Assembly of milling plants. step.by.step instructions

Every spring, the owners of summer cottages and gardens begin the season with the cultivation of land plots. This process is responsible and laborious. This is the main reason for the popularity of walkways designed to facilitate labor on Earth. But here not everything is so simple. There are several options for hinged mills for motoblocks. Each is intended for a specific type of soil and the condition of the site. Of course, after a few seasons, the condition of the milling towers worsens. And then the main question arises for the owner: is it necessary to sharpen them.

There is no unequivocal answer to this question. The opinions of beginners and even experienced summer residents are contradictory. Some argue that sharpening significantly improves and accelerates the process of cultivating the soil. Others argue that there is no sense in this, since even the manufacturers of milling do not require this.

Having summarized the experience of one side and the other, among the arguments in favor of sharpening milling, the following should be distinguished:

- The sharpened cutting surfaces of the equipment penetrate the soil easier, accelerating the process of work.

- The first advantage should be reduced by the load on the power unit of the walk.behind tractor, which extends its life and reduces fuel consumption.

- For light cultivators and with insufficiently high.quality material knives, it becomes almost impossible to work with dumb mills. In this case, sharpening is actually the only way out.

The arguments of opponents of the sharpening of the milling plant are as follows:

- The acute cutting surface contributes to a strong grinding of weed vegetation, as a result of which the process of vegetative propagation is increasing repeatedly. From this point of view, preference is given to the process of winding weeds on a stupid mill.

- As a result of the effects of sharp knives, the meaning of the cultivation of the soil is lost, since the soil instead of loosening is simply cut and remains in large lumps.

- The process of sharpening the milling plants is quite time.consuming, since in addition to the sharpening directly, the cutter must first be disassembled, and then correctly assembled. In this case, the severity of the cutting elements remains for a short time. After that, the procedure should be repeated again.

Is it necessary to sharpen?

There is no unequivocal answer to the question of whether to sharpen the knife, no. The gardeners have their own opinion, but it is contradictory. According to their opinion, the need for sharpening may depend on the type of processed soil. For example, if the soil is sandy or toyan, you can not sharpen a cultivator knife. If they are cultivated by the target, you can repeat more than once about the need to sharpen blades. As for the opinions of manufacturers, it clearly indicates that the sharpening of cutters is not needed.

Often gardeners note that the knives do not dull during operation. Manufacturers indicate that it is more important to remove weeds from the blades, since it is from this that the quality of soil processing worsens.

Experts note that the sharpening of the milling is accompanied by crushing weed grass. This contributes to their enhanced vegetative propagation, and also needs to disassemble knives.

Of course, the unit will work more efficiently for two or three hours, but then the blades will again need to be disassembled and imprisoned. And this will require compliance with the rules of assembly, because after sharpening it will have to be correctly assembled by the working unit, and this may not every gardener. As for a heavy motor.cultivator with fairly powerful cutters, there is no need to drag. In addition to the fact that it will take a lot of effort and time, the user will practically not feel the effect.

Whether it is necessary to hide

The answer to this question is positive when using “goose legs”. There it is necessary to carry out regular inspection and sharpening of the cutting edges. The welded design of such mills does not imply the use of hot metal, and therefore bends, bursts and dulls.

The Many Uses of Mineral Oil. KnifeTips #Shorts

In the case of operation with saber.shaped mills, it is not only inappropriate, but also harmful. In addition, in the passport for the product clearly indicates: “Do not drag the edges”. In their work, the frequency of rotation and the composition of the soil is important. Cultivation. the process of weed combat, destroying crust and mixing top dressing with soil.

Assembly elements of saber.shaped cutting tools

A prefabricated saber-shaped design consists of:

- left and right knife (blades);

- shaft (bushings). a metal pipe with a diameter of 50 mm, wall thickness from 4 mm;

- anthers;

- flange, plates (can have different geometry). a steel sheet up to 15 mm thick;

- fastening elements.

The components of a 4-tie cutting organ cutting blades are connected to the plate by means of bolts so that the sharp edges enter the soil when the walk-behind tract moves forward. In this case, the right and left knives on sections should alternate.

Is it necessary to sharpen mills on a single tractor

Soilines are tools that are hidden themselves. In most cases, additionally sharpening the cutting surface is not advised: this often leads to a deterioration in the structure. For example, sharpening will be meaningless if they plan to loosen heavy soil by a machine with high performance and reinforced knives. In such a situation, you should not waste time on the procedure.

