About hydraulic jack oil: what kind of oil to put in the jacks

To keep hydraulic actuators in operation, they need a special fluid that protects them from wear and tear. Hydraulic jack oil helps the jack system function in various temperatures and humidity conditions.

The main thing that is required of such an oil is to carry out the transfer of energy in steering, driving and drive. This fluid is irreplaceable assistant in maintenance of bridges, production mechanisms, locks and various apparatuses, which need lubricant.

There are different types of hydraulic oils:

- oil for industrial equipment and transport;

- oil for ships;

- oil for aircrafts;

- Oil for shock absorber and hydraulic brake systems.

Each type of fluid has its own composition, and therefore still distinguish the classification “A”, “B”, “C”:

- “A”. mineral oil with no additives;

- “B”. with anticorrosive and antioxidant additives;

- “B”. refined oil, which contains anti-corrosion, anti-wear and antioxidant additives.

There is also an international classification, according to which fluids are divided into synthetic, petroleum and water-glycol ones.

Qualitative characteristics of oils

When choosing a service fluid for tools, you should always pay attention to its qualitative characteristics and compare them with the model of the device, because each of them may have its own requirements.

The main oil properties are viscosity, corrosion resistance, resistance to oxidation, flash and pour point, and lack of aggression to the materials of the mechanism.

Viscosity. It directly affects the power of the unit, the movement of material through the units of the device and the lubrication conditions in general. If the viscosity is minimal, the system is considered more reliable, but it will wear out more quickly with friction and at low values it is still possible for the fluid to leak in the valves. Increased viscosity is not always good for the equipment, since at low temperatures or with low power the whole process becomes more complicated.

Corrosion and oxidation resistance.

The greater the oxidative and chemical stability of an oil, the longer it will be good for your equipment.

If there is not enough stability for oxidation, the viscosity of the fluid begins to change and deposits appear. In addition, the material of the device, which can be metals and alloys, is affected by the oil. When oil oxidizes, acids and water are released, and material corrosion begins sooner or later. And to prevent this, corrosion protection additives and special inhibitors are added to the lubricant to slow down the oxidation process.

In addition to the viscosity and resistance of the oil to oxidation, whether or not the fluid foams is equally important. Inside the equipment, from time to time sharp pressure jumps occur, and then air separates from the substance and then becomes foam, which is not very useful and also affects the appearance of erosion.

What is a hydraulic jack

As is clear from the name, this device uses the force of a pressurized fluid and the communicating vessel principle. Oil is used as the fluid for its optimum performance characteristics for the job. The jack body itself is made of high-grade steel and is both a reservoir of oil used in the work and a guide cylinder for the piston that lifts the load.

The advantages of this device over its mechanical “counterpart” are as follows:

- Ability to manipulate massive loads, high efficiency of up to 80 percent;

- Affordable price;

- Easy to use and compact;

- The overall rigidity and reliability of the design;

- The ability to move smoothly and fine-tune the height to which the load is lifted;

- High prevalence.

Among the disadvantages of such a jack are the inability to adjust the height during lowering, as well as the relatively low overall height to which the load is lifted. Speed of operation also leaves much to be desired.

The hydraulic jack can be of two types. a bottle jack and a rolling jack. The latter, as the name implies, rolls under the load and is very small in size. As for the first one, it is nicknamed as such because of the characteristic shape of the cylinder, similar to a bottle.

What is the jack for?

The first thing that comes to mind is motorists who often use these devices to change wheels. In addition, jacks are used in construction and other works, and there they can be extremely massive and powerful. capable of lifting up to two hundred tons.

In spite of the high pressure and the total tightness with which the jack holds the oil, the amount of oil still decreases due to micro leaks. Bottle jacks must also be stored horizontally, otherwise the oil will leak out. In general, the oil in the jack should be changed from time to time in order to ensure the best operation of the device and its high efficiency. In general, experts recommend that you change the oil at least twice a year. But if the equipment is constantly used, then the replacement, along with flushing, is at all on a monthly basis.

Choice of material

Car owners often wonder what kind of oil they need for the jack.

Tip: Only choose high quality oil and never mix it with any other fluid, including brake fluid or other types of grease. Mixing will lead to breakage and risk of losing the load during the working process.

