How to make an angle on a ceiling plinth?

After installing the ceiling, many people prefer to install skirting boards. They give the interior of the premises of completion and hide the joints. But if it is difficult to install the ceiling yourself, then the skirting board can easily be done independently. And for the ceiling to look neat, it is important to do the work efficiently even in difficult places. Therefore, today we will analyze how to make an angle on a ceiling plinth.

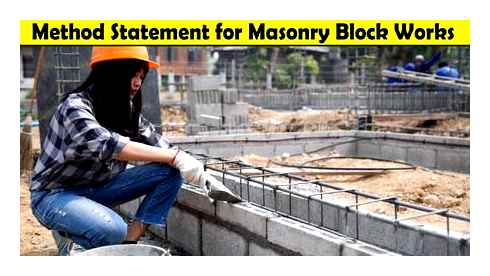

Depending on the type of ceiling plinth, installation and cutting methods differ.

This is one of the most expensive, heavy and fragile types. The advantage of the gypsum is that it allows you to cast complex forms that cannot be cut from wood, and which will not look so good in plastic. Gypsum stucco molding is often ordered to order. It is installed in the room and can be painted.

The problem of decorative elements from gypsum is that they are difficult, fragile and requires quick work with building glue, which cannot be removed if you accidentally stain the wall or ceiling. Therefore, it is better to entrust this work to professionals. The gypsum baseboard is cut with a hacksaw for metal or a drywall saw.

Wood

This design brings heat to the room, which can not be compared with any other material. Just make sure that the tree is properly processed to minimize shrinkage and swelling.

Typically, such skirting boards are installed using glue for wood, screws or finish nails. It is necessary to pre.drill holes for the screws, and then cover them with putty and sanded so that the holes are invisible after painting.

This traditional material is cut by conventional carpentry tools, for example, a jigsaw, manual or electric. The cut places are treated with sandpaper or file.

Polyurethane

Allows you to get the appearance, graceful style and drawings of a gypsum baguette at a more affordable price. It is resistant to changes in humidity, pests and decay, so it can be used both indoors and on the balcony.

To install elements of this type, it is necessary to use finish nails and glue for moldings and panels. It is easily cut, so the tool should be sharp, for example, a construction knife.

PVC (plastic)

The best choice for wet rooms, such as a bathroom or loggia. It has a smooth surface, additional coloring is not required, and installation is similar to a polyurethane type, but requires the use of stainless steel screws with finish heads. Cut by a stationery or sharp kitchen knife, as well as a knife for metal.

Polystyrene (polystyrene)

Is the cheapest and light material for ceiling decoration. Due to the low weight, the installation is as simple as possible. It can be quickly cut with scissors into smaller pieces and installed using simple construction glue, nails or both.

The only drawback. It is necessary to ensure that the edges do not crumble and the burrs do not appear. They are fragile and can be easily crumbled if you are not careful enough.

How to cut off exactly?

One of the necessary stages of the correct trim of ceiling is the preparation of tools to facilitate the task. There are many ways to join and cut, but we will talk about the two most popular methods and give detailed instructions for cutting a neat angle on a ceiling skirting board.

Cutting

The best way. Use the end box. The end box (knock) is a professional carpentry tool developed for cutting skirting boards. When used properly, it allows you to make an even cut at the angle you need.

Let’s see how to use this carpentry tool and how to properly place a plinth in it.

- Install a manual or end saw 45 degrees.

- Place the workpiece on the box for ending or the base of the saw so that the canvas only concerns a pencil mark.

- Make sure the canvas is located at the outer edge of the pencil mark, keeping it.

- Make the first cut.

- Turn the saw of 45 degrees in the opposite direction, then cut the other end of the trim at the opposite angle of 45 degrees.

- Install the first cut off a piece of baseboard in place in the wall and check its length. If it is too long, you can make a thin drink from one end of the profile so that it definitely approaches.

- Do not fix the first piece, since it should be mobile until you cut off the second piece.

- Cut the second piece.

