Mirror surface preparation

First, the entire surface of the mirror must be thoroughly cleaned and rinsed with a soda solution. If there are traces of stains, it is a good idea to clean such areas with alcohol, otherwise the cut line may “go” sideways, and the glass will be damaged. The place where the cutting will take place must be flat so that the mirror fits snugly over the entire surface. In addition, it should not be hard. it is better to spread a soft cloth. After that, the mowing line of the cut is marked.

Then you need to attach a ruler to the mowing line, preferably a metal one. For greater accuracy, you need to prepare a ruler. Two erasers (school eraser) are attached to its ends (for example, with adhesive tape). This will raise the ruler slightly above the surface of the mirror. This technique allows you to control the correct position of the cutting edge of the glass cutter and ensures that the glass cutter does not jump off this mowing line onto the line.

How to cut a mirror neatly and easily at home

Well, let’s start another lesson on the blog Best Houses with a small common truth. “work can only be done efficiently when a good tool is used.” Of course, this truth also applies to cutting mirrors, which we will talk about today. There are two types of glass cutters: diamond and roller, and a mirror at home can be cut by both. In the case of a diamond, the cutting part is a piece of technical diamond, and in the roller. a wheel made of a special alloy of increased strength.

Glass cutting

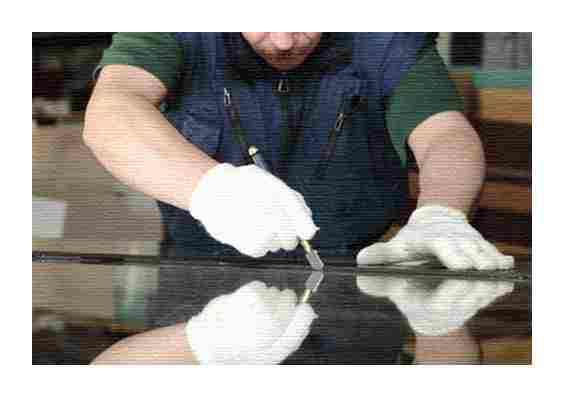

It is understood that the cutting element must be positioned strictly on the marked mowing line and perpendicular to the surface of the mirror. With a slight pressure to the glass, it is led towards you. There is no need to rush. The pressure and movement of the glass cutter must be smooth and progressive. If everything is done correctly, then the sound of glass being cut is heard, it is impossible to confuse it. A squeak indicates either the unsuitability of the instrument, or its incorrect position, too strong pressure. When properly cut, a thin white line will remain on the surface of the mirror.

When the cutting line is ready, the mirror lies on the edge of the surface (table, workbench, stool). You need to put it so that the line protrudes slightly over the edge. After that, holding the mirror with one hand, the other should be slightly pressed down. the cut off part should fall off. If this does not work, then with a small hammer you need to knock on the bottom of the entire mowing line, moving the hammer from its far end towards you. After that, if the piece does not separate, the cutting process should be repeated.

If possible, it is better to purchase a diamond glass cutter. it cuts better and has a longer service life. When using it, you need to focus on the marks, since it has two angles: sharp and obtuse.

It is best to wear protective glasses when cutting glass. If they are not there, then you should not tilt your head too low to avoid damage to your eyes by glass fragments.

See the details of the mirror cutting process on

How to properly cut a mirror with a glass cutter

The gorgeous mirrored elements are firmly embedded in the design of modern living spaces. They are able to effectively expand the space of the room, but in the process of giving them the necessary shape, difficulties may arise due to the fragility of the material. Professionals are often hired to cut mirror surfaces, but subject to certain rules and due care, anyone can do it on their own.

- Required tools

- Work safety

- Small nuances at work

- How to cut correctly: step by step instructions

Required tools

Before starting work, make sure that all the necessary items for work are in stock.

Among them, there should be tools, parts, tools for cleaning the workplace:

- The mirror itself;

- Smooth and clean surface for work (a flat table or a piece of chipboard will do);

- Glass cutter;

- Long ruler (approx. 8 mm thick);

- A piece of fabric (an old sheet or tablecloth);

- Rubberized pliers;

- Roulette;

- Small hammer;

- Fine sandpaper;

- Rag;

- A bowl of water or a bowl;

- Alcohol and soda;

- Marker for drawing on glass, chalk or pencil;

- Molds, plywood or plastic molds (needed if you need mowing line curves).

