Recycling

In Eugene, curbside recycling service is included in the cost of garbage collection. Most recyclable materials accepted should be commingled in your curbside bin, with glass collected in a separate container.

Lane County’s Waste Wise tool can give you more information about what can currently be recycled and where. Simply type the name of the items you have a question about recycling into the Waste Wise tool. This tool can also help you find out how to make an appointment to dispose of hazardous waste or report illegal dumping, and more.

Statewide Changes to Recycling Systems: July of 2025

In 2022, Oregon’s legislature passed the Recycling Modernization Act to update our state’s recycling system by leveraging packaging producer resources to create more resilient and comprehensive recycling opportunities for Oregon residents in the future. These recycling program changes will begin in July 2025 and will expand access to recycling services, upgrade recycling sorting facilities, and reduce plastic pollution. Information on how this new law will affect how we recycle in Eugene will be available here as changes are implemented locally.

Below is a current list of what can be recycled curbside in Eugene:

In Your Commingled Container

Please place the following items in commingled recycling bins:

Know Before You Throw

Contamination reduces the economy and effectiveness of our recycling system. Any items that are not clearly listed in the section below should not be placed in commingled recycling bins. Items that are not clearly recyclable should be put in the trash—when in doubt, find out or throw it out. You can also download our Recycling Flyer that shows what items are accepted and what items are not. Traducción al español aquí.

Recycling FAQs

Intro to Recycling Old Lawn Mowers

But first, can you recycle a lawn mower? It’s hard to know since recycling anything other than everyday paper, plastic, metal, and (sometimes) glass can be a bit of a mystery.

Because lawn mowers are generally made of metal and rigid plastic components, they are, essentially, recyclable. But, put simply, having an old lawn mower recycled is a little more complicated than chucking it in the blue curbside bin.

⚠️ Before we go any further into lawn mower recycling, it’s important that no matter what you do with your old lawn mower, you must make sure it is completely drained of oil and gasoline.

Need to get rid of lawn equipment fast?BOOK NOW ❯

Recycling Old Lawn Mowers Near You

There are more ways to recycle an old lawn mower than hauling it over to Home Depot or your local recycling center. When we usually think of recycling, what comes to mind is the municipal recycling facility with all of its crushing, ripping machines and giant equipment.

The truth is, sending stuff off to someplace we equate with recycling isn’t the only way to recycle, and it’s actually usually the least effective form of recycling out there.

Instead, consider these alternative forms of lawn equipment recycling first when looking for used lawn mower recycling in your area:

- give it to a neighbor

- give it to a friend or family member

- donate it to charity or a nonprofit organization

- sell it on. Craigslist, LetGo, etc.

- sell it for parts or scrap at a junkyard

Obviously, if your old lawn mower is pretty beat up or doesn’t work anymore, you don’t want to choose any of the first four options in that list. If you decide to donate your used lawn mower, it is important that it is still in good, working condition.

Disposing of Old Gas Oil From a Lawn Mower

As mentioned before, no matter how you decide to get rid of your old lawn mower, you have to remove the gas and oil from it before going any further.

If you’re wondering where to take old lawn mowers to be drained, visit a mechanic or a repair shop to pay them to drain the gas and oil if you don’t feel good doing it yourself.

However, this is a fairly simple process that you can do yourself if you’re handy.

Here’s how to drain oil from a lawn mower:

- Use a siphon hose to drain the gas out of the tank and into a clean container. It’s best to use a siphon hose with a hand pump attached.

- Next, unplug the spark plug wire and tilt the lawnmower on its side with the carburetor facing up in the air. Remove the center bolt or bolts that hold the blade in place and carefully slide the blade off the lawnmower.

- Position an oil catch pan under the mower and remove the oil reservoir plug to drain the oil into the pan. The oil reservoir plug location can differ from mower to mower, but it’s usually found under the blade at the center of the deck on a push mower.

⛽ Pro Tip: Never use your mouth to siphon gasoline out of a lawn mower.

If you have a riding lawn mower, the plug should be located on the side of the engine block. You can then take the used oil to an auto parts store or mechanic who can recycle the oil and do small engine disposal for you for a small fee.

However, you will need to dispose of the gas as well, so it’s probably best to take the gasoline and the oil to your municipal household hazardous waste (HHW) disposal facility.

If you don’t know where your HHW facility is, you can find out by checking your city or municipality’s website or by giving them a call.

