STIHL MS 361 18″ chain saw with 33RS chain

STIHL MS 361 3.4 kW professional saw for all manner of forestry work. Felling, limbing, crosscutting. High performance, low weight, low vibration level.

STIHL MS 361 3.4 kW professional saw for all manner of forestry work. Felling, bucking, limbing, crosscutting. High performance, low weight, low vibration.

Standard equipment

The decompression valve lets some of the compressed air out of the cylinder when the engine is started. The result is a significant reduction in the tractive force required on the starter rope. The operator is relieved and the entire starting system is subject to less wear and tear.

Allows for precise oil dosage according to requirements. 50 % less oil flow possible with “E” marking. Additional oil supply is possible for long cutting attachments or very dry wood.

STIHL chain saws with a heated carburetor can be used even in winter. In winter mode, the carburettor is heated by the intake air, preventing icing. Switching from summer mode to winter mode with one hand.

QuickStop chain brake. is a safety mechanism when working with chain saws. The chain brake is activated by pressing on the front hand rest and stops the saw chain in a fraction of a second. The QuickStop chain brake is automatically applied if the kickback speed is high enough.

In the four bypass channels the fuel-air mix is swirled before ignition. The result is optimum fuel consumption and a marked increase in engine efficiency. The result is lower fuel consumption and higher torque over a wider rpm range.

Severe vibration in the handlebar area can lead to chronic circulation problems in the hands. That’s why STIHL has developed a high-performance anti-vibration system (AC). With AC motors, engine vibration transmitted to the handles is noticeably reduced.

STIHL conditioner. regulating body in the carburetor. Almost constant engine power, emission quality and fuel consumption over extended periods of time despite increasing air filter contamination. Air filter only needs to be cleaned if there is a noticeable drop in performance. Maintenance-free operation for extended periods of time is possible.

Machine functions such as cold and hot starting, operating and shutting down are controlled by a separate lever. This makes operation particularly comfortable and safe, since the right hand remains on the handlebar.

The tensioning screw is accessed from the side via the chain sprocket cover. That prevents your hands from coming into contact with the sharp chain and gear tips.

Ematic chain lubrication system

The STIHL Ematic system consists of the Ematic guide bar, Oilomatic saw chain and a variable flow oil pump. Special tire and chain design puts every drop of oil exactly where it needs to go for lubrication. This reduces oil consumption by up to 50%.

The compression pressure causes jolting forces that put strain on the muscles and joints when starting a two-stroke engine. The ElastoStart visibly reduces these harmful influences. The damping element in the handlebar of the ElastoStart alternately takes in and adds power in accordance with the compression process, so that starting is smooth and jolt-free.

Special patented caps for fuel and oil tanks. Tanks, if fitted, can be opened and closed easily, quickly and without tools.

Technical Data

| Working volume, cm³ | 59 |

| Power kW/l.с. | 3,4/4,6 |

| Weight, kg 1) | 5,6 |

| Specific weight, kg/kW | 1,6 |

| Sound pressure level, dB(A) 2) | 103 |

| Sound power level, dB(A) 2) | 115 |

| Vibration level left/right m/s² 3) | 3,6/3,6 |

| Speed at max. torque, rpm | 10.000 |

| Oil tank capacity, cm³ | 325 |

1) Without fuel, without guide bar and saw chain 2) K-factor according to RL 2006/42/EG = 2.5 dB(A) 3) K-factor according to RL 2006/42/EG = 2 m/s²

The product range and details may vary for each export version. Design and technological modifications of the tool and accessories, as well as price changes are possible.

Equipment

Decompression valve

When the engine starts, the decompression valve lets some of the compressed air out of the cylinder. As a result, the required pulling force on the starter rope is considerably reduced. The operator can work more easily and the entire starting system is less subject to wear and tear.

Adjustable oil pump

Guarantees optimum flow and allows accurate oil dosage according to requirements. A 50% reduction in chain oil consumption is possible with all elements of the Ematic system. In the case of long cutting attachments and very dry wood, we recommend that you increase the oil flow.

