Setting up the end saw

A trim saw is an important tool that helps to make even and high.quality cuts of workpieces. However, accuracy can only be achieved on a well.adjusted device. This will not take much time and is quite affordable with your own hands.

Ensuring accuracy and establishing your own tool is extremely important. This must be done before the first use so as not to spoil the blanks. Even the slightest deviation from the given parameters can deform the material.

A small scatter of a couple of millimeters is actually multiplied eight times.

Good disk

If you still use the disk installed by the manufacturer and purchased along with the installation, abandon it. Buy a removable, high.quality and sharp nozzle that can clearly fulfill the specified conditions.

The default disk can perhaps carry out a rough cutting of wooden boards in the conditions of carpentry production. For thin and jewelry, you need to buy special nozzles.

Buy wheels with a diameter of 250–300 mm and the number of teeth 60–80 or 80–100, respectively.

All about end saws

One transverse cut of the board can be made by a manual disk or saber saw, an electrician, even just a hand hacksaw. with varying degrees of accuracy, speed and labor cost. But when it is necessary to saw in the size of a thousand boards, aluminum or plastic profiles, it is better to use a specialized tool: end or end-polling end (it is distinguished by a mechanism for limiting the depth of cutting) a saw (machine).

By the way, where does this name come from. “Usoving”? The mustache not only decorates the carpenter. to saw “on the mustache” means to make cut at an angle to the longitudinal axis of the workpiece not on its entire thickness, forming a through or deaf spike.

In everyday life, an expensive and rather bulky device, most likely, will be superfluous. but if you need to regularly perform various kinds of construction, installation, finishing, carpentry or furniture work, including in small.scale production, then this is an excellent assistant. With the help of a end saw, you can, for example, build a frame building, sheathe lining of the wall of a country house, install shutters or door leafs, lay parquet or massive board and so on. Such a power tool performs operations of sawing the ends of the workpieces at a straight or determined oblique angle to their longitudinal axis, cutting the ends to the normal to the surface, the sampling of the material to a certain depth. With a combined sawing, the cut is obtained simultaneously inclined and at an oblique angle to the workpiece.

Poles saws allow you to work not only with wood: their saw discs on the teeth are fibrous materials, plastic, laminate, aluminum profiles.

R.E.M Losing My Religion (Official Music Video)

The end machine itself is quite simple. the usual disk saw of the electric is placed on a rocker.risk (pendulum) swinging in the plane of the saw disk, jointly connected to a massive supporting plate. This rocker can also rotate relative to the vertical axis of the mounting node, which allows you to make a cut at an angle of 45 ° to 90 ° relative to the longitudinal axis of the processed longer (some saws of rotation are 60 ° x 50 ° on some saws, which allows you not to move massive blanks during processing). The power of the engines of modern network “endings” mainly fits within the boundaries of 900 to 2000 watts, however, the most advanced batteries can also boast of two.kilobatniki.

At the same time, there can be many additional options for end saws. both significant and not very. Consider them in more detail.

Blocking a spindle for replacing a saw disk is a necessary thing, it is difficult to remove a disk without it and put a new one. A massive cast base increases the stability of the cutting block to vibrations, improving the accuracy of the cut. Such a base of steel or aluminum alloy is characteristic of “endings” designed for intensive operation, it is more expensive. Protection of the electric motor from overload allows you to protect the expensive motor from burnout, for example, when jamming the equipment in the processed part. This is a mandatory option in most models. Protection can be active and passive. Passive gives, for example, the belt transmission of the rotating moment from the engine to the saw disk. with excessive force, the belt begins to slip. Active is characteristic of models with a gear transmission or harmless when the caliper sits directly on the engine axis. In this case, the cut.off occurs with a sharp increase in the consumed current.

