How to remove and change a leading asterisk on a chainsaw

Regardless of the complexity, tasks and frequency of use, all tools need periodic maintenance or repair. Chainsaws are no exception, despite the well.thought.out design and operational characteristics. But, like all the equipment with mobile parts, the chainsaws are susceptible to wear and require periodic inspection. And first of all, such parts include a saw chain, to extend the service resource of which the timely replacement of the star is important. This is what we talk about in this article.

Here you should get a special repair set, in which the presence of a drive star and the bearing is foreseen. Then you should prepare a tool and parts that are useful for work:

- universal ward key products of a chainsaw;

- Stop piston mechanism of the mechanism (in standard versions it is plastic or iron)

- A centrifugal mechanism or clutch (selected depending on the chainsaw model).

During the operation, subsequent acts are carried out:

- At first, a saw set is removed, the tire lid nuts are unscrewed by a universal wrench. Remove the lid, the bar and the chain is removed.

- Then the air filter is removed.

- The saw candle is unscrewed by a universal key. The prepared lock stop is inserted in the bonno, which will allow to fix the position of the piston in the cylinder.

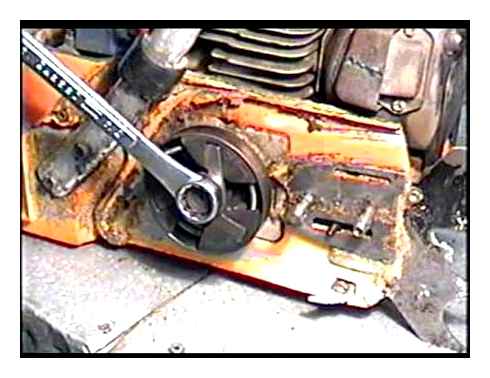

- The clutch pulp fits into the universal key socket. Then, with the help of the purchased device, the coupling turns off. All deeds must be done clockwise.

- Clutch is removed, freeing access to the inner parts. Now you can delete the star (clutch drum).

- Depending on the type of drum, it is examined or inspected. a star or a crown is changed to new. When installing new parts, it is necessary to painstakingly check the condition of the clutch separator. Here you should direct increased attention to the springs of the centrifugal mechanism and fists. If severe wear is found, these parts must also be changed.

- If the condition of the details does not cause shakes, all parts of the chainsaw are collected in a revival order. At first, the piston stopper is twisted, the launch cord is pulled, later the cork is screwed again. Such complex acts allow you to clamp the centrifugal mechanism of the chainsaw on the crankshaft.

- Using a universal key, the clutch is clamped counterclockwise, in other words, against rotation of the chain.

- After that, all nodes and details can be successfully fastened to their initial places.

In order to change the asterisk on the chainsaw, all the work must be done carefully and painstakingly.

Without the presence of special devices, repair work may fail: not only a star or a centrifugal mechanism cannot fall off, and an dust chain.

As can be seen from the information presented, the question is how to remove the star from the saw can be successfully solved without the help of others. How the operation will be performed, it can be done again and again, when the need arises, and attention and accuracy will become the key to perfectly completed work.

The transmission of chains’ chains of at least a design determines the productivity of the tool. Apart from that, the chain will stretch during operation and the teeth of the drive star wear out. The illiterate choice of asteriska will significantly lower the durability of the teeth of the chainsaw, and its incorrect establishment will lead to early wear.

Design features of leading stars

At least some manufacturer in the operating annotation shows a step of teeth. Taking into account the fact that a driven star (created to create the desired tension) is also installed on the saw bus, the step there and there should be similar.

Leading stars of chainsaws can be whole and prefabricated. In the first case, the asterisk contains a hub on which a gear crown is tuned. Specifically such a makar arranged details in Champion chainsaws. The product should be completely removed during replacement, since at home to observe the value of the tights specified at the manufacturing enterprise is almost impossible. And buying a crown separately is also a problem.

In the chainsaws from Stihl or Husqvarna, the replaced crown is located directly on the shaft of the drum, and therefore its replacement does not represent any difficulties.

The wear of the teeth is set according to the following signs:

- In places of transition from tooth to hollow there are clearly noticeable radii.

- Tooth width is uneven in height.

- Metal chips are observed at the top of the tooth.

