A real man must be the master of the house!

How to set the blade in a hacksaw

Hacksaw metal cutting

Work with a manual bench saw

The work is performed in the following sequence:

The canvas is inspected, paying attention to the absence of cracks, bends, as well as the separation of the teeth.

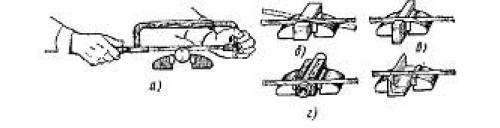

Fig. 74. The direction of the teeth of the hacksaw blade

Check the condition of the frame (case) of the hacksaw: the tightness of the handle, the free rotation of the wing nut, the movement of the sliding part and the tension pin, the presence of pins. Set the sliding part of the hacksaw according to the size of the blade, leaving the pin extended for tensioning 10-12 mm. Install the blade in the slots of the heads so that the teeth are directed away from the handle (Fig. 74). In this case, the end of the web is inserted first in the fixed head until the holes coincide and the position is fixed by the tab of the pin. Then insert the second end of the blade into the slot of the movable pin and secure it with a pin. Tighten the blade, screw the wing nut without much effort without resorting to pliers, a vise and other tools.

75. Arrangement of hands when working with a hacksaw

Standing near the vise when cutting with a hacksaw should be straight, free and stable, half-turn with respect to the jaws of the vise. The left (supporting) leg should be set slightly forward.

The instructor demonstrates the correct holding of a manual bench saw in three steps; 1) the hacksaw is taken in the right hand so that the handle rests on the palm of the hand (Fig. 75, a); 2) the handle is covered with four fingers, putting a thumb on the handle from above (Fig. 75, b); 3) with the fingers of the left hand take the front corner of the hacksaw, lamb and the tension bolt (Fig. 75, rff.

The hacksaw blade is mounted on a wide plane of the wooden block, creating at the beginning of cutting a slight slope of the front of the hacksaw down. To obtain the exact direction of cutting along the marking, it is necessary to put the thumbnail of the left hand at risk, press the hacksaw blade tightly to it (Fig. 76, a), and perform the cutting with the right hand (Fig. 76, b). Continuing the cutting, the cutting edge of the blade is gradually transferred to a horizontal position (Fig. 76, c).

Fig. 76. Work with a manual bench saw: a. setting the hacksaw blade at risk; b. reception of work at the beginning of the resia; in the reception of work in the cutting process

The movements when working with a hacksaw should be smooth, without jerking and in such a way that all the teeth of the blade participate in the cutting. The pace of movement when cutting with a hacksaw should be 30-60 moves per minute. When cutting is completed, you should loosen the pressure on the hacksaw, reduce the pace of movements to avoid breaking the blade and injuring hands. After finishing work, a hacksaw turned with a blade to the vise is placed on a workbench on the right side of the vise.

When cutting a metal bar of square cross-section, first mark the place of cutting, for which measure the length of the workpiece with a measuring ruler, causing risks to the scriber. After that, using a square with a wide base, spend the risks on the upper and two sides of the square.

How to insert the blade into the hacksaw for metal, how much to pull?

Next, the bar is clamped in a vice so that the risk is located on top.

Fig. 77. The position of the hacksaw blade during the initial cutting of blanks of various profiles: a. round: b. square; in. rectangular; g. pipes; d. angular

To preserve the teeth of the blade, the cutting starts g the back edge of the part, tilting the hacksaw away from itself until the cut starts with a slight pressure (Fig. 77, b). The inclination is gradually reduced until the cut reaches the leading edge and the hacksaw blade is horizontal. In this position, increase the pressure on the hacksaw while continuing to cut the bar

Metal cutting with a manual bench saw without turning the blade

For cutting metal bars of circular cross-section, the places of cutting are marked with a scriber. The bar is clamped horizontally in a vice, sliding the cut-off end to the left side of the vice lips so that when working with a hacksaw, its head does not touch the side surface of the vice. If the cutting plane is too far from the jaws, the bar will tremble when cutting, making it difficult to cut. The bar must be secured in a vice securely.

On the workpiece (at risk), a small cut is made with a trihedral file so that the hacksaw blade does not slip on the surface of the bar at the beginning of cutting. Then they take a hacksaw, take the working position, brush the blade with boiled oil, put the cutting edge of the hacksaw blade into the cut and start cutting (Fig. 77, a).

At the beginning of cutting, the pressure on the hacksaw blade should be less, and as the blade approaches the center of the bar, the pressure is increased.

During cutting, the hacksaw blade sometimes “leads” to the side, this creates an oblique slot (due to the weak tension of the blade or incorrect position of the hacksaw and its direction). If the blade is "led away" to the side, it is necessary to turn the bar and begin cutting g of the opposite side opposite the cut. At the end of cutting, loosen the pressure on the hacksaw and reduce the pace of movement.

to the end using the entire length of the hacksaw blade and constantly monitoring the position of the blade and its direction with respect to the risk. At the end of cutting, the pressure is relaxed.