Transmission (if only the sawing card is not planted directly on the engine shaft. let’s say, like the models of Dewalt DW713 or BOSCH GCM 10 S) performs the functions of transmitting torque and lowering the number of revolutions. This is a toothed or belt transmission. each species has characteristic advantages and disadvantages. The belt does not need a closed hard case, it is not critical of some inconsistency of the shafts, provides a certain depreciation for jumps in angular velocity. this is beneficial to the bearings on the engine shaft. When jaming the saw disk, the belt gear begins to slip, saving the engine. In the case of a break in the belt, its stretching or pollution by oil, it is easy to replace it not even with the qualification of the master to the user. For these reasons, belt transmissions are used in many models of most brands. over, such a transmission allows you to move the engine away, thereby increasing the maximum depth of cut. As for the gear, it is demanding on the alignment and rigid fixation of the shafts in the housing of the hermetic gearbox. Although more noisy, such a transmission serves much longer than a belt, but at the same time requires a constant presence of lubrication. But with emergency jamming of the disk, the gears easily fail, leading to expensive repair in the service workshop.

Maintaining constant revolutions of the saw disk at a variable load. the option is rare and not cheap. In most cases, it is not very necessary, but with final cuts of solid materials it will be very useful. Like an electronic speed control (for adjusting the tool for different materials). Smooth start facilitates work with thin.spaced profiles of irregular shape, which can shift on the desktop with a sharp strike of teeth too quickly gaining disk speed. In tools with a capacity of more than 1.5 kW, smooth start reduces the peak load on the mains.

Electromagnetic brake is an important element of safety, it almost instantly stops the rotation of the saw disk when releasing the start button. It is a pity that this option is not on all “endings”. However, in a tool with a collector engine, such braking leads to accelerated wear of brushes. The backlighting of the cut zone contributes to the accuracy of positioning the working body in conditions of weak lighting. It is found, however, infrequently. While the laser indicator of the cut line for accurate positioning is widely widespread, although it is not devoid of “innate” shortcomings. Firstly, its uster is lost from constant vibration. Secondly, the emitter is clogged with dust and requires regular cleaning. Disadvantages of conventional LED backlight and laser pointer are practically eliminated in the brand decision of the Dewalt brand. Two light streams are directed from both sides directly to the saw disk, which forms a narrow shadow strip (XPS system) on the processed surface. Such a scheme does not require regular justification and ensures high accuracy of positioning the working unit.

Battery end saws

Recently, the segment of power tools with power from batteries has been developing and capturing its share of the market. And if in the case of screwdrivers, drones and even angular grinding, the advantages of independence from network cords are quite obvious, then with heavy equipment that includes end-line-ending machines, everything is not so in sight.

Battery ends are available under the brands Dewalt, AEG, METABO, MAKITA, etc. The spectrum of network tools is much wider, dozens of brands produce them, including what is attractive quasi.toned tools with batteries from batteries? Even if there is electricity on the construction site, in a 50-meter extension cord, noticeable losses often occur, which is fraught with a decrease in the power of the tool and overheating of the saw disk. In addition, the voltage in the network can be seized, and the frequency of “walk”, sometimes widely. The battery tool in this sense is more reliable. In addition, it is easier to transfer a not too weighty machine than to wear 6-meter boards to it all day.

The resource of working on one charge of battery “endings” today is not as small as it might seem at first glance. The main mass of the machines has the battery capacity-within 5 A-h, voltage 36 V, the mass of the tool in the range of 10-16 kg (by the way, the mass of network machines can reach 40 kg, you are not very won from place to place). What is enough freshly charged battery? One of the Metabo models pulls up to 200 cuts of soft wood with a cross section of 60 × 60 mm. this may be enough, for example, on a crate during the construction of a wooden house. And some models from Dewalt without recharging cut the same 200 bars, but with a cross section already 50 × 150 mm.

Batteries operate with two stresses (18 and 54 V, while suitable for some types of tools for 36 V). When connecting to the corresponding device, they automatically issue the desired voltage. By the criterion of the life cycle (number of cycles of the charge-discharge), they correspond to the former lithium-ion batteries, because they contain the same cells. New batteries can be saved by brilliant engines with up to 2 kW.

It is best to work with an expensive brand disc for a transverse saw. it gives the accuracy high, and lasts longer. If ordinary nails, modern discs, as a rule, can be cut, then the equipment will definitely crumble on the self.tapping screw. And on the boards stained with frozen cement will quickly dull. Therefore, you can advise you to purchase an additional cheap saw disk for processing “secondary” materials.

In most cases, optimal results are achieved with the following teeth profiles:

variable (alternate deviation of the side cutting surface left-right from the plane of the disk); intermittent (alternation of straight teeth and gaps).