- On the inner surface of the hole in the hub there are numerous bullying and risks (a consequence of poor lubrication).

- The groove from the saw tire is noticeable on the asterisk (you need to change the chain).

- The chain at the initial moment of starting jams.

In the presence of at least one of the above factors, the leading star must be replaced.

Before starting work (especially if the chainsaw has worked relatively little), it is worth checking the fastening of the saw tire. A screwdriver’s screw moved away or the mounting nuts unscrewed-the guide is already inconsistent with the longitudinal braid fishing lines. He begins to contact not with the center, but with the periphery of the teeth of the leading star, provoking their intensive wear. After the tightening of these elements, the chainsaws are checked: if the backlash is not eliminated, then the star will have to be changed.

Clutch drum algorithm

For uninterrupted use of the chainsaws, regular technical inspection is necessary.

When replacing the clutch drum should be used for installation only a strictly defined type of structural element of the device. When replacing the drum, you should simultaneously change the bearings of the structure of the structure.

For repair work, you should purchase a special repair kit, which contains a leading star and bearing. After the purchase of the repair kit, the required materials and tools should be prepared for the repair. The main tools that will be required during the repair are as follows:

- universal key that comes with a chainsaw;

- Stop the piston can be made of plastic or metal;

- Special shooter of the centrifugal mechanism or clutch drum.

The work procedure consists of several stages. Each stage has its own characteristics depending on the design features of the chainsaw, but the scheme and sequence of work are the same for any model of the unit.

Sequence of repair work

At the first stage, the saw’s headset is carried out, the cover of the guide tire is removed. After removing the cover, the guide tire and saw chain are dismantled. Removing the fastening nuts is carried out using a universal key, which is included in the set of supply of the unit.

After removing the saw chain and the guide tire, the air filter is dismantled. Then the ignition candle is dismantled. A traffic lock prepared in advance in a pre.prepared candle. The stopper allows you to fix the position of the piston in the cylinder and prevent crankshaft turning. The clutch coupling should be removed using a special fighter installed in the universal key connector. All actions should be carried out clockwise.

After removing the clutch coupling, an approach to the internal details of the device opens, that is, after removing the coupling, you can remove the star.

After removing the clutch drum, it is carried out, depending on its type, inspection and verification of the crown and asterisk. Depending on the design of this node, the design elements of the structure are replaced. When carrying out the repair, special attention should be paid to the springs of the centrifugal mechanism and its fists. If wear is detected, they should be replaced.

If components do not cause complaints, all structural elements are installed on the chainsaw in the reverse order. First of all, you should twist the piston stopper and pull out the starter cord, after which the piston stopper is installed in place. This complex sequence of operations makes it possible to clamp the centrifugal mechanism on the unit crankshaft. The clutch is installed in place and clamped using a universal key in the set of a chainsaw. The clamping with the key should be counterclockwise.

The last step in repair work is the installation of the remaining structural elements of the device.

When replacing the stars, all work should be carried out carefully and with caution. All repair work should be carried out using special tools, otherwise it is possible to disable a centrifugal mechanism or saw chain.

Read also: fried ice cream what is it

Tips: how to remove an asterisk from a chainsaw

Many tools need constant substitution of consumables. It applies and saw. That is why the question of how to remove the star from the chainsaw, which is often called the clutch disk or centrifugal mechanism, very lively among home masters. In this regard, you need to see what is called an asterisk and for what purposes it is needed.

The clutch drum called an asterisk is an integral part of the chainsaw.

What you need to know about the design of the leading gear on the chainsaw

The operation of the chainsaw can last long enough until there is a need to replace the failed parts. Leading star or gear, through which torque transmission from the crankshaft to the chain has a large operational resource. However, it ends, which leads to the need to replace the part. Before you do this, it will be useful to find out about what chainsaw stars are.

Leading gears are produced by two types. whole or whole.littered with the drum and prefabricated. The difference between these details is not only in the external structure, but also in operational features, which will definitely be interesting to know the owners of the chainsaws.

