What is a wood sander for?

During repairs, and even during the operation of certain products, it is often necessary to bring the surface to a perfectly smooth state. You can do this by hand using sandpaper, but it will take a lot of time and effort. To speed up the process, you can use a special power tool. grinder. These devices are available in several types, have different purposes and are used at different stages of surface treatment.

Belt sander

The wood sander can have different power (from 500 to 1200 W) and belt speed (from 75 to 550 m / min). Some models provide for the adjustment of these parameters, which allows you to choose the operating mode for each surface to be processed and the task being performed. For beginners, a sanding depth limit box is useful. it will not allow you to remove a larger layer of wood than necessary.

Vibrating or flat grinders

This wood sander has a flat rectangular platform. Surface treatment occurs due to the vibration of the platform, on which the abrasive sheet is fixed (a piece of ordinary sandpaper cut to the size of the platform). The sheet is fastened in different ways: on some models with clamps, on others. with Velcro. In either case, the replacement occurs in a matter of seconds.

The sanding platform can be made of special impact-resistant plastics, metals and alloys. When choosing a tool, pay attention to the sole: it must have the correct shape, be free of dents, chips or other damage.

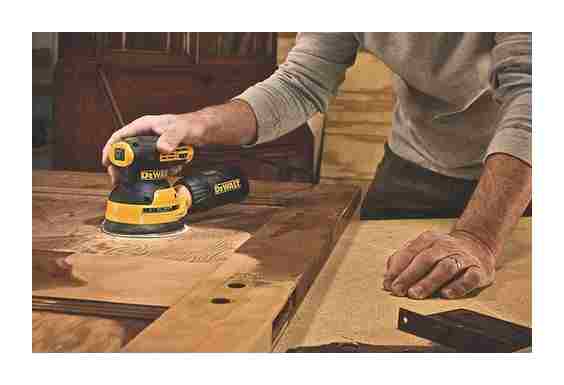

Eccentric or orbital grinders

This type of equipment is used for finishing products. The trajectory of the grinding element resembles an orbit, the speed of rotation of the disc. several thousand revolutions per minute. When operating this type of machine, the dust is very fine, therefore it is advisable to use a vacuum cleaner, not a bag. The wood eccentric sander has an automatic sole stop, rotation speed adjustment and an additional handle. This makes work more comfortable and safer. However, the circular shape of the sanding element does not allow the processing of surfaces in the corners. This is the main disadvantage of this type of machine.

When repairing, making joinery and finishing surfaces, a wood sander helps speed up the work. Reviews of masters and amateurs are unambiguous: this tool allows you to achieve excellent results in the shortest possible time.

What is a sander for??

During any construction and repair work, sooner or later, there is a need for surface grinding. Remove the old coating, prepare the surface of the walls for subsequent finishing, level the parquet or metal surface during welding. all these works require the use of grinders. In this article we will talk about what types of grinders are and for what work each type is used.

Eccentric (orbital) grinders

What is an eccentric sander for? It is used in cases where delicate, high-quality processing is required. Unlike other types, the working surface of the eccentric sander not only rotates but also oscillates. By replacing the emery cloth with another attachment with a softer material structure, you can make the surface absolutely smooth, add extra shine to it, for example, polish parquet or car coating after painting. But with shallow depressions or corners, such a machine will not cope, because the disc will not reach there.

Vibration grinders

This type of equipment, due to the ability to regulate the number of revolutions of the disk, can work with materials such as:

varnished or painted surfaces.

They are not often used in everyday life, but they are popular among professionals in the construction and repair business, tk. allow high-quality finishing of large surfaces (walls, floors). They also have additional functionality. the ability to connect to a vacuum cleaner to collect dust, which invariably forms when grinding any surface.

angle grinder, or angle grinder

Angle grinders (angle grinder) are the most commonly purchased type of this equipment. An angle grinder is needed for a large number of works performed both on a construction site and on a personal plot. Such versatility of this tool is explained by the large number of replaceable attachments:

circles for cutting various materials;

eccentric and emery bits.

