Features of the material

Porcelain stoneware is made by pressing a mixture of clay, quartz sand, a field spar and other minerals with the subsequent high.temperature firing.

The result is a dense material with a meager amount of pores and the highest hardness. 7. 8 units on the Moos scale.

For comparison: Corundum has the same hardness (sapphire and ruby include this variety of minerals), only diamonds and some other materials have a large indicator.

This feature makes porcelain.resistant porcelain, even with the most intense loads, but at the same time very difficult to process.

The problem is aggravated by the fragility of the material: with careless actions on the front side, chips appear. Therefore, the issue of choosing a tool for cutting porcelain tiles is very important.

How to cut porcelain tiles

The methods of processing this material are primarily divided into two types. Each of them has its own indications for use.

Manually

Running manual tools are justified with small volumes of work. Owners of apartments and houses usually resort to it, who decided to carry out repairs on their own.

Electric tool

A professional has to cut porcelain tiles in large volumes, because he cannot do without power tools.

Tile cutting with manual tile cutter

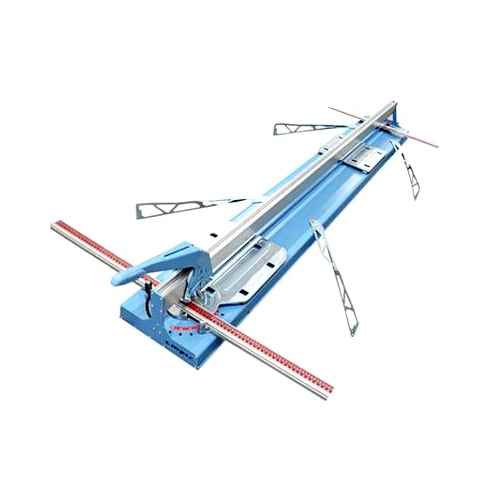

This is the most popular option used by both professional tiles and amateurs. You can find it in a store at a price of 300 and higher, depending on the size, quality and additional bells and whistles, such as a rotary base and a built.in ruler for ease of cutting tiles at an angle of 45 degrees. At the same time, it is better not to buy the cheapest models, they will often break the tiles incorrectly, due to poor pressing to a flimsy base.

- The tile is inserted into the tile cutter, and the marking on it is combined with a special mark.

- The pen drops and is drawn from itself. It needs to be carried out at the same speed and uniform pressure so that the video cuts the glaze to one depth. It will be enough to conduct a roller 1 time. If you drive several times, a breakdown can turn out to be poor.quality.

- Next to the video there are special legs that drop and break the tile into 2 parts, after a sharp pressure on the lever. At the same time, all tiles have a metal tubercle on their platform, and soft lining at the edges. When you click on the edges of the tiles with paws, the maximum voltage will be created at the site of the incision, if you correctly combine it with the lining, and it will break out evenly.

It is difficult to explain this with words, so it’s easier to watch a video that shows how to cut the tiles with a tile cutter:

High.quality tiles allow you to cut even tiles with a thickness of 10 mm without problems. And it doesn’t matter to what angle you will cut it: at least 45 degrees, at least 30.

How to cut the tile with the letter “g”

Since the tile can cut the tiles only directly, many have difficulties in g-shaped cuts. The easiest option is to divide this tile into 2 rectangular elements, but then you get an extra ugly seam that will be striking.

But this can be avoided, if the short side is trimmed with a corner grinder, and then a long one with a tile cutter.

Step instructions on how to make Mr

In the same way you can cut off the external angles. When marking them, you need to take about 4-5 mm, on a seam for grouting 1.5–2 mm and a small indentation from the wall.

The second method: by any method available to you, a cut is made on the glaze, and the excess is gradually broken off by pliers. Irregularities are processed with sandpaper. This option will even allow you to get a rounded incision to adjusting to the risers.

How to cut porcelain tiles

It is believed that porcelain tiles of the hardest material from which floor tile is made. You can cut it in the same way as a regular tile.

3D textured tile manual easy cutting

Sometimes a simple floor tile is more difficult to cut than porcelain tiles. There is a hardened tile, according to which, after a tile, the cut on the glaze is almost not visible. And even a diamond disk on a corner grinder does not take it. the incision turns out to be torn, as after the tractor. In such cases, you need to use the corner grinder, and fel the groove of 2-3 mm from the back to indicate the place of breaks.

