Do-it-yourself rake for the tiller

Every farmer wants convenience and quick efficient work in his work. There is no end to the improvement of small agricultural machinery. A great example is tiller attachments for making hay.

On sale there is a sufficient number of various devices for equipping this type of agricultural machinery, including manual ones, but it is precisely the devices related to haymaking that our manufacturers somehow have on the Boschly side. If there is something like that, it is either cumbersome, or inconvenient, or expensive. In this article we will tell you how to make a rake for a tiller with your own hands, which, by the way, will turn out to be quite universal and will suit both Neva tillers and other brands.

Overseas, things are a little better with this, but the for equipment and transportation do NOT leave most of our farmers a single chance to use These miraculous mechanisms.

Tiller rake drawings

Below, there are drawings of hand rakes, but having remade the clutch assembly, they can be used with a tiller.

drawbar; 2. lever; 3. thrust; 4. struts; 5. rack; 6. rake; 7. hub; 8. axis; 9. wheel

Rake in working position and folded

Rack with braces

bushing (pipe 33.5×3.2, 2 pcs.); 2. crossbar (pipe 21.3×2.8) 3. cross member bushing (pipe 26.8×2.8) 4. struts (pipe 21.3×2.8) 5. leg (pipe 26.8×2.8, 2 pcs.); 6. bushing (pipe 33.5×3.2, 2 pcs.)

Rod and its articulated connection with brackets

thrust (pipe 21.3×2.8) 2. M8 bolt; 3. nut М8 (2 pcs.); 4. bracket; 5. manual console

handle (pipe 21.3×2.8) 2. drawbar (pipe 26.8×2.8) 3. bracket (St3, letter s5.2 pcs.); 4. stop (St3, letter s5, made with dimensions of pos. C without a hole) 5. adapter sleeve (pipe 33.5×3.2)

Drawing of the rake lifting-lowering lever

lever (StZ, strip 30 × 4); 2. handle (StZ, rod with a diameter of 12)

console (pipe 26.8×2.8;) 2. bracket; 3. tooth (steel 45, bar d8,17 pcs.)

Final manual debugging and finishing touches

It is worth attaching a stand with a seat to the drawbar, and the lever can be provided with a spring so that you do not have to hold it with your hands constantly and for better pressure on the soil.

After field trials, it will be clear what needs to be corrected if necessary, the teeth may need to be shortened. All moving parts subject to increased friction should be liberally lubricated with grease, lithol or other thick grease.

Making a rake to the tiller

If you approach the matter with all care, you can independently make excellent productive designs, in terms of reliability and efficiency, and not inferior to factory.

Especially often when harvesting hay, there is a lack of a convenient rake, which would greatly facilitate the work. So they can be made quite simply, having the necessary minimum of tools and experience in welding.

To make a rake for a tiller you will need:

Homemade rake for the tiller. Construction manufacturing process

A horse rake was used as a prototype, which people have used for many years and in some villages of the Russian hinterland they still use it.

The first step is to build the base. the wheels are put on the axle. Two platforms are welded onto it to strengthen the fastening of the rake mechanism. For this purpose, two strips of thick steel are suitable, they need to be strengthened at a distance of 10-12 cm from each wheel. Further, the drawbar should be fixed exactly in the center of the wheel axle. Thick-walled pipe is perfect for this element. At the end of the drawbar, you need to weld a loop for docking with the tiller. The base is ready.

Let’s start making the working mechanism itself. On the wheel, you need to Weld the rack, to which, in turn, attach two pipe sections with a cross section of 40 mm by welding. We insert into this pipe a manual one, it should turn freely. On both sides of the fastening tubes, it is necessary to make retaining rings to avoid manual shifting to the sides. After THESE operations, the rake must be equipped with a lever. It is needed to raise and lower the teeth.

The teeth themselves are attached to the manual axis, from which they can be made of six-millimeter wire, bending from it C-shaped elements of the required dimensions. They can be fastened by welding or mounting in pre-drilled holes.