Strip metal cutting (Fig. 77, c), as a rule, should be performed on the narrow side of the strip, provided that the cutting is performed with at least three teeth of a hacksaw blade. The fewer teeth are simultaneously involved in the work, the less pressure is applied to the hacksaw blade.

Cutting workpieces with a thickness less than the tooth tooth pitch should be done with a hacksaw in an upright position, with a slight pressure on the tool. In this case, work with a hacksaw slowly using the entire length of the hacksaw blade.

When cutting pipes, places of cutting are marked with a template. The template is made of thin tin bent around the circumference of the pipe.

A measuring ruler from the end of the pipe marks the length of the segment. The edge of the template is brought to the mark, applied with a scriber to the risk throughout

For cutting, the pipe is clamped horizontally in a vice. To avoid crushing the pipe, it is clamped in the gaskets (Fig. 77, f). For cutting, select a blade with small teeth (1 mm tooth pitch), make a cut with a triangular file at risk and start cutting. As the hacksaw blade deepens into the pipe wall, the hacksaw is tilted slightly towards itself. After cutting the pipe to the wall thickness, remove the hacksaw, turn the pipe away from yourself by 45-60 ° and continue cutting, combining the rotation of the pipe with cutting along the entire length of the pipe circumference. The pace of movement when cutting pipes should be 35-45 strokes per minute with a small pressure on the hacksaw. At the end of cutting, the pressure on the hacksaw must be loosened.

Before cutting the corner, it is marked on the planes of the shelves. The corner shelf should be installed in a vice (fig. 77, e). The corner must be cut along the narrow edge of the shelf where less cutting force is required. Therefore, cutting will be much easier.

Having cut the first shelf to the inner plane of the second shelf, the corner is set to the cutting position of the first shelf, continuing cutting to the end. At the end of cutting, it is necessary to loosen the pressure on the hacksaw.

The correctness of the cut is checked with a ruler, and the angle of 90 °. with a square.

Metal cutting with a manual bench saw with a turn of the blade

Fig. 78. Techniques for cutting metal with a manual hacksaw with a turn of the hacksaw blade

The work is performed in the following sequence:

- The markup is performed in the usual way.

- The hacksaw is prepared for work, and the quality of the blade and its suitability for work are checked.

- The cloth in the lateral slots of the heads must be installed perpendicular to the plane of the hacksaw (the teeth are directed from the handle); then put the pins in the hole and pull the canvas.

- Set the workpiece and clamp it in a vice on the side, extending the cut-off koice so that when cutting vertically, the hacksaw head does not touch the side surface of the vice and does not interfere with the movement of the hands. In addition, the workpiece should slightly rise above the level of the jaws of the vice, otherwise the workpiece will vibrate during cutting. When cutting, it is necessary to monitor the direction of the blade, maintaining the plane of the hacksaw in a horizontal position.

Movement with a hacksaw should be performed smoothly, without jerking, avoiding skewing of the blade, as this can lead to its withdrawal or damage.

As the metal is cut, the workpiece must be rearranged higher to continue cutting (Fig. 78), reducing the speed of movement and the force of pressing the hacksaw at the end of the cutting.

The size of the cut blank is checked for marked risks.

Related Content

How to cut

The tricks and subtleties of the file. sawing firewood. useful information for those who have not had time to prepare firewood for the winter. &# 128578;

A saw with poorly bred teeth is stuck in raw wood. It is enough to anoint the canvas with soap, as the work will go faster.

In order not to injure your hands while sharpening the saw, you need to close its teeth with a cover from a rubber tube cut along as in the picture on the right.

Firewood

Sawing wood will become much more convenient if you equip the goats with an average support. It should be slightly higher than the extreme, then the log will not clamp the saw.

Collapsible goats

Goats for sawing firewood are convenient to have collapsible and variable lengths. Such goats are convenient to store in the barn, you can cut logs of any length on them. To do this, the crosses must be movably mounted on the rod with fixation (for example, using a coupling clamp under the bolt) in any position. Goats are made of metal or wood, or a combination thereof.

An emphasis for joiner’s workbench

The home foreman should have in his technical arsenal a simple emphasis for the carpentry workbench, which reliably fixes the workpiece and relieves hands from frequent bruises and injuries.

One-man file with a two-handed saw

Everyone knows that sawing with a two-handed saw without an assistant is uncomfortable. But not everyone knows that instead of an assistant, you can put a spring, a thick rubber cord, an elastic bough to work. How this is done is shown in the figure.

Workbench

In the manufacture of such as the drawing on the bench, the idea of a wedge vice was used.

