How to cut tiles with an electric tile cutter: advantages, technical features and video

Renovating a house can be a disaster if you don’t have the knowledge and experience to do it yourself. This applies to every stage of repair, and tile laying is no exception. It is one thing to put a whole tile on a flat surface. It is quite another. to fit it to size, to cut the necessary holes. Here arises a logical question: how to cut the tile with an electric tile cutter qualitatively and quickly?

Before figuring out how to cut ceramic tiles with an electric tile cutter, it’s a good idea to figure out what this tool is. Modern electric tile cutter cuts tiles with a diamond disc, cooling the surface with water. On the principle of operation this tool can resemble a circular saw or mitre saw. They have the same location of the motor, cutting wheel, support platform and bed with a swivel head. The peculiarity of the tile cutter is in the diamond spraying on the disc used, the ability to supply water into the working area. The gripping and positioning of the workpieces is also a challenge.

Electric tile cutter thanks to the use of diamond successfully copes with cutting not only glazed tiles, but also stone (natural and artificial), bricks, concrete, ceramics, faora, glass and many other building materials. The right disc and feed speed are sufficient for this.

water-supply helps to cool surfaces of parts and tools itself, as well as to “bind” dust to such an extent that it is practically absent during work. The supplied water ensures quick and clean cuts, even tile edges, no chipping and no serious damage to the glaze.

To achieve a precise cut in electric tile cutters there is a cantilever plunge mechanism, stop systems (parallel and angular), line pointers and much more.

A modern electric tile cutter has a number of advantages:

- even cut lines on tiles,

- The ability to minimize the number and size of chips,

- The ability to cut parts at an angle,

- Minimal dust during work,

- High safety and good performance,

- Ability to make grooves in the tile, cut it diagonally and from the middle,

- The ability to cut even a few millimeters off the edge.

However, like any other tool, the electric tile cutter is not without some drawbacks:

- no possibility to make curved cuts,

- High enough cost, which is justified by the quality and functionality.

What tile cutter to use for cutting

There are two types of tile cutters: these devices are electric and mechanical. The first type is suitable for industry or construction work. For cutting tiles at home, manual models are used.

Household tile cutters are of three types:

- Roller. The device consists of a handle and a cutting roller. It is used as a separate tool or is used together with a saw station.

- On bearings. This option is used when you want to cut strong ceramic tiles, more than 16 mm thick.

- Mechanical. Thanks to the presence of a rigid carriage with the device it is possible to perform precise cutting.

Important! No model can cut a strip from the very edge, if the width is less than 10 mm. In this case, the employee will need to use wire cutters.

Cutting a tile with a manual tile cutter correctly

Facing work with tiles and porcelain tiles implies the use of various devices, which in construction stores are represented today in a wide range. Among them are mandatory tools to perform the cutting of factory workpieces. Consider how to cut a tile with a manual tile cutter. Let’s get acquainted with the recommendations of craftsmen on the selection and maintenance of devices, so that they serve for a long time.

Design of hand tools

To understand how to use the tool, you need to find out how it works. For cutting tiles, manual tile cutters have a common device. Here the main structural elements are:

This is a solid metal base on which all the parts are located. The tiling material is laid on it, so among the main criteria for choosing the device are the evenness of the support and the size according to the format of the tiles.

Additionally, you should pay attention to anti-slip pads. On one side there is also an indelible scale and a small projection which allows the ceramic piece to be broken along the cutting line.

They are represented by two parallel tubes with smooth outer walls. In more expensive versions, they are replaced by an I-beam. Their function is to keep the working mechanism in the right position for the operator, providing a possibility to exert a certain pressure on the tile. The tool can also be moved along the guide rails.

Rigid tile cutter element to cut tiles by hand. It is fixed cutting wheel, a lever and a special foot for nadrevalnivaniya facing material.

Platform, frame elements under the guides, as a rule, are made of cast steel, because the reliability and durability of the tool depend on their quality. The carriage and the cutting element must be even stronger, so an alloy with m tungsten and cobalt is used for production here. To prevent the platform from sliding on the floor, rubber pads are mounted on the underside.

This handheld tile cutter can be used by professionals and beginners alike. In addition to this advantage, craftsmen note other advantages:

- silent operation;

- the simplicity of the device;

- mobility;

- compactness;

- low weight

- environmental friendliness;

- low cost.

However, there are disadvantages, too. It is difficult to form pieces with a width of less than 10 mm, the break line edge is sharp with small irregularities.

For large areas for tiling and for cutting thick porcelain tiles, masters prefer to choose electric analogues. Also here it is worth highlighting the high percentage of obtaining a cut with low quality. And the novice masters often tile breaks not along the planned line, which can only be straight.