How to Donate Your Old Lawn Mower

You can call around to different charities in your area to see if they’ll accept donations of lawn mowers, big or small, whether they offer pickup services, and what rules and restrictions they have for donating a lawn mower, such as if they accept riding lawn mowers or even old lawn tractors.

While some charities do offer pickup (for a fee) of donated items that are difficult to haul in a car, chances are you will likely need to haul your old lawn mower to a donation center to drop it off.

In fact, no matter how you decide to go about recycling your old lawn mower, it’s highly likely that there will be some hauling involved on your part.

Because most people don’t own a truck or other hauling equipment, it’s a great idea to consider having a junk removal company pick up their your lawn mower to safely dispose of it for you instead.

Selling an Old Lawn Mower

If you’re still looking for where to take old lawn mowers to you and end up bringing the mower in one piece to a scrap metal yard near you, they’ll most likely only pay you the price of aluminum breakage, or dirty aluminum that’s contaminated with steel.

The value of your used lawn mower increases greatly if you disassemble it and separate the different metal and plastic parts from the components that can’t be scrapped. This is because the scrap yard will pay more if they don’t have to spend the money buying used lawn mowers and then also the time taking it apart and cleaning it themselves.

If all else fails, you can always haul your old lawn mower to your nearest recycling facility and drop it off there for you.

Lawn Mower Recycling Pickup Services

Deciding to get rid of your old lawn mower is one thing, but actually figuring out how to do it in a responsible way can be a headache.

Most people aren’t able to leave their old or broken lawn mowers on the curb for their municipal trash removal service to haul away, because most trash services won’t pick them up. Plus, not everyone has the vehicle needed to haul these items to the local recycling center if there is one.

If you just want to be done with your old lawn mower but don’t want to add it to the already overflowing waste stream, having a professional junk removal company pick it up can be a truly eco-friendly option.

Lawn mowers and other landscaping equipment can be cleaned of any fuel residue, broken down into its metal and plastic components, and the materials used in the production of new lawn equipment or other products.

When you call the junk removal pros at LoadUp to pick up and recycle lawn mowers, we’ll also take any yard equipment and you’ll save you tons of time and energy. LoadUp offers easy haul-away and eco-friendly disposal for all kinds of lawn equipment and just about anything else you need to get rid of around the house.

Old lawn mowers wanted

People find us by searching for: cylinder mower. allen spares. atco spares. dennis spares. qualcast spares. ransomes spares. suffolk punch spares. webb spares. old lawnmower. pushmower. push mower. push lawnmower. sidewheel mower. light atco. dennis premier. qualcast b14. ransomes marquis. ransomes auto certes. ransomes certes. ransomes ajax. ransomes 24. ransomes matador. ransomes multimower. webb 14. webb 18. webb 21. webb witch. webb wasp. jp. jp maxees. jp simplex. lawn care. lawn treatment. lawn maintenance. lawnmowing. lawn mowing. lawn cutting. grass cutting. grass mowing

Cricket clubs save money on their equipment by finding us through: cricket mower. wicket mower. wicket roller. cricket square mower. cricket mower repairs. cricket mower maintenance. cricket equipment. cricket pitch. cricket field

People find our blade sharpening kit by searching for: sharpen ransomes. sharpen atco. sharpen webb. sharpen suffolk. sharpen dennis. blade sharpen ransomes. blade sharpen atco. blade sharpen webb. blade sharpen suffolk. blade sharpen dennis. sharpening ransomes. sharpening atco. sharpening webb. sharpening suffolk. sharpening dennis. blade sharpening ransomes. blade sharpening atco. blade sharpening webb. blade sharpening suffolk. blade sharpening dennis. sharpen lawnmower. sharpen wicket mower. sharpen pushmower. blade sharpen lawnmower. blade sharpen wicket mower. blade sharpen pushmower. sharpening lawnmower. sharpening wicket mower. sharpening pushmower. blade sharpening lawnmower. blade sharpening wicket mower. blade sharpening pushmower. cylinder sharpen lawnmower. cylinder sharpen wicket mower. cylinder sharpen pushmower. cylinder sharpening lawnmower. cylinder sharpening wicket mower. cylinder sharpening pushmower. cylinder sharpening lawnmower

History of John Deere Riding Mowers: The 1980s

At John Deere, the 1980s were a time for evolution and reaching milestones. In addition to introducing new designs, such as the R and S Series, John Deere also manufactured its millionth lawn and garden tractor during this decade!