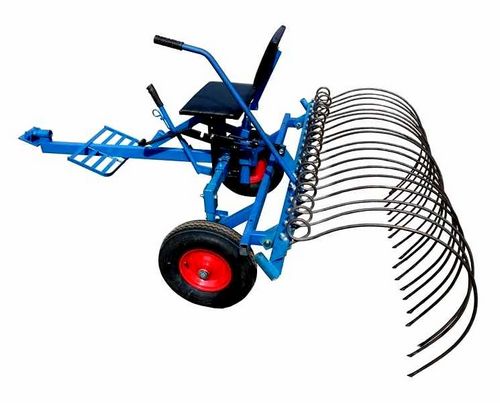

Rake for tiller

On. A review of self-made manual for a tiller, the author shows the main components of the structure, which is a good help to try to make them yourself.

How to make a rake to a tiller?

In cases where this event is approached with all responsibility, then you can make a productive design, which, in terms of reliability and efficiency, will NOT be inferior to factory counterparts.

In most cases, hay harvesting is done by hand, although making a rake for the tiller is not so difficult. But here you need experience with a welding machine and the required minimum of tools.

You’ll need:

- Two wheels (diameter 30. 45 cm).

- Here (you can use a metal rod or pipe, for example a water pipe).

- Thick tube with thick walls for drawbar.

- Metal rods with a diameter of 6-8 mm for working parts.

- Pipes for the manual mechanism (30 mm for the axis 40 mm for its fastening).

- Springs (ready-made or homemade).

Construction manufacturing process

In this case, the prototype was the horse rake, which was used for many years, and in some villages, which are used even in our time.

First of all, we build the base. we put the wheels on the axle. On it, in order to strengthen the fastening of the mechanism for the rake, we weld on two platforms. For this purpose, thick steel can be used, which must be fixed at a distance of 10.12 cm from each wheel. After that, exactly in the center of the axis of the support of the drawbar, which can be made from a thick-walled pipe. But at the end of the drawbar for docking with the tiller, we weld a loop.

Thus, we made the basis for manual.

Now we begin to make the working mechanism itself. On the wheel, we weld the racks, to which, in turn, we weld two pipe sections with a cross section of 40 mm. It is into this pipe that we insert the rake. Here she should turn freely enough.

Further, on both sides of the mounting tubes, we make retaining rings, and therefore it is possible to completely exclude the possibility of manual shift to the sides. After that, to raise and lower the teeth, we supply the rake with a lever.

The teeth themselves are fastened to the manual axis, which can be made from a metal wire (6 mm) by bending C-shaped elements of the required dimensions from it. They can be fixed by welding or mounting in pre-drilled holes.

Manual drawings for installation

Below are the drawings of the hand rake, but in cases where the clutch assembly is remade, they can be used with the tiller.

1. drawbar; 2. lever; 3. thrust; 4. struts; 5. rack; 6. rake; 7. hub; 8. axis; 9. wheel

How to make a rake on a tiller?

Each farmer wants convenience and quick effective work in his work, and therefore agricultural equipment is constantly being improved. A great example is the various tiller adaptations.

Today on sale you can find a wide variety of mechanisms for equipping this type of agricultural machinery, but they just did not think about it in the hay harvesting device. Even if you can find something similar in our country, then they are either cumbersome, or inconvenient, or rather expensive.

But you can still get out of this situation. Namely, make a do-it-yourself rake for the tiller.

Final manual debugging and finishing touches

It is worth attaching a stand with a seat to the drawbar, and the lever can be provided with a spring so that you do not have to hold it with your hands constantly and for better pressure on the soil.

All moving parts subject to increased friction should be liberally lubricated with grease, lithol or other thick grease.

After the first field tests, it will immediately become clear whether it is worth making manual changes to the design or not.

Description of the fixture

The tiller is an indispensable tool in any home garden. For active planting and harvesting, the monoblock is used together with special units, most often mounted, which are capable of digging earth with any structure, as well as loosening it. It can also be used for weed control.

The hay rake is a productive tool for working with soil in spring. Since hand tools are very small in width, a similar version can be attached to the candy bar with great delight. It can make your gardening work more efficient.

Everyone knows that even the fastest manual work will NOT be able to compare with the similar mechanized one. Despite the best efforts, in bad weather it is incredibly difficult to cope with the huge volume of work. And it happens that efforts are simply wasted. After heavy rains, hay harvested can irreversibly deteriorate. Even after drying such hay, it will have NO value and can quickly grow moldy. Such animal feed is unsuitable and can only be thrown away.