Recommendations for the selection of a device

Using the tile cutter properly is not enough to get the desired results. It is also necessary that the tool is of high quality. When choosing, experts recommend paying attention to the following points:

- The rigidity of the platform and frame. The design must be reliable, without wobbling, creaking. The lack of vibration and flexibility of the monolithic device is a guarantee of quality and long life of the tile cutter. Same for the arm.

- The length of the metal base. The shorter models are only considered for one-time jobs, or when you complete your home workshop with an additional compact tool.

- Smooth running carriage. Here, a tool that is equipped with bearings is considered the best solution.

Among other things, additional details can be useful. For example, the presence of a protractor allows you to simplify the process of cutting tiles at a specific angle. Optional tile cutter carriage makes it easier to get the hole in the right place. There are enhancements to increase the tile support area, clamps.

How to use

Before you start working with the tile cutter, you need to check it for proper operation. In particular, the smooth running of the carriage on flat and smooth guides. The cutting roller must be free of defects and must rotate freely. If these conditions are met, it is possible to form a depth and even groove, on which the tile will be broken.

If any nicks or other damage is noticed on the roller, it must be replaced. Guides before the work to be cleaned from dust and contaminants, treatment with machine oil or other means to ensure free movement of the carriage. If necessary, threaded fasteners can be retightened. Some models include the ability to customize the tool to work with a specific tile size.

Example of a professional tool with a wide range of functions

On the face of the tiling workpiece, an orientation line for the trimmer is applied. To do this, you can use a building or stationery marker, felt-tip pen. But most masters prefer a lead pencil, as it is easy to erase from almost any surface.

How to Cut Porcelain and Ceramic Floor Tiles. Tile Mountain

In order to obtain an even cut in the right place it is necessary to properly lay the workpiece on the platform of the tile trimmer. All types of hand tools have an overhang and a guide that runs along the central axis of the platform. The plate with the applied centimeter scale additionally serves as a stop for the tile. It is also secured perpendicular to the guides.

If you need to cut tiles with a handheld tile cutter, for example, diagonally, then the outlined line for the trimmer is enough to align with the roller. To simplify the fixation of the workpiece on the site, additional holds can be provided.

It is important to form a groove across the marking line that is even in depth. That is, you need to press the roller lightly against the tile, press it and run the wheel over the entire surface. Any jerks or uneven pressure can result in a crooked break.

Carving technique with a handheld tile cutter

Correctly cutting tiles with a tile cutter is much easier if the following rules are followed:

Step The tile should be secured and in a straight line along the future break cut.

Step Lower the lever and break the tile into two pieces.

The process is not complicated at all and will not take more than a minute to cut one tile. But, it is necessary to take into account some nuances to make quality cuts and with a clear conscience to use the tiles in construction:

- For a guaranteed straight cut, draw cutting lines on the tile with a felt tip pen. Then, these cutting lines must be aligned with the wheel to make the cut.

- When cutting, use one hand to hold the tile in place and the other hand to hold the handle with the wheel.

- The handle of the tile trimmer must be raised so that the wheel touches the surface of the tile on the upper side. Then move the handle towards yourself.

- A light pressure is sufficient. Do not overdo it so that you don’t break the wheel. The wheel should only need to make one pass.

- The trimmer line is marked. Now it is necessary to qualitatively and evenly divide the tile. To do this, the wings are placed at the base of the handle at the level of the lower third of the tile. It is recommended to cover the wings with adhesive tape, so that there will be no marks on the finished tile.

For good quality breaking of tiles, professionals hold the tile in place, press the handle a little with the thumb and then use the palm of your right hand to hit the handle a little.

If you can not split the tile, you should simply take another one and start the process of cutting anew.

Sometimes the cut edge of the tile can be seen when you put it back in place. Smooth the corner will help sanding stone or sandpaper. It is better to have several kinds of stone on hand, at least for hard and soft tiles.

Useful Tips for Avoiding Common Mistakes

- To ensure that the work went smoothly, before you start using the tile cutter, it is recommended to put a little oil on the wheel and the guide frame.

- To ensure that the cut is not crooked, you must check that the wheel is properly secured. Sometimes it is necessary to fasten it with a special bolt before the work begins.

- To obtain a good result, you must check before you start the work that the wheel is not worn out.

- The denser the tile, the easier it will be to cut it. It is even possible to cut off strips of tile that are only 5-6 mm thick with the described tool.

Article on how to put a tile on the wall. the entire technology of tiling walls with tiles from A to Z.

In detail with all the nuances of grouting tile joints can learn in the following article.

Facing the wall with Venetian plaster, the most complete guide.