With their help, you can cut, remove old paintwork, grind and polish metal and wood. Finishing work in the house, building a gazebo in the country and even making old pans and pots shine again. an angle grinder will help you to do all this.

Other types of grinders

Belt sanders are used for rough primary surface treatment, but this machine can leave marks from the belt (invoice).

Polishing grinders are most often used for bodywork in car services.

Delta sanders are capable of handling hard-to-reach places such as corners, fine thread details.

Straight grinders (drill) are used for processing (more often metal) in hard-to-reach places, they also allow you to work with small parts of various shapes. The working replaceable element of straight grinders are rotary cutters of various shapes.

On our website you can find a wide range of grinding machines of any modifications that suit you both in terms of cost and functionality.

Tape

When choosing belt grinding, you need to look at the following parameters:

-

Length and width of the tape. Belt width. from 6 mm to 100 mm. A narrow blade can handle small parts, a wide blade increases productivity. The length of the tape depends on the model. It is clear that the longer the tape, the longer it works without replacement. When buying a second belt sander, try to find a model with the same length. fewer consumables are required.

The width of the tape can be different

Additional handle allows for tighter control of the tool

You also need to pay attention to how convenient it is to change the tape. There are also models that allow you to quickly change the brushes. Sometimes spare brushes are even included.

Eccentric (orbital)

In addition to all the general parameters described, the choice of an eccentric wood grinding machine has its own nuances:

- The amount of eccentricity. That is, the amplitude of the deviation in a circular motion. It can be from 2 mm to 8 mm. The higher this figure, the higher the processing speed, but the lower its “purity”.

- Outsole diameter. There are 90 mm, 100 mm, 125 mm and 150 mm. Professionals prefer to work with a sole diameter of 150 mm. They have the highest performance and for this size there is a large selection of sandpaper of different grain sizes, there are no problems with spare parts.

Orbital sander for wood: it is important to choose the right eccentricity

How to choose a sander for wood

On the farm, you often have to grind something, clean off the old paintwork. Most of the work is with wood. Few manufacturers sell perfect pieces. Perhaps a carpenter. And if there are perfectly processed boards, then their price is such that you will inevitably want to polish them yourself. Even taking into account the fact that the work is boring and uninteresting. Therefore, a wood sander is one of the tools that should be in the home arsenal.

Technical selection criteria

Any tool is divided into classes that differ in work resource (and price). So a wood sander can be household or professional. Household ones are designed for short continuous work with interruptions. Basically, it is recommended to work no more than 3 hours a day, periodically taking breaks of 15 minutes.

To choose a wood sanding machine, you need to pay attention to the technical parameters

When choosing, the first thing to decide is what class your car should be. I must say that some manufacturers have a good household class, and some also have semi-professional lines. This is an intermediate class, as a rule, for private use it is optimal in terms of price / quality combination. Some models are even used by professionals.

Orbital (eccentric)

The orbital sander for wood has a round sole with Velcro, on which sandpaper discs are attached. The discs are the same as for the angle grinder, so they are interchangeable. There are holes in the sole of the machine to remove dust. Dust is collected in a bag, cassette-type container, almost all models allow you to connect a construction vacuum cleaner.

The eccentric sander allows the processing of curved surfaces

The work of an eccentric sander for wood is based on the simultaneous rotation and movement back and forth (reciprocating movements). This achieves a sufficiently good speed for intermediate and finishing wood processing. When working with this type of grinder, the platform moves in a spiral or orbit. Therefore, this tool is also called orbital grinders.

Eccentric sanders are good for curved or profiled surfaces. the machine is light in weight, makes little noise, is easy to control, the angle of the disc can be used to reach grooves, scraps, etc. With all this, she also handles large planes at a good pace. When installing coarse sandpaper, it can be used for coarse and intermediate sanding. The speed is less than that of the tape, but also quite acceptable. There are such cars with different radius of movement (eccentricity). from 3 to 8 mm. Selecting this parameter and determine the main purpose (more on this below).

