Review of the motoroblock Lynx MBR-9. specifications. device. user manual

On the side of the walk.behind tractor is carried out according to the annotation. The fundamental period first work with the unit is its run.in.

The running-in is carried out from the moment of the first inclusion and lasts about 10-20 hours for 2/3 of the motor power.

The ending of the running.in can be considered completed if the machine works without failures, makes all the functions declared in the annotation and does not issue third.party noise when working.

After the running.in, you should drain the exhaust oil and fuel from the engine, change the oil in the gearbox. Further, it is allowed to start working with the walk.behind tractor, loading it at full force.

After each operation of the machine, the following actions should be performed:

- Cleaning from the mud of working parts: cylinder, milling, protective wings and wheels;

- Checking the level of oil, fuel, as needed, the finish to the norm;

- Properties of consolidating all connections.

Start is created on a flat surface. For the motor, high.octane gasoline and oil of all manufacturers are consumed, semi.synthetic or synthetic for the cool season, mineral. for the summer. For example: 10W30, 10W40, SAE30 (Mobile, Viking, Universal, Shell, and T.e).

For the gearbox: transmission oil SAE 75W-80, 75W-70 (Motul, Castrol, Elf, and T.e).

Fundamentally! Store one.axle tractor empty, without fuel and oil in containers.

User manual

Each new owner must start working with the walk.behind tractor lynx with the study of instructions for operation. This will help to understand the principle of bringing the device to work and handling it. Let’s look at the main aspects of the user management.

First launch and running

- The one.based tractor lynx in disassembled is supplied.

- It all starts with the assembly of the car. This process is described in detail in the operating instructions.

- Then, it is necessary to pour not only fuel, but also motor oil.

- After that, the mode of running in the walk.behind tractor occurs. This period lasts about 8-9 hours and its meaning is to allow the engine to work at a minimum load. Thanks to this, all the components of the motor will be lubricated and will fit among themselves.

- It is recommended to constantly switch the gears during the run.in, so that the checkpoint lever begins to work without failures and sorties.

- After that, motor oil should be replaced, since a large number of third.party impurities will gather in it.

Service

To extend the life of the walk.behind tractor, Lynx must take care of it and monitor its condition.

- Before each exit, you should check the presence of fuel and engine oil, visually evaluate the condition of the machine for failure of parts, check the reliable fixation of the attachment equipment.

- Replacement of motor oil should occur after 25 hours of work of the walk.behind tractor lynx. The manufacturer recommends pouring lubricants with a 10W-30 classification.

Repair of faults

Sooner or later, any equipment fails. There are small breakdowns that can be solved in the garage, and there are larger failures when you should contact the service center to solve them.

Let’s look at the most popular malfunctions and ways to solve them, which every owner of the walk.behind tract.

Pour a clean fuel tank clean and fresh fuel

The old fuel, which was in the walk.behind tractor during conservation, squeeze it and pour a new

Dirty or faulty spark plug remove it. Inspect it, clean it and, if necessary, replace it. Also check the gap between the electrodes

Insufficient oil level in the crankcase check its presence and, if necessary, share

Fuel or air filters clogged with them

Not proper tuning of the fuel mixture in the carburetor, adjust the appropriate position of the bolts

The engine gives out not stable speeds

Contact on the spark plug extends securely fix the electric wire

Old gasoline or water getting into the fuel tank drain the remnants of fuel and pour new

A hole on the lid of the fuel tank, remove the garbage

Clogging of the fuel or air filter see the solution above

Disassemble garbage into the carburetor, wipe it with gasoline and collect it back

As we see, the solutions are intuitively simple. The main thing is to identify the cause of the breakdown.

Description

Before buying technology, you should study the characteristics and features of all the presented models of motoblocks Lynx: MBR 7-10, MBR-8, MBR-16. It is also necessary to inquire about the rules for the use and use of technology.

Lynx motor cultivators are multidisciplinary and compact devices that should be used in agricultural work.

Important! Cultivators are used on any type of soil, regardless of the area that needs to be treated.

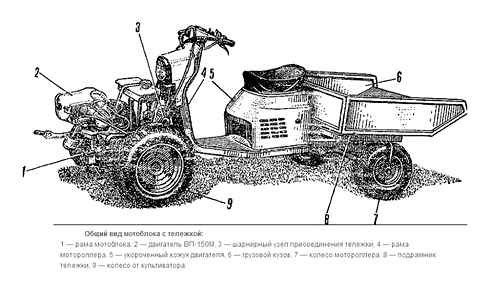

To increase performance is equipped with a trailer.

In this video, you will learn about the walking around the lynx:

- Plowing the soil.

- Extermination of unnecessary plants.

- Cultivation and alignment of soil.

- Mixing various types of fertilizers with soil.

- Cutting tall grass and small shrubs.

- Helping plants.

- A work of landscape works.

- Snow cleaning.

- Digging root crops.

- Landing and sealing of grain and vegetable crops.

