How to cut tiles without a tile cutter: a selection of simple ways

Professional tools for performing high-quality finishes are always very expensive, but what to do if you need to put the tile, and buy because of a pair of sq. m equipment there is no money or desire?

Then the question arises of how to cut ceramic or porcelain tiles without using a tile cutter due to its absence? You should immediately warn you, you can complete this task, but in order to cut it even and with minimal chips, clearly observe the technology.

Cut the tiles without tile cutter methods and nuances

Ceramic or porcelain tiles are very solid facing materials similar in many properties to glass. Therefore, the methods of cutting it will be similar. The same glass cutter, but it is worth immediately warning that not all material can be equally cut off even in this way.

For example, a tile with a relief structure will be a difficult task and sometimes even overwhelming and for glass cutter.

The main task of the Reza is that its cut.out side remains even and there are no chips. Often the trimmed edge is located under the baseboard or closed with vertical tiles, in which case you can not be worried at all, but to take a corner grinder with a diamond cutting circle boldly. But with this tool you should be neat, since you can cut off with a lot of chips.

Consider the most effective methods on how to cut tiles without tile cutter and with minimal marriage. Regardless of what you use to perform cut, drill a tile, you should always be extremely neat and not make sudden movements. You can accidentally move the workpiece and break the thin element. It is especially dangerous when it is M-shared and one side is thicker than the other.

It is also important to provide the necessary conditions for such work. They consist in reliable fixation of the material so that he does not vibrate and does not twitch during its processing.

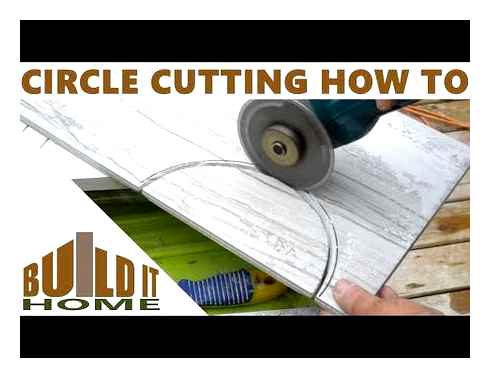

Cutting tiles with corner grinders

Most often, the question is, how to cut tiles for the floor without tile cutter, solve with the help of such a universal tool convenient in the work as a corner grinder, which allows you to perform a diverse in the dimensions and configurations of the line. smooth curved, complex curly, clearly defined straight.

For surgery to cut tiles, you must prepare:

- corner grinding machine, which is more often called corner grinder;

- a cutting circle oriented for work on strong stone products (you can take a diamond variety);

- a vice, a portable clamp or other simple type of clamp for reliable fixation of the cut tile;

- compact vacuum cleaner to eliminate dust;

- protective glasses;

- mittens;

- special dense clothes with long sleeves;

- It is recommended to use a respirator or a cotton pad.

Having determined the necessary dimensions, conducts accurate marking of the tiles. A cutting line for a cutting trimmer must be applied to the front plane, using a sharp tool for scratching. You can use a construction marker. But it must be borne in mind that in the process of work when removing a large amount of dust, an ink line for a trimmer is quickly erased.

If small cuts are made close to the edges of the tiles, then the material is laid on a flat countertop. You can work on the floor. Down to maintain the integrity of the coating.

First cut the tile surface, deepening for several millimeters. Usually during this operation, it is enough to hold the tiles yourself or you can call for the help of the assistant. If curly sections are performed, then before cutting the tile without tile cutter, the material is securely attached to the countertop using a clamp. If possible, then fix it in a vice. For safety, cardboard or linen pieces are placed under the lips.

- Pass through the marking several times, deepening throughout each pass by about 3 mm. Such actions are performed until the necessary fragment of the tile is completely cut off.

- If small segments are cut, about 20 mm long, then the material is cut out immediately completely to its entire thickness.

- When performing complex marginal incisions or curved lines, it is advisable to make markings on both sides. Perform the incision on the front side at first by 2.5-3 mm. Then they turn the material and pass from the inside to the identical depth. Repeat several times. With this method, the front side is practically not damaged.