Working with a hand-held tile cutter, even for a beginner, is not particularly difficult. The main thing is to carefully study the device, to understand how to use it correctly. Tips from the masters presented in this article will help to achieve a perfect result and successfully finish the repair.

The arrangement of hand tools

To understand the rules for using the tool, you need to find out how it works. Manual tile cutters have a common device for cutting tiles. Here the main structural elements are:

It is a solid metal base on which all the parts are located. On it the facing material is laid, so among the main criteria for selecting the device are the evenness of the support and the size according to the format of the tiles.

Additionally, it is worth paying attention to the anti-slip pads. One side has an additional nonerasable scale and a small projection that allows the ceramic piece to be broken along the cutting line.

They are represented by two parallel tubes with smooth outer walls. In more expensive designs, they are replaced by an I-beam. Their function is to keep the working mechanism in the desired position for the operator, ensuring the possibility of exerting a certain pressure on the tile. Also the guides are used to move this device.

The rigid element of the tile cutter to cut the tiles by hand. A cutting wheel, a lever and a special foot for breaking the facing material are fixed on it.

Platform, frame elements under the guides, as a rule, are made of cast steel, since the reliability and durability of the tool depend on their quality. The carriage and cutting element must be even stronger, so an alloy with m tungsten and cobalt is used for production here. To prevent the platform from sliding on the floor, rubber pads are fixed on the back side.

To use such a handheld tile cutter can both professional and novice master. In addition to this merit masters note other advantages:

- silent operation;

- the simplicity of the device;

- mobility;

- compactness;

- low weight;

- environmental friendliness

- low cost.

However, there are also disadvantages. Here it is difficult to form pieces less than 10 mm in width, the break line edge is sharp with small irregularities.

For large sites for tiling and for cutting thick porcelain tile, masters prefer to choose electric analogues. Also worth highlighting here is the high percentage of low quality cuts. And beginners often have tiles that break not along the intended line, which can only be straight.

Suggestions for choosing the right tool

Proper use of the tile cutter is not enough to get the desired results. It is also necessary that the tool is of high quality. When choosing, experts recommend paying attention to the following points:

- The rigidity of the platform and frame. The design must be reliable, without wobbling, creaking. The lack of vibration and flexibility of the monolithic device is a guarantee of quality and long life of the tile cutter. The same applies to the lever.

- The length of the metal base. Shorter models are only suitable for one-time use or if you want to equip your home workshop with additional compact tools.

- Smooth running of the carriage. Here the best solution is a tool that is equipped with bearings.

Among other things, additional details can be useful. For example, the presence of a protractor allows you to simplify the process of cutting tiles at a specific angle. An additional core bit carriage makes it easier to get the hole in the right place. There are enhancements to increase the support area under the tile, clamps.

How does a manual tile cutter with a mechanical stop work?

If electric tile cutters cut completely in two parts of the tile, with manual models it is different. The workpiece remains intact after it is cut by a cutting element. First, the tiles are placed on the bed. The handle with the carriage moves along the rails, simultaneously pushing the lever, so that the roller cuts firmly into the workpiece. When a deep groove appears on a tile, it is simply broken into two parts.

Cheap cutters dull quickly. If they are made of thin metal, there is vibration during work. All of these disadvantages lead to a large number of imperfections. For example, a blunted roller will cut a shallow groove and leave gaps. During pressure, the tile will crack not on the cut, but in a different place. The same applies to vibration. A line for a trimmer cut will turn out uneven. After breaking, the edge of the tile will have to be trimmed with an angle grinder.

Which tile cutter is right for you?

To understand how to use a tile cutter, first of all you need to understand what kind of tool is suitable. All devices are divided into 2 classes. household and electric. The latter are more powerful and are mainly used for industrial purposes.

As for household, these are handheld devices that are suitable specifically for home use. There are 3 classes of such tools:

- With a cutting roller. they are often used together with a sawing station.

- Another way to properly cut tiles with a tile cutter is to use devices on bearings. They are well suited for ceramic products, the thickness of which exceeds 16 mm.

- Mechanical ones are equipped with a rigid carriage, which allows for more precise cutting.

It is important to understand that all these models can cut a strip of at least 10 mm wide from the edge. If you need to understand how to properly cut a tile with a manual tile cutter, so that literally a few millimeters remain, you should use cutters. They provide more accurate results.

How to use the tool

The main question has to do with how to work the tile cutter. This is quite a simple procedure that requires minimal skills. The work is performed in several stages, which are described in detail below.

Preparing

The main way to properly use the tile cutter is related to the preparatory stage. Before turning the appliance on, check that it is in good working order. Most often the roller suffers. Its surface should be perfectly smooth. if there are jagged edges, replacement is required.