Winter-summer shutter

STIHL chain saws with a winter-summer shutter system can also be used in winter. In winter mode, the carburettor is blown with heated air intake to prevent icing. One-handed switch from summer to winter mode.

QuickStop brake for instant stopping the chain

QuickStop chain brake. is a safety mechanism when working with chainsaws. Chain brake engages when front hand rest is pressed and stops chain in fractions of a second. The QuickStop chain brake works automatically if the kickback speed is sufficiently high.

STIHL four-channel technology

Four bypass passages swirl the combustion mixture before ignition. The result is better fuel consumption and high engine efficiency. The result is lower fuel consumption and higher torque over a wider rpm range.

Anti-vibration system

High hand-arm vibrations can cause permanent circulatory problems in the hands and arms. That’s why STIHL has developed a high-performance anti-vibration system to reduce transmission of engine vibrations to the handles.

Single-lever control

Machine functions such as cold and hot starting, operating and shutting down are controlled by a separate lever. It is especially comfortable and safe to operate, because the right hand remains on the handlebar.

Side chain tensioning device

The tensioning screw is accessed from the side through the chain sprocket cover. This prevents your hands from coming into contact with the sharp chain and the tips of the sprocket.

Ematic chain lubrication system

The STIHL Ematic system consists of the Ematic bar, Oilomatic chain and oil pump. The special design of the bar and chain causes each drop of oil to go exactly where it needs to go for lubrication. This reduces oil consumption by up to 50%.

STIHL ElastoStart

Compression pressure causes jerky starting of two-stroke engines that puts strain on the muscles and joints. ElastoStart significantly reduces these harmful influences. The damping element in the handlebar of the ElastoStart alternately takes in and gives out energy in accordance with the compression process, so that starting is smooth and jolt-free.

Tool-less tank lids

Patented, non-lossable fuel and chain oil tank covers. Tanks can be opened and closed quickly and easily without tools.

The product range and information may differ according to the export version. Structural and technological modifications of tools and accessories as well as price changes are possible.

Benefits of retrofitting

The STIHL MC 361 professional saw combines a classic design with the latest technology.

- Not only does it perform as standard in its class, it also has the advantages of an economical engine with vortex fuel mixing.

- Refined spring damper that repeatedly reduces low- and high-frequency vibrations of the tool in various operating modes. This model is equipped with an adjustable oil system for cutting-chain lubrication.

- The STIHL chain saw comes complete with Ematic brake system and QuickStop, which in a split second prevents the chain from moving in an emergency situation.

The merits of this model include optimized engine operation with a 4-channel cylinder, the presence of a booster primer pump in the fuel system, an electronic ignition system controlled by the built-in microprocessor.

High standard of operational reliability

Improved model MS 361 saw is notable for better and more ergonomic design, stable idle and working modes, fast maximum speed, economical consumption of gasoline and oil fuel mixture.

With skilled maintenance, the number of failures and malfunctions of this model per scope of work performed is minimal. The situation when the engine does not start. most often it is the consequence of poor maintenance, economy on the quality of fuel or gross mistakes made during operation.

Appearance

Original saw is twisted with screws “star”. Fakes in 90% either flat or Phillips head screwdriver.

There is a logo on the tank lid. No logo on the knockoffs. Also consider the logo on the screws on the back of the tank.

On the muffler/tire side, the original must have an identification plate with the serial number, which must match the number on the box. Counterfeit saws either have no label or are in bad quality and so the labels will wear off over time.

The muffler body on the original saw has the product part number engraved on it.

Differences in filter elements. Remove the cover covering the filter and compare it to the photo:

Every original STIHL Ms saw is marked with a part number and is perfect. Fakes show mold remnants, plastic molding flaws, missing part numbers.