It is not difficult to make an adapter for a walk.behind tractor with your own hands if you collect everything you need to work, to understand well.

It will be advisable to hide the blades if a very old mill has lost its sharpness. Also, he will subside cutting plates recommend before processing the site with a small light motor.cultivator. However, in these cases, there is a danger of rapid reproduction of weeds due to crushing their root system. The result of this procedure lasts only a couple of hours, and then it has to be repeated. To sharpen the blades, the part is removed from the walk.behind tractor, remove the lumps of the earth from it and carefully pass with sandpaper on each edge in need of sharpening.

How to make cutters on a single tractor with your own hands

For the manufacture of soil.graders, a small set of tools and materials will be required. It includes:

- welding machine;

- corner grinder;

- metal pipe with a diameter of not more than 40 cm;

- a sheet or pieces of metal (preferable to steel) for cutting plates.

The size of the knives is selected individually depending on the conditions of soil processing. Agricultural manufacturers recommend making cutters whose diameter does not exceed 50 cm. In this case, the risk of breaking the home.made design during operation will be lower. The blanks are pulled, and then welded to the metal pipe. The phased scheme for the manufacture of saber.shaped milling cutters is as follows:

- Causing blanks are cut out of the steel sheet. To do this, the finished drawing is printed on the sheets of paper, cut out and glued to a metal sheet. The first part is cut along the contour, and then used as a template for the remaining knives.

- The resulting flat parts are pulled: the first half on the left side, and the second. from the right. Make sure that the parameters of all cutting elements coincide.

- The blanks are bent according to the drawing. To do this, use the assistant device consisting of a pipe parallel and angular stops.

- The conductor is made, and then welded into a solid structure, additionally attaching the studs and fixing the workpiece with a clamping plate.

- Flanges weld to the shaft, creating the right and left blocks. They are placed at a distance of 10 cm and at an angle of 45 ° in relation to each other.

- The last stage is the assembly of law and left-handed knives using nuts and bolts.

In the manufacture and operation of milling plants, they must comply with safety precautions and rules prescribed in the instructions. Before starting work, the cutting plates are located above the ground. In the process of work, the knives should be immersed in the ground slowly and smoothly.

Soilofors. an important part of any motorcycle unit. They are bought in specialized stores or manufactured independently. In any case, the structure has to be assembled independently. If you do not make errors during the assembly, installation and operation of such components, they will cultivate the soil more simple and fast.

Features of operation

If the diameter determines the depth, then the number regulates the width of the capture. The most common option is two or three pairs of elements. Cultivators are found with one or four pairs. By changing the number of soilofors, you can adjust the width of the processed strip.

The number of elements also depends on the type of soil. For processing with your own hands of loose light soil, the maximum number is set. For loam, virgin land, their number decreases.

Sharpening milling: pros and cons of

Open a photo sharpening milling: pros and cons of an enlarged form. If this is a drawing or device diagram, you can download them to your computer by opening in a large size and using the function “Save the picture as. “(The right mouse key). Please evaluate this material by highlighting the corresponding number of stars.

Most often with this material

“Is it necessary to hide the cutters of the cultivator”

View all photos, drawings, pictures and schemes from the category “How to make mills for a walk.behind tractor” by clicking on the link. You will find even more materials with descriptions of how to make a motor.cultivator yourself and adaptations to it in the section “Putton’s equipment for a walk.behind tractor” or by making a sample of all materials from the Motoblok website.Populjarno.COM according to the following marks: cultivator, disadvantages, advantages, for the Grillo walk.behind tract, mills.

It is possible that you are looking for in one of the most viewed sections of our site:

Drawings and photographs of home.made motoblocks and attachments (click on a picture or name):

Комментарии и мнения владельцев on the material “Pluses and minuses of sharpening the milling cutter” are located at the bottom of the page. you can express your opinion here, ask for advice from visitors to our site, share interesting materials, tell about your positive or negative experience during the assembly of motor blocks and trailers with your own hands. If you have questions or suggestions about this material, please leave your comment below.