The diameter of the pipes should be about fifteen centimeters. Making a functional rake for a tiller with your own hands is not difficult. For specimens with a wide hay grip, water pipes of different diameters are excellent.

Practical use

Mowing grass and making hay are some of the most important agricultural jobs. To mechanize THESE processes, a wheeled rake for a tiller is used. Their application significantly increases the productivity of hay harvesting. Haymakers are also used for hay collection, wrapping, tedding and mowing, and wheeled ones can be used on all areas of land with flat terrain.

Manual options

On sale, as a rule, if you can find a rake, then most often they are very bulky and inconvenient or too expensive. Therefore, the best option for many is to make a homemade rake to the tiller from improvised materials with their own hands. Of the main types of manual, universal and hay can be noted.

The universal type of hand is most often used for harvesting hay in a swath. Their grip width is 115-200 cm. These are the most optimal dimensions for this design. Hay is designed for raking and turning green or dry grass and straw. The working tool of such a rake looks like raking fingers on the rods.

How to do it yourself

If you decide to make a cross rake yourself, you will need the following set:

- Hacksaw;

- A hammer;

- Welding machine;

- Puncher;

- Two wheels;

- Metal axle;

- Profile pipe;

- Springs;

- Metal rods;

- Pipes for manual mechanism.

Experienced gardeners recommend choosing a rake model not in one piece, but in a folding version. Cross home-made rake to the tiller, which can be folded in practice, turn out to be more comfortable and mobile during transportation. Here are hand-made, you can achieve maximum mobility of raking hay. That is why they must be fully mechanized to work. The technological process of manufacturing these devices is quite simple.

As the drawings describe, the pipe sections are assembled into a structural solution. They can be scolded tightly into one whole, or you can firmly insert one pipe into another. The traction mechanism will determine the free rotation of the tiller, so the wheels do not need bearings. Having calculated the efficiency of cleaning the hayfield, you can choose any diameter of the rake grab with your own hands.

There are a lot of ideas for making homemade elements for working units. Like the blueprints you want, they are available. Therefore, the best solution would be to use them and make a multifunctional rake for the tiller yourself, because they will significantly increase the productivity of your work.

“How to make a rake for a tiller

Describes how to create a manual for a tiller. In addition, the author explains what is necessary for this and how to properly fasten important structural elements.

How to make a functional rake for a tiller with your own hands. “Tiller hay rake

Step-by-step instructions for designing and creating a manual for a tiller.

Round baler

Tiller round baler forms bales of hay or straw.

- The material is captured by the pick-up and enters the drum compartment, where, under the influence of the grate, it is rolled into a roll.

- An audible signal will notify the tiller operator that the roll has reached the required size and density.

- The roll is tied with twine, after which the rear wall of the drum opens and the finished product rolls out.

- The outer part of the roll is tighter than the inner part, which provides excellent air circulation. In addition, the rolls have the same weight and dimensions.

At the price, the roll hay collector is more affordable than the bale one; if you wish, you can purchase a mini baler for the tiller, which will allow the owners of summer cottages and private estates to improve the procedure for preparing livestock feed.

How all this happens will help the concepts:

Tiller mowers

and more often, you can see how the owners of summer cottages and small farms perform haymaking with a tiller. There are several varieties of this equipment that differ not only in appearance, but also in the principle of operation.

On the market you can find and pick up the following modifications:

- Rotary mowers;

- Frontal;

Front-facing models fall into two categories:

- Segmental;

- Flail.

When choosing attachments for yourself, you should consider the following features:

How the grass will be laid:

- Into rolls. this option will allow you to quickly form a stack without the involvement of additional equipment (manual);

- When mowing. the grass covers the lawn in an even layer, additional equipment will be required for its collection and laying;

- Mulching. the grass is crushed, becoming a natural fertilizer for plants (shrubs, trees, etc.).

Oblique height:

- 5 cm;

- Up to 20 cm.

Grip width. depends on the specific model.

Aggregation method with motorized device:

- Front of the tiller. The most demanded option;

- Behind. these are flail lawn mowers, which are used more and more for lawn cultivation;

- On the side (semi-mounted). the support wheel takes over the main weight of the mower, such models are more relevant for mini-tractors.

