How to properly cut corners on skirting boards

The ceiling plinth performs not only a decorative function, visually separating the walls from the ceiling, but can also hide the joints of various finishing materials of the ceiling and walls. Not every interior design involves the use of a skirting board, but more often than not, the overall appearance of the room seems incomplete without it. There is nothing difficult in fixing this element. fillets. almost all types of skirting boards are attached with glue. But the question of how to properly cut the ceiling plinth in the corners of the premises can confuse many. Indeed, even in the simplest room there are internal corners, where the plinths of the ceiling plinth must be precisely and beautifully docked. And in a more complex configuration of the room, you will also have to dock the skirting boards, performing the outer corner. In this article, we will look at various options for how to cut a ceiling plinth with and without tools at hand.

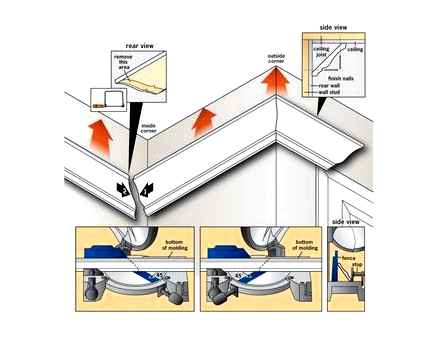

How to cut inside and outside corners for mounting quarter round to a ceiling.

First you need to figure out how to cut the ceiling plinth, the answer to it depends on the material from which the fillet is made. At the moment, we sell ceiling skirting boards made of polyvinyl chloride (PVC), expanded polystyrene (foam), polyurethane and wood.

PVC skirting boards are the cheapest. Dents and creases are easily formed on them, which cannot be repaired, so the product must be thrown away. Also their disadvantage is electrostaticity. the ability to attract dust. You can cut them with a sharp construction knife or hacksaw.

Styrofoam ceiling skirting boards are also cheap. This material is very fragile, it crumbles easily during processing, therefore, it is necessary to cut the expanded polystyrene with a sharp knife or a hacksaw on metal, without making too strong pressing forces.

Ceiling skirting boards made of extruded polystyrene foam are slightly more expensive than polystyrene foam, they are denser and more difficult to cut. However, they crumble less, making them easier and more comfortable to work with. Cut with a construction knife and a hacksaw for metal.

Polyurethane ceiling skirting boards are the most expensive at the moment. They are durable, elastic and moisture resistant, can be easily cut with a construction knife and do not crumble. The disadvantage of polyurethane skirting boards is their dependence on temperature extremes. For example, over a gas stove, a polyurethane skirting board will permanently deform and crackle slightly. If you try to process or cut such a plinth, it may bend or deform in other ways.

Wooden ceiling skirting boards are dense, heavy products that can only be cut with a hacksaw, preferably with fine, dense teeth. You can also use a cloth for metal.

Before proceeding to the enumeration of the ways of how to properly cut the ceiling plinth, I would like to note that there is a possibility not to cut the plinth with great precision. There are special corner pieces on sale into which the edges of the skirting board are inserted. In this case, it is enough to cut the plinth strip at an angle of 90 °, and the corner element will hide all the flaws. But this method is not always used, since the dimensions of the corner elements are slightly larger than the skirting boards themselves, so the corners in the room will stand out against the general background. Sometimes it can look bulky. However, if the design of the room allows the use of corner pieces for ceiling skirting boards, it makes sense to use them. Further instructions will be useful to those who nevertheless decided to accurately cut the skirting boards at a given angle.

How to cut a ceiling plinth using a miter box template

Something resembling a miter box can be done by applying the required cut angles to paper, cardboard or wood. Draw two parallel mowing lines, locate the center, and then set the required angles with a protractor. The advantage of this method is that you can postpone any angle, including more than 90 degrees. Of course, before cutting the corners of the ceiling plinth, you must first check the angle between the walls using a corner and measure with a protractor.

The technique for cutting a ceiling plinth using a painted miter box is exactly the same as using the miter box itself. We press the plinth plinth to one of the parallel lines, then set the hacksaw at the desired angle, which is already outlined, and cut off.

How to trim the corner of a ceiling plinth using ceiling markings

Marking the skirting board on the ceiling also allows you to cut the corner evenly and accurately. The only drawback of this method is that it is difficult and inconvenient to keep the plinth plinth suspended during the cutting process. Otherwise, you can mark the cutting angle in this way even more accurately than in other ways. Applying the skirting board to the installation site, all wall flaws and deviations in the corner size are immediately taken into account.

Cutting the corner of the skirting board:

- Then we first apply one plank, resting its end against a perpendicular wall. We draw a line on the ceiling, outlining the contour of the plinth.

- We remove this bar and apply a striker, also resting its butt against the wall. We outline the line.