Those who want to share their photos by keywords “sharpen the mills, on a single tractor, whether, pros, cons, cultivator, sharpening milling, how to sharpen” or on any other issues about diesel, gasoline, medium, medium or heavy homemade motoblocks. motor cultivators and hinged devices to them. you need to register and use the link “Add photos. “(Visible after registration on the page of all.photoalbums of walk.ashes and attachments). | Dimensions

Is it necessary to sharpen the mills on the motorcycle rack for the main publication

Varieties

To date, two types of mills are known: by location they are lateral and hinged. If you classify them in shape, you can highlight the saber varieties and the “Goose legs” option. As for the saber.type product, these are the most common nozzles for cultivation, which are often equipped with most motor cultivators. Depending on the manufacturer, the products can be delivered in disassembled or assembled form.

These options are an axis to which plates with knives fixed on them are welded in the form of sabers. Sections are identical and connected by means of bolts. The larger the section has attachments, the greater the width of the soil capture and, therefore, the width of cultivation. These cutters cope well with land plots that have previously been processed.

As for the modification of “goose legs”, these mills, unlike the previous option, are non.graceful. Therefore, they will not be able to repair in the event of a breakdown of one element. Here you will have to completely change the attachment equipment. As for the number of sections, it is chosen individually, adjusting to their own interests. It is such nozzles that work with complex soil.

Bushings of such models are round or hexagonal. These modifications cope with the interruption of plants in the process of cultivating the soil. They are characterized by a reduced load on the gearbox.

Products of this type provide for work with motorcycles in which there is an air cooling system. In addition, such mills are easy to control in the process of work.

Another variety of knives for a motor.cultivator are the so.called “virgin lands”. These mills are quite powerful and reliable. They are customary to process the soil at a greater depth. If we consider the best option of three types of knives, it is worth considering the type of soil.

For light soil, there is enough factory saber product. To reduce the load on the motor.cultivator, it is worth purchasing “goose legs”. If you need to process complex soil, it is worth taking a closer look at the “virgin soil” option.

Mohtoblock cutters. Choice, comparison.

Cultivation or milling of the soil is one of the most important stages of processing the land plot. In the process of milling, soil loosening occurs and its mixing. The choice of depth for such cultivation is very important, it will be optimal up to 25 cm. Thus, the properties of the soil, its fertility, are improved, the land is aligned. This process is also often combined with fertilizing.

For the owner of summer cottages and gardens, the mechanization of this process has become more accessible with the advent of motoblocks. The choice between a shovel and a motornote with a mill became obvious. The power of the walk.behind tractor is enough to process not only sandy soils, but also the virgin. Here the main thing is to competently approach the choice of additional equipment.

Which depends on the correct choice of the cutter for the walk.behind tractor:

- Quality of cultivation. In most cases, you can even do without a plow;

- Your strength and time that you spend on the implementation of a certain amount of work;

- Ease of control of the walk.behind tractor and the load on the operator during milling;

- The load on the uniform tractor, in particular on the gearbox.

To date, you can already choose cutters that will aggregate your unoic tractor, depending on its power and the type of soil processed.

Factory mill

Most motoblocks and cultivators are equipped with such cutters when selling. Depending on the situation, they can be collected or disassembled. You can choose a single tractor, but which mill it is initially equipped, unfortunately you can’t choose.

The design is an axis with welded plates, to which saber.shaped knives are directly attached. The finished mill can consist of several such sections interconnected using bolts. By adding or removing the section, you can adjust the width of cultivation.

Tormek T8. Kitchen knife sharpening tomato & paper trick

The most important plus is delivered immediately complete with the walk.behind tractor. The milling cutter does not poorly cope with its main task, provided that the work is carried out in the previously processed area.

Now about the realities. If we are talking about Chinese motoblocks, knives on the cutter are their weak place. Bad metal, will make itself felt, perhaps even in the first season, bolts and welding joints also leave much to be desired. If you cultivate a virgin land or where there are a lot of grass, the process will not be pleasant. It will be difficult to hold the one.axle tractor, and the load on the gearbox will be high.

Is it necessary to sharpen mills on a single tractor

There is no unequivocal answer to this question. The opinions of beginners and even experienced summer residents are contradictory. Some argue that sharpening significantly improves and accelerates the process of cultivating the soil. Others argue that there is no sense in this, since even the manufacturers of milling do not require this.

Having summarized the experience of one side and the other, among the arguments in favor of sharpening milling, the following should be distinguished:

- The sharpened cutting surfaces of the equipment penetrate the soil easier, accelerating the process of work.

- The first advantage should be reduced by the load on the power unit of the walk.behind tractor, which extends its life and reduces fuel consumption.

- For light cultivators and with insufficiently high.quality material knives, it becomes almost impossible to work with dumb cutters. In this case, sharpening is actually the only way out.