- The power of the mowing unit. The higher it is, the more functional the attachment. with its help it will be possible to obliquely only grass, but also shrubs, growth of young trees up to 3.5 cm in diameter.

- Rotation frequencies of working bodies Hay mower.

Belt rake

This equipment allows you to quickly form a stack, grabbing and transferring cut grass, hay and even dried forage crops.

Tedders, whether “Solnyshko” or of the belt type, are much more productive than their transverse counterparts, their design is more complex, and the requirements for operation are increased. In addition, it is important to use them for throwing hay from one side (dried) to the other, for faster drying.

Trimmers to tiller

There is also such equipment as trimmers, which can be attached to the tiller, used autonomously, or have their own wheelset. The main working body of the trimmer is cord (dense fishing line), but special knives may also be included in the package.

In addition, petrol hand trimmers can be equipped with various attachments: brush cutters, pole saws, etc.

We offer you to watch the work of a homemade wheel trimmer for a tiller:

Segment mower

The tiller segment mower is a type of front-mounted mowing machine designed for mowing grass and hay in areas with different terrain, and the grass is cut directly at the root. Such a mower can be attached to the tiller in two ways:

- Front with a drive belt (use a three-ribbed pulley better)

- Behind, using a power take-off shaft (PTO) and a special adapter (adapter).

The attachment is used for both soft and hard grasses, also relevant for stubble mowing.

The design is very simple and unpretentious to maintain. The mower consists of a rigid frame, on which two bars with cutting elements (fingers) are fixed, one of which is completely motionless, the other reciprocates right and left. Scissor principle. grass falls between cutting edges and is cut by them.

We offer you to see the work of the Chinese Tiller Mower:

Balers

This device allows the owner of the land plot not only to carefully select the mown hay or grass, freeing up the soil for further processing, but also to compactly pack them and prepare them for further transportation. The tiller baler can be of two types:

- Bale.

- Roll.

Basically, due to the more compact size and simpler design, in the private sector they prefer to use roll-up sheds. Tyukovy. more typical of farming.

Hay making equipment

Mowers, rakes, a baler for a tiller. these are devices that greatly increase the functionality of the unit, and made it possible to use it to carry out a wide range of agricultural work. Harvesting hay and cleaning lawns are the main areas of work where you cannot do without a mower and second equipment on the site.

We list all the nozzles for the tiller, which are designed to facilitate the work of harvesting feed for livestock and caring for lawns:

- Mowers.

- Trimmers.

- Rake.

- Balers.

- Tedders.

We offer you to get acquainted with the variety of each category of attachments in more detail.

Rake

Rake for tiller. attachments connected to the unit with a special adapter, you can find models that are aggregated with a hitch.

In addition, this equipment has several modifications:

- Belt rake (hay)

- Cross hay rake;

- Rake “Sun”.

Let’s consider each modification in more detail:

Baler baler

The bale tiller baler works according to the second principle. The hay enters the bale chamber in the same way with the help of the auger, then the chamber is filled to the stop and the knitting mechanism starts. two threads tie a rectangular bale, after which it is pushed out. Bale-type units have the ability to adjust the density and height of the finished bale, in addition, rectangular blocks of hay or straw are more convenient to store and transport.

We offer you an overview of the operation of the square baler:

Another useful tiller-powered canopy is a DIY straw chopper. It will help you grind the feed just before serving it to your pets. Tiller drives cutter knives.

How it happens. we suggest looking at:

Varieties of manual for a tiller and is it possible to do it yourself. Describe in detail

Today, tiller manufacturers are trying to complement the complete set of their “brainchild” with a variety of attachments. But often the most useful devices have to be bought separately and hay rakes are one of them.

Are the tiller rakes a much needed piece of equipment??

First, let’s figure out what they are for. With this device, you can level a dug garden, collect mowed grass and hay, and also clear the area of weeds and debris.

The above work takes a lot of time and effort if done manually. Therefore, such attachments as a rake for a tiller are an essential assistant. However, not everyone can afford to purchase this device, and then there is another option, to make them yourself.

