How to adjust the clutch on the tiller

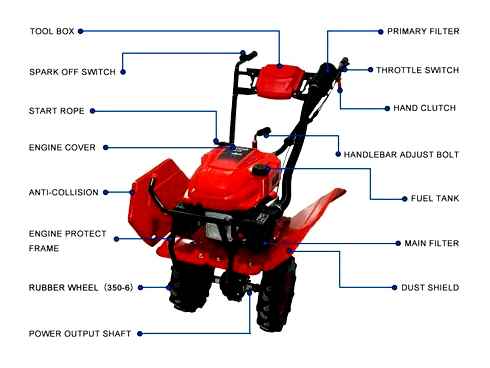

The clutch of a power tiller is one of the important elements of the transmission. It keeps the engine and gearbox disconnected during gear shifting. It makes the single-axle tractor start moving smoothly from a place and also provides its stop without shutting off the engine completely. How to properly adjust the clutch on a power tiller is shown below. If you find it easier to interpret the information visually, you can take a look at AgroMotoCenter’s YouTube channel, where video reviews of the products are posted and tips on their proper use are given. Click here for the video.

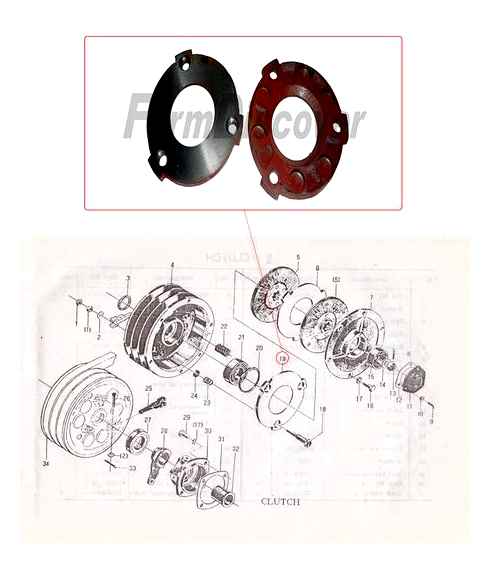

The construction of the clutch for the power tiller includes several important elements such as control devices, driving element and driven parts.The design of the driving part includes a slave and a friction disc. There are cylindrical springs around the perimeter of the pressure plate. They use them to compress the disc that they pick up. The other end of the spring is in contact with the guard. The control mechanism is made of push-up levers, which are connected to the body of the pressure discs by a push-up lever and a push-down lever.

The problem with the clutch because of the new k-65 carburetor | Author of this topic: Ermengard

Who solved the problem with the leg on a new carburetor with an old piston.I have an idea to put an additional pad between the cylinder and the carburetor. I am afraid to bend the blade. Who has any other ideas??

Ovanes (Indrani) Had that problem, just remove the lever and lengthen it by welding on the extension. For example I took half of this lever instead of an extension. You can also lengthen the intake manifold. You would need two longer pins and a flange, which can be ground from an old carburetor.

Vadim (Maksym) how to adjust the clutch correctly?

Alexander (Jerrylynn) clutch is adjusted by tightening the central bolt until it stops and then turn it a quarter turn in the other direction

Gosha (Islam) no one knows how to improve it?? I can’t tighten it strongly enough, there will be problems with starting and it is rather difficult to squeeze it, but if you loosen it, it drives (I can’t find a compromise in any way)

Alexander (Jerrylynn) Gosha Friend of the Cat Friend of the Cat, I understand. The same problem on the Ants. and tried to adjust it with bolts. the same. It is quite tight and does not squeeze out to the end, I have to stand and accelerate.

Anton (Yamina) Inlet manifold extension does not advise, will change the geometry and you will not get the correct operation, I tried to build up the gasket (regular rubber, the same which is there to seal) put them two, the effect is not happy, the engine barely runs. I used a sleeve made from a nozzle of k36g carburetor. Complete silence of the engine, it is impossible to start, I turned the ignition, the most that I got was firing and that’s all. Assembled the design without my improvements, everything runs like clockwork, winds up with a bang (sitting on the seat a little twitch of the left hand crank and forward).

Anton (Yamina) To ease the clutch, the most real way is to increase the clutch lever on the engine, as described by Hovhannes Donakanian. But the clutch handle travel is increased. I also recommend a good lubrication clutch cable. There is another way, but I have not tried it: in the clutch basket diametrically opposed to not put 2 springs, then the clutch will be squeezed easier.

Dima (Donny) do not know how anyone but I bent the foot a little bit. The main thing is not to overdo it.