In a combined disk, one flat cleanser has one flat toe: this improves the purity of the cut of plastic and laminate. District teeth (with peaks alternately mowed in different directions) allow avoiding-scraps when processing plywood, wood-fiber slab, wood-bruise. The number of teeth is selected from the desired ratio performance. accuracy. With an increase in the number of teeth, the accuracy of the cut is growing, but the load on the engine also increases, reducing the performance. Since for end machines, performance is rarely priority, it is better to always have more teeth. It is logical to focus on carbide.fee saw wheels. although they are noticeably more than ordinary steel from high.speed steel, they serve as an order of magnitude longer, maintaining the sharpness of the cutting faces. In small.scale production (for example, doors) of attacks (usually from the alloy of cobalt and tungsten carbide), as they get off by savings, they are undercuted with a diamond instrument, while it is more profitable to purchase a larger snapshot with more bitter.

The saw disk is characterized primarily by its diameters. external and landing. If the latter, with rare exceptions, is 30 mm (there are also 25.4 and 32 mm), then the first is very diverse. But with such wealth, the most common sizes are still distinguished: 210, 250 and 305 mm. There are also discs 190, 205, 216, 254, 255, 260, 300, 315, 355 mm.

What does the end of the end do

Modern models allow you to perform combined cuts of various materials. The disk can rotate in different directions and bend down, which provides the cut in the given directions in the horizontal or vertical plane. Features of end saws for the house represented by manufacturers, which should be paid attention to:

- The slope of the saw node. He can be adjusted in one or in both directions. In principle, both devices are functional to the same extent, because both the same saw can perform the same manipulations on the saw. However, bilateral endings are somewhat more convenient for use.

- The maximum depth of drank at an angle of 45 degrees. In most devices, this indicator is 2.5-12.2 cm. The characteristic is important, because at an angle the end saw does not saw as deep as at 90 degrees. If the depth was small, such a device can be used when working with lining and other materials with a small thickness. In other cases, when choosing a tool, you will have to compare its parameters with blanks that you need to saw.

- The depth drank at right angles. If the device is not intended for industry, but for ordinary users, you can purchase a model with an indicator of 4.5-12.2 cm. The more significant the depth of direct cut, the worter the level of electrical equipment.

- Max. The width of the 90-degree drank. These are the limiting dimensions of the subject that can process the ending. Modern devices are able to saw bars with a width of 8.5 to 43 cm based on their purpose.

The possibilities of end saw

Modern models of ending from leading manufacturers have many basic and additional functions.

If at first glance they may seem insignificant, then in the process of work the realization of how important these options are. They not only expand the functionality of the device, but also affect its durability and safety for users. Constructive nuances that may be useful:

- Clamping system. The more of them, the better the material is fixed at different angles. As a result, the quality of the saw and safety increases.

- Laser pointer. This simplifies the marking process and reduces the working hours.

- Regulation of cut depth. Limiters allow you to get the details of the carpentry compounds of various parameters.

- Maintaining speed at a constant level. With intensive loads, the speed of the disk is reduced, the built.in system allows you to compensate for the difference in speed.

- The presence of an external vacuum cleaner for removing dust particles.

How to choose a end saw

The end saws differ in technical characteristics and can be simple (ordinary) or combined type, which somewhat expands their functionality.

The difference between combined models and usual ones is that their design involves the possibility of transforming the end saw into the circular by performing simple movements of the main elements of the saw.

Model “Zubrov ZPT-255-1800” with belt transmission and length

In addition, an important functional feature is the presence of a broach, also expanding the capabilities of the equipment used.

For a stationary installation, it is better to use models that have a length of a broach that allows you to process wide wooden blanks.

Universal end saw model “Makita LH1040”

Tips for choosing ordinary and combined models

In order to make the right choice and take into account all the nuances associated with the features of using such equipment, it is necessary to listen to the advice of experienced users, which can be formulated as follows:

- The tool should correspond to its purpose. do not buy an expensive and powerful model if it is supposed to use it periodically and for personal purposes.

- In the same way, the presence of additional options that increase the cost of the model, but not used for small volumes of work should be considered.

