How to cut glass without glass cutter?

Glass cutting at home did not previously provide for the lack of glass cutter. Even with cautious actions, not evenly cut, but broken pieces, whose edge remotely resembled a curve fishing line for a trimmer with small bends in both directions. Cut the glass without glass cutter, you can still.

What can be used

Cut glass without glass cutter is not the simplest task set by the newcomer to himself. The difference in methods is in the type of influence on the material itself. Heating, for example, is possible only on a certain section of a piece of glass. Using increased strength allows you to concentrate the force attached to the glass on one line. In the factory, glass cutting is carried out using a liquid under high pressure.

When cutting glass by means of directed heating in a simple case, twine, flammable fluid and matches are suitable. The rope or thread is pulled and tied along the cut line, a combustible or fuel-lubricant material is applied to the strapping. The strapping is set on fire. creating a high temperature, with a sharp difference, it will make the sheet crack. The location of the fault approximately repeats the wrapper or thread contour. When such a “artisan” method is too dangerous (you can set fire to objects around or yourself by negligence), use a burning tool or a soldering iron with a capacity of at least 60 watts. The soldering iron can be replaced with a gas burner with a thin nozzle, the outstanding tongue of flame is not thicker than fire from a lighter.

The impact using the drill through concrete, file, diamond disk, scissors or nails makes it possible to cut the sheet when there is no source of fire or objects nearby that can be redone

Rivalry with factory methods in which it is precisely the diamond knife or cutter that comes into business may not give the perfect result. The fishing line for the trimmer of the cut does not always succeed, as if under a ruler. it will lead to the side.

Files

The file-flair is not suitable for obtaining a relatively flat line. He has rounded corners. Use a square tool or in the form of a parallelepiped. The method is similar to the one in which ordinary glass cutter is used. To get a flat furrow, press the file of the file more on the handle than with its standard use. Make sure that a clear groove has formed on the glass sheet. Then the glass breaks smoothly on the angle of the table. The file with a triangular section is ideal.

corner grinding

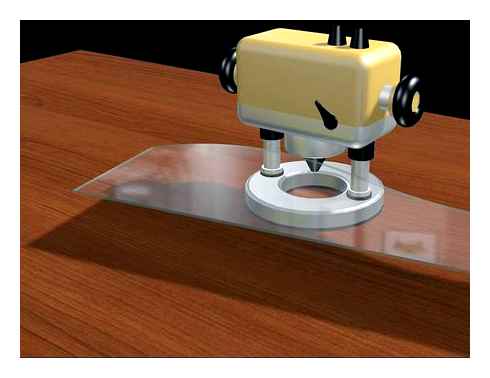

A cutting disk for metal will be required. with a thickness of at least 0.1 mm. The thick disk will not allow the glass sheet to be cut neatly: the area of the disk contact with the surface increases, and the fishing line for the trimmer looks blurry. Disadvantage of the method. it takes not too powerful and large electric drive, otherwise it will become noticeably more difficult to hold it.

Ideal use not of a corner grinder, but a small saw machine made on the basis of a drill. It must be kept not by weight, but to be fixed by means of guide planks with an adjustable height. This will achieve uniformly throughout the length of the disk on the cut surface. One sharp and inaccurate movement. and the glass will not be placed under the fishing line for the trimmer of the desired trajectory, but will fly to the fragments. It is not necessary for a through drunk here, but only immersion to a small depth of a layer not exceeding one tenth from its thickness. Sprinking glass sheet through, the master risks getting many small cracks and thus ruin the appearance of a cut rectangular piece or break it directly during the marking.

Scissors

Cutting glass with scissors in water is suitable for creating a curly rather than a straight line of the cut. It is difficult to cut the glass with scissors in water than 4 mm. In principle, this method is suitable for cutting window glass 2.5-3.5 mm. Water is needed to prevent the rush of fragments and their eyes, nose or ears of the master. The glass is cut in a pelvis or barrel of water. The capacity allows you to accommodate the entire processed piece of glass. The principle underlying the method is a directed chip of material. Water will not allow the glass to crack finally. its resistance softens jerks, pumpkin movements, splitting the same glass without it.