Important! Also, be sure to prepare eye and hand protection from splinters. Take heavy fabric gloves, a patch (to protect the skin on individual fingers), and construction or cycling goggles.

Work safety

It is important not only to properly cut the desired piece of the mirror, but at the same time to protect yourself when working at home.

Round Wood Frame | Circle Frame

Before you start cutting the mirror, you should carefully read the safety precautions.

This will help to avoid injury and material damage during work:

- The workplace must be tidy. There is no place for unnecessary items on the table. Scrap boxes, tools and a mirror are conveniently positioned;

- It is necessary to check the serviceability of all devices before starting work (glass cutter, pliers);

- Rubber tips are put on the lips of the pliers;

- In the process of working with a mirror, you should not worry and make sudden movements;

- Do not touch the mirror cut line with bare fingers;

- It is forbidden to cut the mirror on surfaces that are not suitable for this;

- If the work is carried out at a height, do not throw the cuttings down. All garbage must be taken with you;

- If a lot of scraps have accumulated during cutting, you should transfer them from the boxes to the trash can;

- Remove the pieces of mirrors carefully. If they are cracked, you can take only one piece at a time;

- Do not cut on your knees;

- If an electric glass cutter is used during work, they should be handled very carefully;

- If the mirror was brought from a cold room, you should give it time to warm up;

- Do not blow off glass dust. If you need to sweep the floor and clean the workbenches, use a special brush;

- If a special suit was used during work, you need to shake it thoroughly before removing it.

Safety precautions must not be neglected during work. If you cannot create the necessary conditions for cutting glass, it is better to postpone this activity until a more suitable moment.

Small nuances at work

Before starting work, you must first study the general recommendations, and then the technology itself in stages. This will prevent damage to the mirror, especially if there is no experience with a glass cutter.

What you need to know before picking up the mirror:

- During operation, the tool is held only at an angle of 90 degrees. A slight deviation of a few degrees is allowed. The support for the location of the mirror must also be level.

- The angle of inclination should never be changed during the process. Otherwise, later it will not be possible to separate the cut parts evenly and accurately, they may break.

- The incision is made in one precise, fast and continuous motion.

- It is forbidden to change the pressing force. An exception is the processing of the edges, 5 mm before the end of the glass, the pressure should be loosened, otherwise the glass cutter may slip. Because of this, chips are formed.

- You need to cut from the far side towards you.

- It is allowed to work only from the front side (where there is no amalgam. an alloy covering the back side).

- A good cut leaves a dark mark on the glass. If, when working with a roller tool, it came out whitish, then the notch may remain only on the surface.

- When working with a diamond glass cutter, there is always a white line.

- If you need to get an even cut, use a thick ruler. To avoid slipping, you can put pieces of rubber under it on both sides (use pieces from bicycle tires).

Reference. Do not try to deepen an incision that is bad. Ideally, it is difficult to hit the same line, repeated manipulations will damage the mirror (or you will have to cut out a smaller part from it).

How to cut correctly: step by step instructions

The step-by-step instruction looks like this:

- A cloth is spread on the table, which is able to protect the mirror when pressed on it during cutting.

- The mirror is cleaned first with a soda solution, and then with alcohol. When working on a dirty surface, dust and grease particles from your hands can dislodge the cutter and make the pieces uneven. This is especially true for a roller device.

- Cutting line is applied. It is necessary to make sure that it is located next to the cut point of the glass cutter (located at an interval of 2 mm from the desired point).

- You need to make sure that the tool is perfectly sharpened, otherwise the glass will crack unevenly.

- An incision is made according to the recommendations described above.

- This stage is one of the most important. Special care must be taken when performing it. The mirror is placed on the edge of the table so that the line of the cut protrudes slightly. It is pressed against the surface with the left hand, and a breaking downward movement is made with the right. The fracture should be made in the opposite direction from the cut. If the breaking motion is unsuccessful, a hammer can be used. They should tap on the marked mowing line from the underside of the mirror, working from the far edge.

- If the thickness of the area that you want to break off is too thin to grip, you can clamp it using the grooves of the glass cutter. It is also allowed to use pliers with rubber tips (or tape winding).