- Measure, mark and cut the second part.

- Make sure that the corners are cut off correctly so that the part properly coincides with the angle of inclination of the first part.

- If there are any inconsistencies, carry out the adjustment of the ceiling plinth.

Cutting with a template

This method is an excellent alternative for those who do not want to buy a end box and stands for traditional methods to facilitate installation, but an independent manufacture of a template is required.

What is the template itself? Replaces the end box. It is very easy to make it, since you will need only a few public tools, such as transporter, pencil and ordinary ruler. Having prepared tools, mark the following algorithm:

- Take a large sheet of paper and draw 2 parallel lines. Keep in mind that the distances between them should exceed the width of the plinth.

- Purse a perpendicular fishing line for a trimmer in the middle. Make sure all the angles are straight.

- Divide the line connecting two parallel to two equal parts and draw two more straight lines through the middle point at an angle of 45 degrees.

- Put the bar on the template and use it as if it were a simple bevel box.

The main varieties of floor skirting boards

recently, on the market it was impossible to find other varieties of skirting boards, except for wooden. These products are still popular, although they gradually hand over borders more practical and durable products.

- Wooden. This is a classic option. The reason that such a plinth is still in demand is the source material used in the manufacture. Indeed, during the construction of eco.zhila, people opt for products made of natural materials. Wood products are made of various wood species, and therefore differs in decorative qualities and in the duration of operation.

- Openced. Various materials can be used for the manufacture of the main part, but as the upper coating, exclusively veneer from high.quality wood species are used. During external examination, without knowledge of distinctive features, an veneered plinth is practically no different from a wooden.

- PVC plinth. This variety of products is becoming more popular every year, thanks to its practicality and low price. The plastic skirting board is made with various characteristics, which helps to choose products exclusively for the needs of the homeowner. For example, for semicircular walls, manufacturers are offered flexible options, in addition, they are practically not inferior in decorative properties of wooden skirting boards.

Proper cutting of skirting angles

If we consider the options for skirting boards by the degree of stiffness, then there are two varieties. these are soft and hard. It is the strict ones that are more popular and therefore need to represent the methods of cutting the angles of the skirting board. Next, we will consider several ways showing how to cut off a plastic skirting boat at an angle.

Only from the side, it may seem that cutting angles is simple and not requiring especially knowledge and experience. However, this is only a view from the side. When you take it yourself, especially if you first begin to shake your hands and the slightest incorrectly performed action, will lead to the rejection of the details.

The incorrectly executed cut will lead to the appearance of the gaps, which means that such a connection is not suitable for the docking in the corners: the decorative component is disturbed, and the practical suffers no less.

To make a cut as well as possible, employees use a knife for metal. However, not in all cases, such a tool is suitable. For example, for cutting a thin skirting board, it is better to use a corner grinder or metal scissors. Although these tools need specialist experience.

We use a stencil

This method is suitable if the room where the installations are planned to have non.standard sizes.

- Cut the strip from any flexible material corresponding to the width of the plinth.

- By applying the prepared material to the corner, we form its shape.

- The resulting stencil is applied to the skirting board and an angle is already cut through the resulting workpiece.

Knock. auxiliary tool cutting tool

So that the work on cutting the corners would not be so difficult, the knock was invented, which is a small bar with a recess under the baseboard. The device has special gaps for cutting at different angles.

The skirting board is laid inside, and by choosing the desired angle, a cut is made using a hacksaw for metal or finely tanned spike.

Important! It should be understood that preparations of two skirting boards are used to form compounds, the shapes of the angles of which are mirrored opposite to each other.

Straight String Line Trick ~ 2-Minute Tip

By laying the baseboard in the knock and choosing the angle, pay attention to the workpiece to retreat a little further from the cut site. If the baseboard has smaller sizes relative to the device itself, it is recommended to fix the first. Otherwise, the plinth will shift, and it will not be possible to get a quality cut.

If no, the ruler with a pencil is suitable

The lack of stacked, and the unwillingness to make a stencil leads to the following method, the main tools of which are a ruler and a pencil.

