness. 1.5 mm / 0.058 in. Bar length included in delivery. 45 cm / 18 inches Recommended bar length, min-max 38-71 cm / 15-28 inches Chain speed to maximum. turns out. 21.4 m / s Equivalent vibration level, front / rear handle. 3.5 / 4.0 m / s2 Guaranteed sound power, dB (A). 115 Weight (without cutting equipment), kg. 6.1 kg

A chainsaw is needed in construction, and in gardening, and in landscaping. its presence greatly simplifies the implementation of a number of tasks for processing wood. The main unit of this tool is the engine, the operation of which largely depends on the state and settings of the carburetor. This is where the fuel mixture is prepared. This means that if the saw does not start, stalls or does not provide the required power, it is likely that the reason for this is improper operation of the carburetor. Fortunately, you can handle this yourself in many cases. Only for this you need to know and understand the device and principle of operation of this unit and, of course, the chainsaw itself.

After starting a Husqvarna 372 XP chain saw, you need to fine-tune the carburetor.

First you need to adjust jet L, then screw in idle T and then jet H. The following maximum speed is recommended: 12,500, idle 700 rpm.

During adjustment, the air filter must be clean and the cylinder cover replaced.

When tuning the carburetor with a dirty air filter, the fuel mixture will be too bad if the air filter is cleaned or replaced next time. Too bad mixture leads to engine damage.

Carefully twist the L and H nozzles from underneath, and then unscrew them 1 turn. The carburetor is now set to H = 1 and L = 1.

How to recognize carburetor malfunctions?

Typical carburetor malfunctions are easy to recognize. They are expressed in the fact that the engine of the chainsaw starts up and immediately stalls or does not show signs of life at all. Well, or consumes fuel with might and main, instead of the intended power, producing clouds of black smoke and aggressive vibrations.

The scheme of the chainsaw carburetor

Carburetor settings can be affected by:

-

lack of fixing the adjusting screws;

Chainsaw air filter with nylon insert

If any problems are found, they should be rectified immediately. But how do you know if the carburetor is the problem? To do this, watch how your tool works.

Typical signs that carburetor settings are out of order include:

- Unstable motor operation

As a rule, the reason for this is the use of the wrong (lean) fuel mixture.

- Excessive consumption of fuel

It is expressed in an increased emission of waste exhaust, which turns black. This means that the fuel is not completely consumed, i.e. oversaturated mixture.

Carburetor set correctly. saw starts the first time

- Arbitrary changes in engine power

May be due to damage to the fastening of the adjusting screws or the protective cap.

- Increased fuel consumption accompanied by vibrations and pops

It speaks of critical wear of the piston group, therefore, adjusting the carburetor will postpone the overhaul only for a while.

- Sneezing and jerking of the engine

This picture is observed when the carburetor channels are clogged or its filters are malfunctioning. In this case, the adjustment should be carried out only after thorough flushing of the assembly.

Despite the fact that the carburetor is the most difficult part of the engine, you should not be upset if it detects malfunctions in its operation. Instead, you need to arm yourself with some tool, a constructive node diagram and healthy logic.

Nuances of adjustment

After making the adjustment, the chainsaw should easily pick up and drop speed, work stably at low and high speeds. If the saw chain rotates at idle speed after adjusting the carburetor control screws, this is a sign that the adjustment has been made incorrectly and it is necessary to correct the position of the screw (T).

Also, when adjusting the Husqvarna carburetor, it is worth considering the response time of the chainsaw to the rotation of the screws. The settings do not change immediately, but within five, ten seconds.

One of the indicators of an incorrect adjustment is a strong smoke during the operation of the saw, which indicates a large amount of fuel entering the combustion chamber. If such a situation arises, you need to correct the position of the screw (L).

Factory settings

The factory default setting for the Husqvarna carburettor is the position of the screws (H) and (L) at which a working chain saw is guaranteed to start. For Husqvarna tools, this is one and a half turns from fully tightened screws (H) and (L).

In the process of adjustment, you must first set the screws to the standard position, then start the chainsaw and make precise adjustments to the power, the number of maximum revolutions and idle speed.

Algorithm and description of setting the carburetor Husqvarna

Husqvarna carburetor, adjustable in the same way as carburetor settings on other brands of chainsaws.

Immediately before adjusting, it is necessary to carry out a complete diagnosis of the saw and make sure that there is no obstruction of fuel supply and air leakage into the crankcase of the chainsaw. It is also necessary to make sure that the air filter is clean and, if necessary, replace it with a new one.

- Saw muffled with Husqvarna carburetor factory setting.

- The engine starts and the saw warms up for a few minutes.

- By turning the screw (L) clockwise, the position is found at which the engine develops maximum speed, after which the screw must be unscrewed 1⁄4 back. If at the same time the chain of the chainsaw rotates, then it is necessary to reduce the idle speed by adjusting the position of the screw (T).