- The resulting sections must be securely sanded with fine emery paper (160 to 1400 abrasive particles per square inch).

Important! Beginners cannot get started right away without proper preparation. First, you should practice cutting small mirror elements, and then proceed to the main part.

It is not at all necessary to involve professionals in the process of cutting mirrors for decorating a room; you can easily learn how to use a glass cutter yourself. This activity seems difficult only at the very beginning. You can cut the mirror if it does not differ in an unusual shape with complex bends. Don’t be afraid to pick up a glass cutter! After a couple of workouts, you will definitely get an even cut line.

“Grandfather’s” drilling method

People who were born in the USSR never ask themselves how to drill a mirror at home in the usual way, since they performed similar work at a time when a complex electric tool did not yet exist. To simply and quickly make a hole, you need to prepare the following materials and tools:

- lead or any other material that melts easily;

- clean fine sand without impurities;

- burner or gas stove;

- alcohol;

- old metal mug for melting lead.

How to drill a hole in the mirror at home in this way? You just need to follow these instructions:

- Previously, the mirror is degreased with alcohol, then a little water is added to the sand and this mixture is applied to the surface to be treated.

- Using a needle or awl in the sand, you need to make a small improvised hole in the form of a funnel.

- Lead or tin is melted in an old metal mug and then poured into a sand funnel.

- Then you need to wait a while until the metal hardens.

After that, it is enough to remove the sand and get the frozen piece of metal. High temperatures melt not only lead, but also glass. Reviews say that as a result of such work, a perfectly even hole is formed, while no cracks and chips will be observed.

detailed instructions

How to drill a mirror? Drill glass with a feather nozzle according to these instructions:

- The mirror must be placed on an even and solid base. To do this, you can use sweaty plastic, plywood, chipboard.

- Using a marker, draw a drawing of the location of the hole and its diameter.

- To work with the perk, it is better to use a screwdriver. It is connected to the network and installed on the glass, according to the markings.

After that, using a spray gun, you need to constantly spray water on the mirror so that it does not overheat during the drilling process. Start work at the lowest speed, gradually increasing it to medium speed. During work, you need to constantly raise the drill so that liquid can enter the hole.

The process must be continued until the drill appears on the other side of the mirror surface. Then you need to turn the product over and repeat the steps above. When the pen drill appears on the other side, the mirror will have an even, neat hole.

Rules for working with a drilling tool

How to drill a mirror at home using a quality tool? If the work is carried out with the help of a special drill, it is necessary to use a drill. In this case, the power of the equipment must be regulated. This tool is not always at hand, so you can use a simple screwdriver.

It is imperative to make markings on the glass. It is not enough just to draw a cross at the drilling site. It is necessary to draw a regular square, inside which there will be a circle. This is the diameter of the future hole.

Sometimes, during the drilling process, the tool slides over the surface, and this can lead to damage to the product. To avoid this situation, you first need to make a small wooden blank. A hole is made inside it and attached to the mirror surface with tape. This little trick helps to keep the drill in one position. So that the tool and the mirror surface itself do not overheat during operation, it is necessary to take short pauses. At this point, it is recommended to slightly cool the mirror and drill.

Using a conventional drill

Here are instructions on how to properly drill a mirror with a conventional drill:

- The mirror must be placed on a flat horizontal surface and degreased with alcohol.

- On the upper side, you need to make a small funnel from clay and plasticine, pour water into it. If you have turpentine at home, then it is better to use this particular liquid.

- The tool (in particular, a drill) must be turned on at the slowest mode and, without physical effort, slowly make a hole.

Using an efficient pen drill

Feather gimbals are considered to be of the highest quality. The main element of the drill (metal nib) has high strength. In addition, it is perfectly flat. The diameter of the product does not exceed 10 mm, the cost is not very high. But it must be borne in mind that the service life of the drill is short, it will be enough to make about 8-10 holes, with a mirror thickness of 3 to 5 mm.

General recommendations

Anyone can make a hole in the mirror if they first familiarize themselves with the drilling technology. There is nothing complicated in this, but there is always a risk that the product will crack, completely break. If it is impossible to do this work on your own, it is better to give the product to a workshop that repairs mirrors and furniture. To understand how to drill a mirror at home, you need to familiarize yourself with the main nuances of the process.

