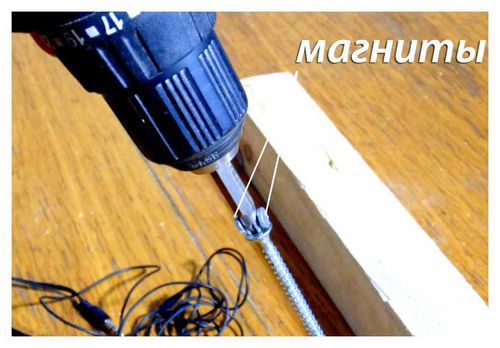

Magnetic tips

Most of the craftsmen, who, even if not great, but still have experience with self-tapping screws, know that at home there must be special magnetic bits for bits. Thanks to the use of such attachments, the screw is held on the surface of the bit, even in the case of difficult work, at a large angle of inclination.

3 ways to keep a self-tapping screw on a broken screwdriver so that it does not fall off

In the modern world, when carrying out construction or repair work, many craftsmen often prefer to use self-tapping screws instead of ordinary nails, as well as special screws. This is due to the fact that a self-tapping screw is much easier and faster to drive into the surface of the wood than a nail. Also, screws are often used in cases where it is necessary to fix the metal of the structure to the surface or to each other. To work with self-tapping screws, a screwdriver is usually used.

In order to quickly, and most importantly, reliably fasten various elements to each other with the help of self-tapping screws, you must first pick up a special bit, which is used in combination with a screwdriver. However, such situations often arise, especially if it becomes necessary to fix structural elements at an angle, when the self-tapping screw begins to constantly slide off the bit of the power tool and fall to the floor. To prevent this from happening, there are several different ways that allow you to securely fix the self-tapping screw and use it when carrying out even the most difficult work with a large angle of inclination of the power tool.

Scotch tape or duct tape

The bit is a special attachment that is installed in the chuck of a drill or screwdriver. Thanks to its use, the user can quickly tighten a variety of fasteners, such as screws, bolts or self-tapping screws. According to their classification, bits are:

- Flat;

- Cruciform;

- Hex.

There are also special nozzles for nuts, as well as similar devices, which are made in the form of an asterisk. So that, during construction or repair work, the self-tapping screw does not constantly fall off the bit and does NOT slip away, it can be glued using ordinary electrical tape. To do this, you need to take a small strip of electrical tape, attach a self-tapping screw to the broken one and pasted it over the outer circle of the cap. It is worth noting that it is not necessary to apply a large amount of electrical tape, since it will still have to be removed after work.

If you don’t have electrical tape at hand, you can use ordinary scotch tape or the so-called masking tape. To do this, cut off a small strip of tape and make a hole in its central part. Then you need to insert a self-tapping screw into the hole and place it on the screwdriver bit. After that, the tape is carefully glued together with a self-tapping screw.

How to magnetize a bit yourself

If you have Special magnetic nozzles, scotch tape, or electrical tape at hand, then in this case you can try to magnetize the bit on your own at home. To do this, you need to take two magnets (preferably neodymium) and place a bit between them. It should be noted right away that this is a very lengthy process, which takes a lot of time.

You can use a battery to magnetize the bit. To do this, take a piece of copper wire, remove the insulation from it and wrap it in small turns along the bit. Then the edges of the wire must be connected to the battery, after which the bit will begin to magnetize. However, it should be noted that in this case the magnetization effect will last for a short time.

It should be noted that today on the market there are special devices that allow you to magnetize a variety of objects and hand tools. In addition to bits, such devices are perfect for magnetizing screwdrivers. Their advantages include the fact that they almost instantly magnetize any metal object.

There are several different methods and life hacks that allow you to screw self-tapping screws into hard-to-reach places, holding them directly on the broken screwdriver, and not allowing them to constantly slide off. However, if there are no Special magnetic attachments at hand, it is inconvenient to constantly use tape or electrical tape (after all, when carrying out complex work, when you need to screw in a large number of screws, it is very problematic to constantly wrap them with electrical tape). In this case, you can take two small magnets, for example from the cheapest Chinese headphones, and attach them to the surface of the bit. After that, a magnetic field will appear, which will not allow the screw to break.

