How to cut a tree with a corner grinder correctly

Corner grinder is a universal tool that is designed for grinding, polishing and sawing concrete, brick, stone, metal. Initially, the tool is not intended for wood processing. But after installing special nozzles and consumables, it is quite possible to use a corner grinder for wood. The main thing is to choose the equipment correctly.

In the professional sphere, corner grinder is rarely used to work with wooden blanks. Typically, masters have a whole arsenal of other tools. But in everyday life, if necessary, woodworking work, buying a set of equipment is impractical. Firstly, various jigsaws and saws can be needed only at once. Secondly, the equipment will cost an expensive. Therefore, it is much easier to purchase special nozzles for a corner grinder. After installing them, you can cut, cut, and grind a tree with any structure. If earlier with the help of standard equipment it was possible to make only a black cut of the workpieces, today there are nozzles and consumables of the commodity brand of combo, which allow you to perform quality processing. With their help, you can perform wood threads and sample, carry out peeling, cleaning and cutting work.

Basic safety regulations

Before cutting a tree, it is necessary to familiarize yourself with the safety regulations before the corner grinder. The main of these rules is as follows:

- Be sure to use personal protective equipment (protective plastic glasses, fabric gloves), work in overalls.

- It is strictly forbidden to use disks having defects.

- It is recommended to hold the corner grinder hard with 2 hands.

- Constantly ensure that the electric cord is not near the rotating disk.

- Put an angular grinder only after a complete stop of the cutting element.

- Do not clean the protective casing.

- Do not work intoxicated.

You can not use equipment that is not intended for work with angular grinder. Cutting equipment for a disc circuit saw should not be used for the following objective reasons:

- The corner grinder has a higher rotation speed than the circular saw. The disk is designed for lower speeds, so at high speed it, cracked, can fly up. Flying fragments can harm health.

- The tree has a more viscous texture and inclusion in the form of knots, because of this, the teeth enter the material unevenly. If the disk is jammed, the tool can be pulled out of the hands, which is fraught with dangerous injuries.

- Due to the uneven loads, the equipment is overheated and failure is possible.

Sawing firewood with corner grinder

Drinking wood with corner grinders can be relatively safe. It provides for a rigid fastening of cutting equipment on a bed with guide elements. This will be stationary equipment for cutting, in which the corner grinder is securely recorded. Do.it.yourself machine works on the principle of circular saws, where the processed material is supplied along the guides.

Firewood can be sawed with corner grinding, but you need to use the devices necessary to ensure safety. suitable for working with wood are a jigsaw, circular saw, manual tool.

How to cut it correctly

First you need to take the tool in your hands correctly. Helpers hold a corner grinder with the right hand for the body. With all this, the circle is placed on the left, and the gearbox on the right side of the machine. With the left hand it is necessary to hold the tool for the handle entered into the body. The right position of the handle. upward. The protective casing should close the disk and hands, casting sparks from the employee. For the left, the hilt is screwed on the other side of the case, the protective casing is turning and fixed in a suitable position.

How and in which direction everyone decides to cut himself, taking into account the fact that when biting out the corner grinder throws in different directions

How to remove tree roots in your lawn

Grinding with professional masters

Choosing professional services of qualified specialists. You get rid of many problems. In our work, we use modern equipment, high.quality grinding nozzles, which we select in accordance with specific working conditions. Grinding is performed with the optimal mode of wood humidity with accurate observance of technology. Our masters have vast grinding experience and know all the subtleties of this work. To leave your application, contact us on the coordinates on the “Contacts” page.

Calculate the cost of painting and insulation of your home right now

Than and how to grind

If you need wood processing, you need to choose the optimal tool. At the same time, it is worth considering the following features:

- A variety of products. It can be supporting structures from a beam, windows and doors, furniture details, decorative elements. Each of the products has the best option that allows you to achieve maximum quality with a minimum of time and effort.