Alexey (Ghinjo) I’m fine with a file

Andrey (Ismo) The shovel can be simply heated with a burner along the bend to a cherry color and it is easy to bend and not break

Danil (Kairava) tell me why the clutch is acting up

Dmitry (Zarwa) Because the clutch is not adjusted

Danil (Kairava) everything is fine

Dmitry (Zarwa) If it runs or slips, then not everything is fine! I changed the discs a long time ago?

Dmitry (Zarwa) Other than adjust I have nothing to say

Alexander (Jerrylynn) Danil, make sure the cables are not broken, then it will be easy to squeeze out and will not lead.

How to make a clutch frame for a single axle tractor with your own hands

Consider how to make a frame clutch on a single axle tractor with their own hands. Belt clutch, which is installed on most cultivators, quickly wears out, V-belt system does not have high strength and reliability, has low efficiency, is not used for cultivators with a powerful engine. Therefore, many owners are remodeling and upgrading such a system.

Consider how to make a homemade clutch mechanism.

- flywheel and transmission shaft from the Moskvich car;

- hub and steering mechanism from the car Tavria;

- metal profile;

- pulley;

- A steel billet from the GAZ-69 car, which can be used as a crankshaft.

Makes a self-made device by sharpening a steel billet on a lathe. It is needed in order to put the hub on the manufactured shaft.

Improvement of the clutch of a motor-block is carried out as follows. After the pulley has been mounted on the shaft, grind the seating according to the diameter of the pulley ring for the thrust bearing.

the hub should fit without play, the pulley must be able to turn smoothly.

After that, you need to turn the device and perform the same steps on the other side. Then use a drill with a 5 mm drill bit to make six holes in the pulley, which are the same distance from each other.

Since 10 mm bolts will be used, on the reverse side, using a drill with a diameter of 12 mm drill holes for the wheel, which is designed to drive the belt.

Then the pulley is mounted on the flywheel and holes are made with the same drill, then the parts are bolted together.

While the pulley is on the flywheel, make a mark on the flywheel through the holes made in it. Then remove the pulley and drill these 6 holes.

After that, it is necessary to tighten the construction using 10 mm bolts. The bolt thread must be 60 mm without a cap. The crankshaft must be ground on the inside with a block. To prevent the flywheel from striking and to move smoothly, its surface must be ground and centered in the seating hole.

How to make a clutch on a single axle tractor. the sequence of actions

The principle of operation of the clutch system, regardless of type, is based on constant friction. As a result, the assembly fails quite quickly. Buying a new quality mechanism is not a cheap pleasure, so many farmers-enthusiasts prefer to make the clutch system with their own hands. It is not as difficult as it may seem at first glance, but before the work is still required to prepare thoroughly.

The first thing to do is to study the detailed drawings of the mechanism. The dimensions of each part and its location in the structure must be specified.

After studying the scheme, you need to prepare the materials and tools available in your garage.

To assemble the clutch will be necessary:

- The primary shaft and a serviceable flywheel. as a rule, these parts are taken from the gearbox of a Soviet Moskvich car;

- idler pulley, on which two knobs are pre-installed;

- undamaged hub and a metal knuckle of swivel type from the car Tavria;

- B-profile;

- A whole crankshaft from the car GAZ-69.

The correct procedure for assembling the clutch mechanism for an existing motor-block is as follows:

- First, it is necessary to carefully grind the taken crankshaft. As a result of modification, the part must not touch other elements of the manufactured motor-block clutch;

- Then the factory hub of the motoblock must be installed on the used shaft;

- On the surface of the shaft it is necessary to arrange the place for mounting bearings. After turning the place, the hub should be mounted without any gaps. In this case, the driven pulley must necessarily rotate directly around its axis without the slightest interference;

- In the next step, you must make six equal holes in the pulley, each with a diameter not exceeding 5 mm. The distance between the holes should be the same. Please note that there should be bolts of 10mm each inside the holes. Because of this, the holes will also need to be made on the back side of the pulley;

- Then the pulley should be placed over the flywheel and both parts should be bolted together. Then it will be necessary to mark the places for drilling holes. in the future, these must coincide with the holes previously made in the pulley;

- After that, you need to pull out the pulley and drill holes in those places on the flywheel, where the marks were previously set;

- After that, it will be necessary to mill the inner surfaces of the shaft and the flywheel available in the design so that both parts do not touch each other;

- The clutch design must include a clutch handle for a single-axle tractor. To make it, you should use a tube with a diameter of about 1 and a length of 3 cm. Next, the lever must be secured to the surface of the pulley;

- To complete the mechanism, you need a clutch cable for the tiller. To this end, you can buy a new cord, and then wind it on any spool, or take a whole rope with a serviceable spool from a household chainsaw.

The homemade clutch made in such a way will be optimally suited for the configuration of motoblocs of the well-known brands Agro and Neva MB-2. The mechanism made by your own hands will last long enough without the need for repairs.

Single axle tractor Neva clutch adjustment

The clutch is tightly interconnected with the gearbox. It has a sufficiently important function. which transmits torque from crankshaft to gearbox, located in the transmission, disconnects gearbox and crankshaft (this is done during gear shifting). This mechanism also ensures the smooth running of the motorblock from the ground. It allows the machine to stop without shutting off the engine (through the clutch lever, cable and the system as a whole).

Functions of the clutch in the construction of a power tiller

The clutch operation is based on the action of the friction clutch. This element of the transmission performs several important functions, among which stands out:

- Seamless transmission of torque;

- Suppression of torsional oscillations;

- Smooth gear shifting;

- Shockless connection of gears;

- Connecting and disconnecting a gearbox with an internal combustion engine;

- Disconnecting the transmission from the flywheel unit.

The clutch device makes it possible to disengage the engine crankshaft and the power transmission of the machine for a short time. Smooth, jerk-free start and stop thanks to clutch.

Owners’ experience in using the Neva MB-2 power tiller. forum reviews

Every farmer’s experience is unique. Especially valuable is the advice of those who use the same single-axle tractor as you do in the work on your plot of land. Further. some tips from the owners of the Neva MB-2 power tiller about maintenance and troubleshooting.

“Bought a Neva mb2 single axle tractor and was very happy. The machine worked fine for a while, but after a week of operation the white smoke came out of the exhaust pipe. Tried to turn down the engine rpm. did not help. Turned out to be water in the float chamber. I drained the gasoline, put it on standby, drained the chamber. After that the single axle tractor worked fine. If anyone has had a similar problem, I suggest using my experience!”

“Ran into such a problem: in first gear my single-axle tractor cultivated normally, but when I switched to the second and worked with the soil. the engine speed did not fall. When digging deeper into the ground, the cutters stop. Knowledgeable people have suggested that it may be a matter of towing the belt. Adjusted the tensioner and shortened the chain on the clutch lever and the problem was solved! Now I work with pleasure, I have been using my Neva MB2 for two years now”.

“I am not a novice with my power tiller, I have been using it for 4 years now. Recently, if you give the load, the engine began to stall, well, as if not pull Barely drove into the garage, and there was no noise or smoke. The reason was simple: the air filter was clogged. I had to replace it and now it runs like a beast.

You can also help other readers of our site with your reviews of this model of power tillers and its maintenance and main troubles.

If you are an owner of this model of power tiller, you can leave a review about its maintenance and operation, or ask any question about the breakage or maintenance of this model below in the Комментарии и мнения владельцев.

The clutch of a power tiller is one of the important elements in the transmission. It ensures the separation between the engine and the gearbox during gear shifting. This enables the single-axle tractor to move smoothly from a standstill, and also makes it possible to stop without shutting off the engine completely. How to properly adjust the clutch on your power tiller below. If you find it easier to read the information visually you can also go to the YouTube channel of AgroMotoCenter, where you can see video reviews of the products and get tips on how to use them properly. To see the video, go to.

Centrifugal clutch. device and advantages

This kind of element is worth distinguishing among other designs due to its reliability and durability. It is used in automatic gearboxes. Its construction consists of the following elements:

- Flywheel;

- Pulley;

- Hubs with keyway and keyway;

- Flange;

- Hubs;

- Casing;

- bearings;

- The locking ring.

One of the most important roles is played by the differential device, associated with the centrifugal coupling. It helps improve maneuverability and ensures smooth cornering.

Together with the clutch, the differential regulates the rotation of the wheels of the power tiller at different speeds. over, the mechanisms that transmit power together act as wheel locks. Some models have a special device instead of a differential that locks one of the wheels of the power tiller at the driver’s command.

modern models have a friction clutch. It is mounted between the engine and the transmission. In this design, the driven parts are closely connected to the gearbox input shaft and the driven parts to the engine crankshaft. In most cases. both driving and driven elements are made in the form of flat round discs, or in the form of a cone. Just like a centrifugal clutch, a friction clutch is actuated by manipulating a separate handle.

How the clutch works

A clutch for a power tiller consists of several important elements:

The drive element consists of the flywheel side of the motor and the pressure plate. The disc rotates with the attached flywheel. At the same time, the disc can also move axially in relation to the flywheel. Between these two elements there is a slave disc that rests on the driveshaft. Cylinder shaped spring elements are arranged around the circumference of the pressure plate. The function of the springs is based on compression of the disc they support.

