How to perform grinding with a bolt cutter by yourself?

The same circles are suitable for chisels, as well as for grinders. They have about the same rotational speed (can vary by 500. 1000 rpm). So if you have concrete circles from an old angle grinder, you can buy a chisel cutter without them, thereby saving a little money.

How to make an angle grinder can saw concrete without clouds of dust

Receive one of the most readable articles in your mailbox once a day. Join us on and

What will be needed: the overhead hinge, self-tapping screws on metal short, screw with nut M3, sewer pipe elbow 50 mm to 45 or 67 degrees, rubber reduction on the sewer pipe 50 mm.

So that you can safely work with concrete, you can equip your angle grinder with an additional homemade protective guide. It will significantly reduce the amount of ceramic dust that can be thrown around. First attach the hinge to the bottom of the existing guard. To do this, you will have to make a suitable hole in the casing. Two elements of the construction are connected by bolt and nut. Remember that the disk should not interfere with the protruding screw and nut.

In the second (still free) part of the loop screw a knee. It is fixed with two self-tapping screws for metal. It is necessary to preliminarily make a cut in a knee for the blade of the angle grinder. To make a groove is possible with the same angle grinder. Then it is necessary to connect the prepared pipe to the elbow and to connect the vacuum cleaner to it.

This construction is perfect for 125mm tool. If we are talking about a more massive angle grinder, the design of the hood will have to be redesigned to suit the size and diameter of the blade. But in general the principle remains the same. The only disadvantage of the device is that the made cover is only suitable for certain discs.

You can not connect a vacuum cleaner to a homemade casing, but then the efficiency of the system will be somewhat lower.

Order of cutting concrete

Determining the type of concrete

Before you saw with an angle grinder concrete, you need to determine what type of concrete you are dealing with. This is due to the fact that different types of diamond blades are used for each type of material. For example, it can be reinforced with metal bars (reinforced concrete).

If the depth of cut is about 10 centimeters or deeper you could come across a metal grid (reinforcing bar) on “your way”. As mentioned above, there are special discs for this purpose.

You also have to take into account that the structure of the material changes over time. Fresh concrete is more abrasive, while old concrete is harder. For this reason, diamond discs for old and fresh material should be different.

If you have the time, you can study the structure of the material in more detail, which will allow you to choose the most appropriate tool for it. For example, if there is basalt or quartz in the composition, it will quickly dull the wheel. This is why the diamond segments should be bonded with a soft material, so that the new diamonds “break in” more quickly.

You should also keep in mind that the size of the filler affects the cutting speed. the larger it is, the slower the procedure is done.

Tip! Diamond tools are not only used for cutting, but also for other concrete work. In particular, diamond drilling of holes in concrete or grinding with diamond cup discs are often used.

Pictured here is a diamond wheel with laser soldering

Choice of disc

When choosing a disc, keep in mind that the segments can be attached to the blade in two ways:

- Silver brazing. These discs are widely used for wet cutting.

- Laser welding. These tools are characterized by high productivity, and are usually used for dry cutting.

In addition, when selecting a disk, it is necessary to make sure that its diameter and the hole for fixing correspond to the technical characteristics of the angle grinder. Maximum cutting speed is also important. It is preferable that the disc is higher than the maximum speed the angle grinder is capable of achieving.

Once all of the above parameters have been determined, you can choose the best type of tool for maximum efficiency.

Concrete angle grinder with segmented disc

Choice of cutting type

Usually cut with water, so the process is dust free. In addition, water can increase the efficiency of work, as well as increase the life of the tool. Due to the fact that the process can be uninterrupted, the work speed will increase. (See. also article Stitch cutter for aerated concrete: features.)

However, there is not always source of water near the work area. In this case the cut is made dry.The dry cutting process should be intermittent, t.е. consisting of several cuts.

Cutting

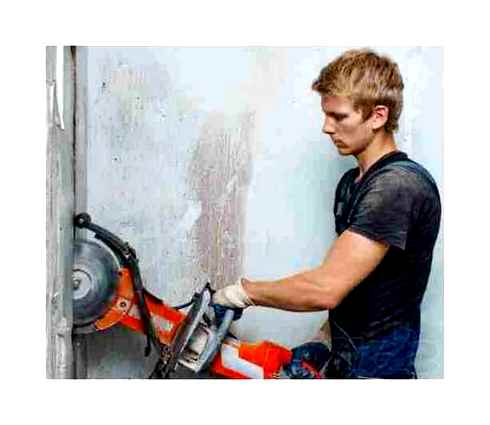

Once the angle grinder for cutting concrete is prepared, you can start working:

- The first thing to do is to mark out the fishing line that will be used to make the cut. It is advisable to fasten wooden bars along the mowing line, which will make the mowing line cut even.

- Then you need to turn on your own hands an angle grinder and make a cut with a depth of about 0.5. 1 cm.

- Next, you should remove the bars and perform the cut to the desired depth. In the process of work it is necessary to spray water on the blade. If the cut is performed dry, the procedure, as mentioned above, should be periodically stopped to allow the tool to cool down.

Note! Protect your respiratory system with a respirator before you start work. In addition, you should also use other personal protective equipment. goggles and gloves.

That’s probably all the instructions for doing this job.

Dust-free cutting, how to saw

In the text above we have already mentioned the two main ways of cutting concrete. wet and dry.

Wet method, features. Wet or wet method is recommended for high-quality and productive cutting of concrete. The cooling of the working nozzle and the surface of the cutting zone with water, will allow you to work without stopping for additional time to cool down. In addition, the water will knock down the dust, and the technological process itself will be performed without the presence of large amounts of dust.

If an angle grinder is used as a tool, the diamond disc and the surface of the cut should be moistened with water to reduce dust. The help of a colleague from work, who sprays the cutting area with a plastic bottle, is very useful.

Attention: water must not get on the angle grinder.

The wet way can be easily used in buildings under construction, where there is no risk of flooding the neighboring premises. In the production of repair construction work in residential areas, such as the organization of additional doorway, wet cutting method is fraught with waterlogged walls and short-circuits electricity.

Makita GA 5030 angle grinder for cutting concrete. 220Volt photo

Dry method, features. To avoid the bad consequences of the wet method of cutting allows dry technology. Here the discs are not water-cooled, so to perform an additional opening in a small-thickness apartment wall by this method is quite realistic. In this case, the angle grinder will have to turn off very often to cool down, and the process will take quite a long time. The use of a special construction vacuum cleaner is mandatory for dry cutting. Wait until the dust settles. this initially condemn the work to fiasco. You will also have to put up with frequent disc changes, as the discs will wear out quickly.

When working in the apartment on the device of the opening in the wall by dry cutting should adhere to the following stages of work:

- The redevelopment project must be coordinated with the relevant authorities;

- Make a thorough marking of the borders of the opening, taking into account the presence of utilities, provide for the presence of fittings;

- Perform a perimeter cut on one side of the boundary;

- drill the corners of the opening;

- Taking into account the drilled holes, perform the cutting of the boundaries of the opening from the back side.

- Dismantle the concrete cut into pieces with a weight allowing them to be transported;

- Reinforce the opening (this step must be stipulated in the agreed project) with metal angle bars or channel bars.

Simple self-made to saw with an angle grinder concrete, brick without dust and dirt

Any repair or construction site is not without garbage, dirt and dust, especially if you are working on sawing construction materials. Concrete, brick, foam or cinder blocks are so dusty that a respirator does not help protect the respiratory system, and in addition the dust prevents you from seeing exactly the markings on which to pass the disc angle grinder. To solve this problem help special attachments on the angle grinder, but there is no point in spending on them if you have a one-time job. To make the simplest version of such a nozzle can be literally for a couple of minutes from improvised materials.

Cutting without dust, how to saw

In the text above we have already mentioned the two main ways of cutting concrete. wet and dry.

Wet method, features. Wet or wet method is recommended for high-quality and productive cutting of concrete. Water cooling of the working nozzle and the surface of the cutting zone, will allow you to work without stopping for additional time to cool the equipment. In addition, the water will knock down the dust, and the technological process itself will be carried out without the presence of large amounts of dust.