There are small and compact, there are powerful, decent dimensions

The disadvantages of this type of machines are the impossibility of processing in the corners. The round platform is simply not included there. Also, there is a zone of uncertain polishing at the edges. it will not be possible to polish close to a wall or a vertical surface.

Oscillating

Strictly speaking, this is not a grinder, but it can be grinded. over, those places that are inaccessible for other types of machines are corners (even sharp ones), places directly at the vertical walls. For grinding, a special-shaped triangular platform is installed on the tool, on which sandpaper is fixed on a self-adhesive base.

This is what a multifunctional renovator looks like, which has a grinding function.

During operation, the platform moves in a horizontal plane with a very small amplitude. the vertices of the triangle deviate by about 1.7 ° (this is an average of 2.5 mm). Due to this small movement, grinding occurs. This machine can be used to grind in corners and close to vertical surfaces. over, you can remove not only wood, but also smeared and dried glue. In general, an oscillating machine is used for finishing grinding in hard-to-reach places. due to its low productivity and a grinding spot, it is unrealistic to process more or less large surfaces with it.

What type of sander to choose

To summarize, we can say that for housework and construction, ideally, two grinders are needed. for a rough and a fine finish. The most commonly used pair is tape eccentric. If you are planning to make furniture, then you cannot do without oscillation.

If you do not like the result of a belt sander, you can purchase two orbital ones with different eccentricities. For rough grinding, a tool with an eccentricity of 6-8 mm is suitable, for finishing grinding and even polishing. 2-4 mm. The only drawback of this solution is that good eccentric sanders are expensive.

If the budget is limited, and the farm has an angle grinder (angle grinder), rough grinding can be done with it, and for intermediate or fine grinding, use orbital or vibration. Just keep in mind that vibration is the least productive, albeit the cheapest. If possible, buy an orbital one. it is more versatile and gives better results.

Popular eccentric sander models

| Makita | BO5031 | 300 watts | 12000 rpm | 24000 rpm | 125 mm | 2.8 mm | 90-120 |

| Makita | BO5041 | 300 watts | 12000 rpm | 24000 rpm | 125 mm | 3 mm | 100-200 |

| Metabo | SXE 450 TurboTec | 350 watts | 13100 rpm | 8500 rpm | 150 mm | 6.2 mm | 185-220 |

| Bosch | GEX 150 AC | 340 watts | 12000 rpm | 24000 rpm | 150 mm | 4 mm | 175-220 |

| Bosch | GEX 125-1 AE Box | 250 watts | 12000 rpm | 24000 rpm | 125 mm | 2.5 mm | 70-90 |

Sander “Makita BO5041

This model is ideal for cleaning surfaces of various shapes. Many buyers choose the device because of its good parameters. In this case, the maximum power indicator is at around 3 kW. All this became possible thanks to the installation of a high-quality single-phase motor. Its limiting frequency is 30 Hz. The grinder can only be powered via a 230 V mains supply.

How to choose a grinder

The choice of an eccentric sander should be based on an evaluation of the parameters of the device. The limiting power indicator must fluctuate around 3 kW. All this will allow you to process even metal objects at a good speed. The rotational speed in this case must be at around 5 thousand revolutions per minute. The level of fluctuations is welcomed at the level of 14 thousand movements per minute.

In this case, the pressure of the generated noise should be no more than 80 dB. Additionally, you should pay attention to the thickness of the sole of the device. If you plan to work exclusively with wood, then it should be 2 mm. over, for metal, the specified parameter must be at least 4 mm. All of this will ultimately ensure low wear on the outsole. On average, a high-quality eccentric sander costs about 6 thousand rubles.