The other end of the springs contact the housing. The springs thereby keep the clutch for the power tiller engaged at all times.

The actuation mechanism is made of push-rod levers connected to the pressure plate housing by draw rods and a foot pedal. By disengaging the clutch, the owner of the power tiller engages the clutch cable, which transmits the force to the release levers. When the springs are compressed, the levers draw the drive plate away from the pressure plate, which results in disengaging the clutch.

Sifang/Aci Power tiller clutch repair.

The bearing reduces friction by preventing the stationary lead from touching the rotary levers. Most models of power tillers are equipped with three levers, located at an angle of 120 degrees with respect to each other. A spring returns each clutch lever to its original position. In doing so, the tines are moved to the desired distance to disengage the levers. If this distance is not reached, the clutch will start to slip.

Accessories

We offer an overview of the equipment, combined with power tillers “Ugra” various modifications:

- Holes.

- Bearing arrangements.

- Cartopelezadniki;

- Bulb Breakers.

- Cultivator Cutters

- Grass cutters.

- Important Vantages.

- Plows.

- Cultivators (orniks).

- Harrows.

- Snigopribilna technica.

- Motorblock adapters.

- Earth auger.

- Filament feeder.

- Crop cutter for power tillers.

- Sniping mechanism.

- Water pump.

Let’s look at each piece of power tiller in detail.

Bowls for power tillers “Ugra”

There are three types of scythes attached to the Ugra power tillers:

Rotary mower Zorya Rotary mower Zorya-1

Rotary and segmental mowing units are the most popular.

Rotary mower “Zorya” for power tiller “Ugra” is designed for:

This equipment can be used on the hills, the steepness of which is up to 20 degrees, and the swell up to 8 degrees.

The scythe “Zorya-1” is a more thorough variant of the popular “Zorya”. It can be successfully joined together with power tillers “KaDVI” (“Ugra”, “Oka”), as well as with other important machines from other manufacturers. Special design and direction of movement of the cutting blades lay the mowed grass in a continuous row.

Characteristics of the rotary mower type “Zorya”:

| Dimensions, mm | 810 930 780 |

| Weight, kg, not more | 33 |

| Grass width, m, min | 0,8 |

| Mower operating speed, km/year | 2,0. 4,0 |

| Height of grass mowed, m | to 1 |

| Efficiency of grass cutting, ha/year, ash | 0,15. 0,2 |

| Rotation frequency of the cutting disc, hr | 1800. 2400 |

| Height of vegetation, cm, not more | 7 |

Characteristics of rotary mowers of rotary type “Zorya-1”:

| Overall dimensions, mm | 492842432497 |

| Weight, kg, not more | 35 |

| Fitting width, m, not less | 0,8 |

| Mower operating speed, km/hour | 2,87 |

| Height of grass mowed, m | up to 1 |

| Grass mowing capacity, ha/year, as follows | 0,2 |

| Rotation frequency of the cutting disk, hr | 2370. 2635 |

| Adjustable cutting height, stem height, cm | 3. 10 |

Attachment for power tiller

Full drive hitch to the “Ugra” motor-block is designed for transportation of piece and large loads on short and medium distances. Canopy capacity is 350 kg. “CaDvy produces unversal drive PMG300-1, which can be combined with machines “Ugra” and “Oka”.

Dimensions and characteristics of the trailer for the motor-block “Ugra” PMG300-1 are shown in the table:

| Producer | CADWI |

| Manufacturer’s country | Russia |

| Lifting capacity | 350.0(kg) |

| Operating speed | 5.0(km/year) |

| Maximum allowed weight | 450 kg |

| Lifetime | 60 mths |

| Cube of the body | 30 degrees |

| Tightness of air in tires | 0.2 MPa |

| Own weight of the trailer | 100 kg |

| Wheel size | 4,00-10 |

| Wheelbase | – mm |

| Number of places | 1 |

| 0(km/year) 0(km/year) over the headland by the disc coulters | є |

| Galma | Tine arms with motorized scissor drive |

| Flip side | Rear |

| Body dimensions | 1200x920x290 mm |

Motorized spudder

Cartwheel. Equipment for mechanical planting of the potatoes. The potato bulbs are piled into the hopper with a capacity of 33 liters. Potato bulbs are placed with special spoon (regulated) and placed one by one into the trench pre-drilled by the grower.

The earthen ridge is immediately formed on top of the potatoes by the disc coulters. For the convenience of the owner of the equipment, it is possible to regulate the knees and the frequency of laying the bulbs.