Application of an electrician

In a situation, if you need to quickly make a decision on how to cut tiles without a tile cutter and corner grinding, use an electric jigsaw equipped with a file with a file.

A similar tool easily performs evenly in a straight line. And also makes high.quality configurations with a sufficiently large diameter. Rounded fragments of a small radius are more difficult.

It is easier to work with a jigsaw (by the way, with a small amount of work, you can use a manual version of the tool) when sawing a relatively thin wall tile.

Difficulties can occur when cutting a denser floor ceramic material.

Cutting tiles with glass cutter

You can divide the tile with glass cutter. over, this tool can be cut precisely tiles. For the cut, you only need to apply to the outer part, which is covered with glaze, a notch with a depth of a couple of millimeters. Glass cutter is carried out on the surface using a metal ruler.

The separation process itself is carried out by a sharp, not strong blow to a wooden angle from a distance of about 20 cm. The tile is taken in two hands along the marking line and abruptly beats against the protruding angle.

Instead of glass cutter, you can use a winning drill.

This method can only be obtained by an even cut, and attempts to make a figure separation or hole in the tile, most likely, turn into a split in building material.

Separation of tiles with pliers

If the task is not worth obtaining a neat fishing line for a trimmer of separation, it is quite possible to use pliers or nippers. This method is very simple: you need to start cutting off pieces of material from the edge until the desired tile size is obtained. The method is not accurate. It often turns out that a large piece of the desired part is broken off with the tool. However, for lack of a different way, you can do with this option.

All described tiles described are quite effective for one.time use. And yet, when for professional use in frequent repairs of premises it is better to purchase traditional tile cutter.

Drill with nozzles

Strictly speaking, the drill is not suitable to cut off the strip. Drill and various nozzles will cope with drilling holes of various diameters in the tile.

The holes of small diameter for dowels are made for fasteners of shelves, cabinets, decor elements. Large holes are needed to bypass pipes, counters, other things.

To work with ceramics, it is better to use not a regular drill, but a spear.shaped drill on the tile, in the common people called a “feather”. It is easy to pass a layer of glaze and the upper layer of ceramics and bites into it so that the tiles without chips on the surface.

When you went through ceramics, replace the “feather” with a concrete drill and continue to work.

Crowns with diamond spraying are excellent nozzles for drilling holes for sockets, switches, counters.

Kusachki

The folk method of working with ceramics is nippers. Picks can make a figured cut, remove a small fragment of ceramics and correct the existing cutting. The advantage of this option is that the quality and accuracy of work depends on you. Manually you need to work slowly.

Mark the contours of cutting. Capture small fragments of ceramics and bite them off with nippers. Advanced to the intended contours. No need to try to bite too much, so you can only spoil the tile.

Tile cutting tools

High.quality and productive cutting of this flooring is carried out with an electric tile, which is equipped with a diamond cutting circle with water supply. The use of this technology allows you to reduce physical efforts and the amount of dust.

But in most cases at home, they resort to the use of another tool. This is due to the fact that acquiring a tile for laying a tile is not always an appropriate activity.

To cut tiles, you can use the following tools:

In addition to the main tool, for cutting tiles are used:

- drill;

- roulette;

- marker;

- ruler-angle;

- table (C perfectly even surface and without grains of sand or other garbage);

- file;

- sandpaper;

- Kerner;

- Diamond disk.

Now directly about how to cut the tile with each tool.

Drill with nozzles

Strictly speaking, the drill is not suitable to cut off the strip. Drill and various nozzles will cope with drilling holes of various diameters in the tile.

The holes of small diameter for dowels are made for fasteners of shelves, cabinets, decor elements. Large holes are needed to bypass pipes, counters, other things.

To work with ceramics, it is better to use not a regular drill, but a spear.shaped drill on the tile, in the common people called a “feather”. It is easy to pass a layer of glaze and the upper layer of ceramics and bites into it so that the tiles without chips on the surface.

When you went through ceramics, replace the “feather” with a concrete drill and continue to work.