Plush-wire-paces

Plig-barrel tiles are cheaper (200–400), and it is suitable only for small volumes of work with thin ceramic tiles at home.

After the cut, press on the tile forking for fault

- Make markings taking into account all gaps and seams (–5 mm).

- Attach a metal ruler to the marking line and draw a cutter along it once. Pressure should be medium to form a visible strip. Lead him from the far edge to you.

- Place the tongs with paws along the scrap line next to the edge. Sponges should be on top of the glaze, and the straightforward part below. The fishing line for the fault should pass right in the middle between the edges of the upper sponge.

- Click on the handles to break the tiles smoothly. At the same time, do not raise it high, otherwise after falling it will break.

Electric stabbing

The electric device is deprived of the shortcomings of the mechanical. Thanks to him, they achieve a very high.quality cut. It allows you to work with dense and thick porcelain tiles without compromising quality. In addition, he can cut off thin pieces of ceramics; In the case of a mechanical tool, even if there is a new video and lubricated runners, a positive result has no guarantee.

Electric tile cutter is not as fast as manual, but it hardly matters where you need impeccable quality. The only drawback is relative high cost. However, the price is comparable to a high.quality imported mechanical tool.

What is an electrophlicist?

Cutting using a diamond circle is accompanied by a large amount of dust, so the device has a hydraulic system that cools the cutting element and prevents active spraying of ceramics. Models differ in water supply scheme. In one case, this is a tank with a liquid into which part of the circle is constantly immersed, in another wetting is carried out with running water. The liquid must be periodically changed to avoid accumulation of waste polluting the diamond element. The latter should also be regularly washed, otherwise the cutting particles are clogged.

Electric tiles with water cooling.

Devices differ and cutting system. In some tile cutters, the circle moves, and the table is motionless, in others, on the contrary, the cutting element is fixed, and the tiles supply due to the movement of the camp. In any case, the preparation of porcelain tile for trimming is similar to the one that we described in the section on the mechanical tool.

Cutting at an angle of 45 degrees on an electric machine.

When using an electric steamer, curly cutting of porcelain tiles is possible. A winding cut with a mechanism is no longer tough, but corner. by the power. The plus of many models includes the ability to cut at an angle of 45 degrees. Today they depart from decorative tiles, preferring a monolithic cladding. You can do without a machine in this situation, but it is very difficult and inappropriate.

Corner grinder

An angle grinding machine is the tool that will help out in the absence of any other cutting tool. Further about the advantages and disadvantages of the corner grinder.

Corner grinding can be trimmed with any shape and size, grind the angle of 45 degrees. For work, you need a special diamond disk according to the tile: smooth and without holes.

- Availability. There is a corner grinder in almost every house, just purchase a diamond circle.

- The possibility of figure cutting. The mobility of the tool allows you to cut out almost any figures. there would be enough skill.

- Many have a certain skill of working with an angular grinder, this ensures the rapid development of the trial process.

- Noise and dust. Working with a corner grinder is accompanied.

- Corner grinder. dangerous tool. Careless movement and negligent attitude to safety precautions easily lead to injuries.

- Poor.quality cut. Depending on the quality of the corner grinder, the degree of chips and microcracks in the tile differs, but there are always flaws. The refinement of the cutting partly solves the problem, but it is better to use a corner grinder to work with a tile that does not have, from an aesthetic point of view, great importance. the cutting places should be hidden.

Safe operations with corner grinding: http: // www.YouTube.COM/Watch?v = fvqotukmgeo outlining a fishing line for a trimmer cut, cut a pair of millimeters from it. a diamond circle “eats” part of the ceramics. Install the circle, according to the direction of the movement of the mechanism, on the cutting element there is a indicating arrow. In the process, try to drive less back and forth, this will reduce the number of chips. This advice does not work when cutting thin pieces of porcelain tile, here the desire to cut off in one pass will turn into a stove crowbar.

Come responsibly to the choice of a diamond circle, buy high.quality consumables. Otherwise, it is fraught with the destruction of the element, which at great speed leads to injury. Give preference to circles without ventilation (gaps), ceramics does not like them. Video about choosing a diamond circle for cutting porcelain tiles: http: // www.YouTube.COM/Watch?v = 5bn8ab9dkri dull “diamond” can be brought into working condition using brick. Walk on it 2-3 times with a cutting element, this will save the circle of accumulated dirt. How to make a narrow pruning: http: // www.YouTube.COM/Watch?v = uctfhey2j7g

What it is

The tile cutter consists of a bed (massive base) and guides fixed on it. A special carriage equipped with a cutting roller glides over these elements. Having made a furrow on the surface of the tile, you press on it with the help of an emphasis, after which the canvas begins to break off exactly along the line.