The jack should be filled with quality oil that meets the following specifications:

- the lubricating fluid must be well filtered;

- the foaming level is as low as possible;

- Viscosity index and temperature limit are chosen as high as possible;

- high index of anti-corrosion protection.

To fill jacks, use fluids of brands I30A, I40A or I50A, used in operation of industrial machines. Specially formulated hydraulic oil is the best option.

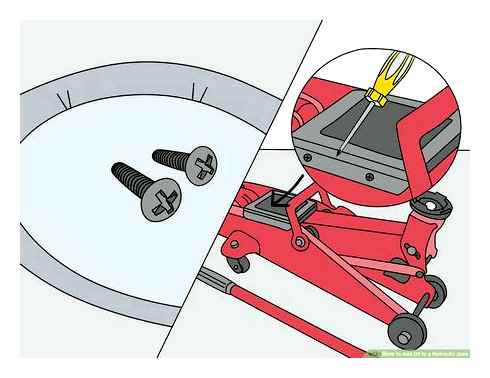

Filling mechanisms

The following is how to properly pour the recommended oil into the jack. Sometimes, if transported incorrectly, hydraulic fluid can leak out, and cavities are filled with air. This will cause the jack to fail. In such a case, oil change is necessary.

The rack and pinion mechanism is quite large, and it is used not only to lift the body, but also to repair old buildings. Before changing the lubricating fluid, it is necessary to lower the mechanism completely. To be sure, you can remove any residual stress by turning the discharge valve counterclockwise.

The filler neck is usually located on the reservoir body, more often on the bottom of the cylinder. Release the neck from the bolt or the plug which protects the oil in the tank. Then, you need a grease gun, the nozzle of which should be inserted into the neck and make the filling.

Hydraulic fluid is sufficient when it begins to overflow. Now turn the bolt or plug tightly.

A slightly different way of filling the bottle jack with lubricating oil. But first you must also make sure that the mechanism is lowered to the stop. Use the same method as for the rack and pinion jack to insure against damage.

In a bottle design, look for the plug on the top of the master cylinder body. Firstly the plug is removed and the filling is made with oil can, which is filled with hydraulic oil beforehand, having removed the air from it. The oil level should be within 1/8 inch of the oil fill hole.

Oil change in the hydraulic jack has its own peculiarities. Before pouring, the mechanism should be disassembled and cleaned. Dirt and rust can form on the piston. Next, the gaskets must be inspected (they wear out quickly enough) and replaced if their integrity is compromised.

Tip: If you drain the old oil you may lose the metal ball in the valve. Without this small part, the jack will not work. Drain with the utmost care.

Do not open the valves yourself. This can put the entire assembly out of service.

Before you fill up with oil, pump the mechanism so that it is free of air and drain the old fluid. Then you can fill it in through the hole in the jack. It closes tightly with a threaded plug.

The required level is marked by a notch on the body of the pump. When the level is reached, the plug is screwed in and the mechanism is pumped to get rid of air voids. The piston should be raised to its maximum. Then unscrew the cap again and refill, then pump again. This is done several times until the liquid begins to pour out. This is an indication of proper priming. The procedure is easier to do with a helper.

As you were able to make sure, filling and changing the oil in the jack is simple enough, you just need to follow the recommendations with which you learned in this article and do this operation yourself will not be difficult.

The primary causes of failure are

The jack, which can be repaired at home, can have several causes of failure. The most common ones are: complete or partial failure of the device to lift heavy weights, as well as oil leakage. Each of these problems needs to be repaired immediately.

The jack (repair, oil change, characteristics are described in detail in this article) very often fails as a result of leaking oil. If so, you must disassemble the unit completely. Be sure to remove the pistons and check for corrosion. Thoroughly clean all components and remove all contaminants of any kind. Now check the stem. If you find that it has a bent and broken shape, you can not even try to perform the repair yourself. In this case, you will most likely have to buy a new jack.

Another common cause of failure of the device is considered clogging or breakage of special valves, which, in fact, are responsible for lowering and lifting the mechanism.

Let’s get acquainted closer!

As the name implies, the hydraulic jack works on liquid (oil). Its leaking glands and valves are the most common type of tool failure. Therefore, when working with this kind of jack, it is recommended to monitor its condition and the presence of oil in the reservoir.