- The presence of protection and safety means is an important point when choosing a end saw, t.to. With improper use, you can easily get an injury by working on such equipment.

- Due to the fact that the power and weight are directly interconnected, then, if necessary, it is better to choose a less powerful model, but with a smaller mass.

- The size of the saw disk and the presence of a broach determine the technical capabilities of the tool for processing the material used.

- The bed should be heavy enough to fix the saw at the place of work, and the turning table and stops must provide reliable fixation of the processed material.

Recommendations for choosing ending machines for wood

Mark “Makita LF 1000”

When choosing a model involving a stationary installation and operation in an intensive mode, you should pay attention to the following points:

- power and weight in this case are not fundamental selection criteria, and the most important indicator will be the speed of rotation of the spindle on which the purity of the cut depends;

- Without fail, all types of protection against short.circuit currents and overheating of an electric engine should have on a stationary tool;

- The size of the saw disk should be as possible, which will expand the capabilities of the device;

- The presence of a stretch mechanism is optional, but it is extremely desirable, t.to. It is also reflected in the functionality and performance of the tool;

- Equipment with additional options should only be welcomed, t.to. This also positively affects the complexity of operations performed on such equipment.

Recommendations for the choice of ending saw for metal

Metal Pille Model Model “Metabo CS 23-355”

The main selection criteria for saws designed for metal cutting are the same as for analogues involving work with wooden blanks, but, in addition, it should be remembered that:

- Different types of disks are used to work with various types of metal, therefore, special attention should be paid to their purpose and size of planting, as well as external diameter.

- The wider metal blanks to be processed, the larger the diameter of the saw disk should be.

- The protective casing should completely close the disk during operation.

- The presence of a cutting depth of cutting expands the machine capabilities.

- A more powerful electric engine has more performance and heats less during operation.

Carpet manufacturers rating

Top saws, like other electric tools, produce in many countries of the world all the well.known brands operating in this equipment market. In our country, they are most popular:

- From foreign manufacturers: Bosch (Germany), Makita (Japan) and Metabo (Germany).

- From the domestic: “bison” and “Enkor-Kravev”.

End saw Model Corveta-4-430

For obvious reasons, domestic models are most popular in the budget segment of equipment, and more expensive foreign analogues in the classroom class of professional tools. The models of which manufacturers are most popular is quite difficult to determine, t.to. In terms of basic parameters, they are similar, and the choice of users in this case is carried out on personal preferences to the brand of the tool for previous experience with a specific brand.

Types of gearboxes, their advantages and disadvantages

The connecting link between the electric motor and the saw disk is a gearbox that transfers and transforms the torque of the engine. Two types of gearboxes are used on end saws. with gear or belt transmission.

Gear gears that provide a hard bunch of shafts seem more reliable. They do not slip and do not fly like a belt, and there is nothing to break there. It would seem that manufacturers of end saws should give preference to such a reliable system. However, in practice, the belt transmission on these tools can be seen more often than the gear.

What is the reason? Reliability of gear gear has a flip side. In the event of a freelance situation, the tooth gearbox may fail, and then it will require its complete replacement or serious repair in a specialized service belt transmission can also be looked at different eyes. Yes, sometimes the belt flies or even breaks, but in order to install it in place or replace it with a new one is not required of special knowledge and skills. an ordinary user will cope with this task. In addition, the belt provides some depreciation of radial and axial vibrations, which helps reduce the wear of bearings and other engine units.

With an emergency overload of the tool (for example, when jaming a saw disk), even a well.stretched belt will slip through, which will save the metal parts of the motor from destruction. Yes, and the noise saw with belt transmission produces incomparably less, which is also a rather significant factor.

Parting saw with belt gear.

By the way, some manufacturers (including such authoritatives as Bosch and Dewalt) at all of their models completely excluded the gearbox, installing the saw disk directly on the engine shaft. Such a solution also has its pros and cons of. On the one hand, the load on the bearings increases, on the other hand, the noise published by the tool is reduced, the reliability of the design increases, maintenance and repair is simplified.

Power and number of revolutions

The power of end saws can vary depending on the model from 800 to 2500 watts. 1600–1800 watts are considered the golden middle. instruments of just such power are most in demand today, because they do equally well with their task both in home workshops and in small production.