- Solid. they consist of a drum with a hub and a tuned gear crown. The part is made by casting. The disadvantage of this type of stars is that if necessary, they must be completely changed. There are advantages of such options for drive mechanisms, the main of which is a long operational resource. The teeth of such devices are cut off extremely rarely, and only in those exceptional cases when marriage is appropriate. The second advantage is the lack of a problem with the search for details, as they are in all specialized stores. If there is a need to replace a whole gear on a chainsaw, then you need to know that such devices are more expensive than prefabricated.

If there is a need to replace the leading star on the chainsaw, then the first thing you need to clarify what type of part is installed on the tool. Manufacturers of different models of chainsaws equip them with leading gears of both prefabricated and solid type. How they differ among themselves is already known. It is only worth adding the following:

- Both types of parts are interchangeable, only replacement is carried out in conjunction with a drive drum;

- By reliability, prefabricated devices win, through which an effective connection with the tool chain is ensured;

- In addition to reliability, the prefabricated types differ in the smoothness of the chain, which is achieved due to the presence of a backlash between the protrusion with the slots on the drum and the crown;

- Due to the presence of a backlash, the operational resource of protrusions on the drum increases, but the entire load falls on the replaced crown.

Prefabricated devices are noisiness compared to solid, but at the same time they are more effective. It often happens that it is not possible to find a replaced crown for the chainsaw star, which leads to the need to install a whole drum.

Do.it.yourself Carburetor Instructions for the carburetor

Basil is needed in construction, and in gardening, and in the improvement of territories. its presence greatly simplifies the implementation of a number of wood processing tasks. The main knot of this tool is the engine, the operation of which largely depends on the state and settings of the carburetor. It is here that the fuel mixture is being prepared. So, if the saw does not start, stalls or does not provide the set power, it is likely that the reason for this is the incorrect operation of the carburetor. Fortunately, in many cases you can cope with it yourself. Only for this you need to know and understand the device and principle of operation of this unit and, of course, the chainsaw itself.

Clutch basket of modern chainsaws. a successful and simple technical solution. Fully meets all the requirements for such a node:

- automatically, without a special turned on the operator, transmits torque from the engine to the gear of the circuit at revolutions above the idle,

- does not move the chain at idle,

- Protects the engine if the chain is clamped in wood (the clutch is slipping, the engine does not stall and does not wedges).

It is through the interaction of these nodes that the clutch automatically turns on with increasing speed.

drum (upper lid with gears), 2. clutch, clutch disc (mechanism with springs), 3. bearing.

The centrifugal mechanism is fixed on the thread of the crankshaft. At low (idle) revolutions, it rotates without touching the led the outer cover with the gear. With an increase in revolutions, centrifugal force extends the clutch segments. They are pressed to the outer cover with a gear and begin to rotate it, adigns with it due to the friction force. The chain begins to move.

With a decrease in the revolutions, the springs are returned (compressed) segments to the previous position, a gap arises between the lid and them, the chain stops.

Features of this design. the wear of the segments of the centrifugal mechanism and the inner surface of the outer cover due to friction.

Also occurs with frequent clamps of the chain in wood. At the same time, the shaft is spinning at high speeds. The segments are extended under the influence of centrifugal force, pressed to the inner surface of the outer cover. That is, the clutch is included in the operating mode. At such revolutions, segments and lid with gears should rotate together, synchronously, and the chain move. But on the brake and when jamming, the clutch slips, between segments and the inside of the lid, enhanced friction, overheating and wear.

There are needle bearings in this node that require regular lubrication. The regulations for their maintenance, as well as the clutch as a whole, is registered in the instructions for operation for each specific brand of the chainsaw.

Alternative solutions

The drive design of most chainsaws presented in the domestic and semi.professional segment of the market are fundamentally similar. The sequence of operations necessary to remove and replace the lead gear coincides.

How to change a star on a partner?

As already mentioned, the best option would be to purchase a regular reptity for this model.

The advantage will be the presence of a kit and bearing. You should also check the presence of a drum puller intended for a given saw, as well as a latch for fixing the piston in a certain position.

If, nevertheless, there is a brilliant idea of “improving” or modernizing this node of the chainsaw, it is better to consult with specialists and just with experienced people.

Husqvarna chainsaw 137. Replacing the clutch drum

The chainsaw drum is one of the most common consumables on the chainsaw, because it sets the cutting chain in motion. The drums themselves are divided into two types. with a welded leading asterisk and with a change of crown, and in the second case only a shift crown wear out, the drum itself changes much less often.