- The next stage is adjusting the power of Husqvarna at maximum speed and adjusting their number. To do this, the tachometer is connected to a running chainsaw, the throttle stick is squeezed out to full, after which the tachometer readings are checked. If the value of the maximum speed differs from the maximum number recommended by the manufacturer, then by changing the position of the screw (H), the tachometer readings are returned to normal.

The structure and principle of operation of the Husqvarna carburetor

To successfully tune your Husqvarna chainsaw carburetor, you need to know how it works and how it works. In fact, everything is not as difficult as it seems at first glance.

The saw carburetor has a built-in fuel pump, which is responsible for transporting a mixture of gasoline and oil, as well as a diaphragm, a needle valve with a rocker arm. Their joint work allows metering the fuel supply to the main chamber and two dampers.

One of the valves is designed to adjust the fuel supply to the cylinder when the gas is pressed, it is called the throttle, the second is responsible for limiting the air supply from the air filter to facilitate starting a cold Husqvarna chainsaw.

At the moment when the operator cuts off the air supply to the carburetor with the help of the air damper, the fuel mixture becomes leaner and its supply to the cylinder increases, due to which the chainsaw starts much easier than when a cold start is carried out in normal mode.

In the operation of the Husqvarna carburetor, a nozzle valve is involved, which atomizes the fuel and prevents air from entering the main chamber. Often, problems during the operation of the saw can be caused by defects of this particular element.

For example, a valve, if the chainsaw is not stored properly, may stick, the fuel supply will stop, which will make the engine impossible to operate. Also, irregularities in the operation of the injector can cause air to leak into the main fuel chamber of the carburetor. In such cases, adjusting the position of the adjusting screws will not correct the situation, it will be necessary to repair or replace the unit.

Three adjusting screws installed in the carburetor body are responsible for setting the quality and quantity of the mixture, as well as the number of revolutions of the crankshaft in idle mode:

- screw (L). adjusts the amount of fuel in the low and medium speed mode;

- (H). is responsible for traction at high speeds and their number;

- (T). changes the position of the throttle valve, thereby regulating the amount of fuel mixture entering the cylinder and the operation of the engine of the tool in idle mode.

Attention! Screws (L) and (H) cannot be adjusted without specific knowledge and experience. Improper adjustment of the quality and quantity of the fuel mixture can cause the engine to stop working or malfunction, leading to rapid wear or even seizure.

DIY carburetor repair

If in the process of carrying out a full diagnosis of the Husqvarna chainsaw, carburetor defects were found, then some of them can be repaired without contacting a Husqvarna AB service center. For example, you can independently:

- change the gaskets under the covers of the main chamber and the fuel pump;

- clean or replace the strainer;

- replace the diaphragm or needle valve of the main chamber;

- troubleshoot the fuel pump diaphragm.

Gaskets, diaphragms and a rocker needle valve can be found in the repair kit provided for each Husqvarna chainsaw carburetor model.

Also, if you have some experience, you can try to restore a faulty injector valve, but you cannot guarantee a positive result when trying to restore an injector, if it is faulty, manufacturers recommend changing the carburetor completely. To do this, you need to perform the following series of actions:

- Before removing the carburetor, clean the saw with a compressor, as dirt can interfere with a quality repair.

- Next, open the top cover of the chainsaw, remove the air filter, disconnect the rods from the air and throttle control levers.

- After that, unscrew the screws securing the carburetor.

- Disassemble the carburetor body for repair. This is quite simple to do. The main chamber cover is held in place by four screws, which can be removed with a regular screw, the fuel pump cover is secured with one wide screw.

Below is a video that will make it clear how exactly you can repair the carburetor without contacting a Husqvarna service center.

Adjusting the carburetor of a Husqvarna chainsaw

Modern chainsaws have a complex system and consist of several main units that periodically require maintenance and adjustment. In this article, we’ll talk about how to adjust the carburetor on a Husqvarna chainsaw.

Tools required for work

Before proceeding with the tuning of the Husqvarna carburetor, you need to take care of having all the tools that may come in handy. To carry out this type of work yourself, you will need:

A regular slotted screwdriver will not work for adjustment, as the adjusting screws on Husqvarna chainsaws may have different cross-sections. You will have to purchase a special, this is a feature of repairing Husqvarna chainsaws, they did everything so that the saw could be repaired only in a specialized Husqvarna service.

When does the carburetor of a Husqvarna chainsaw need adjustment?

There are a lot of problems that can be solved by adjusting the carburetor. Adjusting the carburetor of a Husqvarna chainsaw is necessary when such malfunctions appear:

- increased idle speed;

- strong smoke when the tool is in operation;

- Difficulty starting a cold or hot engine;

- lack of traction and reduced maximum revs.

This is by no means a complete list of problems that can be solved by tuning the Husqvarna carburetor. In some cases, adjusting the quality and quantity of the fuel mixture is carried out after an overhaul of the engine or in the process of scheduled maintenance of the chainsaw.

Husqvarna AB recommends adjusting the carburetor before and after running in the saw.