Attachment characteristics

The main tasks of a manual tedder are collecting grass in windrows, wrapping and raking hay. This technique has many varieties with different technical characteristics.

The different models of the tiller hand hay fall under the tiller attachment category. The rake is attached to this stage using an adapter. This is very convenient because it allows you to use any additional equipment on the tiller. Often, several rakes are already sold in the kit.

Hay rake

There are also such types of cultivators, where the kit has additional equipment. This means that you will have to buy it in any case or make it yourself, using pre-designed drawings.

As a rule, all tillers have a device that allows you to raise or lower the rake. This is done with pens. Most rototillers have a swivel hitch. It is necessary to increase the maneuverability of this wheeled unit, it saves users energy when working with hay, which is important to increase the result and speed up tasks.

Note! The use of handles for raising or lowering the rake is very convenient, because it allows you to work efficiently and cleans the rake better.

Any rake for the tiller Must be strong. It is best if they are made of steel. The metal must have excellent anti-corrosion properties because the rake is in constant contact with water. Anti-corrosion tips will last more than 10 years if handled and stored in a moist air free environment.

Attachments should be stored in a dry area. After use, it must be washed and dried. this way it will be possible to extend the service life.

Manual drawing for tiller

Detailed dimensional drawings for DIY hay picking with a tiller.

- 1. bushing (pipe 33.5 x 3.2 mm. 2 pcs).

- 2. crossbar (pipe 21.3 x 2.8 mm).

- 3. cross member bushing (tube 26.8 x 2.8 mm).

- 4. struts (pipe 21.3 x 2.8 mm).

- 5. leg (pipe 26.8 x 2.8, 2 pcs).

- 6. bushing (pipe 33.5 x 3.2, 2 pcs).

Rod, hinged connection.

- 1. draft (pipe 21.3 x 2.8 mm).

- 2. bolt М 8.

- 3. nut М 8 (2 pcs.).

- 4. bracket.

- 5. manual console.

- 1. handle (pipe 21.3 x 2.8 mm).

- 2. drawbar (pipe 26.8 x 2.8 mm).

- 3. bracket (St3, letter s5, 2 pcs.).

- 4. stop (St3, letter s5, performed with dimensions of pos. C without a hole).

- 5. adapter sleeve (pipe 33.5 x 3.2 mm).

- 1. lever (StZ, strip 30 × 4 mm).

- 2. handle (StZ, rod with a diameter of 12 mm).

- 1. console (pipe 26.8 x 2.8 mm).

- 2. bracket.

- 3. tooth (steel 45, bar d8,17 pcs).

On this, the author shows the principle of operation of a homemade hay harvesting device for a tiller.

Come here

Back in America, Gravely was the largest American manufacturer of tillers, and several more American companies have produced them since the early 1900s. But the larger tractors produced after World War II drained the market for many tractors, and even the Graves stopped production around 2003.

American manufacturers also have never introduced much innovation to this equipment sector. Even in the last days of their production, there were still no reversing rudders at Gravely. While Europeans adopted this extremely practical design in the 1960s, today almost all Tilleri are made in Europe, mainly in Italy, which has more than 15 brands. Two Italian brands found in North America. These are BCS America (based in Portland, Oregon) and Grillo, with BCS being the most famous as they have been imported since the mid 1970s.

Is the tiller suitable for my farm?

You finally got a few acres of land in the countryside and you want to start a farming business: maybe some livestock, an acre of vegetables, an orchard, or even a berry farm. But there is still a lot of work to be done for the earth to take shape. You have to clear all these bushes, knock off all these branches and cultivate the land. The list goes on. You will need something for a haircut, something for shavings, and something for treating the area, which quickly turns into a mass of engines requiring maintenance!

Fortunately, there is an excellent, often overlooked option that is currently the backbone of small-scale agriculture in Europe and Asia, but largely forgotten in North America: the tiller.

How to service a tiller?

Simple and robust tiller design means high reliability and low operating costs.

Typical maintenance consists of changing the oil and filter just like any other equipment; annual lubrication of the control cable; from time to time check the tightness of fasteners subject to high loads, for example, the bolts on which the implements are attached; and replacement of worn parts. Mower blades, cultivator tines, etc., as needed. Potential repairs after hundreds (perhaps thousands) of hours of use may include items such as clutches and PTO clutches; gearboxes practically DO NOT fail.