Soldering soldiers

Sharp heating of irreparable glass makes the last crack. The fishing line for the trimmer of the cut from point heating will not become perfect, as after passing in the right place of glass cutter. It will deviate slightly. But it will be possible to insert the resulting piece into the wooden window frame without spoiling the view of the “eye” of the window. To obtain a curly line (for example, when an original curly frame repeating its contour is made along the resulting line) a soldering iron (or a wood burning machine) is perfect.

In this case, a certain sequence of actions must be observed.

- The cut of glass is drawn using a construction felt.tip pen or marker.

- At the beginning and at the end of the planned cut line. on the faces. the glass is neatly hooked by the file. The notches will help more accurately set the direction of the crack formed from heating.

- Retreating from the edge of the glass by 2 mm, the master applies a heated soldering iron to the edge of the glass. The beginning of the process will be the formation of a small crack. from a sharp temperature difference.

- Repeating the indentation from the heating point, the soldering iron is applied to the glass again. The crack will go further. in the direction set by the master. The soldering iron is brought to the end of the cut line. To accelerate cutting to the glass, a wet rag is applied. so that it cools faster, and the temperature difference is maximum.

The choice of tools

A tool for separating a glass surface into parts is glass cutter. Cut it with glass sheets of various thicknesses. When choosing a tool, it is necessary to ensure that fragments are divided into parts the first time. Glass cutters are the following types:

- Glass cutters used for a long time with a diamond cutting head. The high hardness of this stone determines the excellent quality of the cut for about ten thousand meters.

- Tools in which the cutting function is performed by rollers made of a tungsten and cobalt alloy with special strength.Such glass cutters allow you to cut glass with a thickness of up to four millimeters.

- In the improved design of roller glass cutters, a container with butter is placed in the tool handle, which is supplied to the cutting line. As a result, the depth of penetration of the cutting part into the structure of the material increases. Thick glass at home is cut by oil glass cutter.

- Circular cutouts are carried out by glass cutter, similar in shape to the compass. One end of the instrument is strengthened by the suction of the outline circle in the center of the outlined circle, its radius is set using the adjustable scale, at the end of which there is a cutting element. Typically, such glass cutters are equipped with a tank for supplying oil to the treated surface.

For work, a long and flat line is also needed, according to which a straight line will be outlined for a trimmer of separation. To perform cuts of a more complex configuration, the pattern of the corresponding form is used.

Preparation of material and desktop

To perform a high.quality cut, the glass surface must be cleaned well. If the glass is just acquired, it will be enough to wipe it with a newspaper, which leaves no divorces and villi behind.

Glass, which was used earlier, must be prepared more carefully. To do this, its surface is washed using special cleansing agents, then fat deposits are removed, for example, a rag saturated with the stispirite.

The preparatory stage also includes the calculation of the configuration of surface cutting. It will not work to completely avoid the appearance of waste, but the exact calculation can significantly reduce their number. The resulting scraps should not be thrown away, they can be used in the future. Carpet is a good base for cutting glass

The desktop should be even, without significant slopes. The surface of the countertop does not need to be made too hard, it is best made of wood.bearing plate and covered with soft textiles or other similar material for a more convenient cutting.

How to cut glass at home correctly?

Before you start cutting glass, be sure to test your glass cutter. You need to do this on a small glass section: if a colorless feature remains in the process, then the tool is quite suitable for work, if a white fishing line for a trimmer remains, the video is blurred or worn out.

The glass you are going to cut should be put on an even table or workbench. If you only learn, then it will be easier for you to cut straight. for more even cuts, use a ruler or any straight rail (it is desirable that it is longer than the glass itself). Also do not forget about the marks that you can put a felt.tip pen or pencil.

Where to start and how to cut properly

When we cut the glass, you need to hold the glass cutter vertically. Pass the fishing line for a trimmer should not come off, but even lightly relying on the glass. Remember that you should draw only one fishing line for a trimmer: if you could not cut glass the first time, you can’t duplicate! Turn it over and make a new incision.