We suggest you watch the video, how potatoes are planted with a power tiller “Ugra”:

Felling tiller for “Ugra” power tiller

The manufacturer produces several types of “Ugra” tillers:

- The nozzle. kartoplekopalka. Attached to the motorized device with bolts and a special retractor.

- Potato harvester for power tiller “Ugra” of delicate type (they are also called vibratory). Productivity of this equipment is 97%. The soil is enmeshed with roots by the nozzle and is delivered to the winnowing machine (working depth 20 cm, working width 38 cm). Loads of earth are scraped through the grate, bulbs are fed into a special container, or deposited on top of the ground.

Kartoplekopalka for power tiller “Ugra” Gurkotlivogo type Vykopuvach motor-block VM-1

Other manufacturers offer propshafts similar in design to the rotary ones, with the addition of the eccentric mechanism.

Such functional nozzle can be bought at the appropriate store or you can make it on your own. About how to make a potato digger on a single axle tractor “Ugra” our video:

We suggest to see how the harvesting of crops of potatoes is done with the help of screen potato plow:

The design and principle of operation of the element

This mechanism, which at first glance has a complex design, in practice consists of only a few elements, namely:

- Release bearing.

- Basket, where the discs are installed.

- The disc itself, which, when pressurized, separates into several individual components.

You can also note the presence of couplings and traditional bolt locks, due to which the structure is mounted on the working plane. The clutch assembly is mounted above the transmission. This device allows the main engine pinion to align smoothly with the gearbox pinion.

If the coupling is missing or damaged, shifting becomes difficult and a metallic rattle can be heard at the moment of engagement, because it is difficult for the gears not to align at the same rotational speed during operation. In this case, a smooth shifting is provided by a handle, from which a cable goes to the mechanism. This handle is released when shifting.

In this video you will learn how to repair the clutch:

Important! Despite the simplicity of the mechanism, we can not say that the element is easy to replace or repair, to restore or change the constructive component, you need to have some skills and experience.

Variety of power tiller clutch mechanisms

Modern power tillers are distinguished by design features. There are different types of clutches that can be fitted to machinery:

- friction clutch. This type is the most popular among farmers. Such mechanisms are easy to maintain, they can work for a long time without interruption, have high efficiency;

- centrifugal clutch. Prolonged towing and rapid wear of the parts has caused the centrifugal coupling to fall into disrepute;

- Belt clutch on the power tiller. Such a mechanism is not very reliable, has a low performance, quickly worn out when working with powerful engines;

- hydraulic clutch. Pressing the pedal starts the main piston to move. As it rotates, the lubricating oil is set in motion. Pressure from the piston is transferred to the connecting rod, springs perform automatic restoration of the piston to the starting position;

பவர் டில்லர் கிளட்ச் பிலேட் மாற்றுவது எப்படி? | power tiller clutch GN 121 | sifang clutch

- disc clutch on power tillers. All elements of the mechanism are very reliable and allow the machine to start smoothly. There are single-disc and multi-disc equipment with practically uniform principle of operation.

There are dry, air clutch types and those that work in a bath filled with engine oil.

How to make a clutch mechanism with your own hands?

The clutch on a single-axle tractor works on the principle that provides increased friction of components, so rapid wear can not be avoided. In that case you should try to make the mechanism with your own hands. The construction of the homemade clutch will be made up of:

- transmission primary shaft and flywheel of Moskvich car;

- the hub and knuckle from the Tavria;

- B-profile;

- Two-rod idler pulley;

- Crankshaft from GAZ-69.

The following work on the assembly of the mechanism is as follows:

- First, you will need to grind the crankshaft so that it does not cling to other elements of the motoblock;

- On the shaft put on the regular hub motor-block;

- Next, on the shaft you need to mill the place for the bearing. This operation should be performed as accurately as possible to ensure that the bearing is ideally seated on the shaft. As a result, the hub should fit without any clearance, and the pulley should scroll;

- Then turn the crankshaft over and do the same on the back side of it;

- Next, use a drill with a 5-millimeter drill bit to make 6 holes in the pulley. The distance between them should be the same. Since 10mm bolts will be used, holes must also be drilled on the back of the wheel that drives the drive belt;

- Then mount the pulley on the flywheel, and bolt the two parts together. Then mark the drilling points on the flywheel so that they coincide with the 6 holes in the pulley;

- Remove the pulley and drill holes in the flywheel;

- Then put the pulley back on and fasten the assembly securely with bolts;

- Flatten the inside surface of the crankshaft and flywheel so they don’t bump into each other.

The finished design can be installed on the standard seat in the power tiller. Don’t forget to connect the cables, bringing them as far away from the friction elements as possible.