What gives us knowledge of the magnitude of such a parameter as power consumption? Firstly, the correct correlation of the power of the end saw and the structure of the processed material will avoid overload of the tool, which extends the time of its active operation.

Secondly, the larger the power of the saw, the greater the diameter of the disk that can be installed on it. As an example confirming this statement, we compare the two end saws from Bosch. On the PCM 7 model, whose power is 1100 watts, you should select a disk with a diameter of not more than 190 mm. But for GCM 10 J Professional with a capacity of 2000 watts, a disk with a diameter of 254 mm is suitable. It should be borne in mind that with an increase in the power of the saw and the external diameter of its disk, the dimensions and the weight of the tool increase. So, the first of the models given as an example weighs 9 kg, and the second is already 14.5 kg.

Another technical characteristic that is worth paying attention to when choosing a end saw is the number of revolutions of the saw disk. The value of this parameter lies in the range from 3200 to 6000 about./min. Pure and high.quality cut (without chips of coating, delaying wood fibers, etc.D.) possible only when working at high speeds.

So, for example, with a 260 mm saw diameter, its angular velocity should be at least 2800 about./min. In expensive professional models, the angular speed, as a rule, is not lower than 4000-5000 about./min. Even with large disks diameters. A number of manufacturers offer end saws, the number of revolutions in which can be adjusted depending on the type of work performed at the moment.

How to put a corner on the end saw: how to set 45 and 90 degrees

You can need the adjustment of the angle of the sawing angle both for working with wood and metal. This is especially true for the cut of metal profiles or baguettes, because the exact angle of the cut in these cases is very important for obtaining the desired and accurate result of work.

In order to properly adjust the end saw for an angle of 45 degrees, it is necessary to do the following:

- Adjust the stops of the tool to avoid errors when setting angles;

- Install the tool so that the saw disc is located exactly at an angle of 90 degrees with respect to the table;

- Put his block on the saw table and press the square to the disk so that it does not touch its teeth;

- Now it is necessary to adjust the stops in such a way that there is no gap left between one of the sides of the square with an angle of 45 degrees, and it was tightly pressed to the saw disk;

- In order to check how correctly the adjustment was carried out, it is worth cutting off four parts at this angle and collect them into the frame, if the docking joints are uneven, and there are gaps between the details, then this process should be repeated again.

How to Install a Stair Handrail on Stairs | This Old House

Powering a right angle is somewhat easier. If the end saw has only one stop in the stop, in this case you need to loosen the adjustment part and move the table closer to the disk. If there are two parts, then one of the corners is first set in a perpendicular position to the saw disc, and then the second is aligned in parallel to the first to avoid error when adjusting. In this case, not a square is used, but a rail with a thickness of about 1 cm.

How to adjust the end saw to zero

Usually, in the zero position, the end saw is installed at the manufacturer. But in the event that you have previously adjusted the tool and want to return it to the zero position, then in this case it is worth adjusting the emphasis for 0 degrees and press the disk to the guide tool. In this case, all parts should be tightly pressed to each other, which can be adjusted with screws.

By purchasing a end saw, many even before adjusting it face a problem such as blocking the tool. Most manufacturers for security purposes pack the tool in blocked form. And if from the instructions it is not always clear what to do with this, then for unlocking you need to do the following:

- Click the lever located on the tool control handle. In the process of unlocking, be sure to observe safety precautions, otherwise you risk not only harm the tool, but also get injuries;

- Stretch the locking pin of the end saw. This must be done very carefully and slowly to avoid damage to the tool and risk of injuries;

- Gently lower the lever on the control handle until the instrument blade comes out and the lever itself will take the upper position. At the same time, it is worth observing all precautions and not holding your hands near the saw disk.

That’s all, there is nothing complicated in unlocking the end saw. The most important thing at the same time: do not rush and observe safety precautions. Thanks to simple thought.out actions, you can easily unlock your tool.