- The point of intersection of the marked lines will be the mark at which the skirting board needs to be cut.

- Again, we apply each bar in turn and mark the cutting point on them.

- We draw the line from this point to the other edge of the plinth.

We cut off the skirting boards along the outlined lines, join them and apply them to the installation site. Please note that this method is more convenient to cut the inner corners.

How to cut a corner of a ceiling plinth using a miter box

The miter box is a simple carpentry tool that allows you to cut the workpiece at the desired angle. Most often it is a plastic, wood or metal tray with vertical slots for cutting at an angle of 90 ° and 45 °. There are also more complex miter box designs. for cutting at angles of 90, 60 and 45 degrees. For more professional work, a miter box with a swivel mechanism is used, where the hacksaw can be fixed at any angle to the workpiece.

How to cut a skirting board with a miter box. inner corner:

- We apply the plinth to the ceiling, measure the required length.

- Then we install the plinth strip in the miter box so that the position coincides with the position of the plinth on the ceiling.

- The plinth strip must be pressed against the far wall of the miter box.

- Hold the plinth with your left hand.

- We choose such a position of the hacksaw when the angle is 45 degrees and at the same time the handle of the hacksaw is as close as possible to the left hand.

- We cut the workpiece without making excessive pressure on the saw.

- The next step is to trim the plinth striker. We also install it to the far wall of the miter box.

- Press and hold with your right hand.

- We choose such a position for the hacksaw when the angle is 45 degrees and the handle of the hacksaw approaches the right hand.

- Cut off the skirting board.

Next, we join the trimmed plinths and check the cutting accuracy. For a more accurate orientation, they also say that in order to complete the inner corner, it is necessary to start cutting from the front of the plinth. After trimming, wooden skirting boards will most likely have to be adjusted with a file.

How to cut a ceiling plinth with a miter box. outside corner:

- In order not to be mistaken with the dimensions, it is better to start by marking the inner corner, and then cut out the outer corner. Otherwise, a situation is possible when the planks may not be enough in length.

- It is necessary to attach the plank to the ceiling and outline the dimensions.

- Install the plinth strip and press it against the nearest wall.

- Hold with your left hand and choose a position for the hacksaw at an angle of 45 degrees, when the handle approaches the left hand.

- Cut off the workpiece.

- We install the striker to the nearest wall, hold it with the right hand.

- We set the hacksaw at an angle of 45 degrees, when the handle approaches the right hand.

- Cut off the workpiece and join the corner.

Trimming the workpiece with a miter box is only suitable if the angle between the walls is even. 90 degrees. If the accuracy is poor, you will have to use other methods.

DIY impromptu miter box

Making a miter box with your own hands is also not difficult.

You will need three wooden planks or boards, which must be put together in a U-shaped box. Then the necessary angles are marked on the walls of the box, and a cut is made with a hacksaw. As a result, you should get a wooden miter box, in which grooves are cut.

A combination of an impromptu miter box and a template with marked lines. For the convenience of cutting, it is necessary to build something in which it will be convenient to hold the plinth strip, since it is difficult to keep it suspended. It is enough to put together a corner from two wooden planks or boards. On paper, you need to draw a mowing line with angles for cutting at 45 degrees or at any other. Then we apply the baseboard blank to the corner, press it with our hand, as described in the technology for using the miter box, move the piece of paper with the template under the edge where we are going to cut it, and cut it off. In the process of cutting, we focus on the line drawn on the paper.

As an impromptu miter box, you can use anything you want, anything. that we form a corner. For example, a table pushed against a wall.

Important! Pay attention to the rule of making measurements for trimming the ceiling plinth. To mark the inner corner, you need to measure the length directly from the corner itself. To outline the outer corner, it is necessary to be guided by the fact that the plinth will protrude deep into the room by a distance equal to its width.

You should not fix the plinths of the ceiling plinths before you cut the striker and try on their location. Only after the two strikers are perfectly aligned in the corner, you can start attaching them to the ceiling. Minor imperfections can be finished with a file or a nail file in the case of wooden and polyurethane skirting boards. To fit foam products, you will have to wield a sharp knife.

If suddenly, even after adjusting the skirting boards, a small gap remains between them, do not despair, it can be repaired with a putty. Cutting the ceiling plinth yourself is not difficult. But in order not to spoil many products, it is better to pre-practice on small blanks.

Using factory corners. an alternative to cutting and sawing

Corners for PVC skirting boards

The disadvantage of corner pieces is that they are actually and visually larger than the baseboard, which will make the corner noticeable. This can ruin the look of the room. It is also inconvenient to use the corners where the walls do not join strictly at an angle of ninety degrees. But most of the time they look great.

How to make a miter box yourself?