The arguments of opponents of the sharpening of the milling plant are as follows:

- The acute cutting surface contributes to a strong grinding of weed vegetation, as a result of which the process of vegetative propagation is increasing repeatedly. From this point of view, preference is given to the process of winding weeds on a stupid mill.

- As a result of the effects of sharp knives, the meaning of the cultivation of the soil is lost, since the soil instead of loosening is simply cut and remains in large lumps.

- The process of sharpening the milling plants is quite time.consuming, since in addition to the sharpening directly, the cutter must first be disassembled, and then correctly assembled. In this case, the severity of the cutting elements remains for a short time. After that, the procedure should be repeated again.

Choice for a rotary motor.cultivator

When choosing a milling cutter for the cultivator, it is necessary to take into account how the knives assembled to the shaft were assembled. For example, models can be curved in one, different sides. Options with a one direction direction are convenient in that in this way it is possible to prevent damage to plants during loosening. However, such modifications have a smaller width of the captured soil.

Reliable mills are needed to treat in thick vegetation. The working bodies of such mills are plate knives fixed on rotating shafts.

Here it is necessary to purchase products that can effectively crush the soil with a slight deepening into the ground.

Vertical mills with four rotors, as well as lateral displacement and hydraulic drive, are good for cultivating the rifles in conditions with a small width of the row. In addition to the fact that they are relevant for the removal of weed grass with a low depth of work, they are good for the inter.row processing without creating the grooves with a side displacement.

To choose the right option, you need to consider the type of cultivator itself. In addition, you need to choose the product, taking into account the upcoming works and technical characteristics. However, in any case, the immersion in the soil of the device should be smooth. It is also important to do this slowly, since rush can lead to breakdown of knives.

How to collect correctly

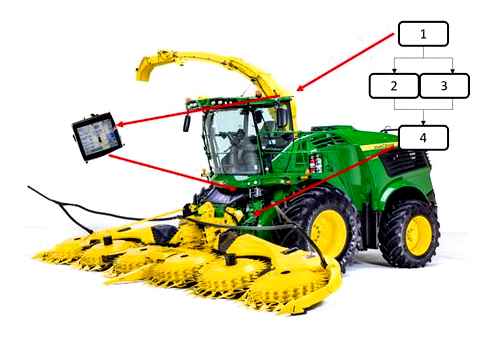

The quality and speed of soil processing depend on the correct installation of cutting elements. Before assembling the milling cutter, it is necessary to carefully inspect the elements included in the kit. On them we will see stamped letters L and R. This means “left” and “right”. In order not to get confused, we will lay them into 2 identical groups. Hubs on which knives are attached can be based on a round pipe or hexagon. It depends on what shaft the cultivator has.

On the one hand, there is a small ledge with a hole for Shplint and a landing place for the first link of the knives. Take one of the pennies. It will be located on the left, in the direction of movement. We collect the first link from the gearbox. The cutting edges are placed so that they make a circle counterclockwise. We put the right and left knives alternately. In the presence of 4 elements, 2 knives lie from below, 2-on them, from above. Where on the pennies a hole under the slap, the knife should lie above in front of the hole. Otherwise there will be difficulties with the installation and extraction of codes.

We fasten the element so that the base plate is between it and the gearbox. Otherwise, the knife may cling to the gear casing. When the first link is ready, the second is collected.

We look at any of the screwed knives, on the next plate we find such a position that the new knife looks in the same direction, but is shifted several degrees counterclockwise.

Which is better

Milling cutters for a motor.cultivator are selected for each type of work and depending on the structure of the soil. Sable.shaped mills, loosening the soil to a depth of 35 cm, are lifted to the surface of weeds. At the same time, they do not cut them into small parts, but wrap them up and shafts. What they do not allow them to multiply. In addition, the soil is a larger “grinding”. But on dense or virgin soils, knives-plots are poorly included in the ground. Large and curly weeds are quickly wrapped in the working part and inhibit processing.

Crossbars “Goose paws” do a great job with difficult soils and all types of weeds. However, due to the fact that they cut them in an acute edge into pieces, weeds propagate. There is a option of combined use. In the fall, you should go through the site with these cutters, and in the spring and during the season to work with saber.shaped incisors.

How to work properly by a walk.behind cutter on cutters. How to configure a cultivator correctly?