Appreciate the power that you hold in your hands

Miter’s saw does not have the same freedom of movement as a circular saw, but it deserves the same respect. This can ruin your work if you do not hold it exactly during cutting, but it will also lead to a short work of your fingers if you do not take care of how you keep your job. Remember that the end saw is intended only for transverse incisions. never try to make incisions. Follow these tips for safe use:

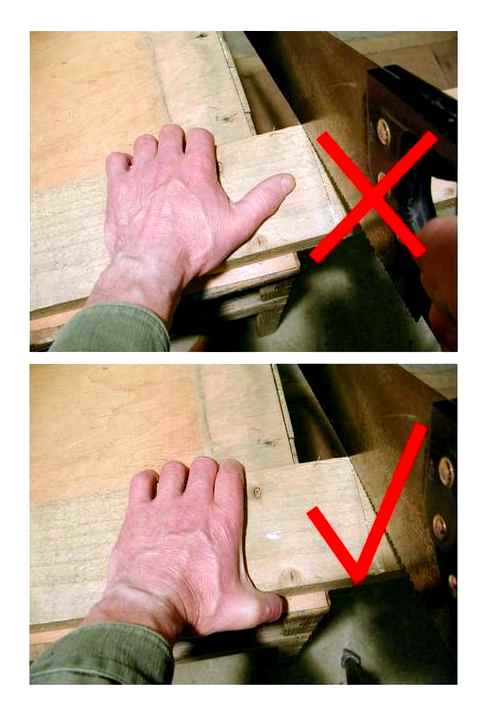

Keep your fingers at a distance of at least 6 inches from the blade to avoid injuries.

- Operate the saw on a flat stable surface. Do not put it on the ground or on a shaky table. Make sure that the region is well lit and free from homeless wood and other garbage.

- Make sure that all the protective equipment of the saw, including the protection of the blade, the engine brake and the rotary locks of the table and saw, is installed and works correctly.

- With one hand, fix the work on the fence, and control the saw with the other hand. Never cut by hand. Keep your fingers at a distance of at least 6 inches from the blade.

- Support the ends of long pieces of wood that hang over the saw table by more than half of their total length. This provides a cleaner cut and prevents fingers slip. Do not cut pieces of wood with a length of less than 8 inches.

- Wear protective glasses to protect your eyes from split wood and sawdust.

- Wait until the blade ceases to rotate before cleaning the wood from the table. Never touch the blade while it still rotates.

Hipples

Read the leadership of your owner. It contains a number of other tips and safety recommendations that you need to know before using your saw.

Cutting installers use the end saw for cutting angles at the ends of the skirting boards.

The cut at an angle can be defined as an angular incision made across the grains of wood. You can note the angle by drawing a fishing line for a trimmer on a piece of wood, or you can use the angular indicator on the table. The drawing of the line independently gives the most accurate results, because table sensors on all, except for the most expensive saws, as a rule, are disconnected by one or two degrees. However, when tilting the ends of wide boards, such as skirting boards, using the endow function, it is necessary to rely on the corner sensor.

- Draw a fishing line for a tree using a bevel or ruler.

- Put the tree on the table and press it to the fence. Comers the far end of the tag about the center of the open throat of the fence.

- Loosen the table lock and turn the saw to the desired angle, then lower the blade and accurately adjust the angle in accordance with the direction of the line. Rightly tighten the lock. Adjust the wood so that the blade is next to it from the pruning side.

- Raise the blade, press the trigger and wait until the blade reaches the maximum speed of rotation. Lower this hand and rotating blade down into the forest and continue to lower it until it drops on.

- Let go of the trigger, raise the blade and wait until it stops rotating before taking off the firewood.

Hipples

Do not start cutting until the blade reaches its full speed of rotation. If you start earlier, the blade can break a tree and spoil the delicate objects, such as moldings or skirting boards.

Using an integral end saw

The composite end saw allows you to simultaneously perform ends and mowing.

On an integral end saw, the adjustment of the bevel and ending does not depend on each other. You make a bevel, setting the saw angle on the horizontal axis on any angle, different from 90 degrees. Usually you have to rely on the manometer to set the angle due to the complexity of aligning the blade with the angle of inclination marked on the tree.

When performing an integral cut (in which pruning and chamfer are performed simultaneously), draw a fishing line for a trimmer for cutting at an angle, set the cutting angle, then set the angle of inclination. Adjust the part on the table so that the saw blade is as if on the cut side of the line, as with a perpendicular section, and then make a cut.