When repairing a clutch of a chainsaw, we follow the rule. When the two chains are completely worn out, the tire changes when two tires wear out, the clutch drum changes. The level of wear of the star can be determined without special tools, just inspect it. The chain, moving at high speed, ultimately wipes the teeth along which it moves. If wear is serious enough, replacing the clutch drum of a chainsaw is inevitable.

The article will talk about the chainsaw of Husqvarna 137. Clutch replacement is a simple procedure and occurs in several stages.

- First you need to remove the tire and circuit brake. To do this, use a combined wrench that comes with a chainsaw.

-

Then remove the air filter lid, unscrew the spark plug and fix the Husqvarna 137 chainsaw piston. For this procedure, it is recommended to use a regular cable, since when using a metal plug there is a risk of piston breakdown.

How to remove a star from a chainsaw: independent replacement

Today, almost every resident of a country house or summer resident has its own chainsaw. You can’t do without it with regular triggers, landscaping and utilities. Demand for chainsaws does not fall, but even grows due to the fact that these devices do not require special knowledge and skills. The only thing you need to do regularly is to conduct technical examinations.

Like any other tool, chainsaws need careful care. It is necessary to constantly check the supply of oil into the circuit, the chain tension, the operation of the brake, the ignition system and much more. Fortunately, almost any problem can be solved at home on your own.

Asterisk Leading for a chainsaw

A sprocket for a chainsaw or a clutch plate serves to transmit rotational movement and power to a saw chain. Three types of leading stars are structurally distinguished;

The star is whole. In such an asterisk, the clutch plate is rigidly welded to the drive crown. In case of wear, such a star changes entirely.

The star is collapsible. It is a plate of clutch with slots on which a drive asterisk is dressed. The clutch plate wears out very little and the replaced whisk is cheap. The collapsible asterisk is very beneficial for large volumes of work and is used mainly by professionals.

Asterisk is a shift crown. This asterisk is used to replace it on collapsible stars.

The selection of a leading asterisk is carried out according to the chainsaw model. If you doubt the choice, call us, try to suggest the correct spare part.

note! Do not try to pick up the chainsaw star in size. Most likely the star you buy will not work. To select a drive asterisk, be guided only by the brand and model of your chainsaw.

We have payment for the current account. Our company is a payer of income tax on a common basis and a VAT payer, so we can provide a full package of necessary documents for legal entities.

Stihl MS361, MS362, MS440, a set. 3/8 ″ 8 Trosubevs

Stihl MS361, MS362, MS440 chain stitch, 3/8 ″ 8 teeth set of chain driven.

There is a product in a supplier warehouse, we can send it within 2-3 days

Star Chainsaw Husqvarna 365, 372xp

Asterisk set with interchangeable lines. For chainsaws of Husqvarna models 365, 371xp, 372xp and Jonse.

There is a product in our warehouse and is ready to send

Star of the chainsaw set STIHL MS 260, MS 270, MS 280

Asterisk set with interchangeable lines. For chainsaws STIHL models MS260, MS270, MS280. Step.325 ″. To.

There is a product in our warehouse and is ready to send

Star of the chainsaw set STIHL MS 290, MS 390, MS 360

Asterisk set with interchangeable lines. For chainsaws STIHL models MS 290, MS 310, MS 311, MS 390, MS.

There is a product in our warehouse and is ready to send

Star of a chainsaw set STIHL MS 361, MS 362, MS 440, MS 460

Asterisk set with interchangeable lines. For chainsaws STIHL models MS341, MS 361, MS 362, MS 440, MS 4.

There is a product in our warehouse and is ready to send

Star Leading chainsaw Stihl MS170, MS180, MS210, MS230, MS250

Star Leading Chainsaw STIHL MS170, MS180, MS210, MS230, MS250ORIGINAL WITHING ACK.

There is a product in our warehouse and is ready to send

Asterisk leading whole chainsaw OLEO-MAC 941C, GS-44, EFCO MT-440.325 ″

The sprocket is the leading whole. Used in OLEO-MAC 941C, GS-44, EFCO 141, MT-440 chainsaws. Star.