First, the device is inspected to make sure that there is no dust, dirt. All parts of the mechanism are tightened using screwdrivers. If you haven’t used it for a long time or if you’re not sure, you can lubricate the carriage with machine oil.

Marking

Before you cut the tile with the tile cutter, you need to mark all the break lines. To do this, determine the required size in advance and put a line for the trimmer with a special marker or pencil.

How to cut tile without cutter or tile machine || DIY || Creativity

Cutting

The next step is directly cutting. To do this, the blade is placed directly over the line and traverses it to the end. If you need to cut a small edge (up to 10 mm), you should understand how to use the tile cutter and wire cutters. This will help in such cases.

On the eve of cutting and during this process it is recommended to act as follows:

- An hour before work, cover the tiles with a wet towel or other cloth. This ensures that the material will not crumble and there will be hardly any splintering.

- Make sure the blade is not moving.

- The cutting part should be placed just above the marked break line.

- Then comes the main stage. you need to get a feel for how to work with a tile cutter.

- The cutter is placed at the very beginning of the line.

- Using a little force, move it over the ceramic surface. At the same time does not have a lot of movement, where to direct it (on itself or in the opposite direction). Work the way you want to work.

After that it is not difficult to figure out how to use an electric or manual tile cutter. Next, once the cutting element has passed the entire strip, the operator gently presses the lever. After that, the product is split exactly along the line.

How to cut tiles without a tile cutter?

Avoid buying a tile cutter if there are other tools at hand with which you can make an even cut.

Pliers. tile cutter

Note that it is suitable for rare use (for example, if you have started repairs in your apartment) and only if the tile is thin.

- Marking. Take into account all gaps and joints.

- Display fishing line for the break trimmer.

- Position the pliers so that the legs are along the drawn line next to the edge. The rectangular part should be on the bottom and the jaws on the front side.

- Smoothly, without haste, gently press down on the handle to break off a piece.

angle grinder

Use it to cut a 0.5 to cm wide strip. With such a task a simple tile cutter can not cope. Drawing a fishing line for a break trimmer. Next, make a burr with an angle grinder with a diamond roller. There is no need to rush and immediately make the cut across the entire tile. There is a high probability that the strip will break off.

Keep in mind that the disc must run along the line. If it goes along the line, the width will decrease. Swipe across the seam a few times to cut the strip.

Cutting is done with a disc. Steel discs are preferred: they are thinner than stone discs and last longer. Steel discs are divided into two kinds:

- Segmented. Divided by slits, which improves heat dissipation and provides free expansion of the metal when heated. Thanks to this, the saw blade is capable of 1 minute. cut tiles without cooling down, then rotate it for 20 to 0 seconds. In idle mode for cooling. Because of dry cutting ability these discs are called dry-cutting discs. Their disadvantage is the poor cut quality.

- Solid. Otherwise known as wet-cutting discs. No slots for thermal relief, so can only be operated dry for 10-15 seconds without interruption. Requires cold water in the cutting zone for extended periods of time. Compared to the segment disc, the solid disc cuts smoother and better.

- Combination disks. Can be used for both dry and wet cutting.

Combination discs rank between solid and segmented discs in terms of performance:

- Cutting quality: better than segmented, but worse than solid;

- Continuous tool life: Longer than solid tools, but shorter than segmented tools.

For one-time work of small volume. the combination disk is considered the most preferable. If the segmented and solid discs for cleaning from crumbs enough to set the other side, with a combined option does not work. Only one side of this cutting piece may be installed. Clean by cutting through sand-lime bricks or concrete tiles.

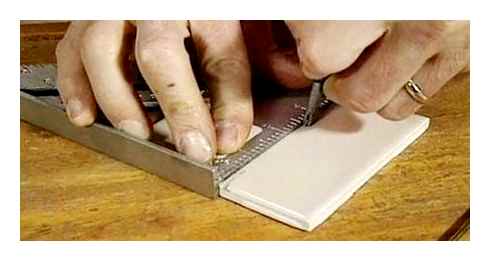

Glass cutter

- Place the strip on a flat table, cut side up.

- Place the ruler along the cut line. Without removing the ruler (which acts as a guide), place the glass cutter on top of the die.

- Using force, run a fishing line to trim the notch, this way you will reduce the resistance at the break.

- Place a nail under the strip.

- Press smoothly on the edge of the tile, trying to distribute the load evenly. The product must break along the cut line.

Drill bit with pobedite tip

This tool is relevant if you plan to make a hole in the tile. Drill bit with a pobedite tip does not cut, but crushes the material being worked.

Waterjet cutting machine

Abrasive waterjet cutting is suitable for any kind of material. This method consists in cutting by using a mixture (water, sand) with high pressure.