- The quality of grinding. This is a fairly important factor. In some cases, it is enough to smooth out large roughnesses, in others. bring the surface to perfection. Therefore, before starting work, it is important to prepare brushes and discs that have different granularity.

- Scope of work. You can handle small structures manually, for large ones. an electric tool is required.

The following devices are used to grind the tree:

What is the difficulty of working with a corner grinding with wood

The first thing experts pay attention to is the corner grinding speed of the disk rotation is much higher than that of the circular saw. Therefore, if you cut not only metal and concrete, but also to work with wood, buy a corner grinder with a drive speed regulator and a smooth launch.

To cut a log, cut a tree with a corner grinding or bring down the barrel, you need to work at medium speeds. at a high speed of rotation of the nozzle, any obstacle to the cutting edge (wire, nails, resin, disclaim of the disk, the irregular angle of the disk, multidirectional wood fibers can provoke) can provoke A powerful leap of the tool, and an angular grinder can simply not be held in your hands. In addition, you can cut a tree on the site with a corner grinder only holding it horizontally, and this is a high risk of injuries.

Before starting work, determine which side it will be more convenient for you to screw the handle-holder of the corner grinder, and which angle should turn the protective casing in order to protect your eyes and face from sawdust as much as possible.

Pre.lay the supply cable along a safe route, and not on the path of a falling tree.

Important! Under no circumstances, do not saw the trunk of a tree or a log of a corner grinder without adjusting the speed of rotation of the disk. Also, do not use metal disks for this purpose, grinding or polishing nozzles. Wood disk is best used with large teeth.

How to choose the right disks for a corner grinder to avoid problems

When choosing a model for corner grinding, it is necessary to determine the nature of the use of the tool. The size of the cut depends on the diameter of the circle, therefore, it determines the type of material processed.

The nozzle of the minimum size (115 mm) is suitable for the simplest work. Due to low depths, it will not go for cutting, and the grinding is very convenient to carry out. The only thing that can be sawed around a small diameter is thin pipe from plastic.

Nozzles with a diameter of 125 mm are considered the best discs for the corner grinder of domestic purposes, the main plus is the variety of the assortment. With their help, you can grind and cut materials whose thickness does not exceed 35-40 mm (tile).

Circles with an outer diameter of 150 mm are designed for the processing of brick, concrete, wood, metal profiles. At the same time, the assortment of such discs is limited.

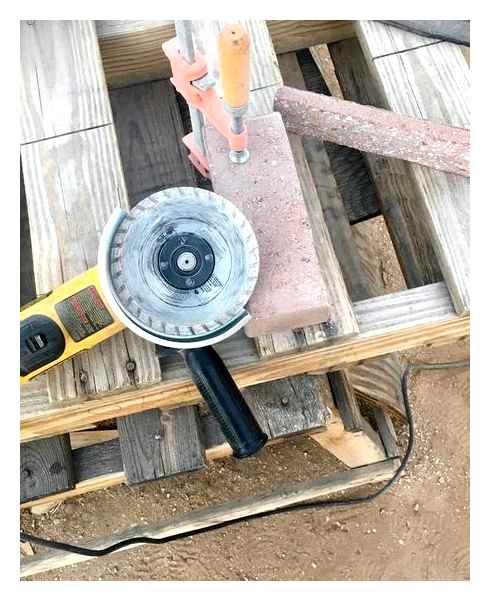

How I Make Straight Accurate Cuts With The Angle Grinder

The optimal option for construction work is the nozzles with a diameter of 180-230 mm. They are installed in professional angular grind. Due to the good cut depth, it is easier for them to process thick pipes, stone, reinforcement, concrete.

You can find out all the useful information about the model by labeling. The following information is displayed in it:

- manufacturer;

- The name of the product (in English the circle circle-Cut.off Wheel);

- purpose. for processing metal, stone and concrete, steel, non.ferrous metals, aluminum or alloys, cast iron;

- dimensions. external diameter, thickness, planting diameter in mm and inch;

- maximum working and permissible rotation speed;

- the technical parameters of the circle (base material, the size of the abrasive grain, hardness, type of ligament);

- safety recommendations (signs indicating unacceptable use);

- the shelf life of the goods;

- regulatory documents confirming the compliance of the product with adopted and international standards.