There is a product in our warehouse and is ready to send

Asterisk leading whole chainsaw OLEO-MAC GS-35, EFCO MT-350

The sprocket is the leading whole. Used in Oleo-Mac GS-35, EFCO MT-350 chainsaws. The star is whole.

There is a product in our warehouse and is ready to send

Asterisk Crown Step Step.325 landing “Smol” 7 teeth

Asterisk is a shift crown. Internal landing size. 19mm. The name of the Oregon labeling.

There is a product in our warehouse and is ready to send

Asterisk Crown Step 3/8 Planting “Standard” 7 teeth

Asterisk is a shift crown. Internal landing size. 22mm. The name of the Oregon labeling.

There is a product in our warehouse and is ready to send

Asterisk Crown Step 3/8 Planting “Standard” 8 teeth

Asterisk is a shift crown. Internal landing size. 22mm. The name of the Oregon labeling.

There is a product in our warehouse and is ready to send

Dolmar PS 34, Makita, 3/8, solid sprocket sprocket

Used in Dolmar PS34, PS45, Makita DCS34 chainsaws. Asterisk for a chainsaw is whole, with a plate.

There is a product in our warehouse and is ready to send

Asterisk for the chainsaw Husqvarna 137, 142, Oleo-Mac 941, solid

It is used in Husqvarna 235, 137, 142, Oleo-Mac 941, EFCO 141 models. Whole sprocket for chainsaw.

There is a product in a supplier warehouse, we can send it within 2-3 days

Asterisk for the chainsaw Husqvarna 236, 240, Partner 350, 351, Jonshed. Oleo-Mac, integral

Used in Husqvarna 236, 240, Partner 350, 351, 352, 371, Jonsered CS2137, CS2138, O.

How to change an asterisk on a chainsaw?

To change the worn element, you will need to buy a part of the same type and with the same size as the standard element. In most cases, a factory chainsaw bearing is also subject to replacement during the repair of the replacement.

It is best to initially buy a repair set, which includes a bearing and an asterisk. To remove the star from the chainsaw and install a new part instead, you will also need to prepare tools. Their list includes:

- universal key that is delivered on sale with a chainsaw;

- Removable key to dismantling a centrifugal clutch. When choosing it, you need to take into account the model of the chainsaw;

- Stop a mechanical piston. A metal or plastic tool is suitable for dismantling the piston.

Replacing the stars on the tire of the chainsaw should be performed in the following order:

- First, you will need to remove the saw headset of the saw. Using a universal key, you need to unscrew the protective covers;

- Next, you need to remove the standard air filter;

- After that, using a universal key, you need to unscrew the spark plug. In its place, you need to install a lock of a mechanical piston. it is necessary to fix the piston in a fixed position;

- Then, in the universal key connector, you need to install a removable key to dismantle the clutch mechanism. Through the resulting device, you need to carefully dismantle the standard clutch clutch. For this, the factory node should be rotated clockwise;

- After removing the coupling, the passage to the internal elements is free. This will make it possible to unscrew the asterisk of the household chainsaw;

- The removed drum will need to be carefully examined. If necessary, the crown or star should be replaced. During the replacement, you will need to check the separator. If necessary, you need to replace worn springs and fists of the centrifugal mechanism;

- After replacing all faulty elements, you can proceed to the feed assembly of the chainsaw. To do this, first you need to unscrew the previously installed piston corkscrew, as well as stretch the cable of the factory starting mechanism. After that, the lock will need to be screwed back. This will make it possible to reliably press the centrifugal clutch of the tool on the crankshaft of the engine;

- Further, through the universal key, it will be necessary to press the clutch counterclockwise;

- At the end, all previously dismantled parts can be installed back on the chainsaw.

To replace the stars on the chainsaw gives its results, you will need to strictly adhere to the described procedure. Otherwise, the owner of the instrument risks damaging the piston and the centrifugal coupling of the saw.

How the star on the chainsaw is removed and changes

A new part is shown on the left, and on the right the device has obvious signs of wear. If, after removing the protective casing of the tool, a chopped gear tooth is detected, then the part must be replaced. To do this, you need to buy a sprocket in a tool store or in an online store, where the choice is much larger, which will allow you to choose the best option.