In addition to the differences of the original saw, the following video shows the distinctive features of the chain and bar:

Selection by model

Chainsaw users sometimes have trouble understanding the size designations of bars and chains. This confusion leads to buying the wrong muffler for the right saw and, not naturally, to wasted money. Chain for Husqvarna 137, 142 and other chainsaws. For the bar 15. Here we will try to point out the typical mistakes and help you not to make them.

Most of the errors are due to the fact that traditionally the saw is specified in inches. It is not convenient for those people, who are used to using metric system. Several factors may be the reason for lack of oil supply to the chain while the chain saw is running, and to determine them it is necessary to disassemble the chain saw. This question is not the reason of most mistakes: in our country the situation is such, that in our country the parameters, expressed not in inches but in millimeters at the same time, are used in characteristics of saw chain, that is not correct in general.

What chain to use for rip sawing?

Chain saw users often ask what chain is suitable for rip sawing and if there are any chains that are specially designed for rip sawing.

At the present moment there are no chains, specially developed for sawing longitudinally along the trunk of the tree and most likely they will not appear in the near future, because. к. Any saw chain can be used for this application. The difference between a regular chain and a barbed chain is the sharpening angle.

With the side dressing machine, it is possible to turn a conventional headset into a special headset. one that makes it easier to cut lengthways. You can find information on exactly how to do this on our website.

Which STIHL or Oregon chain is better?

Choosing which chain is better, STIHL or Oregon, is hard enough. к. they are practically of the same quality. Oregon and STIHL have specialized in chainmaking, and are constantly improving and launching new models.

If you compare at the user level, Oregon is a little softer, they blunt faster, but they are easier to sharpen with a file. Stihl. almost all are hardened, the metal is hard to sharpen, but it keeps its edge a little longer.

Interesting. According to experts, the quality of the chain is a relative issue. Many users initially use used engine oil for lubrication and then say that a particular model and brand of chain is of low quality, although the reason for premature wear is the metal chips in any waste oil, even the one that has had time to mature before filling.

Selecting a chain

If you became the happy owner of a chainsaw (or the electric saw), then at a certain moment of chain-saw use you will have a problem of selection of sawing accessories (a chain and/or a guide bar). And if at that moment you don’t have a specialist within reach to help you solve the problem, it can be a big problem.

The range of chains and bars for chainsaws (and electric) in a specialized store in Khabarovsk (or other region) can be huge and it is easy to get confused in it. Let us try to help you find exactly what you need for your saw.

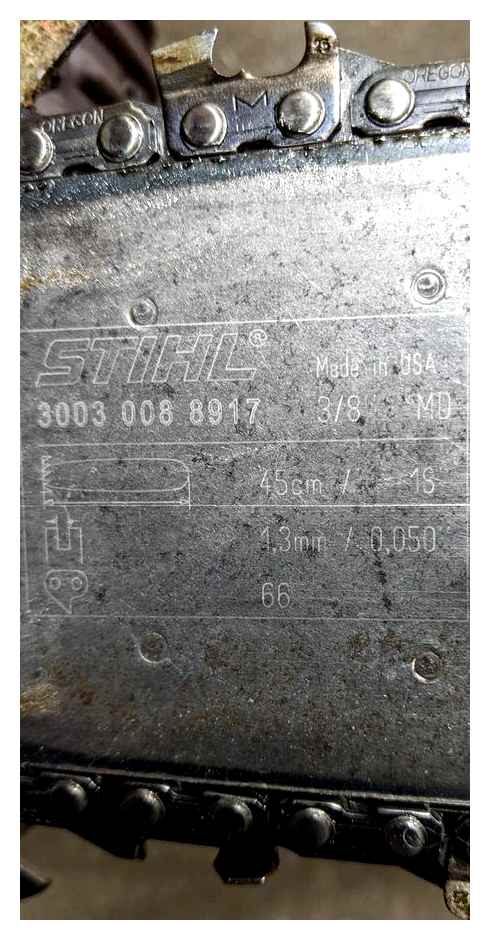

Chains, and therefore guide bars, have three basic characteristics:1. Length (for chain. number of links);2. pitch (1/4″, 0.325″, 3/8″.404″);3. Shank thickness(for chain)/groove width(for bar).