Torx hole

Bits of this type are called asterisks. Provides reliable adhesion to the heads of bolts and screws, eliminating slippage. Used where a lot of force is required to tighten fasteners.

Head bolts of this type are most often found in cars, household appliances.

There are two types of markings, for example Torx8 or T8. Diameter is indicated in mm.

Bits from T8 to T40 are suitable for the screwdriver. In various electronic devices there are also smaller sizes, but working with a screwdriver with such bits will NOT work, you need to use a screwdriver.

Torx hole sprockets may have an internal hole.

PH. short for Phillips

The bit has a cross-slotted, widening near the shank and forming an angle of 55 degrees at the apex, it is clearly and securely inserted into the screw head.

Sizes from PH0 to PH4. The number in the marking indicates the size of the cross. The larger it is, the larger the bit is for the larger self-tapping screw. Bits in size PH0-PH2 are used for the most common screws with a diameter of 2.5-3 mm. PH4 is rarely used, in the repair and installation of large-sized structures, in the automotive industry.

The most popular bits are PH2 and PH3, they are most often used for all types of black screws, including for twisting thin-walled metal profiles. “bugs”.

The PH standard is universal, fits most other types of self-tapping screws.

PZ. short for Pozidrive

Bits are used for screwing self-tapping screws with Pozi standard splines and medium thread pitch and universal countersunk (UP).

This is a cruciform bat with 4 large ribs and 4 additional diagonal ribs forming a “double cross”. The angle at the top is 50 degrees. This design provides a larger grip area than the PH bit.

The torque transmitted from the screwdriver to the bit and then to the screw or self-tapping screw will be much higher.

Before changing the nozzle in the screwdriver, check if it is disconnected from the mains.

In most cases, PZ bits are used for removing rusted or seized screws.

Bits of this type are indispensable for screwing self-tapping screws into materials with a dense structure, such as hard wood, compressed artificial materials. They can be twisted at an angle. Screw heads and bits are NOT damaged.

Sizes from PZ0 for self-tapping screws with a diameter of 2.5 mm to PZ4 for self-tapping screws with a diameter of more than 4 mm and anchor bolts. The most popular sizes are PZ2 and PZ3.

Screwdriver bits: how to choose their types?

- Types and marking of bits

- PH. short for Phillips

- PZ. short for Pozidrive

- Torx hole

- SL. short for Slot

Everyone who has dealt with the construction, repair of premises, household appliances, cars, furniture assembly knows that tightening and unscrewing a large number of bolts, nuts, screws, screws and other types of fasteners is not an easy task, requiring a lot of time and effort.

A screwdriver is similar to an Electric Drill, only instead of a drill it has a bit.

With the advent of soft-start screwdrivers and drills, the job has become much easier. But a screwdriver without bits is a useless thing.

A huge number of bits from various manufacturers are presented in the building materials markets. They have a different look, shape, size, color, purpose. May differ significantly in cost.

Bit. a nozzle used for twisting and unscrewing various types of fasteners. Each type of fastener uses its own type of bit.

A common bit is a hexagonal metal rod. One part of it is working, it is a screwdriver with slots of various configurations depending on the type of fasteners used. The second part is a shank inserted into an adapter or screwdriver chuck.

SL. short for Slot

Standard SL. screwdriver with flat straight slots of different widths, measured in mm.

Marking, e.G. SL6 or Slot6, means: 6mm flat-slotted bit.

Sizes from SL0 to SL7.

They differ in the length of the rod. They can be with or without restraints. The limiter is used so that it is not possible to wrap fasteners deeper than necessary, for example, when installing drywall. Bits of this standard are used when screwing fasteners in soft materials when a large torque is NOT required. Cannot provide a secure grip on the head of a screw or screw.

Types and marking of bits

Bit material and coating

Screwdriver bits differ in the material they are made of and the coating that prevents damage to them. Accordingly, their price differs.