To change the gear, you need to decide which type of device is on the tool, and what will be installed. For each type of mechanism, the sequence of actions will differ. Replacing the sprocket on the chainsaw of the first illegal type option is as follows:

How a protective cover on a gas instrument is removed

In the reverse order, the process of assembling the mechanism is carried out. If you need to replace a collapsible product, then the process will be almost similar, only in the end one crown without a drum is replaced.

Structural differences of the whole and collapsible type gear

If the replacement process is completed, you need to check. The tension force of the circuit is checked, for which the hand brake is turned on, and the circuit is pulled in the direction of its movement. The immobility of the product speaks of the fastening of the mount. To weaken it, you will need to release the tensioner.

Lack of prerequisites for the restoration of a worn star

If the gear has a replaceable crown, you should carefully check the state of the base. If you are detected by nicks, chips, deep scratches, changes in geometry or corrosion, not only the crown, but the whole detail should be replaced. Joint work in one node of worn and new details will lead to a reduction in the service life of the entire node. The risk of jamming or a chain break is increasing significantly.

In addition, the vibrational load on the clutch, transmission and engine of the device will increase. The same factors arise with prolonged operation of one chain.

You should also not change the diameter of the gears (and, accordingly, the number of teeth). When working an enlarged or reduced star in the transmission and engine, efforts arise on which the designers of the device did not count. This will reduce the operational resource of the tool and will not increase its performance.

Despite the presence of security systems in the design, instantly stopping the movement of the canvas when it is broken or destroyed by the tire and protect the torn links from the opening of torn links, it is better not to bring to such situations not to bring. The need to replace the gear is only intensified by safety requirements.

The leading star of the chain chain or electric saw is one of the most important parts of the saw apparatus. The main function of the chainsaw star: transmission of the torque of the engine to the saw chain.

This transmission is carried out through the centrifugal clutch coupling. By type of sprocket can be divided into professional and domestic, as well as chains.

During the operation of the chainsaw and sawing of wood, the leading star, like the chain, gradually wear out.

Husqvarna leading asterisk

Replacing a Chainsaw Clutch Drum Sprocket without Special Tools

Let’s learn in more detail why you need a replacement of a worn sprocket of a chain chain or electric saw and when it is better to perform such a replacement.

The design of its crown is determined by such an important parameter as choosing a chain by step.

- The installation of a new part on a worn sprocket reduces the smoothness of its stroke, forced wear, initiates the risks of its break and create a traumatic situation.

- There is also an increase in operational loads on the engine and elements of the tools of the tool.

- A similar process takes place when installing old stretched circuits on the tire, the diameter of which is adjusted to the size of the tire by removing part of the links.

Experts also do not advise arbitrarily change the size of the stars. The experiment can adversely affect the engine resource and the cinematics of the tool as a whole.

The safety of sawing work of various degrees of complexity is ensured by the effective operation of the emergency stop brake and devices that block the scattering of the ends of the chain in case of accidental breakdown. In any embodiment. the most reliable prevention of emergency situations, maintaining a chainsaw in good technical condition.

The leading asterisk for the chainsaw of any power category is made of special steel, processed according to special technology, so repairing the part with arc welding and subsequent milling is not possible.

The price of the part itself is several times less than the cost of its replacement in service structures.

- Advantages of independent repair of the drive device in lower costs of funds and time.

- If there is an appropriate tool with work, you can manage for a fairly short time interval.

Features of the clutch drum in chainsaws

The drum located in the clutch base of the mechanism is an integral part of the circuit drive system. This part recalls the star with its own form, due to which it received its title. Depending on the type of chainsaw, the part can be professional or household. Because the profile saw is used more often than the household, then the leading star asks for constant substitution. If you read about household tools, then everything is depending on the volume of work performed and the load that is on the device chain.

In most cases, a star, a crown and a saw bearing requires substitution.

How the star on the chainsaw is removed and changes

A new part is shown on the left, and on the right the device has obvious signs of wear. If, after removing the protective casing of the tool, a chopped gear tooth is detected, then the part must be replaced. To do this, you need to buy a sprocket in a tool store or in an online store, where the choice is much larger, which will allow you to choose the best option.