How to use a end saw

When the saw is chosen, it must be configured. Then she will be ready for use. Should act according to the rules. And you need to figure out how to control the tool depending on the processed material.

On wood

A trigger switch is used for launch. But the tool will not start performing cuts until the lock lever is pressed. After that, the equipment is lowered to the material. Before work, it is recommended to put on protection products to protect yourself from chips that will appear when processing wood.

The wooden workpiece should be held with your hand if the cut occurs at right angles. But if the work is performed by a newcomer, it is recommended to use the clamp. It holds the material motionless, allowing you to focus on the cut. The clamp is necessarily needed if they work with blanks not at right angles, but at any other.

To adjust the cutting angle, it is necessary to use the platform reversal. It is necessary to unscrew the handle acting as a turning lock, and squeeze it down. The platform is ready to move.

Attention! When changing the angle, the sawing area increases. This reduces the convenience of using a saw, so it is necessary to use clamps.

To change the angle of cutting of wood, you can use the vertical inclination of the end. The fixation handle is first weakened, set the desired slope and fix it again.

For metal

Before turning on the tool, it is necessary to make sure that its nodes and the capabilities of the disk are free to move. To carry out the oblique saw, it is necessary to loosen the mounting screw at the rotary table and start turning it to the desired angle. The set position is immediately fixed. If the work is long, periodically, you should check how accurate the ending is. This is due to the fact that after some time there is a weakening of the mounting screw.

If you need to saw with the left inclination, then it must be configured correctly. The mounting screw of mounting the inclined angle is released and the desired angle is set. To fix the installed parameter, the screw is tight. After that they continue the saw.

Important! When the work is finished, after turning off the tool, you must wait for the cutting disk to completely stop. After that, the handle returns to the position up.

It is forbidden to remove a protective casing from the device. It rises when the disk is lowered down for the saw.

Safety precautions when cutting a end saw

When working with the tool, you must observe safety precautions. Before starting the saw, you should check the performance of each equipment element. Fixing parts, casing, various protection systems and so on.

Near the worker there should not be extraneous items, blanks. When the tool is turned on, you should hold the handle tightly. The surface to be cut should be held with a clamp and be tightly fixed. Supports are selected taking into account the material with which they work. At the same time, the cut of the workpieces of metal cannot.

After turning on for a few minutes, the tool should work idle. This will make sure that the unit is working. The user must take the most convenient position. For security, it is also recommended to use special means to protect hands, face.

How else can you use the end saw

The presence of a end saw on the farm is a universal tool of a wide spectra, which can be made not only of corner, but also ordinary transverse cuts of various materials. The end can replace the wood machine and the circular saw if necessary, and be used for longitudinal sawing of wood and other materials.

Most importantly, no matter what work you do with a end saw, it is very important to equip it with a sawing disk suitable for this work. Despite the existence of universal multifunctional disks, such options will not give perfect cut results. This is due to the fact that for each material a disk with a certain number of teeth, a specific inclination angle and the type of sharpening are required.

Parting saw: Wastes of work

There are several useful techniques that can certainly be useful to you when working with the end saw:

- For example, if you purchased boards and want to get rid of chips and roughnesses at the edges, you can easily do this with the help of ending by choosing a saw disk with a suitable number of teeth for a tree;

- You can make parts of the same size, for example, if you make a stool or chair using stoppers. In order to get parts of the same size, you will need locking blocks that need to be pressed to the corner of the clamp, and then your details are the same without errors in the length;

- When working with very small details that you slowly lead to a working saw disk, there is a risk of injury. Therefore, for such cases there is a small cunning. You can push small blanks with a pencil with an eraser at the end, which tightly adjacent to the details and does not slip during the pushing process;

- When the accuracy of the length of the workpieces is important, usually the desired length is measured by the ruler. At the same time, many forget to take into account the thickness of the saw disk. To obtain the required size, it is enough just to cut the cut not in the middle of this line, but immediately after it, this will be precisely measured a cut of a wooden workpiece.

Now you know how to saw a ended saw and for what purposes it can be used. The main thing is to remember: for each type of work, choose the right saw disk to get the expected cut and speed. And do not forget about safety measures when working with a end saw.