The durability of a bit is primarily determined by the steel grade. The most reliable products have shown themselves to be products of their chromium-vanadium and chromium-molybdenum alloy with the marking Cr-V and Cr-Mo.

The strength, hardness, anticorrosive properties of the bit are increased by covering its head with titanium, titanium nitrite, nickel, tungsten. This increases its service life. If low-quality steel was used in the production, then the splines are erased after tightening several screws.

If the bit is selected correctly for a particular type of fastener, it fits tightly into the slots, ensuring its reliable fixation. This increases the torque from the screwdriver and its service life. If there is a gap, the splines are erased both on the fasteners and on the broken.

Correctly chosen bit creates a comfortable working environment, reduces the time for its implementation.

Drywall Bits

Bit for drywall with limiters is used when working only with gypsum board.

This is due to the fact that when fastening the sheets, you cannot press hard on the self-tapping screw, and as soon as the limiter reaches the surface of the material, you must definitely stop working.

If this is not done, then the slots from the screw head will be cut.

This can cause the drywall bit to wear out and clog the notches with metal filings.

Bits for nuts and bolts

These bits have a non-standard shape.

Their peculiarity lies in the fact that they have NOT a convex working part, but with a hole, while there are a large number of standard sizes.

It must be remembered that to tighten nuts and bolts with a large head diameter, you need to use a screwdriver with high power.

Spring and magnetic

Bits with a spring clip or a magnetic tip are designed for working on ceilings or other hard-to-reach places.

Retainers are designed to hold the bits in the adapter.

The magnetic tip allows you to securely fix the bit in the screw grooves.

It is also able to prevent the screwdriver nozzle from slipping during operation and allows you to screw the self-tapping screw deeper than a simple nozzle.

The spring nozzle is a special.

It allows you to work with fasteners that are at different angles and in hard-to-reach places.

Most often it is a slot and a base, which are connected with a flexible spring for fastening: you need to fix the slot of such a nozzle manually, insert it into the notches on the screws, while the spring can be bent at any angle, even more than 90 °.

Standard equipment

There are several basic types of bits:

Slotted. classic, universal, for screw heads or screws, their cut fits a flat screwdriver, may differ in tip width and cutting depth.

The most commonly used products are standard size.

Cross. consist of four ribs.

Hex. used for socket head screws.

Bolt and Nut Bits. Suitable for high load carrying capacity external hex fasteners.

Star-shaped. most often chosen for work with automotive equipment.

With anti-vandal slots

A bat with anti-vandal slots is called “snake’s eye” it has a socket for a fork wrench.

Bit marking

Knowing the marking, you will NOT be wrong with the choice of bits for a screwdriver.

A simple slotted slot is marked with the letter S.

Available coverage can be recognized by TIN value.

All parameters are most often indicated on the working part, for example:

S5.5×0.8. standard bit designation;

Slot (Sl). available in the simplest model with a flat slot, products ranging in size from 3 to 7 mm are popular, can be extended and have a limiter;

PH (phillips). cross-shaped nozzle marking, while there is a number from 0 to 4 next to the letters, which indicates the thread diameter, the product is universal, for domestic use it is recommended to choose a model with the PH2 marking;

PZ. a bit designed for working with wood and metal, has additional ribs, is designed for cross fasteners and fastenings with a large area;

H. marking of a hexagonal bit, numbers from 1.5 to 10 are set in accordance with the dimensions;

R is a marking indicating a square slot;

T. designation for a star-shaped nozzle;

SP. indicates the presence of an anti-vandal slot;

Gr. three-blade nozzle.

Bit classification by material and coating

Screwdriver bits are made from various metals, both soft and hard.

The quality of products and their service life primarily depends on the material from which they are made.

The following alloys are considered the highest quality:

Molybdenum and chromium;

vanadium and chromium;

molybdenum and vanadium;

silicon-fired sinter.

Steel options are also on sale, but they are expensive, and they quickly wear out during operation.

Even the presence of victorious soldering is incapable of extending the service life of steel bits.

They can also crumble when colliding with a hard rock of a mineral nature.

Titanium coating can increase the strength of steel tips.

Less reliable is diamond, nickel, and tungsten-nickel alloy plating.