Deere Goes Diesel

In 1984, Deere’s first tractor to combine a diesel engine with hydrostatic drive and power steering made quite the impression in the tractor industry. This impressive machine was the John Deere 430, which was very similar to the 420 model, but powered with a Yanmar 3-cylinder water-cooled diesel engine instead. The 430 weighed 1,170 lbs, making it the heaviest and strongest John Deere of its time.

Evolution of the 300 Series

The redesign of the 300 Series led to the introduction of the 318. What was great for customers was that many attachments of the 140 and 300 Series could still be used on the new model 318; however, many exciting features were added:

- Rear-frame redesign from “closed” to “open” configuration

- Annunciator lights implemented into the dash panel

- Square-shaped fender deck

- Reserve fuel tank for increased productivity

The best part? During this time, John Deere hit the big 1 million milestone – manufacturing its millionth lawn and garden tractor, with the 318 model outselling any other models.

The R and S Series

As we know, Deere always looked to accommodate customers managing both big and small operations, which is why the R Series and S Series were introduced.

The R Series (R70, R72, and R92) was a good fit for customers needing a solution for smaller pieces of land. Key features included 5-speed gear-drive transmission, in-line gearshift, full-length welded steel frame, and a tight turning radius of 27 inches. This provided operators with even more dependability, long equipment life, as well as on-the-go shifting.

For those with a lawn slightly bigger than what was fit for the R Series to undertake, Deere produced the S Series riding mower (S80 and S82). These machines had a 30-inch cutting width, electric start and 8 horsepower engines.

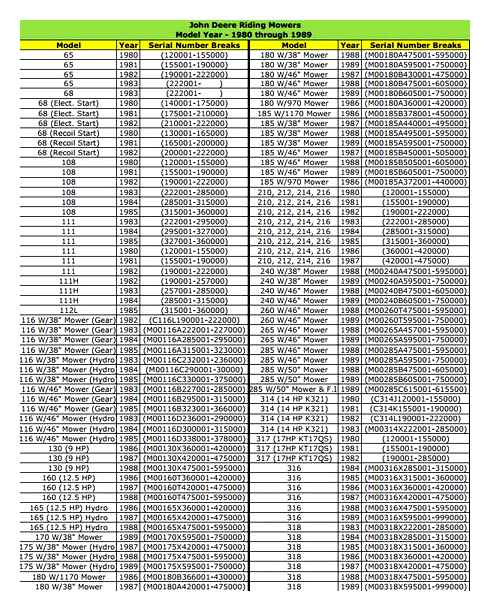

For a complete list of riding mowers by model, year and serial number, check out the charts below.

John Deere Riding Mowers in the 1990s

Not to be undermined by the previous decade, the 1990s carried on the trend of growth for John Deere lawn and garden tractors. With the introduction of several new models, including the LT, LX, GT, and GX series, John Deere hit 2 more exciting milestones before the close of the millennium.

Exponential Growth

The 90s were known for many things but for Deere specifically, this was a time for exponential growth in both numbers and technology. In the 1990s John Deere hit both the 2 million and 3 million milestones, manufacturing its 2 millionth lawn tractor with the LX188 model and its 3 millionth tractor with the LT133 in 1998.

This is certainly a sentiment to how the company increased sales during this time; however, it’s not the only thing Deere was working on during this time. Let’s look through a few landmark models that were critical to the history of the John Deere riding mower.

LT Series

In the late 1990s, the LT Series (133, 155, and 166) became one of the most popular John Deere mowers ever. With this series, operators could experience high-quality wide cuts and a greater amount of fuel compared to competitive models in its class. An emphasis was put on comfort with the adjustable operator seat for those who spent long hours on their equipment The new Xenoy material instead of steel-hood also kept this machine in better condition.

LX Series

The LX Series was first introduced in the 90s and remained for 16 years to follow. Customers remember this series for its versatility, as each model was compatible with several sizes of mower decks to meet operators’ needs. The LX Series was also great for a variety of other projects around the yard. For example, owners could latch a snow blower attachment to the machine to help fight off winter storms.

GT and GX Series

The GT and GX Series were very similar to one another when it comes to style and uses. For customers with plots of land around 4 acres in size, both machines can hook up to other implements like snow blowers, baggers, carts, front blades and a variety of rear attachments like aerators, and utility carts. These machines were best fit for owners who needed a little more power and size for their weekend activities.