Knowing these characteristics makes it easy to find the right bar and chain.

There are several articles on the Internet, where all these characteristics are described in detail. There is no point in reprinting all of this material, especially since you do not want to be accused of plagiarism))) It is better to see this information on the official website of the company

Below is a table with a selection of chains and bars Oregon by brand chainsaws that you can buy in Khabarovsk.

And also the characteristics (in order number of links (pcs). pitch. groove width (mm)) which you can easily match to your tool’s cutting attachments:

| Brand of saw | Model | Length | Feature | Chain | Tire | File | |

| Husqvarna | 236 | 14 | 52-3/8″-1,3 | 91-52 | 140SPEA041 | 140SDEA041 | 4,0 |

| 137/142/235/440/435 | 15 | 64-0,325″-1,3 | 95(20)-64 | 150MLBK095 | 150MPBK095 | 4,8 | |

| 240/340/350 | |||||||

| 445/450/55 | |||||||

| 257/357/254 | 15 | 64-0,325″-1,5 | 21-64 | 158SLGK095 | 158PXBK095 | 4,8 | |

| 455/460 | |||||||

| 262 | 18 | 68-3/8″-1,5 | 73-68 | 39450 | 5,5 | ||

| 365/372/365HH | 18 | 73-68 | 188SLHD009 | 188SFHD009 | 5,5 | ||

| 365/372/576 | 20 | 72-3/8″-1,5 | 73-72 | 208SLHD009 | 5,5 | ||

| 372/576/395 | 24 | 84-3/8″-1,5 | 73-84 | 248ATMD009 | 248RNDD009 | 5,5 | |

| E321 | 18 | 72-0,325″-1,5 | 21-72 | 188SLGK095 | 4,8 | ||

| STIHL | 192T | 12 | 44-3/8″-1,3 | 91-44 | 120SPEA074 | 4,0 | |

| 180/250 | 14 | 50-3/8″-1,3 | 91-50 | 140SPEA074 | 4,0 | ||

| 341/361/390 | 16 | 60-3/8″-1,6 | 75-60 | 163SLHD025 | 5,0 | ||

| 341/361 | 18 | 66-3/8″-1,6 | 75-66 | 183SLHD025 | 5,0 | ||

| 361/440 | 20 | 72-3/8″-1,6 | 75-72 | 203SLHD025 | 5,0 | ||

| Hitachi | CS33ET | 12 | 45-3/8″-1,3 | 91-45 | 120SDEA041 | 120SPEA041 | 4,0 |

| CS33EB | 14 | 52-3/8″-1,3 | 91-52 | 140SPEA041 | 140SDEA041 | 4,0 | |

| CS38EK | 15 | 64-0,325″-1,3 | 95(20)-64 | 150MLBK095 | 150MPBK095 | 4,8 | |

| CS40EA | 16 | 66-0,325″-1,3 | 95(20)-66 | 160MLBK041 | 160MPBK041 | 4,8 | |

| Makita electric grooves 1.3 mm | UC3020A | 12 | 45-3/8″-1,3 | 91-45 | 120SDEA041 | 120SPEA041 | 4,0 |

| UC3030A | 12 | 91-45 | 120SDEA041 | 120SPEA041 | 4,0 | ||

| UC3520A | 14 | 52-3/8″-1,3 | 91-52 | 140SPEA041 | 140SDEA041 | 4,0 | |

| UC3530A | 14 | 91-52 | 140SPEA041 | 140SDEA041 | 4,0 | ||

| UC4020A | 16 | 56-3/8″-1,3 | 91-56 | 160SPEA041 | 160SDEA041 | 4,0 | |

| UC4030A | 16 | 91-56 | 160SPEA041 | 160SDEA041 | 4,0 | ||

| UC4530A | 18 | 62-3/8″-1,3 | 91-62 | 180SPEA041 | 180SDEA041 | 4,0 | |

| Makita electric slot 1.1 mm | UC3020A | 12 | 45-3/8″-1,1 | 90-45 | 124MLEA041 | 4,5 | |