A groove is hollowed out on the right side of the board. Guide plates made of hard wood are screwed tightly to the edges of the groove with its upper edge. Two wedges are inserted into the groove between the guide bars. A metal visor with teeth (ruff) is embedded in one of them, with which it must dig into the end of the workpiece. Another wedge acts as a castle. He firmly holds the wedge with a ruff in the installed position.

Wedges, as well as guide rails, must be made of solid wood.

The part is fixed and freed from the clamp by light blows of a hammer sliding on special cutouts made for this on wedges.

The second emphasis for the workpiece is a check with an iron comb-ruff. It is inserted into one of the nests hollowed into the board.

So that you can fix parts of any length (naturally, within the length of your board), the distance between adjacent sockets should not exceed the length of the groove.

And one more important circumstance must be taken into account. So that it is possible to process thin parts on the bench, the protruding parts of the wedges and checks should not rise above the plane of the board by more than 10 millimeters.

Short log file

What to do if a short log does not want to fit into the goats? We need to take two boards, attach them to the horns as shown in the figure, and now you can safely cut any log.

Two-blade bow saw

For transverse and longitudinal sawing.

A beam saw with two blades for transverse and longitudinal sawing is a thing that is simply indispensable for the household. The tension device. an adjustable strut. is made in the center.

Hacksaw with two blades

For cutting grooves, spikes, rails, etc., it is convenient to put two blades on a hacksaw. The width of the cutout will be determined by the thickness of the insert between the webs.

Flat cut to a predetermined depth

Such a device to ensure an even and even predetermined cutting of the board to a depth can be done in your home workshop.

Two holes are made in the hacksaw (see. Fig.) And through them bolts with wing bolts fasten the line of the limiter with vertical slots. By setting the ruler, you can get an even cut, and if the appropriate divisions are applied to the cut, then the cut will turn out not only smooth, but also accurate to the desired depth.

Send request

How to cut a thin bar

At home, it is not so easy to saw off a thin bar: the saw is constantly coming off a straight line. The matter is facilitated by placing a board from below.

Cutting same stripes

In the technical arsenal of the home master it is very good to have a device that allows you to get the same size strips of plywood, non-thick boards, soft metal, plastic or pestiglass. The simplest design of such a device consists of two bars, fastened together by nails at a constant angle of the cutter, driven into the end of the upper beam.

A more advanced design allows you to use the wing nut to change the position of the torch and get, respectively, strips of any width.

Sawing identical boards

Often you can observe how, cutting a large number of boards of the same length, an inexperienced master walks with a ruler from one end of the board to the other, each time measuring the standard length. An experienced carpenter eliminates the hassle of a rake of the right length with emphasis on the end. It is enough to evenly cut the boards from one end, and then, using the rail as a template, cut them to the desired length.

Angle sawing

The simplest emphasis, made of solid wood, will greatly facilitate the work, when at home you need to cut the bars or boards at the right angle.

Board fixing during sawing

A simple fixture for carpentry. "wooden hook" will allow you to securely fix the board when sawing. With one protrusion, the device is pressed against a stool or table, the board abuts against another protrusion.

Hacksaw metal cutting

Hacksaw metal cutting

Next: Hacksaw cutting of round, square and sheet metal

Manual hacksaw (saw) is a tool designed for cutting thick sheets of strip, round and profile metal, as well as for cutting slots, groins, trimming and cutting workpieces along the contour and other works. Manual bench hacksaw consists of a machine (frame) and a hacksaw blade. At one end of the frame there is a fixed head with a shank and handle, and at the other end there is a movable head with a tension screw and nut (wing) for tensioning the web. There are slots in the heads into which the hacksaw blade is inserted and fixed with pins.

Frames for hacksaws are made either solid (for a hacksaw blade of one certain length) (rarely), or sliding, allowing fixing hacksaw blade of various lengths.

To extend the hacksaw, the knees are bent until the rivet comes out of the cut and displaced. The rivet is inserted into another cut and the knees are straightened.

A machine with a movable holder consists of a square with a handle along which the holder can be moved and fixed in position.

Fig. 1. Crank shears with inclined knives

Hacksaw blade is a thin and narrow steel plate with two holes and with teeth on one of the ribs. Cloths are made of steel grades: U10A, P9, X6VF, their hardness is HRC 61-64. Hacksaw blades are divided into manual and machine depending on the purpose. The canvas is inserted into the frame with the teeth forward.

The size (length) of the hacksaw blade is determined by the distance between the centers of the holes for the pins. Hacksaw blades are most often used for hand hacksaws with a length of L. 250. 300 mm, a height of b. 13 and 16 mm, a thickness of h. 0.65 and 0.8 mm.

Each tooth of a hacksaw cloth has the form of a wedge (cutter). On the tooth, as well as on the incisor, the posterior angle is distinguished, a, the angle of sharpening (3, the rake angle y and the cutting angle 5. a p y = 90 °; and p = 5.