To change the gear, you need to decide which type of device is on the tool, and what will be installed. For each type of mechanism, the sequence of actions will differ. Replacing the sprocket on the chainsaw of the first illegal type option is as follows:

How a protective cover on a gas instrument is removed

In the reverse order, the process of assembling the mechanism is carried out. If you need to replace a collapsible product, then the process will be almost similar, only in the end one crown without a drum is replaced.

Structural differences of the whole and collapsible type gear

Additionally: Makita RP2300FC milling cutter. Review, characteristics, reviews

If the replacement process is completed, you need to check. The tension force of the circuit is checked, for which the hand brake is turned on, and the circuit is pulled in the direction of its movement. The immobility of the product speaks of the fastening of the mount. To weaken it, you will need to release the tensioner.

Asterisk Leading for a chainsaw

A sprocket for a chainsaw or a clutch plate serves to transmit rotational movement and power to a saw chain. Three types of leading stars are structurally distinguished;

The star is whole. In such an asterisk, the clutch plate is rigidly welded to the drive crown. In case of wear, such a star changes entirely.

The star is collapsible. It is a plate of clutch with slots on which a drive asterisk is dressed. The clutch plate wears out very little and the replaced whisk is cheap. The collapsible asterisk is very beneficial for large volumes of work and is used mainly by professionals.

Asterisk is a shift crown. This asterisk is used to replace it on collapsible stars.

The selection of a leading asterisk is carried out according to the chainsaw model. If you doubt the choice, call us, try to suggest the correct spare part.

Replacing a stars on a chainsaw

All household, and professional chainsaws have the same design features, and therefore the answer to the question of how to remove an asterisk from a chainsaw is almost the same for owners of all models of chainsaws. Of course, they can differ in the quality of the assembly and components, by the established additional options and the placement of some components. But, in general, they consist of the same nodes have similar sores and require the same consumables. This remark fully refers to the saw apparatus, which consists of a drive device, tire and chain.

In turn, in the drive device, the leading star is most often out of order. This is due to many reasons that we will consider below. Replacing such an important mechanism may seem to someone a super-complex task, but in fact, repairs can be done at home. This does not require any special tools, nor big knowledge and skills. Immediately note that the technology of repairing the saw apparatus of the chain chain and electric saws does not differ significantly.

Two types of drive stars are used in the chainsaws: whole. components with a clutch plate one whole and collapsible. having a shift whisk with a slotted mount to the clutch plate of a chainsaw. Whole stars are cheaper, at the same time, the star is collapsible during operation is more profitable, as it allows you to change only the fucking corolla. The clutch plate wears out little.

Replacing the leading star on the chainsaw Husqvarna 445e (435-440-450)

This video indicates how to change the worn.out driven star on chainsaws 4 series Husqvarna.

Clutch clutch of a chainsaw closes an asterisk.

At first it is worth noting that when buying spare parts for a chainsaw, it is necessary to strictly observe the type of drum or use the consultation of a specialist if we are talking about its modernization. Usually, with the simultaneous replacement of the drum and saw chain, the drum bearings are replaced.

Here you should get a special repair set, in which the presence of both the leading star and the bearing is foreseen. Then you should prepare a tool and details that will be required for work:

- universal key sold with a chainsaw;

- Stop the piston of the mechanism (in standard versions there are plastic or iron);

- A centrifugal mechanism or clutch (selected depending on the chainsaw model).

During the operation, subsequent acts are carried out:

The scene of the stars of the chainsaw.

At first, a saw’s headset is removed, the tire lid nuts are unscrewed using a universal key. The lid is removed, the tire and the chain are removed. Then the air filter is removed. A universal key is turned out to be a candle of saw. The prepared piston stopper is inserted to fix it, which allow to fix the piston position in the cylinder. The clutch pulp is installed in the universal key connector. Then, with the help of the resulting device, a clutch clutch is wrapped. All deeds must be carried out clockwise. The clutch coupling is removed, freeing the approach to internal details. Now you can remove the star (clutch drum). Depending on the type of drum, its inspection is carried out or a check of the crown. Asterisk or the crown change to new. When installing new parts, you need to painlessly check the condition of the clutch separator

Increased attention here must be paid to the springs of the centrifugal mechanism and fists. When identifying severe wear, these details also need an ineffective substitution. If the condition of the parts does not confuse, all the details of the chainsaws are collected in a flip sequence

First, the piston stopper turns out, the starter cord is stretched, then the lock is screwed again. Such complex acts allow you to clamp the centrifugal mechanism of the chainsaw on the crankshaft. With the help of a universal regular key, the clutch is clamped counterclockwise, in other words against the rotation of the chain. After that, all nodes and details can successfully screw to their previous places.