| UC3030A | 12 | 90-45 | 124MLEA041 | 4,5 | |||

| UC3520A | 14 | 52-3/8″-1,1 | 90-52 | 144MLEA041 | 4,5 | ||

| UC3530A | 14 | 90-52 | 144MLEA041 | 4,5 | |||

| UC4020A | 16 | 56-3/8″-1,1 | 90-56 | 164MLEA041 | 4,5 | ||

| UC4030A | 16 | 90-56 | 164MLEA041 | 4,5 | |||

| Echo | 2600 | 10 | 40-3/8″-1,3 | 91-40 | 100SDEA041 | 100SPEA041 | 4,0 |

| 3050/3500/350WES | 14 | 53-3/8″-1,3 | 91-53 | 140SPEA041 | 140SDEA041 | 4,0 | |

| 3700/4200/450 | 15 | 64-0,325″-1,5 | 21-64 | 158SLGK095 | 158PXBK095 | 4,8 | |

| 3700 | 16 | 66-0,325″-1,3 | 95(20)-66 | 160MLBK041 | 160MPBK041 | 4,8 | |

| 5100 | 18 | 72-0,325″-1,5 | 21-72 | 188SLGK041 | 4,8 | ||

| 680 | 18 | 64-3/8″-1,5 | 73-64 | 188SLHD176 | 5,5 | ||

| 8002 | 20 | 72-3/8″-1,5 | 73-72 | 208SLHD176 | 5,5 | ||

| Elmos el. | 1835 | 14 | 52-3/8″-1,3 | 91-52 | 4,0 | ||

| 2040 | 16 | 52-3/8″-1,3 | 91-52 | 4,0 | |||

| Oleo-Mac | 925 | 10 | 40-3/8″-1,3 | 91-40 | 100SDEA041 | 100SPEA041 | 4,0 |

| 932/GS35 | 14 | 52-3/8″-1,3 | 91-52 | 140SPEA041 | 140SDEA041 | 4,0 | |

| GS35/937/940/941C | 16 | 57-3/8″-1,3 | 91-57 | 160SPEA041 | 160SDEA041 | 4,0 | |

| 941CX/GS44 | 16 | 66-0,325″-1,3 | 95(20)-66 | 160MLBK041 | 160MPBK041 | 4,8 | |

| 947/952/956 | 18 | 72-0,325″-1,5 | 21-72 | 188SLGK095 | 4,8 | ||

| 962 | 18 | 68-3/8″-1,5 | 73-68 | 39450 | 5,5 | ||

| Homelite | 3314 | 14 | 52-3/8″-1,3 | 91-52 | 140SPEA041 | 140SDEA041 | 4,0 |

| 4016 | 16 | 65-0,325″-1,3 | 95(20)-65 | 160MLBK041 | 160MPBK041 | 4,8 | |

| 4518 | 18 | 72-0,325″-1,3 | 95(20)-72 | 180MLBK041 | 180MPBK041 | 4,8 | |

| SunGarden | Beaver 2512 | 12 | 45-3/8″-1,3″ | 91-45 | 120SDEA041 | 120SPEA041 | 4,0 |

| Beaver 3816/4116 | 16 | 57-3,8″-1,3″ | 91-57 | 160SPEA041 | 160SDEA041 | 4,0 | |