After the incision is made, move the glass to the edge of the table and fit it with the help of glass cutter, after which you will see a fishing line for a trimmer (she will indicate where to break the glass). It is not difficult to break it. It is necessary to combine the fishing line for a trimmer with the edge of the table: with one hand, press on the glass and press it to the table, and the other. press on the site, which is light.

Precautions: waste size can be small, therefore, to avoid negative consequences, use pliers to break.

Before cutting glass

The main knowledge of the glass is knowledge how to cut glass, so that the canvas of the required size and shape is obtained, as well as that the edges are even and without chips.

Can I DIY rounded mirrors? (cutting glass at home) | WITHWENDY

Previously, both glass and the tools for processing were expensive and sharply engaged in only masters with good skills, then in our time the situation has changed significantly. Nowadays, work with glass can be carried out by anyone.

Polish Glass Bottle Edges After Cutting

Tool

A very good tool is needed to work with a glass canvas.

That’s why before buying glass and working with it, you need to start purchases with the tool.

But the first tool that came across should not be bought, because it may not be poor and will not be able to cut off the glass as it is necessary.

It is very important to determine which tool you need, because glass cutters come in several types:

Roller

A special video is built in a roller glass cutting for cutting glass, which is made of a very durable tungsten.baltic alloy. The usual diameter of the roller is 6.6 mm, such a diameter of the roller allows you to cut glass with a thickness of up to 4 mm.

Diamond

Diamond glass cutter is equipped with small diamond, this diamond cuts glass. The hardness of the diamond is well known and therefore it began to use it for a very long time to cut glass.

Nowadays, as before, diamond glass cutter is considered the best tool to cut off the glass.

Oil

Not so long ago, a glass of glass cutter was replenished with oil windshield.

This is essentially an improved roller instrument, in the handle of which a tank for supplying lubrication to the roller is built. This lubricant binds particles that formed when cutting glass while ensuring smooth movement. This glass cutter can cut glass up to 20 mm.

A couple of acquisition tips

- Before buying any type of glass cutter, it is best to ask the seller to check the tool.

- In the event that the tool suits you, you can buy it, but buy the one that you were shown.

It is not recommended to buy an unexplored tool, since in most cases the cutting edge happens with a marriage.

Soldering iron or burner

First you need to draw sizes on the surface. You can also use a large sheet of Whatman. Then the glass is placed on top of it and the tool is used along the cut line. Warm soldering iron lead on the surface. In order not to stray, you can use the ruler. You can’t press hard so that the glass structure does not crack.

Under the influence of a large temperature regime, the material cracks in the right direction. To get the desired part, a thick mitten, worn on hand, carefully break off the necessary piece.

You can also use a nail in a similar way. The difficulty is that the sharp part will have to heat all the time.

How to make a hole under the handle

There are several options. either drill with a drill with a winning nozzle, organizing a surface of plasticine with a campaura and turpentine, or the thermal method. To do this, apply moist sand of a small fraction to the glass, and with the help of a sharpened bar they make a funnel in it, where they dripped with molten solder or lead. After a couple of minutes, sand and solder are removed.

Maybe someone considers a list of incomplete methods-we have a lot of Kulibins, and there are many more options for solving the problem. But the plus of the described methods, and fatty, is that they work.

What tools to use?

Many of us are used to believe that only glass cutter can only and qualitatively cut glass. But what to do if you need to cut off a piece of glass urgently, and this tool was not found at hand? There is another unusual, but no less effective way that helped our great.grandfathers to get out of this situation. Such a tool is ordinary scissors that are available in any owner. Consider each method in detail.

glass cutter

Glass cutting technology with glass cutter is quite simple. To do this, you must observe certain conditions and choose the right glass cutter. To date, the choice of this tool is wide enough, which allows you to turn work into pleasure.

- Diamond glass cutter, tested by time and remains a leader in his business to this day. For home use, glass cutters with a beveled cutting edge are suitable for home use. Such a tool is designed to cut glass up to ten kilometers and is suitable for any thickness of the material used. From time to time, such glass cutter needs to be sharpened on a special bar.