Crowns with diamond spraying are excellent nozzles for drilling holes for sockets, switches, counters.

We cut tiles without plates

Glass cutter using a home.made device. It is painted tile up to 60 cm. Not

Work on the front side. The direction of the tool should be on its own. First, mark the fishing line for the trimmer of the cut and tightly tighten the stove so that it does not move during operation, and there is nothing that could prevent cutting the cutting element. Keep the lamp right for a straight cut. If sawing is at an angle of 45 degrees, fix the tool in the right position.

There will be a special cap from the injury, which in the case of a disk will amaze you. However, it is necessary to pay special attention to personal protective equipment. Respirator or mask will cover you from dust and construction glasses from small fragments.

Alternative tools and their features

Let’s look at the most popular ways to cut ceramic or porcelain tiles of acceptable quality. This includes:

- Corner grinding machine with a large disc. There are several types of these tools that can be used to cut ceramics. To do this, buy a corresponding disk with diamond spraying. There are several varieties on sale, depending on the size of the grain and the cleanliness of the cut.

- Electric jigsaw. This is a convenient and very practical tool with which you can perform clean sawdust, but for this buy special files for tiles. Its advantages are universality, t. e. You can perform curved cuts with a large radius.

- Locompler of a manual type. Suitable for smooth cut of tiles with glazed coating.

- Inhaling the holes with a drill. This is a convenient method, but to obtain a high.quality end after cutting, you need to go through the place with additional grinding tools, for example, a file and sandpaper.

For the manufacture of round holes in ceramics, circular saw, crown and drill-ballerina are used. Radius bends with small turns are selected manually using ticks or pliers.

Ways to cut tiles without tile cutter

For all its firmness, ceramic or tile is fragility. irregularities may appear when cutting along the edges, and tiles are often broken. How to independently, quickly and efficiently cut the material so that the tile does not lose its attractiveness?

Cut ceramic tiles without the use of tile cutter in various ways. It is recommended to start preparing for work with soaking material in water for 40 minutes. The next important point that should not be neglected is marking. Before cutting, it is necessary to apply a trial cut on a fragment of tiles. This will help control the pressure of pressure and not damage the material.

Corner grinder and jigsaw

Using an angular grinding machine (corner grinding). corner grinding of a ceramic tile, you can apply a straight view of the cut. During work, it is recommended to use protective equipment: glasses protect the eyes from dust, respirator. respiratory organs, headphones. hearing organs, gloves. hands. It is also necessary to monitor the condition of the equipment. change the discs when they grind them in order to prevent the operator’s injury and the tool breakdown.

First, it is recommended to mark the material using a pointed tool (nail or drill), scratching the tile. The material is laid on the working surface. table or floor. In order not to damage it, you need to put fragments of plywood, cardboard, dense fabric under the tile, fix the material with a clamp.

Segments whose length does not exceed 2 cm are considered small. In this case, the cut is carried out immediately in the entire thickness of the material. When performing a direct cut, it is recommended that the depression on the outer edge of the tile does not exceed 3 mm in one approach. This reduces the likelihood of damage to the material.

To perform curved cuts with large radius of curvature, a jigsaw with a file for ceramics, natural or artificial stone is used. For the convenience of working with a jigsaw, it is necessary to use the “accurate cut” mode.

We focus on: glass cutter and other tools

For cutting thin (thickness of 3 mm) ceramic tiles without the use of tile cutter, tools are also used that have a pointed cutting edge. glass cutters, cords, knives and other devices.

To apply marking with these tools, a ruler is used, a scratch is applied to the upper layer of tiles. The cut is recommended to be performed without interrupting. It is necessary to control the force of pressing the tool so as not to damage it and the material. After the cut is performed, you should break the tile on the edge of the table.

Kusachki

Kusachki is used to perform curly cutting of ceramic tiles. At the beginning of work, it is recommended to mark the outside of the material using a marker. Then, from the edge of the tile, you need to start bite off small fragments of the material, squeezing the nippers. If necessary, with the help of a file and sandpaper, you need to make the edges of the tile more smooth.