Company devices “Bosch

Company “Bosch” today it is very popular, and has been engaged in the production of grinding machines for a long time. Many owners first of all note the excellent quality of the parts. The wear on the outsole is extremely low. Electric motors are usually two-phase. They are able to work from a network in a house with a voltage of 220 V. At the same time, the parameter of the limiting frequency will be kept at around 30 Hz.

If we talk about design features, then the shape of the handles deserves attention. They are made very high quality and hold comfortably in the hand. Thus, the user is able to clean the surface for a long time. Also of note is the large outsole area on some models. The grain size of the web depends in this case on the specific modification. An eccentric sander of the specified brand will cost on average in the region of 6 thousand rubles.

Typewriter “Bosch 440A

Many buyers of the presented model give preference because of the low rate of generated noise. In this case, it is at around 50 dB. All this became possible due to the fact that the manufacturers equipped this model with a rather dense casing. It is located near the electric motor. The casing copes not only with increased noise, but also with vibration.

The power tool is very balanced during operation and can be controlled with great precision on the surface. Thus, this sander is well suited for working on uneven surfaces. If we talk about the lack, then it is important to mention the small speed governor. In some cases, it is uncomfortable to use it. This is especially true when it comes to vertical surfaces. The noise level error in this case is 60 dB. In this case, the vibration indicator is at the level of 2 m / s. The presented eccentric sander on the market costs about 5400 rubles.

The vibrating or eccentric sander is designed for processing wood as well as metal objects. With its help, you can easily remove varnish or paint from the surface. Additionally, it is possible to process plastic parts.

In some cases, grinders are used to clean sharp corners. In this situation, much depends on the design features of the model. In particular, we are talking about the working sole. It can be made hard or soft. The thickness of the working surfaces also differ. If we consider the main parameters, then we can distinguish the limiting power and speed.

What is an interesting model “Bosch 220A

How to repair

The eccentric sander must be repaired in a workshop with all the necessary tools. The rotor is the vulnerability of this device. It can fail for various reasons. In this case, the person is obliged to find out at the first stage. In order to disassemble the sander, it is necessary to detach the work sole. To do this, you need to use a Phillips screwdriver.

The work sole is attached to a special sleeve, and in order to move it to the side, it will take a lot of physical effort. After that, the sole can be pulled out by grasping it with your hands around the edges. It is then important to remove the electric motor of the device. The rotor in grinders is usually located at the top. First of all, its winding is examined for integrity. Next, you need to check his contacts. In some cases, the problem may be a broken ring. This problem can be solved quite easily by simply purchasing a similar part.

Ability to connect to a vacuum cleaner

As already noted, dust removal for various models and manufacturers of ESM is carried out both in a separate dust collector and using a vacuum cleaner. This approach is justified. After all, the dust collector has a small size and is not enough for a long time, and you have to often perform cleaning while taking your time off from work. Therefore, some manufacturers have provided the ability to connect a vacuum cleaner. Unfortunately, not all models of eccentric sanders have this opportunity. But for professional ESM, such as Bosch, Rupes or Makita grinders, a connection to a vacuum cleaner is mandatory.

Of course, there is also another option for connecting to a vacuum cleaner, this is a special adapter. Other manufacturers of ESM, realizing the importance of connection, decided to leave their models of grinders unchanged and began to produce special adapters. Therefore, when buying an eccentric machine, realizing that it will have to work a lot and for a long time, you should ask the seller about the possibility of connecting.

The amplitude of the ESM vibrations

The next parameter that affects the quality of surface treatment and depends on the speed of rotation is the vibration amplitude or, as it is also called, the eccentric stroke of the grinding machine. As noted above, ESM performs reciprocating circular movements. And if the speed of rotation to a greater extent affects the productivity, then the amplitude of movement of the sanding pad is responsible just for the quality of processing.

Basically, the amplitude of the oscillation and the speed of rotation are related. It is the combination of these two movements that allows high-quality sanding. There are models on the market with an amplitude of 2 mm to 5 mm. DWT grinders have the smallest amplitude. The presented photo demonstrates the movements of the grinding pad of an eccentric sander, it can be seen how, depending on the amplitude of the vibration, the quality of surface treatment changes.