- Roller. Following the name, the cutting of such a glass cutter is made in the form of a video from a durable cobalt-wolframa alloy. The number of videos can be from one to six.

- Oil. Such a tool works on the principle of roller glass cutter, with the difference that a tank with butter is built into its handle, which is automatically supplied to the video. Suitable to cut thick glass.

About how to choose good glass cutter, see

So, having dealt with the glass cutter, place the glass on a flat surface. Mark the glass and start work. To facilitate the task, you can use a ruler. It is worth considering the moment that the fishing line for the trimmer must be drawn the first time, otherwise the second attempt will lead to cracking the surface. Cut glass with glass cutter, you need to make the same efforts along the entire length of the line on.

Ordinary scissors

Cutting glass with scissors like paper is not a fairy tale, but a completely ordinary reality. For this purpose, you will need the scissors themselves (sewing are best suited for this) and a tank with water (better hot). It is necessary to mark the markings on the glass in advance, and then elementary physics is included in the work: scissors create a microcrack, and the capillary effect completes the process. Of course, the result will differ from the reached glass cutter, but if necessary, this method can significantly help out.

How to cut other materials?

For acrylic glass, glass cutter is not needed. It is an organic material suitable for cutting and riding with other cutting tools. up to a simple knife. Thickened, more than 2 mm, acrylic sheet draws several times in the same place. A neat score along the line is carried out due to the weakening, thinning of the material at the point through which the fishing line passes for the trimmer of the cut.

Tile or thin tiles are cut by glass cutter in the same way as ordinary glass. Tiles are made of burned clay. Thin, up to 3 mm, sheets and squares of tiles can be cut with ordinary glass cutter no worse than simple window glass.

Porcelain stoneware is much thicker than a simple tile. A universal tool is used for cutting it. glass.draincore.

This is an enhanced and enlarged (in size) variant of ordinary glass cutter, which has greater than a simple tool and thickened along the axis of rotation with a roller (wheeled). In some cases, the number of videos reaches five. the larger there are, the more extended the linear meter of the cut materials.

Floor tiles without the formation of unnecessary chips are cut using roller glass cutters or diamond. Like any product made of burned clay, ceramic tiles are easily cut with glass and tile cutters, corner grinder or sawing machine. Any glass cutter is suitable for cutting the bottle, except for the circular, as well as folk methods, based on a sharp heating and cooling of glass. In the latter case, the glass itself will burst from the temperature difference, if it is not hardened, but the fishing line for the trimmer of the cut will not be quite even.

Useful tips

The secret of successful cutting lies in the following.

- With insufficient linear resource of roller or oil glass cutter, purchase a diamond. Its peculiarity is that the master learns to work with him longer. To adapt to a specific product, often the footage of a trial furrow reaches 200 m. It depends on the angle of sharpening and orientation of the edges how quickly the worker will work with the diamond most effectively.

- If you got diamond glass cutter, consider the cutting edge of the cutting edge for a magnifying glass for the presence of zazubin and chips. The diamond is recognized by the shape of the teeth. gentle and hidden, plus a steep dual.sided. A gentle and straight line must be addressed to the master.

- The task of the master is to determine the slope in which the drawing of the cut line will be extremely lightweight. The furrow from the diamond is much thinner than from the video, and the cutting process itself is characterized by glass ringing, and not cracking.

- Diamond deviation at least by a degree is unacceptable. the furrow will receive more rough, blurry edges from both sides. When cholels, the redness forms that need additional smoothing. Diamond glass cutter is able to cut out more than one linear kilometer of glass. along the cut line.

To cut the perfect round glass, a circular glass cutter is required. But finding it in local construction stores is not always possible. Alternative. the use of ordinary glass cutter with a round wooden template.

Not every master will learn how to cut off the glass with high quality the first time. Practice will quickly develop a certain dexterity with a newcomer. Unsuccessful attempts to go on the remains of glass formed after cutting another master.