In order to change the asterisk on the chainsaw, all the work should be done carefully and carefully. Without special devices, repair work may fail to fail: not only a star or centrifugal mechanism, and a saw chain can break

Without special devices, repair work may fail to fail: not only a star or centrifugal mechanism, and a saw chain can break.

As can be seen from the information presented, the question of how to remove the star from the saw can be successfully resolved on its own

Once the operation will allow it to perform it again and again, as a need will appear in this, and attention and accuracy will be the key to well completed work

Leading star. Correct choice and replacement

EASY! How to change a Husqvarna chainsaw chain in 1 minute

The transfer of the chains of the chainsaw of any design determines the performance of the tool. In addition, during the operation the chain is stretched, and the teeth of the leading star wear out. The illiterate choice of the star will significantly reduce the durability of the teeth of the chainsaw, and its incorrect tuning will lead to premature wear.

Diagnosis of malfunctions

Whatever one may say, but breakdowns are still found

But it is important not only to repair the device, but to determine the root cause

- Oil leaks due to violation of the integrity of the oil hose or its sealing in the places of fastening.

- Oil does not enter the chain due to the clogging of the supply channels with dust and chips.

- The engine does not start or start and immediately stalls due to the unhealthy/malfunction of the carburetor, the clipper of the syncene, the air filter, the muffler.

- The chain wedges due to defects of the leading star.

- The engine is zabulak due to violation of the carburetor and a large fuel supply.

Action order to change the star on a chainsaw with your own hands

There are a lot of videos on the Internet that clearly demonstrates how to replace the clutch (star) drum such well.known brands as Stihl, Husqvarna, Friendship, Urals and others. Finding them is easy.

Each type of chainsaw has its own design features, but the principle of operation is the same for them, so the general idea comes down to such actions:

The chain brake cover is removed. In this case, the brake should be pulled to yourself so that the brake tape does not touch the clutch cup. Next, a pair of nuts holding the lid is weakened. The chain tension is weakened, allowing to completely remove the lid. The tire with a chain is removed, along the way, any pollution is removed. Now it will require fixation of the piston in the cylinder. This is performed using a special stopper and fixer, but you can apply a regular rope. Rotating the clutch, it is necessary to identify the moment when the piston reaches the exhaust hole. The rope drops into the candle hole and fixes the piston. For convenience, several nodes are tied on a rope. After replacing, the rope will need to be removed, so you should not release it. After that, you can proceed to unscrew the clutch nut

It is important not to forget that there is a left carving, that is, you need to twist the clockwise direction. Unacceptable use of a chisel with a hammer

This will damage the nut. Now you can remove the clutch and drum of the leading star. Replacing the clutch drum. Assembly of all parts together in the reverse order.

Also, some oil drives of the chainsaws are equipped with a mustache-spring for transmitting rotational energy from the sprocket to the pump. If when assembling a saw, the mustache does not get into its groove, then the oil will stop getting to the saw chain, which can lead to sad consequences.

To avoid most breakdowns, including the leading star, it is necessary to monitor the technical condition of the saw, regularly conduct inspection, lubrication, etc.P. It is also necessary to ensure that nails, concrete, stone and other obstacles leading to the speedy wear of the details do not meet on the path of the chain.

As for the replacement of the leading star, you should use information about the design features of the saw (Husqvarna, Stihl, Ural, Friendship and others), which can be found from the instructions attached to the saw.

In any case, the main prerequisite for replacing the asterisk is the wear of its teeth with a chain. In this case, when a whole drum is installed in the device, the surface of the chain cuts it out almost quite, which asks for a complete substitution of the entire part. If there is a drum with a replaceable crown, here you can only limit yourself to the substitution of the crown.

Usually, in order to put a star from a chainsaw, many people turn to special service centers, but if there is a need to save a home budget, this work can be done without the help of others.This event does not look complicated, but at the same time it is necessary to have all the necessary details and tools.The process of replacing the sprocket is similar to any device model.