How to correctly cut off the baseboard for the inner angle:

- Remove the size of the width of the product.

- The resulting value is transferred to the end of the baseboard.

- Spend a fishing line for a trimmer with a pencil from the corner to the marked point.

- Cut according to the marked.

- The second skirting board is applied to the first (formed), and also trimmed. It is important that the cut is mirror.

Inner angle

One of the easiest ways to make the inner angle correctly is to use the stupid.

- The blank of the skirting board must be attached to the ceiling and measure the required length. Better to leave a place with a margin.

- The skirting board must be installed in the knock so that it stands in it in the same way as it will be attached on the ceiling in the future.

- The baseboard itself should be carefully leaned against the opposite wall of the device.

- The skirting board must be held with the left hand for the convenience of trimming.

- To trim it evenly and taking into account the right angle, you need to choose an angle of 45 degrees. The holder of the working tool should be as close as possible to the left hand.

- Cut the bar without unnecessary effort so as not to damage it.

- Then you need to carry out the same manipulations with another bar.

- The bar should be located as close to the right hand as possible.

- The bar itself should come into contact with the far wall of the device.

- The skirting board needs to be cut without much pressure, after which the two parts must be connected. If they do not fit perfectly, then it is easy to finish the shortcomings with a knife.

- The angle is trying on the wall without glue and if everything looks good, then it is attached to the solution.

If small errors remain, they can easily be closed with a special solution.

External corner

Often in rooms, in addition to the inner angle, there is also an external angle, which is also subject to special processing.

In order not to miss the determination of the size, first you need to prepare the inner angle, and after starting work on external.

- The ceiling bar is pressed to the ceiling, and the size of the backbone is planned.

- The bar is placed in the device and pressed to the nearest wall.

- Without a strong pressure, the workpiece is cut, the main thing is to leave an extra place.

- Another bar is processed in exactly the same way.

- In this case, the bar must be placed closer to the right hand.

- She is obliged to in contact with the wall of the device, which is located further.

- The skirting board is cut without much pressure, after which the two parts must be connected. They must be done perfectly, if not so, you can fit the bar with a knife.

- If everything is fine when trying on without glue, you can attach it to glue or solution,

- Small shortcomings are easily closed by a special solution.

You can cut the skirting booth with the help of the cushed only in the situation, if the angle has 90 degrees, if it is more or less, then the pruning has to be carried out manually.

How to join in corners

If the installation of the first corner is passed, we can assume that you have already learned to do almost everyone. “Almost”, because you still need to find out how to connect the corners and cut the strips along the length. When some part is already glued and there was a short distance to the corner, as not to be mistaken with the length? The answer is simple: leave the reserve.

At first, you can cut off the piece 10-15 cm longer: there will be an opportunity to redo several times if something does not work out right away. Then make the angle described above, try on dry, adjust everything to make the result. Only after that you can put an already cut bar to a corner and note the place to which it can be shortened. You need to cut at exactly 90 °. Use a knock. Just try to put a knife (knife) perpendicular to the surface.

What to do if the gaps remain?

If defects are found after completion of work, then few people will like the prospect of remaking it. In this case, it is easier to disguise them with one of the compositions. The best option for such processing will be the final acrylic putty. It has white and very plastic. The material is taken with fingers, then it is pressed into the remaining gap, carefully distributing it in the hole, yielding. The remaining composition is removed with a damp cloth. As a rule, there are no traces of imperfections at the joints.

How to cut a ceiling plinth? You need to stock up on the necessary tools and patience, since rush always provokes mistakes. The main thing in this case is the choice of the optimal way. But attentiveness and accuracy are no less important: skirting boards are made of not too strong material (exception. wooden baguettes). They are fragile, so excessive efforts when working with such products are contraindicated.

The author of the following video, which the audience considers the simplest and understandable: about how to cut a ceiling plinth will tell about how to cut a ceiling skirting

Materials for the manufacture of ceiling skirting boards

What options are possible?