Preparatory events

In order for the cut to be of high quality, it is necessary to first prepare the material for work. If the glass is new, then just wipe it. The newspaper is best suited for these purposes, it mainly wipes the surface dry, and also does not leave villi and stains.

If the glass was previously in use, then before cutting the material by glass cutter, it will need to spend a little more time on its preparation. First of all, this surface will need to be washed well using special means to clean the glasses. Then a thorough degree process should be carried out. As an option, you can use kerosene. To do this, soaked in a cloth in kerosene, it is necessary to thoroughly wipe the glass and wait until it dries completely.

At the same time, the stage of glass preparation also includes its cutting. There is no doubt that you will be able to achieve the final result without waste, especially if you need to cut the product of an irregular geometric shape. But if you make the calculation as correctly as possible, then you can reduce the amount of waste several times.

Also, make sure that the working surface is quite even and without slopes, but not too hard, it is advisable to make a working surface from plywood or wood.fiber slab, and cover with oilcloth or soft cloth on top.

How to cut glass with glass cutter: Detailed instructions

If you planned to carry out work on cutting glass, then first of all you should decide which glass cutter is best suited for your case. At the moment, there are two types of tools. it is diamond and roller.

The diamond model is considered rightfully the leader among this type of tools. If you are going to use it at home, then the model that has a beveled edge is perfect, which is very convenient to break off the cut pieces. You can cut glass with such glass cutter almost ten kilometers of material, with a thickness up to one centimeter. But at the same time, it should be borne in mind that there are cheap species in which an artificial diamond is installed that allows you to cut glass not exceeding 5 mm thick.

Unlike diamond, roller glass cutter has a working element in the form of a small roller, as a rule, made of carbide materials, usually a tungsten allframe with a cobalt, which is able to cut the material up to 4 mm thick. The advantage of this type of tool is that the video can easily move around the glass, while without applying much effort to lay the furrow.

The process of work is done in the following order:

On the surface of the desktop, clean and dry glass is laid. The marker is made the necessary marking. Further at both ends, small cuts are made along the marked line. Keep in mind that the material used should be tightly in contact with the surface of the desktop.

After that, you need to put a ruler on the glass and along it with a tool to draw a fishing line for a trimmer. Keeping diamond glass cutter in your hands stands in the same way as a regular pencil, when passing along the marked line, only a slight effort should be made. As a result, there is only a barely noticeable mark on the glass that looks like a scratch. If the tool is quite serviceable, then there must be a characteristic sound resembling crackling. If the sound is creaking, then this means that its cutting element needs to be tapped on a special bar for this.

Keep such a tool during work at a small angle, the correctness of which is determined by the experimental way. Keep in mind, the tool that is in the correct position relative to glass leaves a colorless thin fishing line for a trimmer.

Roller glass cutter, unlike diamond, must be kept strictly at right angles to the surface of the glass, while pressing it with the middle and thumb, and pressing it on it. Keep in mind that on a roller instrument, they press a little more than on a diamond, and the incision itself should turn out to be white.

In order to get a high.quality and, of course, even cut. remember a few simple rules that must be fulfilled while working with glass using a diamond tool:

- Do not press on the glass while moving the glass cutter, otherwise the cut will turn out too deep, and its edges will be uneven.

- On the resulting line, in no case can you make another incision. Otherwise, the glass may split. The cut should be done as quickly as possible. For example, if we cut the length of a meter, then you need to spend no more than two seconds on it.

- In order for the workpiece to break out quickly and exactly along the cut line, you need to tap slightly on the back of the glass. After which you will not need any efforts to break it off.

If you are just a beginner master, then it is best to practice on small pieces, this will help to determine the correct angle of inclination of the tool, gain experience, reduce losses, and also avoid error in the future.

Before cutting glass

The main knowledge of the glass is knowledge how to cut glass, so that the canvas of the required size and shape is obtained, as well as that the edges are even and without chips.

Previously, both glass and the tools for processing were expensive and sharply engaged in only masters with good skills, then in our time the situation has changed significantly. Nowadays, work with glass can be carried out by anyone.

Tool

A very good tool is needed to work with a glass canvas.