How to work with a mirror

When processing fragile mirror surfaces, there are some important rules to follow:

- First, you need to place the mirror on a perfectly flat horizontal surface. For these purposes, you can use plastic, chipboard or plywood. The product must fit snugly against the surface.

- It is recommended to additionally degrease the surface to be treated. This can be done with acetone.

- How to drill a hole in the mirror? If the work is done with a good quality drill, you need to set the equipment to the slowest operating mode. No need to rush, put pressure on the instrument.

- Experts advise not to drill to the end. It is necessary to stop halfway, turn the mirror over and continue drilling from the back side.

Glass cutter application

To be able to make a hole in the product in this way, you will have to disassemble the glass cutter. The fact is that you need to work with a diamond roller. To understand how to drill a mirror at home, you need to carefully study the sequence of actions with a glass cutter:

- From this device you need to get the diamond roller.

- The steel bar should be carefully prepared for work. To do this, you need to make a small slot in it.

- A roller must be inserted into the hole, while checking the reliability of the fasteners.

Thus, you can make a quality drill yourself. They attach it to a drill and begin work.

How to use a glass cutter?

Glass cutters are different, but there are two main types:

- Roller glass cutter.

- Diamond glass cutter.

Important! The diamond tool is sharper and allows you to get the job done faster and better. However, the roller is cheaper, so pick up the one you can afford. Be sure to take into account the expected scope of work.

Technique safely when cutting mirrors

Before cutting a mirror at home, you need to take care of your own safety:

- In order not to injure your hands or cut yourself on the sharp edges of the mirror, prepare heavy-duty fabric gloves. Additionally, you can stick strips of plaster on your fingers.

- The eyes also need protection. For these purposes, use cycling, construction or any other safety goggles.

Important! Before you cut a mirror with a glass cutter for the first time, you need to practice on small glass elements, and after gaining at least some experience, proceed to the critical part of the work.

How to cut a mirror at home?

- Technique safely when cutting mirrors

- How to use a glass cutter?

- Required materials and tools

- Mirror Cutting Sequence

- Curly cutting

- Video

Mirrors play a special role in the interior of the room: they expand the space and make the room more refined. To create a real work of art yourself, you need to know how to cut a mirror at home. If you follow certain rules, then it turns out not as difficult and dangerous as it might seem at first.

Mirror Cutting Sequence

To properly cut a mirror at home, you must strictly follow this algorithm:

- Prepare your work area and place a mirror face up on it.

- Place some kind of soft cloth under the mirror that can help prevent damage to the surface when pressed.

- Tidy up the mirror. first clean it with a soda solution, and then treat the mirror surface with alcohol.

Important! This must be done, as traces of stains and dust can cause the cutter line to shift and the cutter can go sideways.

- Apply the markings. There is one subtlety here: the marking line must necessarily correspond to the mowing line of the glass cutter, that is, move a couple of millimeters away from the future mowing line of the cut.

- After marking, attach a ruler to it. To control the movement of the cutter and to avoid displacement of the cutter, you can slightly raise the ruler. The easiest way to do this is by attaching erasers to the ends.

- Check the tool. For an inexperienced carver, only a perfectly sharp glass cutter is suitable, otherwise the process of work will take a lot of time, or it will even end in failure.

- Proceed directly to the cutting process. After making the cut, position the mirror so that it coincides with the edge of the table and even protrudes a little beyond it.

- Separate the cut section from the mirror. To do this, gently press it against the table and break off the cut part with a sharp downward movement.

the next project part 3 (how to cut a mirror to size and shape)

Important! If you can’t do it with your hands, take a small hammer and tap lightly from the underside of the cut line, starting at the far end. If necessary, resort to using pliers with rubber pads.

- Sand the cut thoroughly with fine sandpaper.

The mirror is ready! Now fix it in the frame and hang it on the wall.