In order to exclude the burden of the cultivator and a number of other common problems, the owner of the equipment must perform a number of actions to prepare and configure it.

- First, the cultivator must be installed on a thick board and remove the factory wheels from it. Instead, you need to fix one set of mills on the left and right side. 8 cutting knives include one set of cutting. this number of elements gives the best result when treating soil;

- When installing milling, you need to pay attention to the position of the knives. They should be directed only forward. The working part of each of the knives should not be acute. Otherwise, the cultivator will not move forward, but will begin to explode into the ground. In addition, sharp mills will cut off the stalks of weeds, and not wrap and pull them out with the roots;

- Further, the equipment will need to be installed in the earring necessary for the installation of a coupon;

- Sushnik is a bar with holes made in it. It is necessary to accurately adjust the position of the milling cutter during the cultivation of the site;

- To fix the council, it must be installed in earring and fixed with cords and bushings. For this, the second hole is selected. The countdown is carried out from the lower part of the council. Thus, the depth of cultivation will be 20 cm. This is enough for high.quality soil processing and eliminating large weeds;

- To increase the depth of cultivation, the couch must be lowered down, and attached to the earlier through the upper hole of the element;

- To reduce the depth of plowing, the couch should be lifted up, and fixed on the earring through its lower hole.

Is it necessary to sharpen mills on a single tractor?

This question cannot be given an unequivocal answer. It all depends on the individual characteristics of the walk.behind tractor, soil and conditions of use. For example, for processing heavy soils with a powerful walk.behind tractor with reinforced cutters, sharpening is optional. You will not see the tangible effect of this procedure, just spend your strength and time.

To process the site with a lighter walk.behind sharpening, sharpening is a good option for improving the quality of labor. But there are also minuses. Firstly, sharpening is enough for only a few hours, then the procedure will need to be repeated, and this is a long and time-consuming process. Secondly, sharpened knives contribute to crushing the roots of weeds, and this in turn can only accelerate their reproduction.

If you still decide to sharpen the cutters. remove it from the walk.behind tractor, clean it from the ground. Extremely carefully with sandpaper, thread each cutting element so as not to damage them.

How to sharpen it correctly

If you weighing all the arguments for and against sharpening the milling plants, the meaning of this procedure has not lost its relevance, then it is necessary to understand the method of completing the task.

The experience of supporters of sharp cutting surfaces of the mounting equipment of motoblocks allows you to distinguish several key stages of work:

- All sections of attachment equipment must be removed from the walk.behind tractor and disconnected. After that, unscrew the bolts of fastening the cutting elements from the body.

- Clean the intended sharpening places from contaminants.

- With the help of a corner grinder of a small diameter equipped with a sharp circle, make a rough correction of the cutting elements by aligning the obvious irregularities of the metal. For ease of work, a small diameter should use a corner grinding machine. The best option will be 115 or 125 mm.

- Make a direct sharpening of a knife at an angle of 450, trying to remove as little metal as possible from a knife as possible. At the same time, striving for perfect acuteness does not make sense.

- Collect all parts of the equipment and install them on a single tractor.

Thus, having fundamentally deciding on the presence of the need to sharpen the cutting cutter, the described procedure will help to use the working tool as comfortable and efficiently as possible and efficiently.

Importable assistants in the country and in rural areas: one.axle tractor and motorbike. Both of these units are driven by a gasoline engine. The main difference is that the first can still transport goods, plow and even mow, and the second can only loosen the soil. Cultivator mills are the knot that makes them similar to each other.

Features of the knife cutters of the cultivator

Clamp for a walk.behind tractor (soil). a device for soil processing. They are installed on light cultivators instead of wheels. For heavy models of motor blocks or ministers, they are made by type of attachment equipment. Use soils for grinding, loosening or alignment of the earth. The attachment equipment in the development of virgin lands has established itself well. As well as it is used to make fertilizers and odorless siderates.

Types of knives for milling cutters

First of all, the design features of the knives determine the depth and type of processed soil. For dense and hard land, as well as more intelligence, thicker. If they plan to process a arable layer of large depths, use long blades. To improve the capture, the cutting tool has a curved shape. The direction of bending is on the right or left side. The cutting organ by the method of attaching to the milling body can be collapsible or monolithic. The latter is a whole design without the possibility of replacing damaged parts. practical is the collapsible option. In this design, it is possible to change the failed component. In addition, having a set of replaceable knives of various lengths, you can quickly perform tincture of the device for processing the soil to different depths.