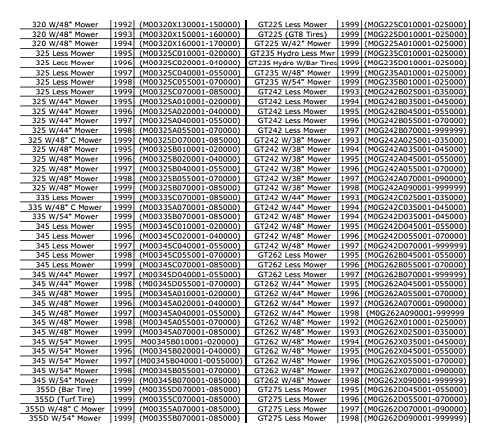

Check out the charts below for a complete list of riding mowers by model, year and serial number.

John Deere Riding Mowers in the 2000s

Last but certainly not least, Deere made a few noteworthy updates to existing models in the 2000s. The FOCUS here has largely been around offering more power to customers thanks to models in the LA and X Series.

LA Series

This model combines power and versatility to make a perfect fit for medium-large-sized lawn owners. Key features include the full-length steel welded frame, full pressed lubrication, cast iron front axles, headlights, translucent fuel tank including a sight gauge, comfortable operator station, Edge Cutting system, and option for Reverse Implement. Backed with plenty of power, this series also incorporates John Deere’s trademarked CargO Mount system, allowing for a large bagger or other heavy rear-mounted equipment to be easily attached. Other attachments like lawn sweepers, front blades, tractor shovels, mid-mount blades, carts, snow blowers, sprayers, and aerators can be easily added to the LA.

X Series

What’s unique about this series of John Deere riding mowers? The technology is what sets this machine apart, as it transfers power to the wheels through the use of the hydrostatic transmission to save time during operations and eliminate unnecessary gear-changing to speed up or slow down. The X Series also incorporates the Edge Cutting System and tight turning radius. This all helps improve convenience, performance, and reliability.

The charts below provide a full list of these riding mowers by model, year and serial number.

We hope this historical breakdown helped you get a better idea of how riding mowers got to where they are today. Still interested in learning more about the history of John Deere riding mowers? Be sure to check out some of the related articles listed below.

History of John Deere Riding Mowers FAQs

When did John Deere produce their first lawn tractor?

In 1963, John Deere entered into the lawn tractor market by introducing the model 110. The John Deere 110 had a 4-stroke petrol-fueled engine with 7 horsepower.

When was the first John Deere diesel lawn mower created?

In 1984, Deere created their first tractor to combine a diesel engine with hydrostatic drive and power steering.

What riding mower series were released in the 1970s?

3 new series of mowers that were designed in the 1970s including the 200 Series, 300 Series, and the 400 Series.

What decade did John Deere produce their millionth lawn and garden tractor?

John Deere manufactured its millionth lawn and garden tractor in the 1980’s.

What’s unique about the X series of John Deere riding mowers?

The technology of the X series is what sets this machine apart. It transfers power to the wheels through the use of the hydrostatic transmission to save time during operations and eliminate unnecessary gear-changing to speed up or slow down.

Related Articles:

If you have any questions about John Deere lawn care equipment, you can contact your local John Deere dealer.

If you enjoyed this post or want to read others, feel free to connect with us on , , or !

Who we are

Hustler Turf is a company thriving on American know-how and innovation. Developing new products and improving existing ones is source of pride for the Midwest craftsmen and women at our company. And it’s that pride, plus hard work and ingenuity, that all comes together as we strive to create the most innovative and best-in-class outdoor power equipment solutions in the industry.

Our Story

Our Rich Heritage

Inventor John Regier recognized the simple need for a riding mower that could maneuver irregular landscapes, so he set to work creating a mower from farm machinery and mower parts. The mower could hug a flagpole or reverse directions at a fence with a turning radius of zero. With this, the world’s first zero-turn mower was born.

Excel Industries

Mr. Regier couldn’t maintain the production demand, so he brought his design to Excel Industries. Excel wanted to expand its product line and when they saw the mower in action, they knew the product would revolutionize the mower industry. Under the direction of company president Roy Mullet, Excel began production at its plant in Hesston, Kansas and introduced the Hustler in 1964.