Important! It should be noted that for some pneumatic ESM, reciprocating movements are created using special levers-nozzles. Depending on which arm is installed, this will be the diameter of the grinding orbit.

EShM type

For the operation of ESM, various energy sources are used, depending on this, there are several types of eccentric grinders. It can be a power or battery powered electric machine, or it can be a sander that uses compressed air. This variety allows the use of ESM both where there is electricity and where it is not. Choosing this or that option, it is necessary to clearly understand why and where ESM will be used.

How To Use A Random Orbital Sander

If everything is more or less clear with electric grinders, then a little should be said about pneumatic. The eccentric pneumatic grinding machine is mainly used on an industrial scale, since it requires the installation of additional equipment in the form of a compressor or compressed air cylinders. These ESHM perfectly serve in the garage, service station or in the workshop for the production of furniture. Their main advantages are their low weight, it is only from 600 g to 1000 g. As well as a small number of moving parts. Since, using compressed air, the need for an electric motor has disappeared, there are correspondingly fewer parts. This affected both weight and service life. In addition, the low weight allows for a longer and more comfortable use of the tool itself. One of the manufacturers of such ESM is Dynabrade, with its Dynorbital eccentric grinders.

EShM weight

As previously noted, the weight of an eccentric sander directly depends on its power. It’s just the engine. The more powerful it is, the heavier the machine. Weight does not directly affect the quality or productivity of the work. But this parameter is important for the comfortable work of the master. So ESM with a large weight will be more difficult to process vertical surfaces, as well as the ceiling. For processing horizontal surfaces, this parameter has little effect on the comfort of working with it.

The main parameters of the eccentric sander

When choosing an eccentric sander (ESM), you will have to immediately decide how often it will be used. If from time to time and for short-term work, then when buying, you can take a budget option. But if the loads on this tool are frequent and rather large, then you can safely take a professional ESM. Of course, if the tool is purchased for yourself and so that it will serve for a long time, then you can look after a professional ESM without hesitation. True, the price for a professional eccentric sander will be much higher than for a regular one.

Having determined whether it will be an ordinary or professional grinder, it remains to figure out the characteristics of the ESM itself. Without this, it will not be possible to determine which is the best sander from the entire possible range you need. All characteristics can be roughly divided into two categories. The first category is the performance characteristics that determine the quality and efficiency of working with a particular eccentric sander. These include power, vibration amplitude, rotational speed, abrasive wheel diameter, weight and power supply of the tool. The second category is the additional functions of the machine, which ensure the convenience and comfort of working with the tool. Additional functions include speed control, dust collector option, the ability to connect to a vacuum cleaner, a second handle, starting current limitation, pressure indicator.

Second handle

The specificity of working with an eccentric machine provides for pressure on it from above. Even the very shape of the instrument is wholly and completely directed towards this. But quite often the starting mechanism and the electric motor are somewhat off-center, which creates certain difficulties in operation. In this regard, the manufacturers of ESHM have added an additional handle that compensates for the pressure on the other side and makes it easier to work with the machine. The handle itself can be removable or stationary. It all depends on the model. For example, the Makita BO5040 / 5041 sander has a removable handle, while the Bosch PEX 400 AE is equipped with a stationary additional handle. Of particular note are the DWT grinders. They have equipped their ESM with side handles, which provide additional convenience when working on vertical surfaces.

ESM power

The main characteristic of any power tool is its power. And eccentric sanders are no exception. It is this that should be taken into account in the first place when choosing a grinder. The high power of the ESM allows you to use the tool longer and with greater efficiency. In addition, the quality of the work performed, the speed of rotation of the sanding pad, as well as the weight of the machine depend on this parameter.