At first glance, there is nothing complicated here. But even having studied the guide for use, some craftsmen do not always understand how to use the devices. Over time, the experience comes, but its price depends on the volume of spoiled tile products.

First you should find out about the material part. There are many types of this tool. They are designed for tiles of different sizes and varieties, as well as for different volumes of work.

Table electric

This variety of tiles is a circular saw, which is fixed on the guides. At the bottom there is a table for processing with fixators.

The tile is fixed at a certain angle, and the master should simply draw a circular on its surface. In this case, special discs are used with diamond spraying.

The rotation of the saw occurs at high speed, which allows you to make an even and whole cut. Some models of tile cutters are equipped with a liquid cooling system.

Using this tool, you can make high.precision cutting. The master has the opportunity to cut off a strip of several millimeters wide, which cannot be done with a mechanical tile cutter. Another advantage is the ability to make a groove.

Stationary apparatus

In fact, this variety is a full.fledged machine designed for cutting tile products.

Has the same functions as the desktop version. But the quality of processing and capabilities in it is much higher. Tile cutting table is suitable for any tile size. Also in the electric stationary model, a higher power engine is installed.

In addition to high cost, this unit also requires a lot of space. Therefore, such equipment is used only by developers of large objects characterized by large volumes of work.

Among other things, electric tile cutters will not work to make a curved fishing line for a trimmer.

Manual mechanical tool

If you need to make an apartment repair on your own or you are building a stone house, then you will not be able to do without this tool. You can use the equipment rental service, but the cost of a mechanical device allows you to purchase it for constant ownership.

This tool should dwell in more detail. Using a hand.type tile cutter is not so easy, despite a simple design. However, glasses are far from immediately becoming. special knowledge and skills are needed.

Drilling porcelain tiles

Using porcelain tiles in the interior decoration of the premises, it is impossible to do without it drill. But how to drill porcelain tiles? Porcelain tiles are difficult to drill, because it is durable material. But small errors and shortcomings in the process of drilling can lead to tile breakdown. Therefore, you need to know not only what, but also how to drill a porcelain tile, preserving intact both tiles and a working tool.

Drinking porcelain tiles only on the front side, because, as when drilling any tile, when the drill is released, the flip part of the hole is obtained with chips. If you drill from the face, then chips on the inside of the tiles will not affect the properties and beauty of the tiles. To increase the life of the drill, the hole is drilled by two.thirds or three quarters of the thickness of the tile. Then the hole is pierced with a sharp blow. So the drill retains the resource.

Before drilling porcelain tiles, you need to outline the place and determine the necessary diameter of the hole. If the diameter of the hole is more than 6mm, then the drilling should be performed first with a smaller diameter, and then the necessary. The tile needs to be put on a flat surface by placing a wood-brown slab, a plywood or something like that, so as not to spoil the flooring.

To drill the hole of any diameter, it is better to use a powerful, low.cost drill. “Dolbeshik” when drilling tiles is not needed. You need to drill at low speeds with great effort by pressing on the drill. This is how the overheating of the drill arising due to friction decreases. It is necessary to drill strictly perpendicular to the plane of the tile, so the wear of the drill decreases so that it is better to use perpendicularity to use the rack for the drill.

So that the drill does not overheat, as well as the diamond crown along the porcelain tile, quickly wear out when overheating. Therefore, you need to monitor their cooling. Just supply a little water on a drill or crown, the water wives into the place of drilling and cool the tile and the tool.

You can drill porcelain tiles with a simple drill, with a solid tower,

tubular drill with diamond spraying

All this is suitable for drilling holes in porcelain tiles, they only break out of how many holes their resource is enough.

Advantages and disadvantages of manual tiles

Like any other tool, manual tile cutter has positive and negative qualities that should be taken into account when choosing a device for cutting tiles.

The following characteristics are distinguished among the advantages:

- independence from electric networks;

- the ability to use at any temperature and humidity;

- compactness;

- low weight;

- Low cost.