Required materials and tools

Before you start cutting the mirror with your own hands, be sure to prepare all of the following tools and materials:

- Glass cutter;

- Mirror;

- Long thick ruler (8-10 mm);

- Smooth stable table (chipboard plate is suitable);

- Small hammer;

- Fine sandpaper;

- Linen (a regular sheet will do);

- Pliers with rubber gaskets;

- Capacity with water;

- Alcohol, soda;

- Roulette;

- Rag;

- “Steklograph”, “Tecnolux” or other suitable pencil;

- Patterns made of plastic or plywood. will be needed only if curvilinear drawing is supposed.

to the content

General rules of application:

- It is very important to hold the glass cutter correctly. at a right angle, however, a slight deviation is still allowed (in this case, an acute angle will be working).

- The tool must be fixed with the thumb and middle fingers and pressed down with the index.

Important! The position of the cutter cannot be changed. The cut should be done in one quick motion, as repeated actions will damage the mirror.

- The pressing force must be uniform, with the exception of the edges: 5 mm before the edge, reduce the load to prevent the tool from slipping and chipping.

Important! You need to cut strictly from the far edge towards you.

- A thin white notch means that the roller could not penetrate the mirror body to the required depth. A good cut has a dark color (this does not apply to the diamond, as it leaves a thin light strip).

Important! Do not try to deepen an unsuccessful cut. it is better to back off a couple of millimeters and make a new.

How to make a hole in heat resistant glass?

This is a very laborious operation, and in such situations the limitations in the methods due to the fragility of ordinary glass no longer matter. In some ways, such cutting is similar to the processing of metal surfaces. If we are talking about thin glass, then you can try drilling using diamond and solid-state bits. In any case, they cope with metal. But how do you make a hole in a large diameter glass? To do this, you can use a powerful hammer drill with a crown equipped with the same diamond elements. Alternatively, you can try grinding with an abrasive wheel, but it will provide a very rough result, which is not always suitable.

How to make a hole in glass: methods and instructions

Making holes in glass may seem like a simple operation, but in practice it is a rather complicated and demanding procedure. The structure of the glass is malleable for mechanical processing, but at the same time it is very fragile. Therefore, the peculiarity of the operation is not so much in the choice of the force of influence as in the approach to its organization. The main task of the master is not to lead to the formation of cracks, chips and faults of the main surface. How to make a hole in glass without violating this condition? You can accomplish this task with the help of special technologies and tricks that are available to almost any master. The following will discuss the most popular and effective methods.

The nuances of making holes by drilling

Glass cannot be drilled with the usual drilling method. If we are talking about a workpiece of the same small dimensions, then you can use a standard set of drills and drills, but before that, the work equipment should be prepared in a special way. First of all, a drill of a suitable standard size is heated to a white shade. Next, it must be immersed in sealing wax and held until the latter melts. After that, the tip is moistened in turpentine and you can start the working process. There is another option that allows you to make a round hole in the glass by drilling. its step-by-step instructions are presented below:

- Camphor and coarse sandpaper particles are crushed.

- The prepared elements are poured into a small container and diluted with turpentine.

- A small piece of copper wire is prepared for the drill, which must be clamped in the chuck.

- The previously prepared paste is placed on a cleaned glass surface.

- A plywood guide is prepared for positioning the copper tooling.

- You can start drilling.

Smelting a hole

In this case, you will need to initially prepare the equipment for the preparation of liquid tin or lead. The glass surface is also prepared accordingly. It should be treated with gasoline, acetone or alcohol. Further, moistened sand is poured onto the marked hole formation zone. There should be enough of it to create a funnel, the bottom of which will fit the edges of the hole. After that, metal is poured into the created funnel. It will cool down in 1-2 minutes, after which it will be possible to remove the sand snap along with the cast mold. This is the best option if the question is about how to make a hole in glass without a drill and with smooth edges. But the problem may arise in another aspect. No matter how accurate the sand funnel is, it will be impossible to control the diameter that will form when glass is melted with metal.

High-tech processing methods

This category of methods for creating holes is more likely to be industrial, although private craftsmen also acquire the appropriate equipment for their needs. We are talking about lathes and units that provide sandblasting abrasive cutting. The best quality result is given by waterjet. how can you make a hole in glass using such equipment? First, the installation is fixed in machine clamps. there are practically no restrictions on dimensions, including thickness. Next, consumables are refueled. They are composed of sand and water. The hole is created as a result of circular cutting with a water-sand jet along the previously marked mowing line. Automation itself will position the cutting direction, providing an almost perfectly straight cut.