Due to the simple design used by most of this equipment, even these repairs can usually be done at home by anyone with decent mechanical ability; many practical documents and available on the internet. If necessary, the equipment can be delivered to the dealer for repair. In this case, the tillers have the advantage that a huge truck or trailer is not needed to transport them; Thanks to the adjustable handlebar design, which allows them to be folded into a small package, any tiller will fit in an SUV or most station wagons.

Last but not least, the main benefit of a tiller is exercise. How many times have you heard from the doctor “Walking. Better exercise “or” You really should be walking more “? How many Americans buy a health club membership and walk on a treadmill and then go home and get on a lawnmower? Strollers allow you to do your job and exercise well while you do it. Truly the best of both worlds for the hobby farmer.

Types of manual for tillers. do it yourself, drawings and dimensions

Most manufacturers, together with tillers, also produce various attachments. Some are supplied with the unit, but most canopies are purchased separately, including the rake. This device can be made independently, saving personal funds.

Enter the site

Homemade technique

Is it right for me?

Most of the equipment is of scale and tillery is NOT an exception. You don’t buy a 50 horsepower tractor to mow one acre, and you don’t want a tiller to mow 50 acres.

For proper scaling of the walker Extremely practical. They are great for a garden or lawn of up to a couple of acres, 15 acres of hay, and 10 acres of bush trimming. Because they are very stable on slopes and take up very little room to maneuver, the steeper and rougher the terrain, the more attractive walking becomes.

You will definitely need to be able to walk around the equipment in order to use the pusher correctly. There is a seat for riding while mowing, but it is bulky and cannot be relied on. These machines are made to go from behind!

How to make a rake for a tiller with your own hands?

A rake is made to the tiller, following a simple scheme. You need to start with the axle and wheels, which act as the base for holding all the structural elements. Separate construction details can be purchased, but it is quite possible to make them yourself from scrap materials.

Manual creation scheme:

- Wheel. You can use the disc of an earth seeder, even a broken one. The bearing is knocked out, which will interfere with the tight fit of the disc. Dimensions of the metal bar: 1.7 meters long, 4 centimeters wide, 2 millimeters thick. The strip is wound and welded around the disc. The resulting product should be four centimeters wide;

- Here. A metal rod (optimal diameter 1.4 centimeters) is inserted into the wheels, leaving one or two centimeters protruding edges. In the inner part of the retaining ring, in the outer hole for the cotter pin. To create it, you need a drill with a diameter of 3.2 millimeters. The cotter pin can be the rod of the quarrel electrode;

- Strengthening the structure. For the convenience of using the device, two plates are placed at a distance of 10 centimeters from the wheels. They are welded to the axle with a welding machine. Plank dimensions: 10 centimeters long, 3 centimeters wide, 2 millimeters thick. Due to the considerable weight of the structure, additional reinforcement may be required to prevent subsidence. A 15 mm square may be suitable as a reinforcing element;

- Drawbar and racks. Oblique supports are welded. Used squares with dimensions of 2525 millimeters. Welded feet Must be flush and can be fitted by an angle grinder. The drawbar is fixed between the welded supports. The drawbar is a thick-walled pipe with a length of 150 centimeters. It must withstand a high level of stress;

- Drawbar hook. The most convenient for operation will be the C-shape of the drawbar hook. Used 6mm stainless steel wire;

- Manual plank. The bar is fixed on the traction. It is necessary that the device be raised and lowered during operation, the force on the ground should be adjusted. You will need a one and a half meter pipe for the working grip of the device. Two tubes are welded to the racks (length 15 centimeters, diameter 4 centimeters), into which it is inserted here. The pipe should turn freely. The rake is attached to the retaining rings on the tubes.

- The “ear” is welded from a fifteen-centimeter pipe. The rod is welded at the top, one edge touches the middle of the drawbar. By pressing the handle, the rake goes down and up (this is the so-called standby mode).

At the final stage, all rubbing elements are oiled and the rake is ready for testing. The ready-made design is suitable for tilers Neva, Centaur, Zubr. Self-made attachments are attached to the “native” adapters. This is a universal device that can be installed on different units.