Today

Since then, Hustler has become one of the leading brands of outdoor power equipment. Across the globe, the Hustler brand signifies Innovation, quality, strength, performance, and superior customer care.

Our products are designed by a team of innovative Excel engineers, always living up to the highest Hustler standards. With every Hustler product, our mission remains the same. to provide the most dependable products that complete more work in less time, while maintaining unmatched customer loyalty and the best warranties in the business.

Our Core Values

From local involvement to connecting with Hustler mower owners, we are committed to our community

At Excel Industries, we are committed to being good stewards of the world around us and aim to be the turf industry leader in sustainable environmental practices. Our team designs and manufactures innovative products that meet and exceed the U.S. government’s environmental standards.

We are actively involved in helping make our local community a better place to live and work. Excel Industries continuously supports Hesston College and the local United Way chapter, as well as locally-focused philanthropies created through Hustler Turf Equipment.

Excel Industries is a member of the Outdoor Power Equipment Institute (OPEI), the major international trade association representing the manufacturers and their suppliers of consumer and commercial outdoor power equipment. OPEI promotes the effective and safe use of outdoor power equipment.

X750 Signature Series Lawn Tractor

Manufacturer’s suggested price does not include taxes, freight, setup, delivery, and optional accessories or attachments. Model and equipment availability vary by dealer and region, and not all products, options, and accessories are available in all regions. See Dealer for availability, details, and final price.

Features

24-HP (17.9-kW) diesel engine

Diesel engine

A liquid-cooled, 3-cylinder diesel engine provides exceptional power, performance, fuel economy, and durability to handle commercial-use applications:

- Large displacement provides exceptional torque

- Cast-iron block improves noise absorption

- Quality features include cast-iron cylinder liners, overhead valves, full-pressure lubrication, and replaceable oil filter

- Solenoid-shift starter ensures easy starts, even in cold weather

- High-energy glow plugs ensure quick starts in cold weather; an automatic sensing system tells the operator when the engine is ready to start

- Mechanical fuel bleed eliminates the need for tools and fuel leaking onto the ground when bleeding the fuel system:

- Simply pump the fuel pump that is located on the side of the engine

- Also provides plenty of power for 12-volt-powered attachments and accessories

- Overhead valve design for efficient airflow

- Swirl chamber combustion design for efficient combustion

- Liquid cooled for more consistent operating temperatures

- Closed crankcase ventilation recirculates and burns crankcase hydrocarbons

Air-intake system

Air intake screens on hood and pedestal

Radiator screen pulled out for cleaning

Engine intake air is drawn in through screened panels at the base of the pedestal and on the right and left sides of the tractor:

- Cleanest and coolest area of the tractor

- Pre-cleans the air to keep large chaff and debris from entering the radiator or air cleaner

- Easy to clean and service so engine operates at optimum temperature

Diesel engine air cleaner

Replaceable air filter

The diesel engine uses a heavy-duty cyclonic canister-type replaceable air filter:

- Completely sealed for effective cleaning

- Cyclone action that is designed to eject 90 percent to 95 percent of the dirt before it reaches the paper element

- Secondary safety element that provides additional filtering

- Total effective filter area of 512 sq in. (3303 sq cm)

Air filter restriction indicator

An air filter restriction indicator is standard equipment:

- Indicator light on the dash alerts the operator when the air filter is dirty and needs to be replaced

- With a visual check, air filter daily service is simplified

- Indicator extends the engine life by eliminating inadvertent dirt entry into the engine from over-servicing of the air filter

Fuel tank has a large 5.2-U.S. gal. (19.7-L) capacity

Fuel cap and tank (shown on X758 Diesel Tractor)

Fuel filter, separator, and shutoff

A large, 5.2-U.S. gal. (19.7-L) capacity fuel tank holds enough fuel for extended operation between refills:

- Fuel-fill location is on the left fender for easy access, increased safety, fewer spills, and convenience during filling.

- A fuel filter/separator with replaceable element includes a shutoff valve and is conveniently located on the front of the engine.

Battery and alternator are large capacity

Battery located at front of tractor frame

A high-capacity, regulated alternator charging system provides plenty of power to quickly recharge the battery and run electrical equipment, such as lights or a sprayer:

A large-capacity, 500 cold-cranking amp battery provides plenty of cranking power for quick, sure starts in cold weather:

54-in. (137-cm) and 60-in. (152-cm) High-Capacity (HC) Mower Decks are heavy duty

X739 Tractor mowing with 60-in. (152-cm) HC Mower Deck

Side view of mower deck

A deep-deck design of 5.5 in. (14 cm) delivers excellent airflow so material can be processed quickly and efficiently. The deck is forged from 9-gauge, 0.15-in. (3.8-mm) steel and has welded-on reinforcement at the bottom edge for extra strength and durability.