Tungsten is responsible for high strength, and nickel protects the product from corrosion.

Shape

bits for straight slot

They are most like a simple screwdriver.

At the end they have a slot, which can have different widths.

This allows you to choose the optimal size to achieve your goals.

Width is measured in millimeters.

This parameter is indicated on the working part.

On the construction market, you can purchase products for a straight slot with a width of 0 to 7 cm.

They also differ in length.

Some products are equipped with special stops that allow you to adjust the screw-in depth.

Most often this type is used to work with drywall structures and furniture.

cruciform bits

Classic cruciform nozzle has 4 ribs.

Allows you to work with metal and wood products.

Cross-head bits with a cross piece in the form of a flat tip can be considered universal, since they allow you to work with countersunk screws, fasteners with a medium pitch and with Pozi fasteners.

The working part is a double cross with 4 main and 4 additional ribs.

The sizes of self-tapping screws with which you can work vary in the range from 2.5 to 4 mm, while the presence of rust or damage on them does not matter.

Another cross-shaped bit can be used to screw in and out screws and bolts, which are at different angles.

hex bits

Hex bits are used in furniture assembly.

Designed to work with internal hex fasteners.

There are models with a hexagonal hole, thanks to which the device does NOT slide off the screw.

The size of the nozzle can vary from 1.5 to 6 mm.

There are products with increased length.

They are used extremely rarely, although they are characterized by practicality and convenience.

The length of the nozzle can vary from 50 to 100 mm.

star bits

The slot resembles a hexagonal star, while there is a choice of different diameters.

This parameter is measured in millimeters.

Star-shaped models are most often used when working with automotive equipment or where you need to apply high forces to tighten fasteners.

The advantages of such a product are that it does not need to apply large forces to create torque, and the risk of the device slipping is minimized due to the fact that the entire load is distributed over six points.

This reduces wear and tear.

Models with a hole inside.

Most often they are used in assembly plants.

The tightening process with its help is characterized by increased reliability and does not require special efforts.

non-standard bit shapes (special)

They can also have non-standard forms of inserts, for example, a square working half, four blades, etc.

Such products are highly specialized, therefore they are practically NOT popular.

Screwdriver bits

Bits for a screwdriver are almost always necessary for repair and construction.

It is difficult to imagine repair work without screwing in screws, screws and other similar parts.

When the number of fasteners is large, a special electric tool is used, but its functionality largely depends on whether the bits for the screwdriver are correctly selected.

Rating of well-known brands of manufacturers of bits and attachments for a screwdriver

Manufacturers, whose name is heard by the majority of people associated with construction or repair work, have established themselves properly over the decades of work in the Russian market. Among the demanded firms, they stand out for the quality of the bits:

Quite junk, products from Metabo. The destruction of their faces is noted; such rapid wear is characteristic only of plastic. Bit hardening can improve edge quality, see bit hardening:

Screwdriver bits. how to choose, marking, types and hardening. How to choose the right bit for a screwdriver that would last for a long time?

The main reason for the rapid wear of the bit is poor quality and misuse. Of course, if you work with wood or assemble furniture, the question is not so acute, but when working with a professional screwdriver related to metal or concrete, not every bit will last at least a month. There are several rules and techniques, knowing which, even with a not very good bat or head, you will use for a very long time, but more on that below in the text.

To be honest, I bought bits in the set only once, with the very first “Shurik”, this set without two bits, is still lying in the box, “just in case”.

Bits of medium quality, only suitable for wood. For long, hardened self-tapping screws, I buy bits by the piece, before starting big work. I choose hardware with which I will work and equipment for them immediately. The head of the bit holder can be attributed to the equipment, with the help of its bit it is fixed in the screwdriver and does NOT fall out during operation. Why is there a small chamfer on the hexagon. Bit holders are collet and magnetic:

What are the bits and heads for a screwdriver?

- Basic;

- Special;

- Combined.

Most of the popular bits are listed below. They are also divided into some types depending on the shape of the working element of the slot of the bit:

- Straight bits;

- Cruciform bits;

- Star-shaped bits;

- Hex heads;

Special bits are divided into:

- Triangular;

- With a persistent stop for drywall;

- With spring clips and others.