To begin with. a few words about what ceiling plinths can be made from.

The classic material for the manufacture of such elements of interior decor has long been gypsum. It was from it that the various details of the stucco moldings decorated the halls of rich houses and palaces. Gypsum skirting boards, as a rule, had intricate reliefs and different sizes.

Gypsum skirting boards are produced today, but due to considerable cost, heavyness and fragility, it began to lose in popularity to products from other materials

Today, real gypsum products of such destinations are usually made to order, as they have a fairly high cost both in manufacture and installation. Most often they are cast in small batches for restoration work when restoring architectural monuments.

However, the appearance of gypsum fillets is still attractive, as it is an excellent completion of the decoration of premises made in various styles. Therefore, in our time, customers are offered a wide variety of analogues from other modern, cheaper and light materials. polystyrene foam and polyurethane. They perfectly imitate natural gypsum fillets.

Ceiling plinths made of polystyrene foam. by visual perception after completion of the decoration from gypsum, it is almost impossible to distinguish

Such fillets have a number of undeniable advantages. this is small weight, which greatly facilitates their installation, a wide range of relief drawings and width of the strips. They fit perfectly into different design solutions of both classical and modern interior design styles.

The manufacture of wooden skirting boards decorated with carvings is a very time.consuming process, and this affects the cost of such products

It is impossible not to say about wooden skirting boards, since they are quite popular for rooms lined with natural lining, which never goes out of fashion.

Skirting boards from this natural wood or from composites based on it have their advantages. this is durability, the possibility of repeated repainting into various shades and colors, as well as high reliability of fastening on the surfaces.

Wooden skirting boards with various relief drawings are made to order. The disadvantage of wooden fillets can be called their high cost, since very often they require handmade work of the master.

Cutting the skirting board made of any material, as well as adjusting its corners according to the same methodology. The difference can be in the use of tools for marking and cutting, in the methods of attaching fillets to the surface of the wall or (and) ceiling.

Features of cutting skirting boards from different materials

Due to the fact that the materials from which the fillets are made react differently to the effects of cutting tools on them, before proceeding with the cutting of the baseboard, you should familiarize yourself with some features of the process. This information will help to avoid random damage to products.

- The wood can be called the most durable of all of the listed materials used in our time for the manufacture of decorative ceiling strips. Therefore, with its cutting, there is a greater resistance, due to which burrs and chips can easily form on the cut. Wooden skirting boards, especially those that have a small width, must be cut with a hacksaw on wood with small teeth or an electric jigsaw, also with a “delicate” file.

- Polistyle foam (polystyrene) is the most fragile of all these materials, so it can easily begin to crumble. It is best to cut it with a sharp stationery or construction knife. When conducting the cutting process, it is not recommended to press the Blade on a filler with a blade, since the cut area can be served, which will spoil the appearance of the bar. The work must be done extremely carefully, not in a hurry, not allowing either deformation or cringing on the cut.

Installation of these products must also be carefully done. Polistyal planks are not devoid of elasticity, but it is not so expressed that it would allow skirting boards to completely repeat the shape of an explicitly uneven surface. And with a strong press on the baseboard, it can just break.

Given the shortcomings of polystyrene foam, it is best to purchase strips with a margin, in case of damage. The low cost of such fillets allows you to do this.

- Extruded polystyrene foam is more durable and reliable, it is easily cut and not crumble. It is much easier to cut a baseboard from this material, since burrs or shells rarely form on it. However, as well as polystyrene, they do not have sufficient flexibility, so they are problematic on the curved area of the surface.

Cutting products from this material can be made using a sharp knife or hacksaw for metal, a canvas with small teeth.

- Polyurethane. Both strict and flexible skirting boards are made from it, so they can be fixed to a not very even wall or a curved section of the finish (for example, when framing the arched vault, column, etc.P.).

You can cut flexible products from this material only with a sharp knife, and strict ones. just like extruded polystyrene foam. The cost of polyurethane skirting boards is quite high, so the negligence or errors made can cause considerable unnecessary costs.