Read also: What is the width of the profiled sheeting

In addition to oil leaks to the problems of the hydraulic jack can include corrosion, which leads to limitations when lowering the mechanism, and the bending stem from the excessive load.

Do not forget about the timely maintenance of the hydraulic jack, the need to replace the o-rings and the oil itself. But before you run headlong to buy a tool and look for places to fix parts, it is worth examining the manual that comes with the jack.

If it is not available, consult the manufacturer. Better yet, find a video on the Internet, where someone before you dismantled a similar type of device. Also remember to buy a repair kit for your jack. Its not including delivery (for Moscow and Moscow region). Agree that it is much cheaper than buying a new device. it is possible to do still other and to pick up similar sealing rings and gaskets in automobile and sanitary stores (thanks it mainly consists of them).

Construction of a hydraulic jack

Hydraulic jacks are designed to contain fluid. They can be by device:

There are hooked, jacking, two-level, bottle and diamond-shaped hydraulic jacks.

The design of any jack consists of the following parts:

- body. is a cylinder in which oil is poured;

- the lever;

- piston or plunger. is inserted in the housing and is the main working element;

- Drive handle;

- discharge and suction valves;

- Pressure pump.

Operating principle of a hydraulic jack

The design uses the communicating vessel principle. Force is applied to the actuator handle (by electric motor or by hand). The lever is used to apply the force to the discharge pump. Oil gets to the bottom of the cylinder, when you pull the lever or start the electric motor. piston rises. Pressure relief valve, which consists of a discharge valve and a suction valve, keeps oil pressure at a constant operating level. The suction valve is on the inlet to the tank and does not let oil back in when the piston is lowered. The discharge is installed at the cylinder inlet and does not allow oil to escape while the piston is being lifted.

To release pressure and lower the weight, open the valve with the special screw.

What is the difference between hydraulic jacks and other types of lifting equipment?

- They work smoothly and quietly thanks to the fact that the working fluid is not compressed;

- very stable;

- the design is rigid and sturdy;

- small dimensions;

- The crispness of the brakes;

- low force and high efficiency (up to 80%);

- precise stopping;

- high load capacity.

The hydraulic mechanism can work with objects set very low, lifting them off the floor. This is a big advantage over other types of lifting devices.

- low speed of operation;

- low lifting height;

- inconvenient transportation (must be positioned strictly vertically to avoid oil leakage);

- The lowering height of the load cannot be adjusted.

In the event of a breakdown, repair is more complicated and expensive than its mechanical counterpart. The hydraulic lifting device works with loads weighing from 2 to 200 tons.

Special purpose devices are capable of lifting very bulky loads to great heights, locking and holding.

The single-rod hydraulic bottle jack is very easy to use, so its variations are the most widely used.

The jack has a low seating position and is mounted on the wheels. The levers for lifting the load come out of the body. Usually such equipment has a drive handle of sufficient size to reduce the forces applied. This type of mechanism may only be operated on a firm and smooth base.

Long jack use is possible only if rules of operation are precisely observed. One of the prerequisites is a timely oil fill, control of oil level and cleanliness.

How to fill the jack with oil correctly

Before changing or refilling oil completely, drain off old oil and disassemble the jack and clean all parts from deposits and dirt that may have accumulated. Check the rubber parts for wear and damage. Replace them if necessary.

Valves must be treated with particular care during cleaning. Do not disassemble them unnecessarily, so as not to lose or damage small parts. springs and balls.

After cleaning, reassemble the jack and lower the jack to the stop. To do this, turn the exhaust valve head counterclockwise and apply some force to the stem.

There is an oil fill plug at the top of the master cylinder housing. It must be removed.

We have already decided what kind of oil we are going to pour into the bottle jack and what kind of oil the hydraulic jack will protect in the best way.

Use a grease gun or syringe to force hydraulic oil into the fill hole. Make sure there are no air bubbles in the fluid. air in the system prevents the jack from functioning properly.

The fill level should be about 3-4 mm below the lower edge of the fill hole.