Forceps with a cutter

First you need to mark the outside of the material using a marker and ruler. The side of the forceps on which the cutting part of the tool is located is carried out on the front side of the material, while it is recommended to control the force of pressing the material so as not to damage the tile. They start from the far edge along the marking line, directing to themselves. If necessary, the operation repeats. Then turn the tool so that it captures the material along the cut line. The final stage. compression of the forceps, the edges of the material, if necessary, can be leveled with the help of a file and sandpaper.

Coramic tiles

The final stage of work on the cutting of ceramic tiles is the splitting of the material. There are several types of cracking of the tile at the place of the fault: O Table’s edge, along the solid rod, between the clamp.

How To Cut A Floor Tile Circle For Toilet Flange

When cracking ceramic tiles using a solid rod, you can crack the material into large and smaller fragments. At the same time, a rod is used, the diameter of which is 8. 15 mm (core, nails, pencils and other devices), length. 2/3 from the length of the fault. Ceramic tiles are laid on the rod, aligned at the place of fault. The final stage. pressure on the material.

When using the method of cracking the material between the clamps, ceramic tiles are fixed between two fragments of plywood, bars and other improvised materials. The tile is installed on a fishing line for a fault trimmer, clamped. The final stage. pressure on the free edge.

Thus, you can cut the tile without using tile cutter in various ways. For convenience in preparation for work, it is recommended to soak the tile in the water for 40 minutes. When carrying out work, it is also recommended to mark the material and control the pressure of pressure so as not to damage it.

The use of corner grinder for tiles

For cutting karemberitic tiles, an angular grinder is often used. This method is considered alternative, but it has its advantages. First of all, it should be noted that the corner grinder allows you to cut much faster, which affects labor productivity. The principle is similar to the action of an electric tile cutter, but in this case, a cutting disk is cut. The negative point is that at the edges of the tiles after cutting, small chips are formed. The number and size of chips largely depend on the accuracy and skill of the tile. Therefore, before cutting the tile of a corner grinder, it is better to slightly increase your own skills in this tool on unnecessary trimming of the material.

The tile needs to be fixed on a flat surface. A flat fishing line for a trimmer is drawn on its front side. The corner grinder should be taken in the hand so that the cutting occurs in the direction of. Be sure to put on the goggles and a mask in order to protect the eyes and breathing organs from ceramic dust. This cutting method is quite dangerous and noisy. A lot of dust is formed during work. Without experience, there will be a lot of inaccuracies and errors. This should be remembered, all important points are discussed in the video to the lesson.

What to cut. what affects the choice

Before we consider the methods of cutting ceramic tiles at home, we will decide on what affects the choice of a method or another.

- The nature of the cut. You need an even slice or rounded.

- The thickness of the tile.

- Quantity. Which is good for several tiles, it may not be profitable for a large volume.

The quality of the material also has an impact. For example, some tiles have a glazed surface. Given that such a surface is soft and easily crumble, it is recommended to use manual tiles or glass cutter for cutting.

These cutting tools will not cope with harder surfaces, for example, ceramics. If you have porcelain tiles, then electric tools will be required.

Cutting porcelain tiles at home with a manual tool is impossible. And the stronger the basic material, the more thorough the tool should be selected. For example, you can use an electric tile cutter, an angular grinder and the like.

Important! If the tile has a relief structure, then you must be especially careful with its edges. Even with a slight deviation, there is always a risk of chipping and violations of the pattern.

Tile cutting methods

Cramping of ceramic tiles can be performed using the following tools:

Consider the technology of how to cut the tiles with these tools.

Manual tile cutter

Mechanical tiles is ideal for large volume. Work on this machine does not represent serious difficulties. The resulting cut is perfectly flat.

- Marker put the cuts for the cut.

- Put the tiles on the tabletop of manual tile cutter.

- With the help of the holder, press the tile tightly so that when cutting it does not move to the side.

- Put a carriage with a cutter exactly according to the marks.

- The incision on the marks is performed at a time.

- After the tile along the cut, it is necessary to break a special holder.

In this way, you can cut ceramic tiles only in a straight line. This is the main drawback of this technology. If a figured cut is needed, then another technology will be required.