How the corners of the ceiling plinth are adjusted

Preparatory work

Before moving directly to work on the formation of angles, it is necessary to take some preliminary measures consisting of the organization of the workplace and the preparation of the necessary tools.

- Ruler, roulette, construction square, pencil.

- Augoter or transporter.

- Chancellery or construction knife with replaceable blades.

- Hacksaw with small teeth.

- Flow.

- Laser level. desirable, but optional.

The knock is not an expensive complex device, so it can be purchased even if it is required for one repair. It will even be good if this tool complements the standard set of home workshop. Fetling is a kind of box, in the walls of which the guide cuts for cutting are made, made in both sides at an angle of 45, 60 and 90 degrees. The tool can be made of plastic or wood. In its bottom part, holes are often provided for attaching it to the workbench. to ensure immobility.

Ways to form angles

As a rule, ceiling skirting boards have a complex embossed surface. It is she who creates difficulties when forming from two of its segments of a right angle without leaving the gaps.

In addition, the corners in the premises of apartments and houses are quite often different from the straight lines, that is, from 90 degrees, which also complicates the adjustment of the skirting board. And it must be cut so that there are no gaps at the junction, otherwise they will spoil the appearance.

Another nuance that is important to consider when cutting the planks is the location of the corners. As you know, there are two of their types. internal and external. Most often, only internal corners are present in the standard rooms of modern apartments. External corners are characteristic of rooms with one or more turns, for example, an entrance hall or a corridor, or in which there are niches or protrusions.

Trimming the baguette for the design of external and internal angles is slightly different among themselves.

Scheme of internal and external angles

There are several ways to achieve an ideal or almost perfect angular joint of the baseboard. In one of them you can use the stupid, in the other to use the laser level, thirdly. marking using a square and ruler. The simplest of them is the first option, but its use is possible only if the neighboring walls of the room form an angle of 90 degrees.

Using the stir

Before starting work, you will have to monitor the perpendicularity of the walls in the corners to measure to make sure that it makes sense to cut the skirting board by the strules. Control is carried out using a large square or a special tool. an angular. Augoter is a professional tool, and not everyone has it, but you must have a square in your household.

Augoter. a device that allows you to accurately determine the size of the angle

If it turns out that the corners are still straight, or are not very different from the desired 90 degrees, then you can safely cut the strips at an angle of 45 degrees, laying them in the stupid. It will be better if the knock is pre.fixed to the countertop. If you allow displacement during operation, then in the cut plinths serious errors may occur, entailing the inaccurate of the joint.

So that the skirting boards perfectly coincide with each other at an angle of 90 degrees, their edges should be cut in a mirror display at an angle of 45 degrees. They can be cut both separately and at the same time, a package.

- When choosing the second option, the strips must be folded together with the back side to each other, and then fix it in this position in several places with stripes of painting tape. If the skirting boards are not fastened, then when cutting a package of their displacement cannot be avoided.

- If the decision is made to cut each bar separately, then they are laid and cut alternately, but when cut, they are laid in the opposite direction. That is, one baguette is cut off on the left guide cuts of the stir, located at an angle of 45 degrees, and the second. on the right.

- The next step, two cut slices must be combined with each other. First, the check is carried out on the table, and then installation is carried out under the ceiling in the trimmed corner. Only by applying the baguette to the place of future installation can you see the real picture. If small errors occur, then the ends of the baguette segments should be adjusted using a sharp knife.

- Only after the strips are ashamed as much as possible, they can be fixed to glue.

As for the difference in the performance of cuts made using rushed for different types of angles (external and internal), it is well shown on the submitted schemes below.

Demonstration of examples of cutting cuttet using the internal and external angle of ceiling plinths

If you carefully study the schemes, you can see that the cuts are made from different sides of the edge of the baguette, that is, for the inner angle, the hacksaw is installed at an angle of 45 degrees from the main surface of the bar to its edge (if you look from top to bottom), and for the outer corner. on the contrary. on the contrary.