Making large holes

Drilling methods are not always theoretically permissible for making holes in glass, and not only for reasons of a high risk of the formation of the same chips. In the case of holes with a diameter of more than 10 cm, no household equipment can cope with this task. But in this case, too, there is an exit in which the drill is also used. It is necessary to make a small through point in the prepared surface in the very center of the planned hole. To do this, you can use any small-format glass with a diameter of less than 1 cm. You should not be afraid of third-party chips, because they will fall on an area that will be removed anyway. Now another question: how to make a hole in the glass, having a small through opening in the center? A piece of wire is pushed into the created small hole and fixed. The other end is fastened with a glass cutter. Further, after checking the reliability of fixing the elements and the smoothness of the tool in a circle, you can start cutting in a circle.

Glass preparation for processing

Before any operation to create holes or simply cut, appropriate preparation should be done. The working surface of the glass should be clean and, if possible, have no defective areas. during drilling, they can chip off the sides, which will ruin the workpiece. It is recommended to mark the cutter line of the future hole so that the physical surface imperfections are within the circumference, but not outside. As an additional measure, the glass can be treated with chemicals, which, in particular, will rid it of oil traces. If there is a question about how to make a small hole in the glass, then you will have to prepare the fixing equipment. The method of fixing the workpiece will depend on the technology for creating the hole, but in most cases such elements are mounted on a vise of a suitable configuration. damping soft material is placed directly into the contact areas.

Soldering iron cutting

From the point of view of the quality of the result, this option can be called the opposite of the previous one. In this case, the master will be able to relatively accurately maintain the boundaries of the marked hole diameter, but the edges may be uneven. The process begins with the creation of risks using a file. The task of this operation is to accurately mark the depth of the future melt with a soldering iron. Now you can proceed to the next step. how to make a hole in the glass without drilling using a soldering iron? After warming up the tip of the machine, you can start cutting. over, one should not rush in this process. It is advisable to perform reflow in small pieces, if necessary, cooling the glass. otherwise there is a risk of deformation and areas not intended for processing.

Glass cutting technology principle

Here’s how to properly cut a mirror with a glass cutter at home:

- First you need to prepare the mirror surface and tools.

- After that, mark up with a ruler and marker. For the curly version. use special patterns.

- Then carefully draw the line with a glass cutter, observing the constancy of pressing.

- Then very gently tap with a hammer, through several layers of fabric, the edge of the mirror, which will need to be removed. Before this, it is previously slightly suspended from the edge of the table, without fail supporting it in such a way that the mirror or glass does not fall to the floor.

- After that, the work is carried out on a break. That is, they are trying, by applying minor efforts, to break off an unnecessary piece from the base. Then wipe the cut edge with a damp cloth, which was previously folded in several layers. This is done in order to remove small glass particles.

Get professional advice when cutting mirrors.

How and how to cut a mirror at home

Reading time:

Sometimes, when it is not possible to take the mirror to the workshop in order to cut the desired size and shape, such a manipulation can be carried out at home.

Mirror is an integral part of any interior.

But, for its successful completion, it is necessary to know the basic technological steps of glass cutting, with what tools it can be done, and also not to forget about the precautions.

- Precautions and safety precautions

- Necessary tools and materials for cutting glass at home

- Rules for using a glass cutter

- Mirror surface preparation

- Glass cutting technology principle

- Is it possible to cut glass without a glass cutter at home

- cutting mirrors with glass cutter

Mirror surface preparation

It is important to understand that before you start manipulating a mirror or glass, it must be wiped in order to remove all dirt and dust from the surface. But, it is better to do this with baking soda, as it helps better cleanse. If the soda turned out to be powerless against any stains, then you can apply alcohol.

Use modern mirror cutting techniques.

It is also allowed to use a special liquid for glass. It does not matter which cleaning liquid was used, after that, wipe the surface dry on both sides with a cloth that has a good level of hygroscopicity. Only she will allow you to collect all the remaining moisture.

Carefully start cutting the mirror.

Precautions and safety precautions

Before cutting off the mirror, you need to understand that this type of activity carries a potential threat to the performer.

Many design projects require custom mirrors in the interior.

Therefore, in order to protect yourself from unforeseen industrial injuries, it is important to adhere to the following safety measures:

- Always wear protective goggles and gloves. Eye protection is required, since small fragments that can accidentally fall on the mucous membrane will subsequently cause irreparable damage to the organ of vision.