Cutting wood corner grind

In the absence of special equipment for working with wood, it is allowed to cut wood with an angle grinder. But the thickness of the material cut by the corner grinder should not be more than 4 cm. It is necessary to use special cutting wheels and wood cutters recommended for working with a corner grinder.

Keep the cutting tool perpendicular to the surface to be treated. If it is possible to adjust the speed of the corner grinding, then you should set the minimum value. You cannot exceed the recommended maximum values (the corresponding marking is applied to the disk). When cutting at high speeds, the wood begins to burn, a large amount of smoke is released.

It is not recommended to use a button lock during operation to be able to turn off the device and minimize possible damage. In order for the tool not to jerk at the end of the drink, experts advise first to tie the workpiece at the edges, and only then cut it.

Cutting wood corner grind

In the absence of special equipment for working with wood, it is allowed to cut wood with an angle grinder. But the thickness of the material cut by the corner grinder should not be more than 4 cm. It is necessary to use special cutting wheels and wood cutters recommended for working with a corner grinder.

Keep the cutting tool perpendicular to the surface to be treated. If it is possible to adjust the speed of the corner grinding, then you should set the minimum value. You cannot exceed the recommended maximum values (the corresponding marking is applied to the disk). When cutting at high speeds, the wood begins to burn, a large amount of smoke is released.

It is not recommended to use a button lock during operation to be able to turn off the device and minimize possible damage. In order for the tool not to jerk at the end of the drink, experts advise first to tie the workpiece at the edges, and only then cut it.

Sawing firewood with corner grinder

Drinking wood with corner grinders can be relatively safe. It provides for a rigid fastening of cutting equipment on a bed with guide elements. This will be stationary equipment for cutting, in which the corner grinder is securely recorded. Do.it.yourself machine works on the principle of circular saws, where the processed material is supplied along the guides.

Firewood can be sawed with corner grinding, but you need to use the devices necessary to ensure safety. suitable for working with wood are a jigsaw, circular saw, manual tool.

The principle of operation of the corner grinder

To understand whether you can cut a tree with a corner grinder or not, we’ll figure out how this tool works. An angular grinding machine is a power tool that is used for processing, grinding and cutting stone, granite, various types of metal, cement surfaces and others. Consists of several parts:

- The case (often has a cylindrical shape).

- Protective casing to ensure the safety of the master during operation.

- Engine.

- Reducer case.

- Surprising coupling.

- Clair clip nuts.

- Back and off buttons to replace the disk.

Different models of grinding cars may have differences depending on the manufacturer and model, which in most cases are small. Due to the variety of nozzles, the tool is considered universal.

Why experts do not recommend using a corner grinder for cutting wood?

Specialists are united in the opinion that for processing wood, special power tools should be used, designed specifically for working with this type of material. If you use an angular grinding machine for cutting bars, then the master may encounter the following problems in the process:

- During processing the tree, the working disc will overheat a lot, which directly affects its strength. If you mow the angle a little, then the probability of a disk rupture increases significantly. Neglect of this paragraph can lead to serious injuries.

- The teeth of the disk during the processing of wood material often capture more raw materials, from which the tool can simply break out of the hands in working condition. The result may be deplorable for the master.

As you can see, the main problem in the operation of a corner grinder on wood is the inability to ensure proper safety for yourself and others. Even experienced experts can not always guarantee one percent good result of work, instrument safety, protection against possible injuries.

How to cut a tree with a corner grinder

Прежде чем начать… Не забываем подписаться на мой YouTube канал, а так же иногда посещать мой блог. Спасибо!