Making a bunker or template

If the corners in the room were even, but there is no stir at hand, then such a device or a simplified option. the template can be made independently. You can make it in several ways.

First option

If the knock is required for constant work, and there is no opportunity to purchase it for some reason at the moment, then you can make such a tool from plywood or well-processed board. For this purpose, you will need to prepare three wooden details. The walls should have a size of 500 × 100 × 15 and 500 × 80 × 15, and the bottom part is 500 × 200 × 20 mm. Different wall height will contribute to a more comfortable cut of details. A peculiar box without end walls will be assembled from the parts.

Features of the tool

Fetling is a specialized device designed to drain floor and ceiling skirting boards at different angles. The device is made in the form of a box with absent end walls and without a lid. In the lateral surfaces, several pairs of slots are formed, which have through execution and located at certain angles relative to the central axis of the base. The width of the slots allows you to freely place a hacksaw or saw in them, provided a small divorce of the teeth.

Some models of tools are equipped with a universal hacksaw equipped with an upward handle. This contributes to the special incisions of the cut and allows you to easily hold the hacksaw cloth in a horizontal position.

If the cutting tool is not equipped, then when choosing it, it is necessary to take into account the material of the manufacture of skirting boards. So, when cutting plastic skirting boards and products made of wood.fiber slab, it is better to purchase a hacksaw for metal, for a wooden product. select a wood saw with frequent teeth, and use a stationery knife for sawing polyurethane or polyurethane baguette.

During operation, the knock is fixed on a workbench or table and reliably fixed with a clamp. This does not allow the tool to shift under the influence of the cut and makes the work with it comfortable and completely safe. The process of pruning skirting boards with the help of the cashed is quite simple and looks as follows:

- The baseboard is laid on the bottom of the tray and fixed in the right position;

- Then, in the guide grooves that determine the desired angle and located on the opposite walls of the tray, the canvas of the hacksaw is inserted and the plinth is cut.

To prevent the creases and stinging of the baguette, it is recommended to produce a trial nozzle, during which the pressure and intensity of the cutting canvas should be determined. This is especially true for foam and polyurethane ceiling plinths, which, if pruning, begin to paint and crush.

The carpentry of the cushed is classified according to three signs: size, manufacturing material and type of structure. According to the first criterion, standard products designed to process narrow and medium baguette are distinguished, and large.sized models that allow you to saw high floor and wide ceiling skirting boards. The width of the slots in overall products is no different from the similar indicator of medium and small samples, however, the side walls of the tray and the width of its base are much larger.

According to the material of the manufacture, carpentry were divided into wooden, plastic and metallic.

Wooden

Wood models are the most massive type of tool, which is due to their good working characteristics and the possibility of independent manufacture. Wooden products have a classic device and are represented by a design of three boards, one of which acts as a base. Two side boards are equipped with paired grooves, allowing to cut off various corners. Despite the low cost and ease of manufacture, wooden models have a great drawback: when the metal or saw, the grooves are graded when working with a hacksaw or saw, due to which, with regular use of the device, its service life is significantly reduced. However, to carry out one.time work, for example, when carrying out repairs in an apartment, wooden models are quite suitable.

If wooden knock is planned to be used more often, then you can purchase a special saw that saw exclusively a skirting board. This will protect the wood from the saw and significantly extend the life of the tool.

For the independent manufacture of a wooden rod, the boards of boards 10 and a length of 50 cm are taken and with the help of the transporter, the angles of 45, 90 are measured on it, and if necessary, 60 degrees. Then the sidewalls are screwed and the markings of the corners from the base are transferred to them. Next, check the transferred marks by the transport. if everything is in order, then they begin to form grooves. The cut is made until the hacksaw begins to touch the upper surface of the base of the tray. The grooves should be formed so that a hacksaw or saw can easily enter them, however, and they should also not be done too wide. After the tool is ready, the plinth is tested at different angles, after which the blanks are removed and the angles are measured using the transporter.

