Angle grinder is in demand on the farm along with an electric drill or hammer. This name in everyday life is so akin to this electric tool that its official name. an angle grinder (angle grinder) is used much less often, and for a considerable number of inhabitants it is completely unknown.

Despite the fact that it was originally conceived and created for grinding, today it is the main tool for cutting a wide range of building materials (metal structures, profiles and pipes, tiles, slate, brick, stone, concrete, etc.).

A variety of interchangeable accessories (grinding wheels, cutting and transfer discs, brushes, etc.) allows the same tool to grind, grind, polish or cut a wide variety of materials.

This makes the angle grinder popular among both professional craftsmen and ordinary citizens. For the latter, buying an angle grinder often becomes a daunting task. Below are discussed the main criteria for its optimal choice for domestic needs.

MAIN CRITERIA FOR SELECTION angle grinder

Initially, you should determine the list of main tasks and the amount of work that will need to be performed. Like other power tools, angle grinders are available in professional and household variations. They differ in the duration of continuous operation at full load, which does not lead to rapid wear and failure. Professional models are more durable, but at the same time they cost significantly more than household ones.

Disk size (tooling diameter)

The first thing you should focus on when choosing is the diameter of the interchangeable equipment, that is, the size of the used circles / discs or other consumables. It is precisely on what maximum diameter the cutting wheel or grinding disc can be installed on the angle grinder, its working capabilities depend in many respects.

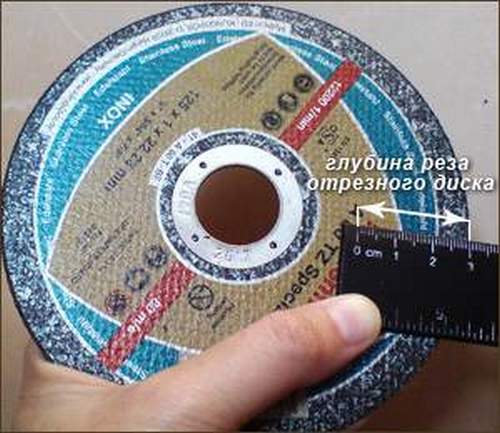

The size of the cutting wheel determines its penetration into the material, that is, the depth of cut. This will be the maximum pipe diameter, channel width, etc., when they can be cut without turning, in one pass.

It should be borne in mind that the technical specifications indicate the outer diameter of the disk, part of the working surface of which is “eaten up” by the tool body. So an angle grinder with a disk diameter of 125 mm will have a cutting depth of only 30 mm. In addition, the circles are grinding during operation, which also reduces this indicator.

Discs for the angle grinder have a standard bore Ø22.2 mm, which allows the use of consumables from different manufacturers. According to the outer diameter of the used wheels / discs, the angle grinder forms a number of sizes from 100 mm to 230 mm:

- Ø100 mm. small battery models.

- Ø115 mm. optimal for grinding work due to low weight and small overall dimensions. It can also be used for all kinds of fine stripping and cutting.

- Ø125 mm. universal for cutting, grinding, grinding or polishing. Light weight plus compactness allow you to work comfortably in a limited space and standing on a stepladder. It is for this size that the largest variety of consumables is produced.

- Ø150 mm. an averaged variety of the previous and next sizes for those who can not decide on the choice between them. Such an angle grinder is not particularly in demand, since the cutting depth of them is not particularly noticeably higher than the indicator of 125 mm models, and the weight and dimensions are close to 180 mm for the tool.

- Ø180 mm. power and a large depth of cut are combined with decent dimensions and weight. Easily copes with cutting a variety of metal structures and a small cross-section profile, pipes, etc. But grinding, grinding or fine cutting with such a clumsy angle grinder will be rather inconvenient.

- Ø230 mm. capable of effortlessly coping with cutting bricks, stones, borders or tiles, not to mention pipes or channels.

- Ø300 mm. specific manual cutting disc machines (for example, Hitachi CM12Y or Bosch GWS 24-300J) are equipped with such circles.

Power Angle Grinder

The second selection criterion is power. As a rule, for an angle grinder, its value is in the range from 0.5 kW to 3 kW. It should be noted that this indicator is not determined by the diameter of interchangeable equipment. That is, 115 mm and 180 mm angle grinder can have a value of 1 kW. But the weight of the angle grinder and its power are directly proportional. And if a variety of techniques can still achieve an increase in compactness, then with the weight of any tricks do not pass. The combination of powerful and lightweight angle grinder is not applicable.