The difference between the combined ones and the Special and basic ones is that at both ends of the bit there are working parts of different shapes or of the same shape, but of different sizes. They cost a little more than two second types, which is not always justified. This will help to verify the study of the properties of screwdriver bits, discussed in detail below. However, the above classifications are NOT the only ones as there are multiple bit standards.

- Ph (abbreviated from Phillips). cross-shaped bits with a conventional size from 0 to 4; characterized by a widening of the spline towards the base, as well as an apex angle of 55 degrees. The most popular size among buyers is Ph2;

- Pz (Pozidrive). the apex angle is 50 degrees; the products are an improved version of those previously described; are distinguished by the presence of two or four additional slots at the base;

- Sl (Slot). straight slot, varying in width; the number in the marking means the slot width;

- Torx (also found TX). a spline in the form of a hex star; it is used for structures, which are subject to increased strength requirements;

- HEX. bit used for fastening screws with an internal hexagon; most often used when assembling furniture; special bits for nuts or bolts with an external hexagon and used for fastening roofing screws or press washers.

Pay special attention to the differences between the PZ and PH bits. they are two different standards, although very similar. The taper angle and the slot angle are difficult to distinguish with the naked eye. The differences between THESE competing standards are shown in the figure below:

How to use a bat correctly for a long time. 5 tips from the master

1) Exact match of screw head and bit.

In any master, if the beloved bit, and that lives in a screwdriver for a long time, when buying hardware, try to choose screws or screws for it. There are a lot of configurations of heads, there are many, sometimes you have to work with such crap in this case, keep an inexpensive set of bits on hand, maybe even made in China.

2) don’t forget about ratchets.

While screwing the dowel nails into the “jerk”, just in case, set the ratchet limit a little more than the maximum effort. If a

the self-tapping screw will rest against the concrete, this will not allow the splines to be ripped off. When working with drywall and metal profiles, the ratchet will protect the surface of the gypsum board from ruptures when the screw head is too deeply immersed.

3) Grease for the thread of a self-tapping screw or screw.

Before screwing in, lubricate the working surface, this will significantly reduce the effort and, as a result, unload the screwdriver and the bit will live much longer. If you screw in a self-tapping screw “forever”, such as stretching the floorboards of a wooden floor, it is better to lubricate with water, then it is very difficult to unscrew such a self-tapping screw. But if it is supposed to later Unscrew the screw, then you can grease it with kerosene or WD-40. Such a grease will dry quickly and will NOT affect the quality of the fastening, but it will screw in like a knife into butter.

4) Keep the angle!

Trivial advice, but most often the slots break down precisely because of the “unsteady hand” or haste. The bit must fit into the barrel-to-barrel head, without backlash. If possible Use spring-loaded bits, it slows down the work, but only at the beginning, over time your hands will do everything right and quickly.

5) get a box for old bits

After the completion of large volumes of work, bits remain “tired”, a little loose or worn out. These can be folded for future use, and later this box will help you out more than once. These bits are still useful for unscrewing. I have a powerful magnet in this box, in addition to being able to magnetize any bit, it often helps out in hard-to-reach places.

Kinds of bits

- Straight

- Cruciform

- Hex

- Star-shaped

Special bits can be classified into the following groups:

- Triangular

- With persistent drywall stop

- Spring-loaded and others

Combined are excellent in that they have different shapes of the working part at both ends. The cost is one level higher than other types.

Several bit standards are also distinguished:

- Ph (derived from Phillips). cruciform bits, which have a conditional size from 0 to 4;

- Pz (Pozidrive). the angle at the top is 50 degrees; the products are an upgraded model of those previously described; are distinguished by the presence of 2 or 4 additional slots at the base;

- Sl (Slot). straight slot, varying in width; the number in the marking means the slot width;

- Torx (also found TX) is a hex star spline. Suitable for structures that require a high level of strength.

- HEX. a bit that is used to fasten screws with an internal hexagon; usually used to assemble furniture.