From plastic

Plastic rods made on the basis of polyvinyl chloride are a good alternative to wooden models. The advantages of such products include their low cost and low weight. The tool is presented in a huge assortment of sizes, which allows you to purchase a model for almost any skirting board. The disadvantage of plastic devices is one. this is the rapid expansion of working grooves, which subsequently leads to great deviations from the required size of the angle and makes the tool unsuitable for further use. However, as in the case of wooden models, for one.time use, plastic casers are suitable as possible.

How to use?

In order to correctly cut the skirting booth using a bunker, the following accessories will be required:

- Kryazhovka for metal, the step of the teeth of which should correspond to the material of the manufacture of the skirting board;

- mounting or stationery knife (for cutting ceiling products from foam);

- transporter and simple pencil (preferably very soft);

- Small sandpaper.

How to cut a plinth?

Before cutting the baseboard, on its front side, the required angle is measured by the transport and with a soft pencil. Further, the workpiece is laid in the knock so that the outlined fishing line for the trimmer is strictly located on the axis connecting two paired slots. Then the baseboard is pressed to one of the side walls, hold it tightly with your hand and inserted a hacksaw in the grooves. Spining the angle should occur clearly by marking, otherwise the geometry of the connection will be disturbed and the work will have to be redone.

How to cut and place plinths

Experienced craftsmen recommend a trial cutting. In case of improper selection of a saw or hacksaw, this will help keep the working material intact.

How to cut off an arbitrary angle?

Arbitrary angles are cut using a rotary or electric model. To do this, the skirting board is placed on the work surface, fixed and laser markings are applied using the built.in angler. Next, cutting is carried out, after which parts are combined as control. Camping of angles through such tools is characterized by the ideal shape of the spile and high accuracy of measurements.

How to saw off the inner and outer angles?

When forming internal and external angles, there are some rules, having familiarized themselves with the difficulties in cutting the skirting board. The inner angle is formed as follows:

- The knock is placed on the table or a layout of the side to themselves;

- The skirting board is placed, according to its left or right.wing belonging, and closely moved to the opposite wall of the tool;

- The left element should be placed in Stusl on the left side, and the angle is sawn down on the right and vice versa: the right parts should be started on the right, and cut the angle on the left;

- Wrinkled is performed without allowances, strictly under the outstanded line;

- After the left and right angles are sawn down, both blanks are combined and checked for the density of the fit of the parts among themselves.

The outer angle is formed a little differently, namely: the skirting board is pressed not to the opposite, but to its side, after which the left part is installed not on the left, as it was in the previous case, but on the right, and sawn off the angle. They act with the right fragment in the same way: install it on the left and cut off the angle. When working with the stall, it should be remembered that the cutting of skirting boards in both cases is carried out on the front side.

If after cutting there is a loose fit of the angle of elements, then with small flaws the surface can be cleaned with sandpaper, in the case of obvious deviations, the work will have to be redone.

What joints to be designed

There is a big difference how to cut the decorating joints of the floor and the walls of moldings, depending on which one will be finished. There are two types of them:

Naturally, the strips will be cut off in different ways and the parameters of the cut, which should be focused on will also differ. It is to navigate, since the ideal joints of the walls and surfaces in our apartments, alas, do not exist and there is always a small deviation. Therefore, it is often necessary to deviate from the ideal geometry of the node to obtain a high.quality connection.

A small digression: the most ideal option with uneven angles will be preliminary preparation of planes in the form of alignment to an ideal of ninety degrees. However, not everyone can afford this, and for the performance of work, certain skills are needed.

It is in this regard that you have to compromise: not to create the perfect joint, but to allow the formation of small cracks or the cut of the planks is not perfect. At the same time, it is better to avoid cracks. it looks very ugly. It is better to make a more accurate, although not forty.five degrees, the connection of the planks than to leave the cracks. In such a situation, you will have to abandon the use of special devices and saw everything off on your own marking.