That’s why before buying glass and working with it, you need to start purchases with the tool.

But the first tool that came across should not be bought, because it may not be poor and will not be able to cut off the glass as it is necessary.

It is very important to determine which tool you need, because glass cutters come in several types:

Roller

A special video is built in a roller glass cutting for cutting glass, which is made of a very durable tungsten.baltic alloy. The usual diameter of the roller is 6.6 mm, such a diameter of the roller allows you to cut glass with a thickness of up to 4 mm.

Diamond

Diamond glass cutter is equipped with small diamond, this diamond cuts glass. The hardness of the diamond is well known and therefore it began to use it for a very long time to cut glass.

Nowadays, as before, diamond glass cutter is considered the best tool to cut off the glass.

Oil

Not so long ago, a glass of glass cutter was replenished with oil windshield.

This is essentially an improved roller instrument, in the handle of which a tank for supplying lubrication to the roller is built. This lubricant binds particles that formed when cutting glass while ensuring smooth movement. This glass cutter can cut glass up to 20 mm.

A couple of acquisition tips

- Before buying any type of glass cutter, it is best to ask the seller to check the tool.

- In the event that the tool suits you, you can buy it, but buy the one that you were shown.

It is not recommended to buy an unexplored tool, since in most cases the cutting edge happens with a marriage.

How to cut glass

The glass sheet is not so easy to cut off, as it seems the first time. To make a cut of glass, preparation is necessary.

Training

- It will be quite well cleaned by the dust from dust and wipe with dry newspapers, for such work, the fabric is not suitable.

- In the event that you have to cut the old glass, then first it should be degreased, after which the glass is well washed with water and detergents.

- After all the above manipulations, the glass will need to be dried in a closed and clean room.

Cut the glass

Also, preparatory work includes both glass cutting and preparation of containers for waste collection. There should be two containers, that is, to collect small waste and for collecting larger ones, which may come in handy for something in the future.

Cutting glass is best started with simple window glass, and then switch to more complex options.

Glass cutting technique

-

First you need to prepare a table or other surface for cutting glass. The surface is covered with a newspaper of four or five layers, such a procedure is necessary in order to protect the table from glass crumbs. And also this will distribute the pressure of the glass to the surface of the table, avoiding glass cracking.

- The glass canvas is placed on the table, while it is necessary to retreat from the edge of the countertop five or seven centimeters. In order to fix the body and at the same time freely move the body above the cutting place is best to spread the legs shoulder.width apart. This position of the body allows you to achieve a good result.

- When cutting glass, it is best to hold the canvas with a free hand to avoid vibration. But keep in mind that the glass is fragile and with greater pressure it can crack.

- Glass cutter needs to draw a fishing line for a trimmer from one edge to another. In this case, the glass cutter must be carried out clearly along the marked line and the windshielder should be at right angles.

When using diamond glass cutter, it is necessary to hold it at the very bottom of the handle and draw a fishing line for a trimmer along the ruler, almost without pressing on the glass.

When cutting glass, roller glass cutting requires a small pressure and when the glass cutter moves on the surface of the glass, a whitish strip appears and deeper than when using a diamond tool.

Possible mistakes

Try to press the tool when cutting glass evenly along the entire length of the cut.

If you noticed chips when cutting glass, then this only means that you press too much on the tool. So that this is not, reduce the pressure on the glass cutter.

The final stage is a glass of glass

Thin glasses break their hands. A piece of glass, which has already been cut, must be put on the edge of the table, so that the fishing line for the trimmer of the cut is on top and protrudes slightly beyond the edge of the table, and the main part of the glass should lie on the table.

It is necessary to press the glass blade with one hand, and the second you need to take up the protruding part of the glass and smoothly press the glass with your hand down.

If the edge that needs to be broken off is small and it is impossible to break off it with your hands.

Knowing the theory of cutting the stele allows you to put these knowledge in practice. That is, you can take a small piece of glass and practice it.

After you try cutting glass in practice in the future, you will be more confident in your skills. We hope that this information will be useful. We wish you good luck and patience!