60-in. (152-cm) HC Mower Deck top view

54-in. (137-cm) HC Mower Deck bottom view

High-capacity mower decks are formed in a hydraulic press to minimize the number of welds and provide a smooth underside for reduced material buildup:

- Wider and higher discharge opening provides an even clipping dispersal for an excellent finished appearance in all conditions.

- Durable plastic deflector spreads grass clippings evenly across the lawn, is hinged, and can be raised to minimize the storage space required.

- 1-in. (2.5-cm) cold-forged spindles are heat-treated for strength and supported by ball bearings.

- Front edge is raised above the blade plane to allow even cutting of tall grass.

- Blade overlap is greater than many conventional decks for a clean cut.

- Mower can side-discharge, mulch (optional), or use a Power Flow collection system (optional).

Tire-grab feature and shark tooth shaped grips

Drive-over ramp removed for spindle access

Ramps are provided to permit driving over the mower deck for installing and removing it from the tractor:

- Constructed of 30 percent glass-filled polypropylene for strength to carry the weight of the tractor

- Polypropylene material will not rust or corrode for lasting good appearance

- Shark tooth shaped grips designed into the ramp inclines for added wheel traction when driving onto the mower deck

- Tire grab at the rear of the ramp gives extra wheel traction

- Ramps removed and replaced without tools to permit convenient servicing of the mower spindles

Mower wash port

Mower wash port with hose connector

A wash port is provided to make cleaning the underside of the mower deck easy:

Optional high-performance mulching attachment

Mulching attachment components (48 HC shown)

The high-performance mulching attachment provides excellent mulching performance:

- This is a high-performance mulching attachment that includes formed steel baffles to control the material and special mulching blades for superior performance.

- The special mulching blades that are included can also be used for side discharging and collecting, though overall performance may be slightly less than with the standard blades.

Optional MulchControl attachment

Optional AutoConnect drive

AutoConnect option installed on X758 Tractor

The AutoConnect driveshaft is an optional kit that will automatically connect or remove the drive from the mower deck to the tractor’s mid power take-off (PTO) shaft.

The AutoConnect drive does not need to be removed from the tractor when using front-powered equipment.

MulchControl with baffle closed

MulchControl with baffle open

The MulchControl attachment makes mulching more practical for many mowing situations because it not only does an excellent job of mulching but it also allows the mower to be easily converted for times when it is more desirable to side discharge or collect the lawn material. Advantages of mulching grass clippings include:

- A beautiful looking lawn

- Grass clippings not blown onto the operator, driveways, or flower beds

- Less fertilizer use

- Elimination of the effort needed to dispose of clippings

MulchControl is an innovative, simple design that is easy to use and maintain:

- The MulchControl attachment includes baffles to control the flow of material under the deck.

- The left mower blade area is completely enclosed and optimized for mulching, thus will mulch even when the mower is in the side-discharge mode.

- Baffles around the center and right blades are optimized for mulching when the discharge baffle is closed.

Four-year or 700-hour bumper-to-bumper warranty is standard

An exclusive 4-year or 700-hour (whichever comes first), single-source, bumper-to-bumper warranty is standard for all John Deere X700 Series Tractors.

- The warranty is hassle free, with one company handling all of the paperwork.

- Premium features of X700 Series Tractors allow for this longer warranty period, with more coverage than comparable tractors.

Term limited to years or hours used, whichever comes first, and varies by model. See the LIMITED WARRANTY FOR NEW JOHN DEERE TURF AND UTILITY EQUIPMENT at JohnDeere.com or JohnDeere.ca/TUWarranty for details.

Operator station is comfortable and convenient

X739 Tractor mowing

Tilt steering wheel

The tilt steering wheel can be adjusted for optimum operator comfort:

- Six positions can be selected with the push of a lever for the most comfortable setting.

- The full-up position makes getting on and off the tractor easy.

- The steering wheel is designed for comfortable, no-slip operation.