The working conditions of the hacksaw blade differ from the working conditions of the cutter, so the angles here are different. When cutting metal of large width, cuts of considerable length are obtained, in which each tooth of the blade removes shavings that look like a comma. This shavings should be placed in the chip space until the tip of the tooth comes out of the cut. The amount of chip space depends on the size of the rear angle a, the front angle y and the tooth pitch S.

Fig. 2. Manual bench hacksaw (machine): a. solid, b. sliding, c. with a mobile holder, d. hacksaw blade; 1. wing nut, 2. frame (machine), 3. movable head, 4. hacksaw blade, 5. fixed head, 6. shank with a handle, 7. pins, 8. slots, 9. tension screw, 10. movable staple

Depending on the hardness of the metal being cut, the rake angle of the teeth of the hacksaw blade may be zero, positive or negative.

The cutting performance of a hacksaw blade with a zero rake angle is lower than a blade with a rake angle greater than 0 °.

For cutting harder materials, we use canvases in which the angle of sharpening of the teeth is larger; for cutting soft materials, the angle of sharpening is smaller. Cloths with a large sharpening angle are more wear-resistant.

For cutting metals, mainly hacksaw blades with a pitch of 1.3-1.6 mm are used, with 17 to 20 teeth on a length of 25 mm. The thicker the cut workpiece, the larger the teeth should be, and vice versa, the finer the workpiece, the smaller the teeth of the hacksaw blade should be. For metals of different hardness, canvases with the number of teeth are used: soft metals. 16, medium hardness. hardened steel. 19, cast iron, tool steel. 22, hard, strip and angle steel. 22.

When cutting with a hand hacksaw, at least two or three teeth must be involved (simultaneously cutting metal). To avoid jamming (pinching) of the hacksaw blade in the metal, the teeth are bred.

The wiring of the teeth of the hacksaw blade is done so that the width of the cut made by the hacksaw is slightly larger than the thickness of the blade. This prevents the web from jamming in the section and greatly facilitates the work.

Video: How to Put a Canvas on a Hacksaw

Fig. 3. Elements of a tooth of a hacksaw blade: a. teeth of a hacksaw blade; tooth rake angle: b. positive, c. zero, d. negative; d— step

Fig. 4. Installation of a hacksaw cloth: a. correctly, b. incorrectly, c. tension of a cloth

Depending on the size of step S, the wiring is done along the blade and along the tooth.

Hacksaw blades with a tooth pitch of 0.8 mm (also allowed for 1 mm pitch) must have a tooth layout on the blade (wavy), i.e., every two adjacent teeth are bent 0.25. 0.6 mm in opposite directions. The wiring is performed at a height of not more than twice the height of the tooth. The wiring step is taken equal to 8S.

The blade with a tooth pitch of more than 0.8 mm is bred along the tooth (corrugated bend). In this case, with a small tooth pitch, two or three teeth are moved to the right and two or three to the left. With an average step, one tooth is taken to the left, the second to the right, and the third is not taken away.

Hacksaw blade

With a large step, one tooth is removed to the left, and the second to the right. Tooth wiring is used for canvases with a pitch of 1.25 and 1.6 mm.

The wiring of the hacksaw blade should end at a distance of no more than 30 mm from the end.

Preparing to work with a hacksaw. Before working with a hacksaw (hacksaw), the material being cut is firmly fixed in a vice. The level of metal fastening in a vice should correspond to the growth of the worker. Then choose a hacksaw blade, in accordance with the hardness, shape and size of the cut metal.

For long cuts, hacksaw blades with a large tooth pitch are taken, and for short cuts. with a small tooth pitch.

Hacksaw blade set in the slot head so that the teeth were directed from the handle, and not to the handle. In this case, the end of the web is first inserted into the fixed head and the position is fixed by the pin tab, then the second end of the web is inserted into the slot of the movable pin and fixed with a pin. The fabric is pulled by hand without much effort (the use of pliers, a vice, etc.) is prohibited by rotation of the wing nut. At the same time, due to fear of tearing the blade, the hacksaw is kept remote from the face.

Tightly stretched fabric with a slight bias and slightly stretched with increased pressure create an excess of the canvas and can cause a break. The degree of tension of the web is checked by lightly pressing a finger on the web from the side: if the web does not bend, the tension is sufficient.

The position of the working body. When cutting metal with a hand hacksaw, they stand in front of the vice directly, freely and steadily, half-turn with respect to the jaws of the vice or the axis of the workpiece. The left leg is slightly advanced forward, approximately along the line of the object being cut, and the body is supported on it. The feet are placed so that they form an angle of 60. 70 ° at a certain distance between the heels.