| Beaver 3614 | 14 | 52-3/8″-1,3″ | 91-52 | 140SPEA041 | 140SDEA041 | 4,0 | |

| Beaver 4518 | 18 | 72-0,325″-1,3 | 95(20)-72 | 180PXBK095 | 4,8 | ||

| Beaver 4618 | 18 | ||||||

| Beaver 5220 | 20 | 76-0,325″-1,3 | 95(20)-76 | 4,8 | |||

| Beaver 5020 | 20 | 76-0,325″-1,3 | 95(20)-76 | 200MPBK095 | 4,8 | ||

| Beaver 6224 | 24 | 84-3/8″-1,5 | 73-84 | 240SLHD176 | 5,5 | ||

| SCS 1800 | 14 | 52-3/8″-1,3 | 91-52 | 140SPEA041 | 140SDEA041 | 4,0 | |

| SCS 2000/2200 | 16 | 57-3/8″-1,3 | 91-57 | 160SPEA041 | 160SDEA041 | 4,0 | |

| Partner | 350 | 14 | 52-3/8″-1,3 | 91-52 | 140SPEA041 | 140SDEA041 | 4,0 |

| 351/352/371 | 16 | 56-3/8″-1,3 | 91-56 | 160SPEA041 | 160SDEA041 | 4 | |

| 740/840/842 | |||||||

| Patriot | 2512 | 12 | 45-3/8″-1,3 | 91-45 | 120SDEA041 | 120SPEA041 | 4,0 |

| 3816/4016 | 16 | 57-3/8″-1,3 | 91-57 | 160SPEA041 | 160SDEA041 | 4,0 | |

| 3818/4018/4318 | 18 | 64-3/8″-1,3 | 91-64 | 4,0 | |||

| 546-18 PRO | 18 | 62-3/8″-1,3 | 91-62 | 4,0 | |||

| 943-16 PRO | 16 | 57-3/8″-1,3 | 91-57 | 4,0 | |||

| 4518 | 18 | 72-0,325″-1,3 | 95(20)-72 | 4,8 | |||

| 4520/5220/5820 | 20 | 76-0,325″-1,3 | 95(20)-76 | 4,8 | |||

| 6220 | 20 | 72-3/8″-1,5 | 73-72 | 5,5 | |||

| Champion | 325 | 16 | 57-3/8″-1,3 | 91-57 | 160SPEA041 | 160SDEA041 | 4,0 |

| 242 | 18 | 60-3/8″-1,3 | 91-60 | 180SPEA041 | 180SDEA041 | 4,0 | |

| 255 | 18 | 72-0,325″-1,3 | 95(20)-72 | 180MLBK041 | 180MPBK041 | 4,8 | |

| Husgvbarna China | 5200 | 18 | 72-0,325″-1,3 | 95(20)-72 | 180MLBK041 | 180MPBK041 | 4,8 |