К слову, в конце публикации будет интересное видео с лайфхаками для угловой шлифмашинки. Ну это так, лирическое отступление =)

But still, at first I would like to warn what can categorically cut a tree. This is a saw a wooden disk for an angular grinder, like that on a circular saw. We look at

When we cut the tree with a manual disk saw, we pour the tool into the workpiece and push it forward along the planned line. How do we fix the manual circular? We put it on the workpiece, rest it, and so that it would be controlled by the shoulder.

Typically, manual circular circus is not very powerful, and even if the disk jams in a tree, a solid male shoulder is enough to keep the tool. The instrument disk itself does not lead to the right or to the left, since the support does not allow the disk to mate.

And even if there is a hard part of the wood, it is unlikely that the disk will click.

But the corner grinder, unlike the circular, has no support, and this completely changes the mechanism of work.

- As you can see in the photo, we do not fix the tool with the shoulder, as soon as the disk closes with the material, it will simply be physically almost impossible to hold.

- From the foregoing, it becomes clear that the main danger in the case of such a saw disk is the pushing of the disk with material (wood).

- As an option, you can use a chain disk for an angular grinder,A sort of mini chainsaw.

If we use a similar disk, then in principle we are no longer scared, if it clings it, since in this case the chain will simply scroll and the tool will not tear it out of your hands.

But with this disk there is another danger. a chain break. If it occurs by chance, then the chain will fly not much weaker than a bullet released from combat weapons. After all, we do not forget that the 115th corner grinder is spinning at fantastic speeds at 11.000-13.000 revolutions per minute.

The safest option is Three.toothed disk for wood.

This disc without any problems even cuts nails. Safety when working with a saw disk is achieved due to the radius shape of the teeth, and this is probably the only relatively safe saw disk for wood that can be installed on the corner grinder.

Why relatively safe? Because, after all, the corner grinder is not designed to cut the tree, and you need to do this in the most extreme case, and it will perfectly use the circular saw instead, which is created to cut off the tree.

Буду благодарен, если посетите мой сайт LoftStyle.site, я очень буду рад гостям и критике.

Если вам была интересна и полезна статья, то обязательно, просто обязательно ставим лайк и подписываемся. Так же не забываем про YouTube канал, там тоже все интересно.

All sentences, wishes and criticism send to Badart@yandex.ru or in a commentary under the publication or through feedback on the site!

P. S. работа с любым электроинструментом требует доскональное знание Техники Безопасности. Перед началом работы ознакомьтесь с инструкцией и рекомендациями производителя на вашу конкретную модель. В данной статье я не даю ни каких рекомендаций, а просто делюсь субъективным опытом. Все, с меня взятки гладки =)

Recommendations for work

There are a number of small technical and operational subtleties that are important to consider in the process of processing the tree:

- Many, in attempts to make work more comfortable, get rid of the protective casing. But this is categorically impossible to do, since the casing is the only barrier in front of the operator and disk, the destruction of which can lead to injuries.

- A special device will help to increase the reliability of the physical maintenance of the tool. the supporting base. She will make a machine from a manual apparatus.

- To ensure a more tenacious grip, it is recommended to saw a corner grinding of a corner grinder in building gloves with rubberized pads.

- If the model of the angeling machine used is provided with the lock function, it should not be used. Complex situations may require instant disconnection of the device to minimize the damage, and the lock on will not allow this to do this.

Grinding: nozzles and process

Grinding plates are disks that produce by layering of several different integuments. To improve the characteristics of the abrasion of the processed surface, the initial layer is made rubber, sometimes replaced by rigid plastic. The second level of the nozzle, allows for the fit of the plane of the working part to the grinding surface, it is made of foam rubber. The main, the working layer is a sheet of sandpaper.

The use of grinding plates allows you to work qualitatively with already painted surfaces. It is possible to polish the unprocessed surface in a rough way.

Label.type discs are suitable for the same purposes, only in black is turned out to be faster. A disk of this type is sandwiches attached to the work surface of the disk.

To remove paint, it is best to take special devices with the functions of the peel. A steel cup, with attached steel fibers made of hard wire is perfectly abrasion, additionally grinding a tree.