Reinstall the oil fill plug. Pump the jack without load until the jack stops and lowers the rod. Remove plug and add oil to correct level. Replace the plug and repeat the pumping process several times. This will remove any air trapped in the system.

Oil Change Recommendations

Before changing or refilling the operating fluid, read the jack operating manual carefully and follow the recommendations in it.

The hydraulic jacks should not be filled with brake fluid or alcoholic beverages as they can damage the rubber seals and gaskets used in the unit.

The oil should be poured into the jack in small portions, making sure there are no air bubbles in the fluid. After filling it is necessary to bleed air that got inside together with oil. To do this, the jack must be fully inflated several times (raising to maximum and then lowering). After that the plug is firmly seated in the filling hole.

Do not disassemble the check valves and blocking valves unless necessary. Valve springs and balls must be handled with particular care.

Only use special quality formulas to fill the jack. Saving on quality will not only shorten the life of the tool considerably. Fluids not designed for hydraulic jacks reduce the safety of these devices and cause accidents.

Timely maintenance and the use of quality oil for a hydraulic bottle jack will ensure a long service life.

Filling the bottle jack

It remains to consider the topic of filling the bottle hydraulic jack with oil. As mentioned above, its design is somewhat different from that of the rack and pinion model. Of course, the process of filling the oil in this case will also be different from the first variant.

You should start the work from the same place where you started the previous time. First, make sure that the hydraulic bottle jack is completely lowered. You can use the release valve, which turns counterclockwise, to remove excess tension.

Now you need to look for the fill hole. In this case, it is located on the main cylinder of the device. This refers to the cylinder, which also has the function of the housing. The plug is most often positioned 1.3 inches from the top of the unit.

Now you can proceed directly to the process of filling the hydraulic jack with oil.

First of all you have to remove the bolt or the plug from the oil filler neck.

It is done very simply, so there is no need to go into detail about this process.

The filling process should be stopped as soon as the oil level rises to 0.3 cm under the fill hole.

Then the oil can is taken again. It must first be filled with oil. This is very simple to do. By the way, you can use the most primitive version of this device in your work. The air is simply bled out and the remaining space is filled with hydraulic oil. advanced versions of the devices can be used. The market offers many solutions for this problem. In some cases, homemade units can also be used. This is not forbidden. It all depends on a person’s abilities, as well as what equipment he has at his disposal. So, the spout of the oiler is placed in the filling hole.

Read also: Metal hardness translation table

The next step is the actual filling process. This must be done very carefully so as not to spill unnecessary drops on the housing. Pour the fluid in until the distance in the reservoir from the oil to the fill hole is 1/8 inch. The action should now be stopped and the oiler removed from the cylinder.

All that remains is to put a plug or bolt in place. It is very important to keep the hydraulic jack in its original position so that the fluid does not start to spill out.

The main causes of failure

The jack, the repair of which can be carried out at home, can have several causes of failure. The most common of these are: complete or partial failure of the unit to lift heavy loads, and oil leaking. Each of these problems should be repaired immediately.

The jack jack (repair, oil change, characteristics are described in detail in this article) very often fails as a result of leaking oil. In this case you will need to completely disassemble the device. Be sure to remove the pistons and check them for corrosion. Thoroughly clean all components and remove all contaminants of any kind. Now check the stem. If you find that it is warped and distorted, do not even try to repair it yourself. In this case you will most likely have to buy a new jack.

Another common cause of failure is considered a clogging or breakage of special valves, which are actually responsible for lowering and lifting the mechanism.

Types of jacks

To work with this device does not require much physical effort. Just push the lever and the hydraulic piston begins to lift the load. Such systems are capable of easily lifting a structure weighing 50 tons. The industry produces several types of these systems:

The main advantage of these products is their large lifting capacity. This made it possible to work with jacks at service stations, to perform various repair operations with any kind of heavy machinery.

The only disadvantage of this apparatus is considered the impossibility of transporting the jack in an upside down position. Transportation should be carried out only in an upright position.

Choice of material

Car enthusiasts often wonder what kind of oil is needed for the jack.

Tip: Choose only high quality oil and never mix it with any other fluids, including brake oil or other types of grease. Mixing will lead to breakdown and the risk of losing cargo during the work process.

It is necessary to fill the jack with quality oil that corresponds to the following indicators: