How to remove the chain sprocket from a chainsaw Husqvarna, Partner, STIHL with your own hands

Gasoline chain saws, like most other tools, require periodic diagnosis of failures and replacement of worn parts. A significant portion of these are related to the chainsaw drive sprocket or clutch disc, one of the important elements of all chainsaws without exception. Despite the relative simplicity of its construction and the hints of the instruction manual, every year thousands of inexperienced masters are stumped in this matter and spend money on service centers or make it wrong, which further aggravates the problem.

That’s why we will focus on this topic and understand the structure, functional features and repair of this working unit of chainsaws.

The structure of the chain saw sprocket

The sprocket or centrifugal mechanism is a part that resembles a star in shape. It takes up the motor’s torque and transmits it to the guide bar and saw chain. This guarantees the rotation of the cutting attachment and the sawing process itself. It operates in automatic mode, which depends on the RPM of the machine.

The clutch drum can be located on the outside of the chain saw or inside the chainsaw. under a separate cover. The clutch is not a safety device, not only for the sprocket material, but also for the operator who can be injured with it in the process of operation. In addition to the chain rotation function, the drive sprocket prevents malfunctions in the engine system if the chain jams or stops turning.

When the clutch needs to be replaced

The clutch is removed and disassembled in the following cases

- If the spring has broken, when the motor is functioning unsteadily;

- The spring has broken;

- The drum is chipped and you hear a noise;

- Natural wear and tear after continued use.

The engines, with which almost all modern chainsaw models are equipped, are connected by a gearbox to the sawing surface. The chain moves, but if the idle is on, it remains stationary. When the load is much greater than allowed, the clutch stops delivering torque to the tire. This will cause the engine to stop. If that happens often, it will wear out the clutch more quickly. Some manufacturers specifically state in their tool instructions that the clutch is not a major part that needs to be replaced after a.

Chainsaw clutch replacement. Recommendations and video reviews

Chainsaw clutch failures are one of the most common failures of this equipment.

Over the question of how to remove the clutch on the chainsaw at home correctly and not to harm the tool, think not only inexperienced technicians, but also experts who have more than once made its repair.

In cases where the gasoline-powered cutters start badly, stalling instead of starting check the clutch for malfunctions is mandatory, recommendations for which will be presented below.

chain saw owners must have repeatedly wondered how to change the clutch on their chain saw? on most chainsaw models the disassembly and the clutch replacement can be done manually by the owner, on few models the unscrewing of the drum can be done only in the workshop (those are, for example, Husqvarna 137 or Partner 351).

In this review we will learn how to remove and change the clutch on a chainsaw yourself, when to do it and what tools you may need.

Chainsaw clutch drum is one of the most common chain saw consumables, because it is the one that drives the cutting chain. The drums themselves are divided into two types. with a welded drive sprocket and with a replacement ring, and in the second case, only the replacement ring wears out, the drum itself is replaced much less often.

Performing the repair of the chainsaw clutch, adhere to the rule. when two chains are completely worn out, the tire is replaced, when two tires are worn out, the clutch drum is replaced.

The wear level of the sprocket can be determined without special devices, it’s enough to inspect it. the chain, moving at high speed, in time rubs the teeth, on which it moves. If the wear is severe enough, replacement of the chainsaw clutch drum is inevitable.

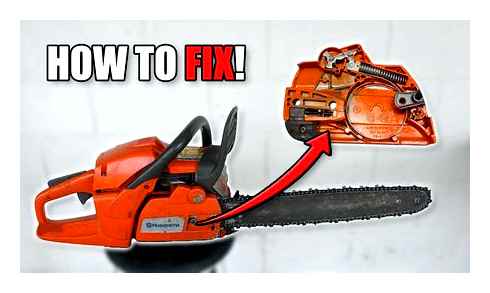

This article is about the Husqvarna 137 chain saw. The replacement of the clutch drum is not a complicated procedure, and takes place in a few steps.

- First you have to remove the tire and chain brake cover. The combination wrench that comes with the chain saw is a good way to do this.

- Then we remove the air filter cover, unscrew the spark plug, stop the piston of the Husqvarna 137 chain saw. For this procedure it is recommended to use an ordinary rope, because if you use a metal stopper there is a risk of puncturing the piston.