If desired, the miter box can be made at home. It can be crafted from wood or iron. The dimensions of the workpiece do not play a special role, but the wider it is, the more accurate your cuts will be. However, if the width is greater than the length of the hacksaw, with which you will cut the baseboards or boards, then it will be extremely inconvenient to saw, so you do not need to take a workpiece that is too wide.

First, a transverse line is marked in the center of the workpiece. Then, at a distance of 1/2 the width of the workpiece from the intersection of the straight line with the edges of the workpiece, marks are made. Then these marks are connected crosswise, as shown in the figure.

Wooden miter box, fastened with self-tapping screws

Next, the process of marking the side walls of the miter box begins. Attach them to the already marked base and make marks based on the base markings. Then draw straight lines from these marks across the entire wall.

After that, the process of mounting the miter box begins. The walls must be attached to the base with self-tapping screws if the fixture is made of wood or chipboard or bolted corners if it is made of steel. Only after installation in the miter box are sawed slots for the saw.

After making the slots, the miter box is ready. If you have a large amount of work or want to repair regularly (on a professional basis), this simple device can speed up the process of cutting skirting boards by 5-10 times.

What tools can be used?

The feasibility of using certain tools is associated with the materials from which the skirting board will be made.

Tab. 1. Varieties of materials and features of their use.

DIY Coving Cornice Cutting Tips for Beginners

| Polyvinyl chloride (PVC) | PVC skirting boards are distinguished by the fact that they are easily damaged when pressed and no longer restore their former appearance, since they are devoid of elasticity. Therefore, such skirting boards cannot be pressed when cutting. | Cut with a construction knife or a hacksaw for metal. A blade or a sharpened kitchen knife will also work. |

| Styrofoam | Foam plinth is also not very durable, but better than PVC counterparts. Easily crumbles. | The same tools can be used as for PVC |

| Wood | Stronger and more aesthetically pleasing than their polymer counterparts, but expensive. | It is best to cut the tree with a hacksaw, you can use metal, although this way you run the risk of hammering the teeth of the blade with wood sawdust. A hacksaw with fine teeth is best. |

If the angle is not right

Unfortunately, in some cases, the angle between the walls in the room is not straight, but sharp, or, conversely, obtuse. This is due to structural defects that have arisen through the fault of non-professional builders, the architect’s idea or the result of soil subsidence some time after the construction of the building. This is especially common in village houses and summer cottages.

No miter box or a drawing replacing it will help in this case, and you will have to do the markup in place.

- Attach the workpiece to one of the walls so that it rests against the other wall with its end.

- Run the line on the ceiling along the workpiece.

- Perform the same operation against another wall.

- At the intersection of the two lines, put a mark on the workpiece itself.

- Draw the line from the mark to the corner of the workpiece and cut along it.

- Do the same with the workpiece, which you will attach to another wall.

- Glue both blanks; they will come together tightly.

Using a miter box

The miter box has a recess for a cut-off board or plinth and saw slots at an angle of 45 and 90 degrees. You will need to cut the skirting board at a 45 degree angle.

To cut the skirting board with this device, you need to follow these steps.

- We apply the plinth to the future attachment point.

- We mark where we will cut.

- We put the plinth in the gutter of the miter box so that the lower part is pressed against the surface of the device, and the part that will be greased with glue “looks” up.

- Cut off the area by inserting the saw into one of the 45-degree holes.

- We correct the cuts with a knife or the same saw (remove irregularities).

How to cut the corners of a ceiling plinth with a miter box

After that, the skirting board can be glued in place.

How to cut a skirting board without a miter box?

The easiest way is to draw the future cut line on paper (cardboard, wallpaper), and then, attaching a baseboard blank to it, cut.

To do this, you must first attach the skirting board blank to the paper and draw two parallel mowing lines that will mark the sides of the skirting board. Then, using a protractor, you will have to measure 45 degrees and draw the line of the future cut. Then the drawing is used in the same way as the miter box: a blank is placed on it and the excess is sawn off along the mowing line.

How to cut the corners of a skirting board without a miter box

The disadvantage of this method is that the saw will have to be held on weight, focusing on the drawing, and not inserted into a previously prepared slot.

Outside corners

It happens that the room has not only internal, but also external corners, which also need to be pasted over with a plinth (see photo). How to do it? There are several ways here as well. The easiest way, as is the case with the inner corners, is to cut them with a miter box. The outer joints must be cut so that the side that will be glued to the ceiling is on the surface of the miter box, and the side pressed against the wall is facing the wall of the fixture.

As with the inside corners, you can also use in-place markings, that is, draw the mowing line on the ceiling. Here, the technology is exactly the same as that used for the inner corners.