If you use an angle grinder as a tool, moisten the diamond wheel and the cutting surface with water to minimize dust. The help of a colleague at work, who will water the cutting area from a plastic bottle, is very useful.

Attention: water must not get on the angle grinder.

The wet method can be used without problems in buildings under construction, where there is no risk of flooding the neighboring premises. In the production of repair construction work in residential areas, such as the organization of an additional doorway, wet method of cutting is fraught with waterlogged walls and short circuits electricity.

Makita GA 5030 angle grinder for cutting concrete. 220Volt photo

Dry method, features. Avoiding the bad effects of the wet cutting method is possible with dry technology. Here the discs are not water-cooled, so perform an additional opening in a small thick wall of the apartment with this method is quite realistic. In this case, the angle grinder will have to turn off very often to cool down, and the process will take quite a long time. The use of a special construction vacuum cleaner is mandatory for dry cutting. Waiting until the dust settles. this initially condemned to a fiasco execution of works. You will also have to put up with the frequent replacement of discs. they will wear out quickly.

When working in the apartment for the device opening in the wall method of dry cutting should adhere to the following steps works:

- The redevelopment project must be coordinated with the relevant authorities;

- Make a thorough marking of the borders of the opening, taking into account the presence of utilities, to provide for the presence of the armature;

- Perform perimeter cutting on one side of the borders;

- drilling into the corners of the opening;

- taking into account the drilled holes to perform the cutting of the boundaries of the opening from the back.

- dismantle the cut concrete and cut it into pieces with a weight that allows their transportation;

- reinforce the opening (this step must be stipulated in the agreed project) with metal angles or channel bars.

The essence of concrete cutting technology

Frozen concrete mass is very difficult to machine cut or drill. Lightweight, unreconstructed concrete surfaces can still be partially cut with an abrasive disc filled with silicon and aluminum carbide and oxides. already a year after the mortar has set, concrete can only be cut with a diamond tool. There are several reasons for this:

- High abrasion resistance of hardened concrete grains. Any metal, even titanium or tungsten, loses its cutting edge sharpness in a matter of minutes;

- High hardness of sand and gravel fillers, especially for heavy concrete. In this case the traditional method of cutting with peorators is not able to overcome hard basalt or granite;

- The presence in the concrete mass of reinforcing steel and glass plastic rods, grids, reinforcing bars.

This achieves almost perfect geometry and smooth texture of the cut surface edge. Due to the high precision of the mitered saw blade, diamond cutting of openings in concrete is used as the main method of processing. Even plasma torch cutting or laser cutting of concrete will not provide the proper quality and accuracy. In addition, thermal methods that are commonly used for quarry cutting granite and basalt cannot be applied to concrete massifs. In this case the cutting line is covered with cracks, and internal stresses are created that should not be allowed to occur in concrete structures.

Dust-free concrete cutting with your own hands

Cutting concrete without dust is almost impossible, because in the process of sawing and processing stone, in one way or another, there is a lot of dust, the volume of which can only be reduced. But it is also desirable to do, as too much dust in the process of work carries a lot of trouble: it spoils the tool and blunts the parts, settles in the lungs and on all surfaces in the room.

How to cut without dust

With the use of modern equipment, sawing concrete has become easier. there are special tools for cutting, consumables for them. The devices can be manual or stationary, powered by electricity or other sources. As a rule, all tools for cutting concrete are equipped with diamond parts. chains, discs, bits, tips, etc.д.

So, to perform this operation, you first need an angle grinder for concrete, which is popularly called an angle grinder. As an attachment, it is necessary to use a special diamond wheel on concrete for the angle grinder.

It should be said that they exist of several types:

Segmented circles are not the best solution, as when cutting with them, certain problems may arise, which is associated with their segmented edges.But, however, the advantage is the low price, compared to other types of nozzles.

The turbo diamond discs with wave-shaped casing make it possible to perform the most demanding cutting, for example, when you want to cut reinforced concrete. Of course, this nozzle type is the most expensive.

Tip! Cutting of reinforced concrete with diamond wheels is first performed to a depth of about one centimeter. If the problems with the angle grinder or disc are not detected, the procedure continues. Each subsequent cut should not be deeper than 1.5 cm.