Manufacturer analysis

In order to understand the range of products and choose the right bit for a screwdriver, you should get acquainted with the most famous manufacturers.

AEG manufactures coldfire bit sets to help increase metal strength.

Dewalt provides an extensive range of accessories, both individually and in sets.

The DT 7246 includes a PH2 with a torsion bar. Also very popular is the model called DT 71517 with bits and angle attachment. The number of revolutions is 1500 rpm, the tightening force is 150 Nm.

Bosch deserves worldwide recognition for its high quality. Extra Hart are characterized by increased strength and long-term operation, painted in gray. Max Grip with titanium nitride substance improves grip on the mount, gold color.

WHIRLPOWER is one of the most popular brands in many respects. The firm was founded in 1983 in Taiwan. The quality is time-tested, which is why many experts prefer this particular brand. The geometry of the working part is perfectly machined. All nozzles are thermally treated and protected with a special coating.

Quality assessment criteria

When choosing nozzles, you need to focus on the features of the work performed. One of the reasons for the rapid deterioration of equipment is misuse. It is one thing to screw self-tapping screws into wood when assembling furniture, and another thing is the installation of metal structures, where the equipment experiences increased resistance during the screwing process. An impact screwdriver must necessarily be provided with special equipment, since standard equipment will NOT be able to withstand shock loads.

To correctly approach the choice of bits, you need to Pay attention to the following parameters:

The material of manufacture affects the strength and durability. For conventional modifications, steel R-7. R-12 is used, which is distinguished by excellent resistance to interaction with any type of metal. Chromium and vanadium coatings are added to protect against corrosion. The strongest are tips with a titanium-nitride coating of a golden hue. Bits with titanium and tungsten plating have also shown themselves well in practice. For overly active use, experts recommend diamond-coated nozzles, due to which the chance of grinding the edges of the working area is reduced.

Processing technologies. Milling and forging The most popular methods. During milling, the top surface is removed to give the work area the desired shape. Forged tooling features increased strength, the material is not disturbed during production.

The hardness of the material of the screwdriver bit ranges from 58-60 HRC. Soft attachments wear out faster, they are most of all designed for hard mounts, as they are resistant to damage. Hard ones will last longer, but rather fragile.

Design features. The magnetized work surface makes positioning in the slots easier, but sometimes this magnet is unnecessary. For an impact screwdriver, bits with a torsion part are suitable. Attachments are capable of Smoothing impact by withstanding high loads during operation.

Reliability rating

Manufacturing companies, which are trusted by qualified specialists, have proven themselves best in construction and renovation areas. The reliability rating is headed by the following brands:

Choice of bits for screwdriver

- The main

- Specialized

- Combined

Tips for choosing

If you are planning to purchase attachments for attaching components, follow these tips:

Focus on the material. Highest quality alloys:

- Chromium and molybdenum;

- Chromium and vanadium;

- Tungsten and molybdenum.

Steel bits It is not recommended to use, as they grind off almost after the first second of work.

The presence of a special coating on the bit is encouraged. Titanium, diamond or nickel are optimal materials that will not let the metal rust and will last a long time. Titanium plating is often found at Bosch.

It is advisable to buy products with a magnetic tip. Working with him will be much more comfortable. The best representative of this property is WhirlPower.

Experienced craftsmen advise taking kits from bits. It often happens that there is a lack of a certain mount for work. Therefore, it is best to immediately stock up on a set of 30-50 attachments of various sizes and shapes. However, which bits are best to buy for a screwdriver is up to you.

How to recover a broken screwdriver: an easy way

Probably, everyone faced such a question, and went on a hike for new consumables. However, there is a more elegant solution. repair in place of the old bit.

The fact is that if the latter is used improperly: skewed when twisting or weakly pressing on the tool during operation, it grinds off at the tip, forming a thin cylinder. If you remove it, and sharpen the edges of the bit a little so that it goes into the groove of the screw, then the bit can be considered working.

What is needed for this?