Two-piece tilt-back seat

Seat has convenient tilt-back feature

Seat tilted forward

Two-piece, 21-in. (53-cm) high-back seat, with John Deere branded embroidery, has a thick seat cushion for lasting comfort, even after a full day of use. The back can be angled to maximize operator comfort by using a convenient lever on the side of the seat.

A four-bar adjustable seat suspension and 7-in. (18-cm) slide-rail fore-aft adjustment are provided to optimize operator comfort.

Optional armrest kit

Adjustable armrest option

Left armrest in raised position

Optional armrests increase operator support and comfort, thus reducing fatigue and improving productivity, especially when mowing for extended periods of time. Armrests are adjustable to suit the operator. The embroidered logo on the seat back makes this upscale seat look as good as it feels.

Optional air-ride suspension seat

Optional air-ride suspension seat

Seat pressure switch and fore-aft adjustment lever

The optional air-ride seat minimizes vibration the operator feels while using the tractor and provides a very smooth ride. This seat has a full pneumatic suspension that is easy for operators to adjust to suit their individual needs. Wide, shaped ergonomic cushions are comfortable and reduce back strain.

- Simple switch on the front of the seat makes adjustment easy

- Back-angle adjustment

- Three-position lumbar adjustment

- Armrest height adjustment

- 7-in. (18-cm) fore-aft adjustment

- Provides maximum ride comfort and quality, thus minimizing operator fatigue

- Dampens lower frequency vibration better than mechanical suspensions

NOTE: The air-ride seat is compatible with all X700 Signature Series Tractors, model year 2013 and later (serial number 010,001-). Plug and play wiring harness for use with the air-ride suspension seat has been added to model year 2019 tractors (serial number 70,001-) to reduce seat-installation time. Model year 2013-2018 (serial number 010,001-070,000) requires AM146765 wiring harness. See DTAC solution 115258 for more information.

Foot pads

Foot pads

Foot pads help isolate the operator’s feet from vibration:

Handgrips, toolbox, cup holder, and 12-V outlet

Toolbox and handgrip

Toolbox with cover open and cup holder

The fender handles provide a convenient handhold to use when getting on and off the tractor and when operating on slopes:

- Plastic material is durable and will not rust.

- The cup holder is designed to hold a variety of drink container sizes.

- Toolbox provides a safe and convenient location to store tools and supplies.

- Exact Adjust mower leveling tool and gauge storage features are provided in the tool box.

12-V outlet

12-V outlet

12-V outlet with cover open

12-V outlet located for the convenience of connecting a variety of electrical and electronic equipment:

Headlights and taillights provide good visibility

Two high-quality headlights

Large, automotive-type headlights and taillights provide unsurpassed nighttime illumination:

Snow removal and yard care equipment

An advantage of X700 Series Garden Tractors is their ability to use attachments for snow removal and a variety of other yard-care tasks.

The front quick-hitch mounting system allows for a tool-free change between the front blade, rotary broom, and snow blower. Additional attachments available for use with the equipment listed below include:

- Quik-Tatch tractor frame weights to add ballast for traction and stabilityNOTE: Ballast is required for some applications.

- Tire chains or TerraGrip traction belts for extra traction when using snow-removal equipment

- Weather protection (shown below) for operator protection and comfort

47-in. (119-cm) and 54-in. (137-cm) Quick-Hitch Snow Blowers

47-in. (119-cm) Snow Blower on X739 Tractor

54-in. (137-cm) Snow Blower on X739 Tractor

The 47-in. (119-cm) and 54-in. (137-cm) Snow Blowers have the capacity to handle big snow-removal jobs.

The front quick-hitch mounting system allows for a tool-free change between the front blade, rotary broom, and snow blower.

54-in. (137-cm) and 60-in. (152-cm) Quick-Hitch Front Blades

54-in. (137-cm) Quick-Hitch Front Blade

60-in. (152-cm) Quick-Hitch Front Blade

The 54-in. (137-cm) and 60-in. (152-cm) Front Blades are excellent for moving snow, gravel, dirt, sand, or other loose material. They can be hydraulically angled up to 27 degrees right or left or used in the straight-ahead position.

52-in. (132-cm) and 60-in. (152-cm) Rotary Brooms

52-in. (132-cm) Rotary Broom

60-in. (152-cm) Heavy-Duty Rotary Broom

The 52-in. (132-cm) and 60-in. (152-cm) Rotary Brooms increase tractor versatility by allowing use for a variety of sweeping jobs. The broom effectively meets the needs of commercial, farm, home, and estate operators with four-season versatility:

Spring Rotary brooms can be used to dethatch lawns and clean off tennis courts and other areas quickly and effectively.