- On the clutch disc itself there is a direction for its removal and two holes for the clutch puller.

- Unscrew the clutch clockwise and remove it. There is a pressure washer under the clutch disc and this must also be removed.

- Under the clutch drum itself, there is an oil pump with a washer on which the new drum is mounted.

- Reassembling the chainsaw is done in reverse order except for tightening the clutch disc. After the clutch is threaded, the piston must be re-locked to prevent deformation of the starter group, which is on the other side of the crankshaft.

Chainsaw clutch drum replacement is an essential part of maintenance that will extend the life of all cutting equipment components. It takes only a few seconds for the chain to stretch if a new chain on a worn drum is fitted.

In turn, this will cause a slight increase in chain pitch, increasing the load on the bearing and sprocket on the bar itself.

So if you decide to skimp on timely service, then be prepared for the fact that after a short period of time you will need to make a much more serious investment in the purchase of all consumables of the cutting equipment.

Read more: Chainsaw chain. Chain marking and beginner’s guide to sizing chains

When servicing clutches yourself, you need to know that:

- Some saws have a washer between the sprocket and the clutch, and between the sprocket and the motor. This must not be allowed to be damaged or moved back into its original position;

- The special spring for the oil pump actuator must not be damaged during disassembly and must be returned to its original position. If not, the chain will not receive enough lubrication or will stop lubricating.

Any repaired tool should be checked to make sure the bolt ties are secure, the chain is lubricated and the motor is running smoothly (it should start smoothly and run smoothly). Only then can it be operated.

Repair chainsaw clutch with your own hands is carried out only in special protective clothing: mask and goggles.

The main faults, their causes and solutions:

- If the chain mechanism constantly rotates with unstable operation of the power unit. This could be caused by a failed spring. In this case, it is recommended to replace the damaged mechanism with a new one.

- During the movement of the chain, you hear extraneous noises. This problem may be caused by an overheated cam or a cracked spring. You should inspect the system externally and replace all worn parts.

- If breakage is caused by the fact that the hitch slips often, you need to replace the mechanism completely.

In addition to the basic rules of operation described in the previous section, it is worth remembering about some nuances when replacing the clutch. Use only original parts of the manufacturer. this is the guarantee of a long and productive work of the tool. The clutch thread on all chainsaws from any manufacturer is always on the left. Before removing the clutch, carefully remove all dirt and dust from the tool so that it does not get inside.

Champion chainsaw starter unit

The Champion chain saw has not too many design features that distinguish it from other well-known makes. At the same time, without exception, all parts in the design of Champion chain saws are of excellent quality and high reliability.

To start the Champion chainsaw, your unit has a starter motor, which has no additional springs. Its engine is responsible for the stillness of the chainsaw’s saw element at idle for the clutch tool.

Every Champion chainsaw has comfortable, ergonomic handles with rubberized surfaces. Levers and switches are responsible for turning the tool on, monitoring, and turning it off. Champion chainsaw accessory includes a bar and a chain.

Champion 240 Purpose

As a rule, the Champion 240 chainsaw is purchased for working in the countryside. The model class allows the saw to be used for more demanding applications. At the same time, many owners recommend using the product only for household needs. Based on the manufacturer’s recommendations, the Champion 240 chainsaw can be used

- for cutting material in the construction of wood premises on the site;

- when making firewood;

- for garden maintenance work;

- at the logging company for simple tasks.

Types of stars

Depending on the class of the chainsaw, all sprockets are divided into two groups. professional and domestic. The first type of parts have increased wear resistance, made of durable metal alloys, not subject to corrosion and mechanical damage. Domestic more often require replacement and scheduled repairs, with active use of the tool, diagnosis is recommended every six months. The following types of sprockets can be distinguished according to their design features:

- Prefabricated. Removable crown gear is easy to unscrew from the drum axle, making it easy to check and replace. Almost all European chainsaw models are equipped with such stars.

- One-piece. They consist of a hub and a stationary ring (the number of teeth can be different, it is necessary to read the instructions of the chainsaw carefully). Because it is pressed in place at the factory, it cannot be removed separately from the hub, so if it fails, the entire clutch drum has to be disassembled. This mechanism is commonly found on Chinese models.

If you plan to service your chainsaw yourself, it is advisable to buy a tool with a professional type drive sprocket. It should be demountable, which makes repair and maintenance of the tool cheaper.

Block: 3/7 | Number of characters: 1176

chainsaw sprocket design

The chainsaw has not only a drive sprocket, but also a driven sprocket. The chainsaw drive sprocket is in the structure of the tool, and the idler sprocket is on the end of the bar. The purpose of the slave tool is to align the tension and direction of movement of the chain block.

Drives are available as one-piece or modular units. Solid products consist of a hub with a pressed ring gear. When replacing, you must remove the complete gear assembly because the toothed structure is one piece. Many well-known chainsaws are equipped with solid gears ex-works.

What a solid pinion looks like on a chainsaw

One-piece products are more advanced because the process of their replacement is simplified by the simple design of the mechanism. Only one ring gear is replaced, which costs half as much as a prefabricated mechanism. The following signs are an indication of proper gear tooth wear:

- Having large radii at tooth junction points

- Uneven tooth width

- Metal chips and shavings detected on top of the teeth

- Burrs and risks on the inside surface of the hub bores

- Chain jamming is detected when the tool is started

If the drive unit is worn, it is imperative that it be replaced. You can do it yourself, for which you first disassemble the tool, and determine the option of the installed device. Even if a non-dismountable pinion is installed on the tool, it is possible to install a prefabricated mechanism instead of it, which is more rational.

There are two different types of drive sprocket mounting on chain saws. The first method involves placing the pinion on the outside. Such designs are the most common on STIHL chain saws. The design of such a device is shown in the photo below.

The product is of the non-disassembled type on the tool

The second option is characteristic for tools of Chinese origin. The gear teeth are not located on the outer side, but on the inner side, that is, the device is positioned backwards.

Construction of a sprocket on a Chinese chainsaw

Depending on the design of the tool, the process of dismantling the products in question will differ.

This is interesting! To extend the service life of the chain saw pinion, it is necessary to run in the tool and not to overload it while working, which depends on the purpose (domestic, semi-professional or professional). You can cut wood with a common tool, but this is not what the saw was designed for, and frequent use with overloading will wear out the components.

Block: 2/4 | Number of characters: 2644

Replacement of worn out parts

If the pinion gear has an interchangeable ring gear, the condition of the base should be checked thoroughly. If you notice chips, cracks, deep scratches, altered geometry or corrosion, replace the whole part and not just the ring gear. Working together in the same node of worn and new parts will lead to a reduction in the service life of the entire node. The risk of the chain jamming or breaking is greatly increased.

In addition, the vibration load on the clutch, transmission and engine of the device will increase. The same factors arise when you use the same chain for a long time.

Sometimes folk “craftsmen” reanimate the stretched web chain, simply by throwing out one or two links and re-pressing the axle. In this case, the chainsaw needs to be replaced with a sprocket.

You should also not change the diameter of the gears (and therefore the number of teeth). Operating a larger or smaller sprocket will cause forces in the transmission and motor that the unit designers did not anticipate. This will reduce tool life and will not increase tool performance.

Despite the presence in a chainsaw design of safety systems that instantly stop the movement of the blade at its breakage or destruction of the bar and protecting from flying torn links, such situations are better not lead to. The need to replace the pinion is only strengthened by the safety requirements.

Are there any ways to extend the life of an existing sprocket??

The main ways to extend the service life of a chainsaw drive sprocket:

- Use more than one chain (preferably three). This method is the gentlest and most convenient for the chainsaw owner because it is not necessary to constantly retighten the chain after intensive work. Using three chains in a row will keep the sprocket in good working order and delay replacement;

- Good maintenance of the drive sprocket bearing. This part plays an important role in the function of both the drive sprocket and the engine. Special grease is recommended for lubrication. The sprocket bearing is not engaged all the time, but only at idle speed, so it needs periodic lubrication. You can use a tire nose grease, such as standard grease from Repsol or Husqvarna.

Constructional problems with different models

The problem is complicated by the design of brand-name chainsaws, which provide for the replacement of the worn drive only after the complete removal of the clutch mechanism and other components. Alternatively, in order to remove the sprocket from a chainsaw, it is necessary to have a special wrench.