Glass cutter

Cutting tiles with glass cutter is a simple action. Glass cutter is in the presence in almost every house. Therefore, if you need to cut one or more tiles, then this tool is an excellent solution.

The principle of how to cut the tile with glass cutter is no different from the technology of cutting glass. The algorithm of actions is this:

- Pre.soak the material in water.

- Put the marks with a pencil at the site of the future cut.

- Put the tiles on a perfectly flat and smooth surface.

- Apply a ruler to the marks

- Tightly clamping the ruler, strongly carry out glass cutter. It is necessary to make a deep slot at a time.

- After that, the glass cutter must be carefully tapped along the cut line.

- Put the cut place on the edge of the countertop and press.

- As a result of these manipulations, the tile should be broken out strictly along the cut line.

How to cut tiles with a hand glass cutter. video

What if the edge is broken off not clearly along the cut line? You can use nippers or pliers to tear everything. So that the cutting line for the trimmer of the cut is even and smooth, it should be finalized with sandpaper.

round marble tile cutting

A simple way to cut tiles at home. video

Corner grinder

You can cut the tiles with a corner grinder. This tool is mainly used for solid materials, although not necessary.

Cut the tiles of a corner grinding using the following technology:

- On the corner grinder, install the cutting circle. A cut circle should have diamond spraying or intended for cutting stone. An ordinary metal circle will not work!

- Apply marking to the surface with a pencil.

- On a flat surface, reliably press the product.

- The cutting process begins without sudden movements. The tile should not be pressed much.

- Move corner grinding is necessary from yourself.

- To begin with, a shallow incision is performed along the entire cut line.

- After that, you gradually deepen the furrow.

A break can be done according to the principle, as in the case of use of glass cutter. Also, the cut can be made completely angular grinding. But in the latter case, it is necessary to keep the material so that it does not fall to his feet.

Important! Working with corner grinder requires strictly observing safety precautions. First of all, protective glasses are dressed in the eyes. Open areas of the body are also reliably protected so that the fragments do not stick into the skin.

Electric tile cutter

If you need to cut tiles at 45 degrees, then the best option is to use an electric tile cutter. The cutting process is carried out using water, which excludes the dust.

The disadvantage of this technology is the high noise and the high cost of the machine. This tool allows you to cut material of different thicknesses and density. The process of work is largely the same as described above.

First, marking is applied. After put the tiles on the bed and set the cut place strictly along the cutting circle. Turn on the electric tile. You can start work when water begins to enter the disk.

Do not rush and forcefully put pressure on the machine. The result is a perfectly even cut and, as already mentioned, this machine can be cut off at an angle of 45 degrees.

Kusachki

In the case when a cut of irregular shape is required, the nippers are an indispensable tool. This process is long and painstaking. First, marking is applied to the smooth direction.

Put the nippers in place of the line and break off with small fragments. You should not rush, since you can accidentally break off a large fragment or break the glazed surface of the material. A lot of dirt appears during work. But the plus is that there is absolutely no dust.

The process of refusing must start from the edge and slowly moving to the middle. As a result of such actions, the region will be very uneven. To correct them, you can use sandpaper of a large fraction or a special grinding machine.

When working, you should also be careful not to cut your fingers and hands. Therefore, it is recommended to work in gloves work.

Lobby

To work with ceramics, you can use another electric tool. a jigsaw. With this tool, you can perform a figure cutting. In addition to a jigsaw, a special saw with diamond spraying will be required to work at home.

General information. Varieties of cut

Now let’s move on to the consideration of tile cutting methods.

Tile cutting methods

The methods below are mainly suitable in order to cut the tile at home. But such methods can be used or limited to use them and for other types of tiles. Cut the tiles without such a tool as a tile cutter, you can five ways presented here.

Grinding corner machine (angular grinder)

In general, an electric angular grinder is a universal tool, since before talented masters could cut so much wood with only one ax to build a beautiful, large and warm house, and with the help of one corner grinder you can cut everything that the soul pleases. Using a corner grinding machine, you can even cut the perfect even and round hole with a diameter of 4.5 cm!

note, that this method is suitable for figured, direct species and if there are at least minimal skills in handling tools for curvilinear lines of various configurations.