| 5200 | 20 | 76-0,325″-1,3 | 95(20)-76 | 4,8 | |||

| Parma | 2м | ||||||

| Ural/Druzhba | 20 | 64-0,404″-1,6 | 59AC-64 | 203SLFM015 | 5,5 | ||

| Carver | RSG 45-15 | 15 | 64-0,325″-1,6 | 21-64 | 4,8 | ||

| RSG 52-18 | 18 | 72-0,325″-1,6 | 21-72 | 4,8 | |||

| RSG 252 | 20 | 76-0,325″-1,6 | 21-76 | ||||

| RSG 246 | 18 | 72-0,325″-1,6 | 21-72 | 188SLGK095 | |||

| RSG 241 | 16 | 57-3/8″-1,3 | 91-57 | 160SPEA041 | |||

| RSG 238 | 16 | 57-3/8″-1,3 | 91-57 | 160SPEA041 | |||

| RSG 255 | 12 | 45-3/8″-1,3 | 91-45 | 120SDEA041 | |||

| TAIGA | 17 | 64-3/8″-1,6 | 75-64 | 178SLHD010 | 5,5 | ||

| Kraton | GCS-07 | 14 | 53-3/8″-1,3 | 91-53 | 140SPEA041 | 140SDEA041 | 4,0 |

| GCS-08 | 16 | 66-0,325″-1,3 | 95(20)-66 | 160MLBK041 | 160MPBK041 | 4,8 | |

| GCS-09 | 16 | 57-3/8″-1,3 | 91-57 | 160SPEA041 | 160SDEA041 | 4,0 | |

| GCS-10 | 18 | 72-0,325″-1,3 | 95(20)-72 | 180MLBK041 | 180MPBK041 | 4,8 | |

Chains Rapid Micro Comfort

The comfort version of the universal saw chain Rapid Micro, with its low vibration level, smooth cutting action and lack of tendency to shake. all this thanks to the beveled bottom of the tooth, as on the Rapid Super Comfort and Rapid Super Comfort 3 saw chains. Usage: pruning, felling, crosscutting in construction and logging operations.

German saw chains are characterized by their technical innovations and high manufacturing quality. The following are some convincing quality indicators.

Chain extraction

Delivery in Moscow and the Moscow region

Delivery within the Moscow Ring Road. from 400 Beyond the MKAD (Moscow Ring Road). 30 /km.

Goods priced over 30,000 within the MKAD (Moscow Ring Road) are delivered free of charge.

Self-delivery

You can pick up the goods yourself in our store at the address:

Delivery within Russia

Delivery by transport companies.

Delivery to the terminal of the transport company in Moscow. 200.

Further the cost of delivery in your region is defined by the carrier chosen by you.

The cost of preparation includes: unpacking and checking completeness (opening will check availability of spare parts), assembling the ready item (if necessary), checking adjustments, filling the equipment with oil, refueling, checking lubrication in gearboxes and transmissions, and starting the equipment. Lubricants and oils are not included in the price. Gasoline is filled in a minimum volume, sufficient for a single start of the engine, necessary for checking its performance. The cost of preparation depends on the degree of difficulty of assembly and the time spent. For terms, terms and exact amount of assembly/pre-sales preparation check with the manager when placing the order.

All STIHL and VIKING products are available for free pre-sales only !

Dismantling and mounting of additional attachments on tractors and power tillers is paid for separately and depends on the type and complexity of the work. Check terms and cost of this service with our managers.

Causes of saw headset rupture

Sometimes the chainsaw headset can break while working. This is not a very common occurrence, but it does happen from time to time. There may be several reasons, the first and the most common is heavy wear and tear. The chain can not hold up to the pressure and tears as the metal chipper rubs against the guide bar.

Important! Use of high-quality adhesive oils greatly extends the life of the saw unit.

The second reason is the late replacement of the drive sprocket and bar or changing them seperately. According to the recommendations given by the manufacturers, the saw headset, guide bar and drive sprocket should be changed as a set. This prevents wear, stretching and tearing due to increased loads.

Third, it is a defect in sharpening with a special sharpening machine. The machine wheel rotates at high speed and if the wrong depth is set or the stroke is increased for any reason, a split second is enough to undercut the edges of the connecting link. If you do not check the quality and cut links after sharpening, the cut link can break when working under load.

Fourth and last, a riveting defect. A common cause of chain breaks is incorrectly joined or reused connecting links. If your cutting attachment breaks, information on how to connect the chain is very useful.

Scope of application

Carbide chain is well suited, and sometimes simply indispensable for sawing hard and extra hard wood. For example:

- stained oak;

- steamed wood, similar in density to bone;

- hardwood of the first cut (from the stump), the rump, especially dry and swollen (with twisted fibers);

- dry wood with heavy knots

- wood with ice on the surface or contaminated by sand or soil.

Chainsaws with carbide chains are used for cutting ice for any purpose, including making ice sculptures.

EMERCOM rescue teams routinely use only such cutting equipment, even when debris from normal wood has to be removed. In extreme situations, there’s no time to keep a chain in place. Cutting edge often touches rock, earth, metal in wood. A normal chain will break down in a moment and need to be replaced, but in an emergency there is no time for that.