Damaged bits during operation

To restore the bits you will need:

- Screwdriver

- Metal file

A quick guide to recovering a bit

Recovery process

Installing the bit in a screwdriver

If you have a file on hand, but there is an emery wheel on a small grinder, this will also work fine. Using diamond files will do the job of re-gauging.

Removing the worn-out part of the bat

So, to ghost the bit in a working state, you need to remove the part that has been ground off. To do this, insert it into a screwdriver.

Bit edge processing

We turn it on and with the help of a fine-grained file removes an unnecessary pimp. The file must be driven progressively, slightly pressed against the rotating bit, until the worn-off part is completely removed.

After maintaining an angle of approximately 30 degrees in relation to the bit, its edges are processed. The nose of the bit is too wide and it will not go into the grooves of the screws, therefore it needs to be sharpened.

The work is carried out until the broken dowry is in its original form. You should not be zealous, because during turning you can overheat the metal.

As soon as the appearance of the recovered bit is satisfactory, the first test can be performed.

In this way, the bat can be repaired one or two times. its design no longer allows. But this is quite enough, since the restored instrument will last as long as the new one.

It should be mentioned that the bit can be restored in the future, only it will have to be done manually and with a calibration tool. It will be necessary to process Not only the edges, but also the grooves between them, and it is difficult to do this without files.

How to recover a broken one for a screwdriver

How to recover a broken screwdriver: an easy way

Feedback from our readers is very important for us. Leave your rating in the comments with the reasoning for your choice. Your opinion will be useful to other users.

Main criteria

The main criterion when choosing bits for a screwdriver is the specifics of the work. Heavy loads and improper use lead to early wear of the product. After all, for example, wood and metal are materials of different strengths, which means that bits must be selected with different characteristics. What should be noted?

- The material on which strength and wear resistance depend. The most common material for bits is steel R-7. R-12, but corrosion is protected by a chromium coating. Bits coated with titanium nitride will be distinguished by increased strength and service life. Titanium and tungsten plating also has a good effect on product performance. For the most active and difficult work, you should choose a diamond coating, which also reduces the likelihood of thinning the edges of the product.

- Processing methods are also an important selection criterion. There are two main ones. forging and milling. Great strength is characteristic of forged bits, because the top layer of the product is removed during milling. There is also a special technology to improve the positioning of the working part. Profiling. After this procedure, the bits can be used in hard-to-reach places, but it is not recommended to come into contact with chrome or brass coatings. For this case, nozzles with rough working edges are suitable.

- Of great importance is the hardness of the material, which should be 58-60 HRC. In turn, hard bits are divided into hard (suitable for soft screwing, but not subject to rapid wear) and soft (wear out quickly, but suitable for working with hard fasteners).

- Bits designed for different materials differ in structural features. For example, when working with metal, a bit with magnetized parts will only complicate the process. For an impact screwdriver, you should choose a nozzle with a torsion tip: it is more resistant to loads and is durable.

Offers from different manufacturers

Having decided on what characteristics of the bit are suitable for this particular type of work, you should study the range of different manufacturers.

“AEG”. the tools of this company are distinguished by their durability due to a special manufacturing technology.

“Bosch”. a proven German manufacturer, guarantees the durability and strength of its products. A distinctive feature. the bits are made in gray.

Whirlpower is a Taiwanese company whose quality is tested all over the world. The material from which the manufacturer makes the attachments is stainless steel, which provides excellent wear resistance.

Recommended reading

Bituminous shingles: technical characteristics and installation features What you need to know about choosing a kitchen? Choosing a high-quality water tank How to choose the right air conditioner for various types of premises

How to choose bits for a screwdriver: useful tips

Bits for a screwdriver very often cause complaints from buyers because of their fragility. Of course, work productivity is reduced due to constant breakdowns. Masters ask themselves the question: how to choose high-quality equipment, corresponding to the specifics of work, tools and working material. Price is NOT the main criterion for choosing.

Add a comment Cancel reply

The high attention to the ability to make the home as cozy and comfortable as possible deserves praise. This is really worth doing, especially since the opportunities for the most impressive results are quite enough.

Today, the process of choosing a bed can be extremely interesting if you pay maximum attention to it and really take advantage of all the opportunities provided.