Hand position (grip). The worker’s position is considered correct if the right hand with a hacksaw mounted on the jaws of the vice (in the initial position), bent at the elbow, forms a right angle (90 °) between the shoulder and ulnar parts of the hand (Fig. 121, a).

The handle (handle) is grabbed with the right hand so that the handle rests on the palm of your hand (Fig. 5, b). The handle is wrapped around with four fingers, the thumb is laid on top along the handle. Fingers of the left hand grasp the nut and the movable head of the hacksaw.

When cutting with a hacksaw, as well as when filing, strict coordination of efforts (balancing) should be observed, consisting in the correct increase in hand pressure. The movement of the hacksaw must be strictly horizontal. They press on the machine with both hands, but the greatest effort is made with the left hand, and the reciprocating movement of the hacksaw is performed mainly with the right hand.

The cutting process consists of two moves:

– the worker when the hacksaw moves forward from the worker, and idle when the hacksaw moves back towards the worker.

When idling, the hacksaw is not pressed, as a result of which the teeth only slide, and when working, both hands create a slight pressure so that the hacksaw moves in a straight line. When working with a hacksaw, the following rules must be followed: short workpieces are cut along the widest side. When cutting rolled angular, tee and channel profiles, it is better to change the position of the workpiece than to cut on the narrow side;

– all hacksaw blade should be involved in the work;

– work with a hacksaw slowly, smoothly, without jerking, making no more than 30-60 double strokes per minute (hard steel. 30-40, steel of medium hardness. 40-50, mild steel. 50-60).

Fig. 5. Position at work: b. the right hand, c. the left hand, and. the case and hacksaw g. legs

At a faster pace, fatigue is more likely and, in addition, the canvas heats up and dulls faster:

– before the end of the cut, the pressure on the hacksaw is weakened, since with heavy pressure the hacksaw blade jumps out of the saw sharply, hitting a vice or part, as a result of which it can cause injury;

– When cutting, do not allow the blade to heat up. To reduce the friction of the blade against the walls in the cut, parts are periodically lubricated with mineral oil or graphite lubricant, especially when cutting viscous metals;

– brass and bronze are cut only with new canvases, since even little-worn teeth do not cut, but slide;

– in case of breakage or chipping of at least one tooth, the work is immediately stopped, the remnants of the broken tooth are removed from the cut, the blade is replaced with a new one or two or three adjacent teeth are ground on the machine and then work continues.

Fig. 6. Hacksaw cutting with deep cuts: a. without turning the blade, b. with the blade turning 90 °, c. work in a closed loop, d. the position of the fingers of the left hand

Read more:

Hacksaw cutting of round, square and sheet metal

Related Articles:

Advertising:

Home → Directory → Articles → Blog → Forum

Universal mini. hacksaw for metal

Hacksaw

A hacksaw for metal is a multifunctional tool with which you can perform various types of household work. For example, if necessary, you can cut a piece of pipe, saw off metal workpieces, and much more. In addition, with the help of such a hacksaw you will get the opportunity to work not only with metal, but also with many other types of materials. For example, she will be able to cut wood or plastic, if you do not have a special saw for wood.

What does a hacksaw look like?

The main element of a hacksaw for metal is its working part, which is a thin serrated blade. It can be made of composite material or steel.

The handle of the tool is of great importance for its convenient use. The best option is a two-component handle equipped with a rubber insert.

Different models of hacksaws for metal can be supplemented with such functions:

- the ability to adjust the angle of inclination;

- shortened frame;

- the possibility of replacing old canvases with new ones after their wear.

Types of hacksaws for metal

Classification of hacksaws implies their division into two main types:

The choice of tool, as a rule, depends on how much work is planned to be carried out. A mechanical hacksaw for metal is used for relatively small work. In addition, she will help out in those situations where there is no possibility of connecting to the mains.

Depending on the design, mechanical hacksaws for metal can be divided into the following types:

- machines with double-sided web attachment. are quite common. Their main function is to tension the web;

- machines with a wooden horizontal handle. this design is considered obsolete and inconvenient, therefore it is quite rare in recent times;

- machines with a closed handle. consists of a half frame, bent at an angle of 90 ° C, with a closed handle, slightly tilted forward. Such hacksaws are very popular due to their easy-to-use construction;

- machines with one-sided web fastening. designed to work in hard-to-reach places;

- circular saws. they require special blades with curly grooves for attachment to the machine.

The use of an electric hacksaw for metal has both its pros and cons. The advantages of such a device include:

- ease of use. It cuts metal with ease and effortlessly;

- the ability to carry out work much faster.

Among the shortcomings of the electric hacksaw can be identified:

- the need for the mandatory availability of an electrical network;

- much heavier weight compared to a mechanical tool;

- high price.

Mini Hacksaw

One of the varieties of the tool is a mini hacksaw for metal. It is distinguished by its miniature canvas size. For most devices, a blade size of 300 mm is typical, while a mini hacksaw has a blade with a length of about 150 mm.