Video: Choosing An Angle Grinder 125 For Home

The more powerful the angle grinder, the less it wears out under load, more stable and longer. But at the same time, weight and cost are increasing. So models up to 1 kW weigh somewhere between 1.5–2 kg, for 1–1.5 kW, the weight will range from 2 kg to 3.5 kg, and at 2 kW and above, you will need to hold a 4–6 kg or more tool in your hands.

For cutting metal corners, channels, concrete or stone, not only the depth of cut is important, but also power. Not only the severity of the work planned for the tool, but the weight of the consumables used should be taken into account. So when grinding with an abrasive thick wheel Ø115 mm, the angle grinder used must have a power of at least 1 kW.

That is, the larger the diameter / weight of the circles used and the higher the load, the more powerful the angle grinder should be. It is better to purchase the 125 mm version with a power of about 1 kW, buy 150 mm from 1 kW, choose a model of 180 mm of at least 1.5 kW, and take a 230 mm tool more powerful than 2 kW.

Thus, if you plan one angle grinder for all occasions in life, it is preferable to choose a model for 125 mm interchangeable equipment. But it is most optimal, especially when living in a private house, to have a 125 mm and 230 mm angle grinder in the household, which will allow you to comfortably carry out all types of work in almost any environment.

ADDITIONAL CRITERIA FOR SELECTION angle grinder

The presence of various options expands the functionality of the tool, but at the same time, each of them increases the total cost. A protective casing and an additional replaceable handle today a priori come with a decent angle grinder. It is better to choose those models in which the position of the casing can be changed without using a key. It is convenient and speeds up the work.

On devices with a maximum snap diameter of 115 mm or 125 mm, the housing often plays the role of the main handle. Such an angle grinder is classified as one-handed and, due to its greater compactness, it is more convenient to wield in a limited space.

But they are harder to hold, so the case is a powerful model with a large diameter of consumables equipped with a separate handle and such devices are two-handed.

Regardless of the level of “sophistication,” the angle grinder should have rubberized handles, since the safety of work depends on the reliability of its holding. Special recesses for the fingers will also be quite useful.

In this case, the main handle should be provided with the possibility of rotation around the axis and fixation in four positions. And removable. to be cast and have a damping insert at the base of the vibration damper.

The most useful additional options are smooth start and dust protection. When you turn on the angle grinder with a smooth start, the speed is gradually gained without a jerk. This option will be especially useful for a powerful tool in the hands of a novice user. Also, the smoothing in this case of power surges in the mains saves wiring in the house.

But it should be borne in mind that the announcement of such a function for cheap models and its availability in an expensive tool are two big differences. You can feel it yourself, including various angle grinders with a heavy disk installed.

Protection of bearings and the engine from dust can significantly extend the "life" of the tool when processing concrete, cinder blocks, sandstone, limestone and other similar materials.

Regarding bearings. often in low-cost household models, plain bearings are used, that is, bushings, and bevel gears are made of plastic, which makes the device one-two-time.

Since the buyer is not able to inspect the internal filling of the gearbox, he can be attracted by such solidifying options as changing brushes without disassembling the case.

Sometimes an angle grinder has a gearbox with a plastic case. It removes heat much worse than metal and is less durable, which in this case does not justify the gain from weight reduction. If possible, ceteris paribus it is better to choose a specimen with a gearbox made of magnesium alloy, which is lighter, stronger and has greater heat transfer. In it, immediately after the purchase, it is desirable to replace the grease with a high-quality synthetic imported manufacturer.

Convenience and speed of work also increases the availability of self-locking nut, which allows you to change equipment without the use of additional devices. Under it, when fixing the consumables, put a ring of rubber or thick cardboard.

Multitasking angle grinder significantly expands such an option as speed control. For cutting metal, high speeds are needed, which provide the cutting disc with high speed. But grinding is performed at reduced speeds. Also, high torque and, accordingly, low revolutions are required when cutting many types of stainless steel, stone, viscous materials.

In addition, productivity and ease of use of the angle grinder are enhanced by options such as maintaining constancy of turns under load, jamming protection interchangeable equipment (does not protect against destruction of disks and expansion of fragments), automatic balancing consumables. The latter function is realized due to the design features of bearings, which eliminate runout during uneven wear of equipment. This is especially true for large diameter circles and brushes.

Thus, the final set of additional options when choosing an angle grinder depends on the main tasks for which the tool is purchased, and the financial capabilities of its future owner.