Manual tile cutter

The device of manual tile cutters is the same, there are only some differences regarding the functionality. The following working parts are distinguished:

- the base serves as a platform for the location of all working elements;

- tubular guides, along which a carriage with a cutting wheel moves;

- carriage. in addition to the cutting roller, it is equipped with a special concave paw to break off the cut part of the tile;

- The cutting element is a carbide roller rotating on the axis;

- The handle with which the carriage moves.

How to cut tiles without tile cutter

Other tools are also used to cut tiles.

Plutcore forceps

Special forceps with a plate on the top sponge. The cutting video is set from below.

It is required to conduct a video on the material, then capture it with lips, so that the furrow is in the center of the plate, and squeeze the tool.

Forceps can also be useful in the presence of a tile cutter.

With their help, fragments of small sizes are bitten off (when cutting with a tile cutter, the width of the cut part should be more than 1 cm) and form curved cutouts, which is not capable of manual tile cutter.

Corner grinder

If the tile cutter is highly specialized, then the corner grinder is used to solve a wider range of problems and therefore is available in almost every farm.

Therefore, when performing one.time work, cutting tiles are more often implemented by this tool.

Cutting is carried out by a disk. Steel discs are preferred: they are thinner than stone and serve longer.

- Segmented. Divided by slots into parts, which improves the heat sink and ensures free expansion of the metal when heated. Thanks to this, the disk is capable of 1 min. cut tiles without cooling, after which it is twisted for 20. 30 seconds. in idle mode for cooling. Due to the ability to cut the material dry, such discs are called dry cutters. Their disadvantage is the low quality of the cut.

- Solid. Another name is a disk for wet cutting. There are no slots for thermal unloading, so you can work dry without a break only 10-15 seconds. For long.term operation, it requires the supply of cold water to the cutting area. In comparison with the segment, the continuous disk cuts more evenly and better.

- Combined. Can be used for both dry and wet cutting.

In their characteristics, combined discs are located between solid and segmented:

- Cut quality: better than segmented, but worse than that of solid;

- Continuous work time: more than continuous, but less than that of segmented.

For one.time small volume. a combined disk is considered the most preferable.

If the segmented and continuous disks for cleaning the crumbs is enough to install by the other side, then with combined this option does not pass. This cutting element can be installed only by one side. Cleaning is carried out by cutting silicate brick or concrete tile.

Solid varieties of tiles, for example, porcelain tiles, cut discs with diamond spraying. According to the method of fixing diamond crumbs, disks for domestic use are divided into two types:

The second are more expensive, but they serve longer and better tolerate overheating.

To cut off the tiles of the corner grinder correctly, you should adhere to the rules:

- They start from the front side: most chips are formed when disk exit from the material.

- Tiles are cut in one pass. With each new time, the number of chips increases.

- In case of low requirements for the quality of the edge, the tiles are not completely cut: they are applied, then the module is broken. Dust is formed much less.

Since in the absence of experience it is difficult to make an even section of a corner grinder, it is recommended to leave a 3-5 mm allowance for the finish processing with a grinding nozzle.

Glass cutter

With thin tiles with a thickness of 4. 6 mm, this tool will cope. It is better to choose a type with a diamond video. Having cut the furrow, the module is laid on the edge of the table and broken.

Drill with a winning tip

Use a drill with a diameter of 6. 8 mm. It is grinded with a diamond circle to the shape of a pencil, but so as not to flow the winning attack. The tip is rounded. In the presence of faces, the angles between them are voltage concentrators, which is why the strength decreases.

A sharpened drill cut through the furrow in the same way as glass cutter. Then part of the tile is broken off.

Hydroabrizie installation

Such equipment is available in large workshops. The machine supplies under high pressure a stream of water with a diameter of 0.2 mm with the addition of abrasive crumbs. Cuts tiles evenly, quickly and along the trajectory of any curvature.

In the absence of tools, you can order cutting tiles in such a workshop.

After a short training, even a novice master makes a cut with a manual tile cutter cleanly and evenly. It should only be based on the tips above, choose a high.quality and working tool.

If it is not there, you can use an alternative option: corner grinding, special forceps or a home.made tile cutter from a drill.

What tile cutting for cutting

Choosing manual tiles, pay attention to the following characteristics:

- The mechanism of the carriage. There are two varieties: roller and bearing. The roller carriage of high.quality tile cutter initially moves easily, but soon loses its smoothness. Bearing tiles are more expensive, but have a number of advantages: they serve longer, cut more precisely and provide the carriage with a smooth move.