This type of tool will provide indispensable assistance in the case of the need for accurate work that requires high precision. It will allow you to get to hard-to-reach places where access for a conventional hacksaw is limited. For example, a mini hacksaw will help to cut in a narrow closed pipe.

Thus, a hacksaw for metal is a device that will help you with household or repair work. Depending on their volume, you can choose a tool with the most suitable characteristics for you.

installation of a hacksaw blade

Hacksaw blades

Hacksaw is a hand tool that is used to cut profile metal and pipes. The simplest hacksaw for metal consists of a machine tool and a hacksaw blade. The machine, in turn, consists of a frame into which, on the one hand, a handle is inserted that has a device for fixing the web, and on the other hand, a device for fixing and adjusting the web tension. The tensioning device, on the one hand, has a groove for inserting and fixing the web, and on the other hand, a screw with a ram which is used to tension the web.

The hacksaw blades for metal differ from each other in width, long, thickness, distance between the teeth and their height. The use of a particular blade depends on the thickness, hardness and shape of the material to be cut. Manufacturers of paintings made sure that you could pick up a canvas just for the material that you need to cut, whether it be aluminum, copper, bronze or even plastic. The dimensions of the blade, namely the length, width, dimensions of the teeth and the grade of steel, can be found on the hacksaw blade purchased.

How to set the blade in a hacksaw for metal?

As shown in the first picture of the article: the teeth are down (if the blade is one-sided) and the teeth are directed forward from the handle. When you saw, you apply pressure down and forward. the hacksaw teeth should be directed in the same way, down and forward. To install, loosen the tension screw, remove the old canvas from the pins, put on a new one and tighten it so that the canvas rings like a string from the click of a fingernail. The main thing here is not to overdo it and not break the canvas. Empirically, you will find the optimum tension.

The tension is made using a ram on the adjusting device, that is, spinning the ram you will pull the canvas. So when pulling a hacksaw blade you need to find a middle ground. Also, make sure that the blade is installed evenly, without distortions, as the distortion will result in uneven cuts during cutting.

How to cut?

Since you were interested in the question of installing the blade, then the advice on how to use a hacksaw for metal would not hurt. Grasp with one hand (right, if you are right-handed or left, if left-handed) by the hacksaw handle, with the other. by the vertical edge of the hacksaw arc opposite the handle. Place the blade on the cut line. Guide the blade exactly in the direction of the cut line. Make the angle of the hacksaw small. The canvas should almost lie on the part, usually at an angle of 30-45 degrees. So there will be less vibration, noise and a smoother cut line. Cutting across the material, with an angle of 90 degrees, is only necessary in emergency cases, for example, when turning the cut line. The smoother you need the cut line, the smaller the angle.

The first movements need to be done with little effort so that the blade crashes into the material and does not slip away from the cutting line. Making smooth movements, strictly progressively, press the hacksaw to the part when moving forward and weaken the pressure when returning to its original state. When the canvas clings to the material. you can work at full strength.

The range of motion is maximum, from the edge of the blade to the edge, without hitting the part with an arc of a hacksaw. No need to stagnate. you will quickly erase the canvas in one area and have to throw it away, because it is impossible to use a flawed canvas. Keep the hacksaw arc straight, do not let it bow in different directions. The direction of cutting corresponds to the plane of the hacksaw’s arc, therefore, chatter here is contraindicated. In addition, the blade breaks easily with sharp jerking jigsaws to the side. The properties of the web material are such that it holds the longitudinal tensile force very well, but is very brittle to bend.

Cut with a hacksaw along a curved line.

A hacksaw for metal is also valuable in that it allows you to cut in almost any curved line. In order to cut along the arc without stopping the translational movements of the hacksaw, align it perpendicular to the end face of the material of the part (i.e., the angle of inclination is 90 degrees) and gradually smoothly turn the hacksaw arc so that the blade follows the intended line. Yes, it is always necessary to mark the cut line with anything. with a pencil, marker, scratch with a nail. The main thing is to see it when you work. Turning the canvas should be done as gently and smoothly as possible, otherwise it will break; turns are extreme for a hacksaw blade for metal.

If you need to make a sharp turn, say, by 90 degrees, you will have to practically stomp on the spot, continuing to saw and smoothly turn the hacksaw arc, periodically stepping back so as not to go far from the turning point, using the side of the material to turn the canvas that external for the part.

To cut the inner corner, you first need to drill a straight line with a thin drill slightly longer than the width of the blade, thread the blade into this groove and cut further with a hacksaw. In general, practice will show how this is done. Nothing complicated here.

The figure below shows another way to use a hacksaw for metal. For this method, you need to reinstall the canvas by rotating it 90 degrees.

Hacksaw blades for metal

Send request

Metal cutting is a laborious task, requiring serious patience, and requiring good tools.