Power range of eccentric sanders from 160 W to 900 W. But low-power and high-power ESM can be enumerated on one hand. The most common grinders with power from 300 W to 600 W. The most popular ESM segment with a power of 300. 600 W is the Bosch eccentric sander. When choosing, you should pay attention to ESM with high power ratings. over, if the difference in power is 20. 50 W, then there will be no special differences in the quality of processing. But if the difference is 100 W or more, then preference should be given to a more powerful instrument. The quality of work, their duration and service life of ESM will be high.

Pressure indicator

One of the additional functions useful for a beginner is the pressure indicator. This is especially useful for those who have not yet learned how to feel their pressure on the instrument. This indicator, in case of excessive or insufficient pressure, will allow you to correct it in order to perform the grinding properly. This function will be useful for professionals as well. It will allow you to assess the degree of your skill in working with ESM and facilitate the grinding process itself.

Eccentric sander

In addition, the rotational movement of the disc promotes more efficient (in particular, in comparison with a vibrating grinder) removal of dust generated during grinding. An eccentric machine removes a layer of material larger than a vibratory grinder, but slightly less than a belt one (the latter, in fact, is intended for rough roughing of workpieces).

Eccentric machines are universal in their application. They are suitable for sanding not only wood and metal, but also painted surfaces. Often they are also used for polishing finished surfaces.

In most models of eccentric machines, the disc does not have a rigid connection with the drive axis, therefore, at idle speed, its rotation speed is high, and with strong pressure, the disc can stop. Eccentric grinders of some manufacturers have special devices that limit the speed of rotation of the disk at idle, which excludes the possibility of deep plunge into the workpiece at the initial moment of processing.

In some professional models of eccentric grinders, the possibility of forced rotation of the disc and with strong pressure on the tool is provided.

Power consumption of eccentric grinders. 200-500 watts. However, for their performance, the size of the disc is of greater importance, the diameter of which can be 115 mm, 125 mm and 150 mm. Small discs are usually equipped with cars for amateurs, medium ones. semi-professional tools rather great. professional machines that can easily handle large surfaces.

Most eccentric sanders have a built-in dust extraction system consisting of an impeller and a dust collector. It is possible to connect them to a vacuum cleaner or to another dust extraction system. High efficiency of dust removal is ensured by the holes in the working disc. It is important that the holes in the sanding paper match exactly with the holes in the disc of the machine, both in diameter and position. Consider this when purchasing replacement accessory discs and sanding skins.

The choice of auxiliary disks of one or another hardness depends on the shape of the surface of the workpieces being processed. Smooth surfaces are best sanded with a harder disc, while convex or structured ones, on the contrary. softer.

The electronic control system of the eccentric sander allows for optimal processing. In simple cheap models, the rotational speed of the disc is changed manually by turning the corresponding regulator. Better and more expensive ones. the set number of revolutions and during operation under load is maintained automatically. When polishing lacquers and other heat-sensitive surfaces, it is important to reduce the speed in time.

Sanding and polishing skins for eccentric sanders have on one side “Velcro”, which allows you to quickly replace one skin with another. The main thing is here. align the holes in the disc and the skin through which dust is sucked out. Replacing the sanding paper is a snap. Attaching it to the disk, you need to combine the holes in the disk and in the skin and press the skin with your palm. The assortment of sanding skins for eccentric machines is very rich. Red-brown corundum with a grain size of 40 to 400 is used mainly for processing metal, wood and painted surfaces. For the treatment of lacquered surfaces, stone, glass and non-ferrous metals, white carborundum skins are better suited. For sanding rough surfaces of wood, plastic and painted workpieces, it is advisable to use special steel sanding blades.

In addition to grinding, eccentric machines are also used for polishing using the appropriate accessories. Foam sponges are used for waxing and polishing; felt polishing pads. for rubbing polishes and polishing plastics; fur nozzles. for polishing varnished surfaces. The fur auxiliary disc can be used to polish the lacquer finish to a high gloss while operating at low revs.