- The bed should have sufficient stiffness, which is provided by the ribs under the bed. The low.strength bed is bent under load and the tile breaks crookedly, not along the furrow.

- The thickness of the guides. The higher this parameter, the lower the probability of the appearance of the carriage play.

- The diameter of the cutting roller. There should be the more, the thicker the tile.

- The size of the bed. It is advisable to purchase a tile cutter with a fairly large bed, which allows you to cut large floor tiles and perform diagonal cuts.

- Manufacturer. A guarantee of the quality and durability of the tool are well.proven, time.tested brands: Sigma, First, Matrix, Rubi, S.A., Germans Boada.

- Additional opportunities. These are the ruler (allows you to evaluate the width of the cut off and the remaining parts) and the rotary bed (it is used to cut at different angles).

Before use, the serviceability of the tile cutter according to the following criteria is checked:

- The diamond video is sharply sharpened, there are no chips and potholes on the cutting edge. Otherwise, the tile breaks crookedly, you get a lot of marriage. The inferior roller is changed.

- There is no karetka backlash. In the presence of a backlash, it is eliminated by adjusting screws. If it does not help, the tile cutter is repaired or changed.

- The carriage moves smoothly. If you fuck, lubricate the guides. It is useful to lubricate and the video so that it rotates easier.

- Pure bed. Ceramics are like crumbs on it.

- The condition of rubber mats that prevent tile gliding. They must fit tightly to the base.

- The angle between the emphasis and the axis of moving the carriage is 90 degrees. Checked by the square.

Round and curly cut

Often the question arises, than cutting ceramic tiles, if you need to not reduce its length/width/divide by diagonally or at an angle, and make a round hole.

For these purposes, a coronet drill or, otherwise, a diamond crown is best suited. This issue is considered here in more detail here. It is worth noting that the presence of a more rational version of drilling on a tile or separately, but for the sake of one hole, buy expensive drills on a tile and porcelain tile, of course, you should not. And to work with the ballerinka and for drilling, it is advisable to tap the future center of the hole. Successfully removes the problem of vibration, work with tiles laid on 3 5 mm layer of water in a form coinciding with its dimensions.

The combination of several sawdust, straight and round will help to make a more complex neckline. If the transitions of the curve along which the incision is performed is quite smoothed, or a broken fishing line for a trimmer is used, it is convenient to use an angular grinder and an angle grinding machine with an appropriate disk.

Safety measures when working with tools

A hand tool is less dangerous than an electric counterpart. Dust, sharp solid particles of the processed material do not fly from under it. The need to use glasses, respirator is no longer. Many masters do not even use gloves. However, it is impossible to completely neglect security measures.

Some types of tiles have a glossy coating. When cutting and breaking tiles, this layer crumbles, flies away with small sharp particles. Working with such materials, it will not hurt to wear glasses and gloves.

When working with a hand tool, they do not always use personal protective equipment, but this is not recommended for their own safety

Before using a manual roller tile cutter, check its performance. It is better to ruin a piece of unnecessary tiles than a new workpiece. Before cutting, the workplace is prepared. Nothing should interfere under hand. The table is freed from extra items. Prepare a place where to put the necessary and unnecessary blanks.

Manual cutter is considered safe due to the lack of rotating mechanisms at high speed. A person performs all movements himself. However, the danger of injury exists. Often, during cutting, they hold the workpiece so that it does not move. You need to find its correct location, where the cutting is lacking during cutting.

Life hacks of the finisor. how to professionally cut different types of tiles

Tile work. work is not easy for beginners, requiring thoughtful preparation. In addition, it is important to find an individual approach to the varieties of material to reduce waste, and therefore the financial costs of the customer.

Tile cutting formula without prejudice to material

Considering the topic of how to cut tiles correctly, professional tiles are based on general principles.

The material must be carefully cleaned. It should not have traces of tile glue, dust.

The work involves dust formation, therefore they advise you to wear protective eyes for the eyes.

Using a hand tool, you can not overdo it. Otherwise, the broken tile is guaranteed. Having selected the power tool, you need to act confidently, clearly, but neatly.

For a spectacular resolution of the problem, cutting tiles at home, the construction environment offers different modifications of tools.

That the main thing in the operation of different units associated with the tile sharp?

It is better to work with glass cutter. expert opinion

I answer, cut the tiles, first select the right glass cutter. It is presented in the market with three variations.

Roller glass cutter. is used most often. The advantage is a thin clear fishing line for a trimmer.