One of the most common tools is a hacksaw for metal. Basically, the type of hacksaw is about the same; the blade replacement mechanism is different.

Two fastenings of the web are common, this is a threaded clamp, the web is fixed and tensioned with a special nut with a wing.

Another type of attachment is a linkage. Hacksaw blade for metal in this case is removed and installed with the participation of a small lever.

In the latter case, according to the manufacturers, the removal and installation of the web is faster. But the cost of such a hacksaw is much more expensive.

It is somehow difficult to imagine a person who would work without breaking away with a hacksaw all day, and the speed of changing the blade would be very important for him.

Therefore, the choice of the mechanism for fastening the hacksaw for metal depends solely on your desire, no more. Well, from the fullness of the wallet, too.

There are plenty of hacksaw blades to this day. The choice is primarily between domestic and foreign manufacturers.

Domestic canvases do not differ in quality, they quickly blunt, teeth fall out. But their cost is five, and sometimes fifteen times lower than foreign.

Metal sheets as red-hot and bimetal are also distinguished. The latter are more flexible, less likely to break, but also more expensive than red-hot ones.

Hacksaw blades differ in the number of teeth, they come with 18, 24 and 32 teeth.

To cut a harder material, you need to take a blade with a large number of teeth, and vice versa.

If you take a sheet of metal with a small number of teeth for cutting solid material, then sawing will be much more difficult.

It is necessary to install the blade in a hacksaw for metal correctly, the teeth should be directed in the opposite direction from the working one.

Only in this case, less work will be spent on working with a hacksaw and metal cutting will be easier and faster.

How to correctly and quickly saw with a hacksaw for metal?

To be honest, I don’t know any special secrets, but there are some nuances that should be observed.

About 30 years ago, when it wasn’t particularly about fortunes and angle grinders that my father heard all the work with metal, it was an ordinary hacksaw for metal. And a hand drill.

Firstly, I would advise you to choose a hacksaw, as in the second photo. This option is more convenient to work with. It’s just more convenient to hold it in your hands and the handle will not slip in your hand.

When installing the blade, pay attention to the correct positioning of the teeth. As shown in the photo, they should go away from the cutter. When cutting, you need to apply force when the saw comes from itself. Returning the saw back, you need to slightly raise the handle and relieve pressure on the saw itself. So the teeth will remain in working condition longer.

It is also worth paying attention to the tension of the blade when installing it in the saw. If the blade is slightly stretched or too tight, then with the slightest oscillation of the saw, it simply breaks.

Well, so that the blade does not get too hot, a couple of drops of oil can be dripped into the cut area.

Well, do not forget that the metal that is cut can simply be broken. That is, sometimes it is enough to saw off half, for example, a pipe or corner, and simply break the rest of it, by bending to one and the other side.

I would also like to draw attention to the fact that the part that is supposed to be cut is desirable (if possible) to be firmly fixed, for example, in a vice.

the author of the question chose this answer as the best

There are no secrets. It is necessary to remember several important points and the metal will dissipate like butter on a knife.

You need to choose a saw with a comfortable handle and durable. We choose a canvas not from cheap, but with a spray on the teeth of a durable composition. Placed the blade in the saw so that the prongs of the blade were facing away from you.

When performing a split, you need to actively use force when moving the saw away from you and simply carry out the movement away from you without load. Try to perform a cut with the position of the blade with the maximum contact area of the teeth of the blade with the surface of the object that needs to be sawn or sawed. As for the split of the pipe, it is enough to file the pipe to half and a little more, as it can break clearly under your little effort. Much depends on the thickness of the pipe and its age.

add to favorites link thank

As many colleagues have already noted, when performing work with a hacksaw for metal when cutting (sawing), it is necessary to pay attention to the following points:

- strong and with a convenient handle frame saw;

- high-quality and appropriate steps for a particular metal (depending on the viscosity and hardness of the metal) hacksaw blades;

- the direction of the teeth is set by yourself;

- hand movements should be smooth and with a wide amplitude.

As for the nuances, I can say that hacksaw blades are a material with high hardness and brittleness and are afraid of overheating. Therefore, make permanent stops at work and the saw will serve you for a long time.

add to favorites link thank

The secret of your acquaintance is probably not in the way of working with the tool, but in the tool itself. Handling a hacksaw for metal is taught back in school (many made hammers, corners, etc.), so there are no special secrets: put the canvas correctly and keep it flat when you saw it. But in my practice, there were special canvases for metal (I don’t remember exactly from where: either from a fur saw, or from some other machine, but not the point.), Which easily cut pipes in an apartment and other metal objects that are easier it was cut with a hacksaw, than to rotate an angle grinder for the sake of this business.

add to favorites link thank

I can offer several recommendations that will speed up the sawing of metal with a hacksaw:

- Use a hacksaw with a sturdy frame made of composite materials.