Summer Rotary brooms effectively perform a wide variety of sweeping jobs, including cleaning sidewalks, parking lots, driveways, construction job sites, and barns. They can also be used for backfilling trenches.

Fall Rotary brooms can be used to sweep leaves and windrow pine needles. They sweep artificial turf and clean up spectator areas after sporting events.

Winter Rotary brooms effectively move up to 2 in. (5 cm) of snow, which may eliminate the need for a snow thrower, depending on the geographic area.

47-in. (122-cm) Rotary Tiller

647 Rotary Tiller

The 647 Rotary Tiller is 47-in. (122-cm) wide and ideal for preparing seedbeds, controlling weeds, and other tillage jobs for homeowners, golf courses, hospitals, schools, and estates. It requires a tractor equipped with a Category 1, 3-point hitch and 540-rpm rear power take-off (PTO).

Weather enclosure and hard-side cab

Weather enclosure

Hard-side cab

The roomy steel-frame weather enclosure shields the operator against snow, rain, sun, and wind.

This hard-side cab is rollover protection structure (ROPS) certified for extra protection:

- An electric front windshield wiper is included.

- Optional attachments for the hard-side cab include a heater, heater disconnect kit, inside and outside mirrors, rear window wiper, strobe light, work lights, switch panel fuse block kit, and optional tractor alternators to provide extra capacity to operate the cab accessories.

Instruments and controls are easy to find and use

Instrumentation and controls (switch turned off)

Gauges and indicator lights (switch turned on to illustrate functions)

The contoured dash has clean, attractive styling and ergonomic controls for easy use:

- Controls are color coded for easy identification by the operator.

- Controls are logically placed and easy to reach.

- The power take-off (PTO) switch allows the operator to get fingers underneath it, like a T-handle, to pull up for easy activation.

- The reverse implement option (RIO) switch is an easy-to-see and easy-to-use yellow button.

- Cruise control activation is handled by an automotive-style button.

- Functional design of the throttle control provides good appearance and a comfortable feel.

Display panel illustration with descriptions

The instrument display has the look and feel of a modern automobile. A power-up sequence cycles lights and gauges to indicate they are working:

- Display features dark-cockpit design to minimize operator distractions.

- Display is back lit for night visibility.

- Night visibility is especially useful with snow blower use.

- Target-zone graphics inform the operator of the engine speed range to use for best cut quality.

- Damage can be prevented and repair costs reduced by addressing problems early.

- The indicators are also useful to identify the reasons the PTO or engine may have shut off when an interlock is unsatisfied.

- On-board diagnostics provides trouble codes for use by trained technicians.

- For example, a technician will be able to test switch functionality and circuit continuity without tools.

Twin Touch foot control is easy to use and has cruise control

Twin Touch foot control

Cruise control

Twin Touch foot pedals control the speed and direction of travel:

- Automotive-type accelerator control for easy operation

- Twin Touch design that allows operator to change direction without lifting foot off platform

- Large pedal surface for increased operator comfort

When the master brake pedal is depressed, the PTO and cruise control disengage.

- To engage, push in on the cruise lever and hold until the foot is removed from the forward pedal.

- For emergency stop, the cruise control can be released by pushing on the master brake pedal or pushing down on the forward pedal.

Differential lock

Differential lock control

A foot-operated differential lock supplies positive power to both rear drive wheels for increased traction:

Two-function hydraulics give effortless control of equipment

Dual hydraulic control levers

A two-function hydraulic control system is standard equipment.

The hydraulic system allows effortless equipment control:

- Raising and lowering

- Angling and spout rotation

- Control levers

- Levers are positioned on the steering pedestal for quick, easy, and precise fingertip control of equipment.

- Lower lever has a float position, allowing front-mounted equipment such as a blade, snow blower, or rotary broom to follow the contour of the ground.

Hydraulic power steering gives effortless control

X739 Tractor trimming around a tree

Power steering control valve

Power steering is standard equipment. It provides effortless, automotive-like control:

Two-wheel steer (X730, X750)

Four-wheel steer (X734, X754)

Full-time four- wheel drive (X738, X758)

Uncut circle radius (60- in. (152-cm) mower deck)