You can use the markings on the wall by attaching a workpiece and drawing a fishing line along its lower edge (see photo).

If the outer corner turns out to be too rounded, you can finish the joint with a knife.

Trimming the ceiling plinth. Outside and inside corners

To the point where they converge, the line is drawn directly along the future part of the connection. From the point that is on the ceiling to the second. The resulting marking will be the line along which you need to saw off or cut off the connecting parts. Using these techniques, you no longer need to wonder how to cut the corners of the ceiling plinth.

How to cut skirting boards to the ceiling: corners

Today it is impossible to imagine the interior of a residential building or apartment without ceiling plinths. The skirting board covers the irregularities of the suspended ceiling or wallpaper, cracks and imperfections in the walls, and gives the interior completeness. But how to make the skirting board perfectly fit in the most important place. in the corner? There are several ways.

How to get the correct angle

Most of the problems when working with skirting boards arise in the design of corners. Since the surface of the products is complex, it will not be possible to simply cut off at the desired angle: it is also necessary to cut so that they dock and, preferably, without large gaps. In reality, there are several ways to make the corner of a ceiling plinth perfect (or almost).

How to make a miter box for a ceiling plinth with your own hands

If there is no such useful device as a miter box, you can replace it or make it yourself.

In simple cases, for example, for cutting foam plastic, ordinary cardboard or a sheet of thick paper plays the role of a miter box. 2 parallel segments are laid on it and the planned cut points are marked with the help of a protractor. Then they simply attach a piece of the product and cut it off using cardboard as a template.

If the material is wide, hollow inside, or made of such a strong material as wood, it is impossible to do without a miter box or its equivalent. Then do this.

- A template is made on cardboard or thick paper.

- Then, corners for the ceiling plinth are made from any suitable material. from two strips, for example. The material is inserted into the element as in a miter box.

- Then the device is placed over the stencil so that the end of the plinth is above the pattern. A profile is inserted into the miter box substitute and cut with a knife or saw according to the mark.

At the same time, the knife blade rests only on a homemade product, so you need to be careful when working.

What is it made of and what is it called

The very first skirting boards on the ceiling were made of plaster. They were cast in special molds and then installed on the ceiling with mortar. Such figured ornaments were called fillets. Today, you can rarely see them: they are expensive, and outwardly they are almost indistinguishable from the cheaper options. And the name is almost lost.

The most popular ceiling skirting boards are made of polyurethane or polystyrene. They are inexpensive, look great, are easy to install, have a wide range of profiles and patterns. The width can be from 5 mm to 250 mm. They are used in almost any room, decorated in any style. An exception is wooden houses with a corresponding interior. Wooden products are most often used here. the style dictates its conditions.

There is also a similar plastic finish. It is mainly installed in bathrooms. But even in damp rooms, you can safely mount polyurethane strips. they are not afraid of damp.

You need to cut the ceiling plinth in the corners of any material in one of the ways described below. The only exception is plastic skirting boards: you can arrange such a corner only using ready-made corners.

How to cut skirting boards to the ceiling: corners

Today it is impossible to imagine the interior of a residential building or apartment without ceiling plinths. The skirting board covers the irregularities of the suspended ceiling or wallpaper, cracks and imperfections in the walls, and gives the interior completeness. But how to make the skirting board perfectly fit in the most important place. in the corner? There are several ways.

Used tools

Depending on the material of manufacture, various tools are used to adjust the skirting boards: when working with wooden skirting boards, use a hacksaw for wood, and when working with plastic or polyurethane skirting boards, it is better to use a hacksaw for metal. Styrofoam decor elements are easily cut with an ordinary, sharp stationery knife. In most cases, a miter box is used, which allows you to cut the plinth evenly at a certain angle. If a hacksaw is used for metal, then you should not press hard, since the cut may turn out to be uneven, with burrs, and the material can be crumpled and unusable. Polystyrene and polyurethane ceiling skirting boards must be handled with care.

If there is no experience with such tools, as well as decorative elements, it is better to take a small piece of finishing material and practice with different pressing forces, which will help in solving the problem in the future.

Outside corners have to be dealt with if the room has niches, bay windows, protruding boxes or columns. Here, too, you need to cut off the ceiling plinth at 45 degrees.

- In fact, the difference between these two cases lies only in the correct measurement. The bar is placed along the joint and the mark is made on the inside.

- The product is put into the miter box in the same way as it was tried on, that is, with the ceiling part up. The edge of the fillet is placed so that the mark on the inner side coincides with the slot, but at the same time the outer part of the plinth protrudes somewhat beyond the edge.

- A hacksaw is inserted into the slot and cut off. The second fragment is prepared in the same way, but in a mirror image.

For cutting a hard baguette, for example, a wooden one, it is better to use a jigsaw.