- for work, it is better to buy canvases bimetallic, with hardened teeth.

- for metals of different hardness, select a blade with the appropriate number of teeth:

for soft metals, the number of teeth should be minimal. 16-18pcs / inch.

for hard metals. maximum (32 teeth per 25mm).

- it is more rational to use new blades for cutting softer and more viscous metals (aluminum, brass, bronze, copper.), and second-hand. for hard (steel, cast iron.)

- if the blade is broken, it is necessary to clean the cut from the fragments of the blade that may have remained there and only after that continue to work with a new blade.

By the way, if only one or a couple of teeth breaks down, the blade can be saved from further destruction if done on an emery (grind) in this place an arc (notch) with rounded edges.

- not always a high pace of work means fast cutting of metal. There is a certain dependence of the number of reciprocating movements on the hardness of the metal.

The harder the metal, the less intensive it is to work, otherwise the canvas will overheat and will quickly sit down.

The position of the hacksaw, arms, body and legs is clearly demonstrated by this figure.

To learn how to quickly saw with a hacksaw for metal, you need to understand the following!

First. the hacksaw is sawing only in the forward direction.

The second is that in order for the hacksaw to saw metal, it is necessary to apply uniform force when feeding the hacksaw forward and completely weaken it when pulling back.

Thirdly, the movement of the hands should be as confident, uniform as possible, as flat as possible (without swaying to the sides, blockages to the sides and forward, without twists and turns).

Fourth. the need to lubricate the hacksaw blade with machine oil on both sides, before sawing, and with significant cuts and applying grease to the blade as it develops.

Fifth, it is necessary to periodically water the incision so that it does not overheat and does not overheat the hacksaw blade, because of which hardening can be released and the blade will simply be erased.

Sixth. the metal that you are going to saw certainly matters, because not every metal can be easily sawed with a hacksaw, but there are some that cannot be cut at all, it is advisable to use a diamond cutting tool.

So these are the nuances. I hope to stop on the choice and installation of the canvas is not necessary, and in the previous answers it is already more or less described.

No comments yet!

How to cut metal manually

Metal cutting is one of the most common methods of processing this durable, hard and elastic material. Without the use of sophisticated equipment, using simple mechanical devices, you can get parts of the required shapes and sizes at home. Consider the basic tools and the range of tasks that they solve.

Manual metal cutting is performed with or without chip removal. In the first case, use hacksaws, in the second. scissors, pipe cutters, nippers. Based on the thickness, shape, and size of the metal profile, one or another tool is preferred.

Scissors for metal

Manual scissors are used for cutting sheet steel with a thickness of 0.5 to 1.2 mm. They allow you to develop significant effort thanks to their long handles and short blades that are hardened to high hardness (52. 60 HRC).

Distinguish between left and right scissors. Left are called scissors, in which the bevel of the cutting part of the lower blade is located on the left. It is convenient for them to cut metal in a straight line, as well as counterclockwise.

Manual scissors can be with straight or curved blades. The latter are used when cutting holes, parts of complex shapes.

The edges of the scissors should be sharpened sharply and abut against each other with a small gap along the entire length. If the gap is small, this will lead to rapid wear of the tool, if large, to the crushing of the metal.

Manual reinforced scissors have the same dimensions as conventional ones. However, they allow you to develop great efforts thanks to a system of two levers connected in series with each other.

Lever shears are used for cutting steel up to 4 mm thick and non-ferrous metal. up to 6 mm. They consist of two knives, one of which is fixedly mounted on the bed, and the other is driven by a long handle. In addition to sheet steel, manual lever scissors allow you to work with bar and profile metal.

Hacksaws

Hand hacksaw consists of a frame and a hacksaw blade. They are used for cutting profile, sheet metal, cutting blanks. Hacksaw frames are made whole or sliding, allowing the use of paintings of various lengths.

The hacksaw blade is a hardened narrow steel plate with teeth hardened up to 60 ÷ 63 HRC. The thicker the part to be cut, the larger the teeth should be.

Canvas for hacksaw for metal. How to choose and install?

Their number per unit length may be different. In plumbing for soft metals, hacksaw blades are typically used having 16-18 teeth per inch.

Pipe cutters

Pipe cutters are used for cutting metal pipes of various diameters. ¼. 4 inches. Compared to hacksaws, they are more productive.

Pipes of small diameter are cut with three-roll pipe cutters. They have two rollers (discs) mounted in a housing on fixed axes. The third roller in the cutting process is pressed against the pipe with a screw.

Nippers

Nippers are designed for cutting metal rods, wire, wires. According to the location of the cutting edges, two types of this tool are distinguished: end and side nippers.

Bolt cutters are used for biting thick wire, bolts, reinforcement. They allow you to develop significant cutting forces due to their double-lever design.