The oil type model works similarly, providing cutting without damage. Thanks to the clock, the task can be performed easily and quickly.

Diamond glass cutter is more intended for an experienced craftsman, since there is a great risk of getting uneven edges. In the case you will need a “strained” hand.

A competitive technical advantage of the means is the possibility of cutting not only in a straight line, but also figured cutting of tiles is quite aesthetic. Glass cutter is used when working with tiles, ceramics.

Recommendation! For porcelain tile, hand glass cutters, electrolobsics are better not to use. They can be used as an additional tool.

The tile must be placed on a geometrically even surface, removing small particles of dirt, glue. When performing the line, you need to make efforts. The outlined edge is removed with nippers.

Advice! Approaching the line planned by the glass cutter, the nippers should grab small fragments. If you use the “big step” plots in the department of the almost cut part, there is a risk of going beyond the edge of the line and ruin the appearance of the product.

An important point remains: cutting ceramic tiles you need to completely wrap the glass cutter and keep it strictly perpendicular. Sometimes the master can be difficult, because often such tools are more used by professionals for thin types of tiles.

At a construction site where the deadlines are running out, the foreman is in a hurry, the cutting of ceramic tiles is faster than the corner grinder is carried out. But you need to know certain tricks with her.

Basic methods of cutting corner granite grinder

This type of tile is the hardest. It is wear.resistant, suitable for public premises. Deciding to cut porcelain tiles should be based on two methods.

The evenness of the line when using a corner grinder depends on the correctly selected disk. Two paths are possible here when choosing discs.

Continuous discs are applicable in the case of “wet” cutting with water to cool the tool and reduce dust. It is appropriate to use them in working with tiles.

Deciding to cut porcelain tiles at home, it will be appropriate to contact a segmented disk that suggests a “dry” method of processing. But it is not recommended to cut more than 2 minutes. We need to take a break.

How To Cut Porcelain Tile-using a tile cutter

Using a standard corner grinder, representatives of the construction sphere do not advise buying disks with a thickness of less than 2 mm. Before each procedure, checking the state of the disk for the information appearance of the chip to zero is required.

The specialist marks the future cut with a marker, placing tiles on a prepared flat surface. It is better to fix it on a workbench. Cutting is carried out on the front side. In some cases, it makes sense to make a double cut. From the “face” to the product is slightly pressed, conducting a fishing line for a trimmer, the main cutting is carried out from the end part. This secret answers the question of how to cut the tiles of a corner grinder without chips, without losses for the owner of the room.

Proven methods of cutting ceramic tiles with a tile cutter

Ordinary ceramics for the bathroom, for example, is also cut with the participation of a corner grinder. Although at home it is often more appropriate manual tile cutter.

Minimization of the formation of dust, flaws on the tile.

The tool is light, contains a cutting video that relatively quickly carries out the task. The probability of marriage is reduced at times even compared to a corner grinder. Having placed the tile under the paw on the metal platform of the structure, in one motion it is possible to quickly perform the cut. There are several types of manual tiles.

Roller options are quite simple, suitable for standard tiles.

For more solid types of ceramic tiles, mechanical tile cutter with a hard carriage is advised.

To process a particularly durable material up to 16 mm thick, the model on bearings will be the best solution.

To perform a large amount of work, this tool with a system of air and water cooling is useful. What are its advantages?

It is possible to cut tiles at an angle of 45 degrees for the design of the angles between the walls.

Ability to cut a stone, porcelain stoneware.

In the process, the head depth plays a role. Recommended value. 3 cm. The length of the cut, equal to 50 cm, matters. And the power of the motor. Before the execution, you need to make sure that the wheel is fixed, checking its degree of wear.

What useful tips should be taken into account more?

The end of the tile material is sometimes cut at an angle. Using a corner grinder, you should choose a continuous disk designed for tiles. High.quality cutting of tiles under 45 degrees will turn out when installing the product on the rib, starting to grind the rear clay part. Having discovered irregularities, it is allowed to repeat the operation.

Get a smooth edge conveniently contact diamond “turtles” or sandpaper. Professionals also advise using a corner grinder with adjusting speeds to avoid burning of the edge.

The trick from the pros! For maximum aesthetics of the angle, it is not recommended to reach the icing part by about 1 mm. Filigency of skill is determined by the experience of the operator. Passing on the glaze with a tool, the edge is not very beautiful.