You will need the following for cutting:

Now you should make markings in advance on the tile, it is advisable to make it possible to scratch the lines with any sharp tool. In the most extreme case, you can apply lines using a conventional construction marker. During operation, a lot of dust will form, and the marked marker lines can simply be erased.

Small sections of direct type along the edge of the tile can be drawn if it is laid on a flat surface, on the floor or on the table. First you should cut the surface for several millimeters, and at the same time there is enough friction strength and its own mass of the tile so that the product remains in place and does not slip. With the rest of the passes that will be deeper, you can also additionally step on the edge or ask the assistant to step and hold. With curly cutting ceramic tiles without tile cutter, it is better to attach the products to the countertop using a clamp or fix it in a vice, but before that you should put pieces of cardboard or dense fabric under the lips.

Useful advice! A piece of plywood should be placed under the product so as not to spoil the surface of the floor or table.

The cut should be carried out using several main methods:

- On the outer edge of the mark should be made several times in the entire length. For one pass, a recess of 0 is permissible.3 cm. The operation should be repeated until the desired result is obtained.

- With a small segment, which is no more than 2 cm long, you can do everything at once for the entire thickness.

- Marking should be applied to both sides. A surface cut with a deepening of up to 0 should be carried out on the front.3 cm, and then you can cut everything in the opposite direction with the same deepening until you get a cut. This method makes it possible to avoid random damage on the front side using a cutting tool.

We recommend using methods for complex cuts. on curved or at the edges. The fact is that in this case there will be a lot of dust, a large consumption of the cutting canvas, labor costs and a lot of time spent. But the usual straight line for the trimmer can be cut much easier.

If you do not have a corner grinder and a cutter for tiles at home, then you may find or ask your neighbor an electric jigsaw. This tool is underestimated by many people, and very vain!

note, that in the same way you can use a manual jigsaw with a nail file, but in this case, the speed of cut will not be so large.

All materials can be sawed in the usual way. It will be problematic to cut too rounded slots, as the file will get stuck. The tool for cutting not a thick wall tile is perfect. Floor porcelain tile an electric jigsaw can almost never overpower. In order to facilitate work, you can soak the material a little in advance. We also advise using this tool if it is necessary to cut out curved segments with large radii of curvature.

Glass cutter/pointed tools

To cut ceramic tiles at home, use glass cutter. By the way, in this way only a tile can be cut, and only in a straight line, but there is another restriction. all parts should not have a width of less than 2 cm.

- Glass cutter. instead you can use any tools that have a cutting pointed edge. It is desirable that cutting tools are made of solid materials, namely the winning, diamond and other things. As an example, the drill will lead ordinary and spear.shaped, household knives and so on.

- Metal rail or metal ruler. In extreme cases, if there is no metal product, use direct oblong items from any other material, but in this case you will need to extremely carefully apply the fishing line for the trimmer of the cut, since it is likely to cut the ruler and the scratch in this case will go to the side, right along the front side of ceramics.

In order for the cut to go even, clear, without any chips and departures to the sides, apply scratches neatly. It will be enough to apply a scratch on a glossy, upper layer.

Useful advice! During application, you should pay attention to the beginning and end of the scratch. Most often at the very beginning and end of the scratch it seems not deep enough, and this is due to small pressure and human psychology. At the very beginning, we only try on and for this reason the pressure is weakened, and at the very end we usually accelerate and therefore there is a great risk of “lubrication”. This can lead to the fact that in such places a break will go to the side.

Because of this, when applying risks with a knife, several passes should be made to get a scratch deeper. The application of the scratch will depend on how sharp and solid tool used. If it is quite solid and sharpened (glass cutters with sharp rollers, a winning sharpened jacket and so on), then even one pass with a good effort is enough. If the tool is made of soft metal or dull (for example, household knives), then you will need to make several passes. Ultimately, the beard must begin to deepen below than the glossy layer.