One of the constructive characteristic of chainsaw imports is that the sprocket is placed on the clutch mechanism.

- When significant wear of teeth is observed, the drum that makes one with the drive unit should be replaced.

- advanced design of the drive sprocket makes it possible to restore the performance of the part by replacing the rim.

In the list of included with saws factory kits, such a tool is extremely rare. The problem can be solved by having the worn out part replaced at a service workshop or by making the necessary tool at home.

Features of the clutch drum in chainsaws

The drum, located in the clutch base of the mechanism, is an integral part of the chain drive system. This part resembles a star in its own form, due to which it received its name. Depending on the type of chainsaw the part can be professional or household. Because the professional saw is used more often than the household saw, the drive sprocket needs to be replaced all the time. If we talk about household tools, then everything depends on the amount of work performed and the load on the chain of the device.

In most cases, the sprocket, sprocket shaft, and saw bearing need to be replaced.

Drive sprocket for chainsaws

The chain saw drive sprocket or clutch plate serves to transfer rotational motion and power to the saw chain. There are three types of drive sprockets structurally;

One-piece sprocket. In this sprocket, the clutch plate is welded hard to the drive sprocket. If it wears out, it needs to be replaced as a whole.

The sprocket can be dismantled. The sprocket consists of a clutch plate with slots that fit the drive sprocket on the end of the sprocket. The clutch plate wears very little and the replacement sprocket is cheap. A collapsible sprocket is very advantageous for larger workloads and is mostly used by professionals.

Replacement sprocket. This sprocket is used for replacement on collapsible sprockets.

To find the right drive sprocket for your chainsaw model. If you doubt your choice. give us a call, we’ll try to advise you on the right replacement part.

What tools do you need to change a sprocket?

To replace the drive sprocket you will need the following tools and parts:

- A special wrench for removing this part (usually supplied with expensive brand-name chainsaws; cheap saws do not have such a wrench);

- aluminum or copper mallet (only soft metals and only if you don’t have a wrench)

- hammer (to hit the hammer while unscrewing the sprocket)

- A flathead screwdriver to tighten the nut;

- Grease for the sprocket bearing.

Sequence of work

The following steps should be followed during the repair work:

- First remove the saw headset, and use a universal wrench to unscrew the nuts on the bar cover. The cover is removed, and then the bar and chain are removed.

- The air filter is removed.

- Unscrew the spark plug of the device with the Allen wrench. Insert a piston stopper in its place so that the piston can be locked in the cylinder temporarily.

- The puller is inserted into the socket on the universal key. The resulting device then allows the clutch to be freely unscrewed. All actions should be clockwise.

- Remove the clutch, this will allow access to work on the internal parts. Then the sprocket (clutch drum) is removed.

- Depending on the type of drum installed in the unit, inspect it and check the crown gear. The sprocket or crown is replaced with a new part. When replacing them, it is mandatory to check the condition of the clutch in the cage. The springs in the centrifugal mechanism and the cams should be checked particularly carefully. If any are found to be excessively worn, they must be replaced.

In order to correctly and without defects replace the sprocket on the chainsaw, it is necessary to perform all work in a quality and accurate manner. If you do not have special tools for repair work, the process of replacing the drum may fail, because there is a chance of breaking not only the sprocket or centrifugal mechanism, but also the saw chain.

Reassembly procedure

To assemble your chainsaw you need to reverse the order. First place the sprocket on the needle bearing, then the clutch drum, the washer, and the clutch itself. Tighten it counterclockwise, but without excessive force. The piston also needs to be fixed, but with the left side rotation a few millimeters to the maximum upper point.

Note that sometimes the oil actuator is equipped with a spring that transmits motion from the sprocket to the pump. If the spring is not in place, the oil will not flow to the chain. Usually the correct position is marked with a color, if not, you must slowly rotate the part until the characteristic click.

Next you need to put the guide bar on the chainsaw. To put the chain, you must loosen the handbrake by pulling the lever toward you (toward the handle). It is important to make sure the chain teeth fit into the slots of the sprocket. If you are not careful, you could miss this point and the chain could break quickly. Its correct direction is indicated on the body by characteristic pictograms. After installing it, it must be tightened until it is in working order.

At the end you need to remove the piston lock, install the spark plug, the air filter. Reattach the upper housing cover.