- Prepare a special box in which the production scraps will be stored. It is imperative to do this to prevent small pieces of glass from getting on or cutting your clothes.

- The surface on which all manipulations will be carried out must be extremely flat and large in area. All the tools and materials at hand should also be nearby.

- After you have cut glass or a mirror at home, you need to wipe the work surface and the floor around it with a damp cloth. This manipulation must also be performed with all precautions. Otherwise, you can drive small fragments under the skin, which will be quite problematic to get rid of later.

Before cutting a mirror with a glass cutter, read the safety requirements.

Rules for using a glass cutter

So, how to cut a mirror at home is not so easy, especially without skills, you need to know exactly how to use a glass cutter correctly.

- First you need to check the tool. it should not be loose and the wheel should rotate smoothly. This is a prerequisite for round glass cutters.

- If you need to cut a mirror with a diamond glass cutter, then you need to make sure that the stone is fixed securely enough and at the correct angle.

- The pressure should be even and smooth. Even slight deviation from constant pressing force and the mirror surface will crack.

- When carrying out manipulations, it is necessary to listen to the sounds that the instrument makes. There should be no squeaks. If, nevertheless, sounds appeared, this means that the glass cutter has already become dull.

Additional Information! If the cut is made with a deviation from the established mowing line, do not try to fix the defect. You just need to step back a few millimeters in the desired direction and re-cut the line. This is a prerequisite for both straight and curly ways of cutting out mirrors and glass.

Necessary tools and materials for cutting glass at home

To know how to cut a mirror correctly, you need to understand not only technological actions, but also what tools it will be carried out.

There are special tools for cutting mirrors.

Here is a list of everything you need:

- High quality diamond glass cutter. It is he who will allow not only to quickly and accurately cut ordinary glass, but also to cope with tempered.

- If it is decided to use an angle grinder for manipulation, then it must be equipped with a diamond-coated disc. But, it is worth remembering that in this case there is a high probability of crumbling the material.

- You also need a large and always flat surface. The main condition is full adherence of the glass over the entire area to the table. At the same time, cracking is easily avoided.

- You will also need a hammer and pliers.

- For marking, you need to take a long ruler and a square. You will also need a marker for marking.

- If it is necessary to carry out curly cutting of a mirror, then you will also additionally need. already made patterns (they can be made of thick cardboard or plywood), as well as a knife for shoemaking or a jigsaw.

Important! If you need to cut tempered glass at home, it is best to do the work on a machine that is equipped with a diamond-coated wheel. In this case, the crumbling process of the heavy-duty mirror or glass can be avoided.

Is it possible to cut glass without a glass cutter at home

Not everyone knows that ordinary glass can be cut using the most familiar scissors. The main conditions in this case are sharp. sharpening of the cutting edge. In this case, it is necessary to place all the glass in a sufficiently large container so that it is covered with water.

Sometimes there is a desire to acquire a mirror of any intricate shape.

It is the liquid that prevents the appearance of chips and cracks. Then, carefully with scissors, begin to cut off small pieces, achieving the desired shape and size.

Cut a mirror of any shape.

Note! This type of mirror processing is suitable only if its thickness does not exceed the 4 mm mark and it is necessary to perform curly cutting. Most likely, in this case, you will not be able to cut off the straight line.

You can use another way. For example, take a file with a rectangular or triangular cutting edge.

The cutting element must be positioned strictly on the marked mowing line and perpendicular to the mirror surface.

The technology of actions in this case is as follows. with the edge of the file, cuts are made on both sides. Then the main line is scratched and breaking off is carried out. But, to implement this option, you need the skill of working with materials such as glass and mirror.

If you have never worked with a mirror, then get help.

You can also try using a winder drill. Here, holes are made in several places. They all lie on the cut mowing line. Then a thin line is scratched between them and tapping, and the unnecessary part is eliminated by breaking off.

If everything is done correctly, then the sound of glass being cut is heard, it is impossible to confuse it.

Important! If the work is carried out with a drill, then it must be turned in such a way that only an acute angle enters the glass. Otherwise the mirror will crack.

Given all these features, at home it is quite easy to trim or curly cut out a mirror.