Inner joint

The workpiece is placed in a special device. knock. This simple tool is inexpensive and it must be purchased for sure. Consider the maximum width of the cut.off bar, which can fit into the knock. it should be no less than the width of your details. Cleaning the bar to the wall, you rushed through a slot, under which there is a designation “45 degrees”, saw off the skirting board. It turns out one workpiece. The second is heated in the same way, but, the cut is made in the other direction and the bar must be applied to the opposite side of.

After these operations, two elements are obtained, perfectly adjacent to each other. As a result of the connection, the internal joint is obtained in ninety degrees. Before installation, it is recommended to carefully clean the cut with sandpaper. If wooden blanks were sawn down, then a wood putty is needed to obtain perfect joints. often during sawing, small chips appear.

How to cut a plinth if the angle does not correspond to 90 degrees

Perfectly even angles of 90 degrees. this is a luxury that is quite rare. There are no problems with such correct angles. The design of the skirting board under them on Stusl will be performed along the guides at an angle of 45 degrees.

And what to do when the corners of the room deviate from the standard value of several degrees in one direction or another or even have non.standard parameters? In this case, you will need to mark the floor: where the boundary of the profile location is drawn from both boundaries of the angle.

As a result, a small rhombus is obtained, the diagonal of which is a fishing line for a trimmer of a saw. Then the skirting board is applied to the marking and marks are placed on it in accordance with the diagonal of the rhombus.

На заметку: резку плинтуса лучше делать немного меньше намеченных линий. Это дает возможность оставить себе шанс на исправление допущенных погрешностей.

Отрез плинтуса в зависимости от очередности установки по периметру комнаты

Плинтус для первого стыка в комнате обрезается незначительно. После проведенных замеров требуется убрать минимум ненужной части. В большей степени проводится выравнивание первого профиля.

На заметку: новичку отрезать меньше 1 см буде сложно. Высока вероятность повреждения профиля. Поэтому допустимо на этом этапе убрать 2-3 см, чтобы плинтус удобно было зафиксировать в стусле.

Если край профиля имеет правильный угол, то можно обойтись без пропила, а только отшлифовать место среза.

Как подогнать угол плинтуса в соответствии с расстоянием

Второй и последующие углы нужно делать на определенном расстоянии. Если следующий угол такой же, как и предыдущий и расстояние до него не больше оставшейся планки, можно использовать ее, так как градус и направление надреза соответствует.

Нужно измерить расстояние с помощью метра. Важно, замеры проводятся от угла до угла. Полученные результаты переносятся на профиль. В стусле или любым другим удобным способом нужно отрезать плинтус по линии.

Если при примерке профиля углы прижались к противоположным стенкам или есть незначительный зазор – не более 2 мм, замеры и резка прошли отлично. Если несоответствия значительные, профиль забракован и придется взять новый плинтус и повторить действия проведя более внимательные замеры.

Не всегда длины профиля хватает на стену. В таких случаях приходится стыковать отрезки плинтуса. Проще всего это сделать при прямом срезе. Но во время эксплуатации такой вариант может начать расходится, образуя заметную щель.

Чтобы избежать эстетичной непривлекательности, срез для состыковки профиля по прямой можно сделать под углом. Для этого на первой планке делается срез стандартно под наклоном в 45 градусов. К готовому плинтусу, как к трафарету, прикладывается второй отрезок и отмечается место надреза.

На заметку: если плинтус имеет достаточную толщину, места стыков можно дополнительно обработать клеем в соответствии с материалом. Излишки убрать сразу, дать просохнуть и можно монтировать.

Важно: независимо от назначения формирования среза, место пропила рекомендовано дополнительно обрабатывать шлифовочным материалом. Это обеспечит более плотное соединение деталей.

Чем резать плинтус, как подгонять углы, какие инструменты понадобятся – завершающий этап ремонта пугает подобными вопросами. Но если вооружится полезными советами, терпением и внимательностью, то резка плинтусов окажется не таким сложным процессом, как может показаться на первый взгляд.