- Transportation of objects and goods

During the production of parts for motor blocks, specialists use high.quality materials, so that the motor.cultivator is used for a long time.

Reviews of farmers and ordinary consumers indicate that the equipment works without violations and does not require additional maintenance and repair.

All types of motoblocks are equipped with a four.stroke Lifan gas.cooled gasoline engine.

- Model MBR 7-10: Seven horsepower with an engine volume 170 cm³.

- Model MBR-8: has eight horsepower with an engine volume 170 cm³.

- Unine tractor lynx 16: 16 l. With. with an engine volume 440 cm³.

The internal combustion engine is made in China.

Specifications

| Class | average |

| PTO | there is |

| Type of | The same tractor |

| Power selection shaft type | pulley (belt) |

| Engine power | 7 l.With. |

| Manufacturer and engine model | Lifan 170f |

| engine’s type | gasoline, 4.stroke, cylinders: 1 |

| Engine volume | 212 cubic meters. cm |

| Number of programs | 2 forward, 1 ago |

| Drive (gearbox) | chain |

| Transmission | Mechanical |

| Reverse | there is |

| Type of adhesion | belt |

Since the hinged options are not included in the basic equipment of the equipment, they have to be purchased in addition. But this is more advantage than a lack. The manufacturer specifically gave such an opportunity to customers so that they themselves could choose the right equipment based on their needs. We highlight some types of attachments that are in greatest demand among summer residents and farmers:

- Potato.cap

- Potato.resident

- Plow

- The enchanter

- Sower

- Soil hook

- Plow

- The enchanter

- Cart

- Hayfield

- Cultivational mills (additional)

As apparently, the capabilities of the motor block are extensive and diverse. Naturally, not everyone wants to buy all options from the presented list. That is why everyone will choose for himself what corresponds to his agricultural tasks. Some experienced gardeners develop homemade hinged options, since this is provided for by a simple and universal design of a walk.behind tractor.

Specifications

The Unoic Tractor Master with the American engine Quantum has the following technical characteristics:

- engine power. 5.5 l.With;

- tank capacity. 3.6 l;

- fuel consumption. 1.2 l/h;

- soil processing depth. 25 cm;

- capture width. 60 cm;

- Weight without additional options. 45 kg;

- The length with the handle in the working position is 130 cm;

- width. 70 cm;

- height. 98 cm;

- Dimensions in the transport state. 78 × 57 × 75 cm.

You can buy a new uniform tractor for 23000-25000, a full set of production options will cost another 9000-11000

Analogs

Closed in terms of dimensions and technical characteristics of the walk-behind engineer Master MK-265 are the following models:

- Champion BC 6712;

- Farmer;

- Centaur;

- Al-ko MH 4005;

- Gardena EH 600;

- Daewoo Dat4555;

- Lux 1400;

- GMC-1.eight;

- Zubrov NT 105.

The price of the product depends on the type of power plant, the country of manufacturer and configuration.

How to disassemble the engine

It is also necessary to disassemble the engine engine and inspect all nodes. All faulty, deformed or damaged parts should be replaced with similar new. You can also inspect the carburetor, air filter and muffler, because there may be problems such as blockage or simple pollution.

In this case, you need to urgently inspect, disassemble and clean every detail and assemble it again, if you do not do it and use the engine further, despite the poor condition, then new, already faulty breakdowns may appear. There may also be problems with the clutch body or a ratchet, then you need to disassemble the starting unit and replace the faulty part with the new. It is also advisable to inspect the cylinder.piston part of the engine, because they also tend to wear and break, if so, then they should also be changed to new.

On the forums you can find many positive reviews about this model. Owners note the functionality, power and high performance of the unit. Of the minuses, you can highlight its noise and strong vibration.

Alexander, Voronezh region.:

“I chose the same.based tractor for a long time, I am a picky buyer, so it is important for me to completely find out all the details of the work. I liked the lynx of MBR7-10 both in terms of technical parameters and in appearance: an impressive device, the wheels are large. I read reviews that supposedly such wheels as in the basic configuration are not very suitable, and more are needed. I will say that this is complete nonsense! With the basic configuration, everything is in order. The car is powerful, it works like mad, just have time to control and direct. Some also sin in weight, they say, not very heavy, we must take weight. I processed 30 acres, the unoic tractor works fine! Do not believe negative reviews, check for yourself and work according to the instructions, then there will be no problems “.

Dmitry, Ryazan:

“Lynx is a Belarusian one-based tractor, when I bought it, some advised me to take something simpler and cheaper, as a plot is only 10 acres. But I wanted the equipment powerful and such as not to spend the constantly on spare parts. MBR7-10 I have for the third year. I would like to write in more detail, maybe my review will be useful to those who still think what’s what. So, at first, the advantages: moderate, for a heavy unoic tractor with such a motor, I think, is not expensive. Good mills, take any land with a bang, but after each passage you need to be cleaned if the earth is soft or raw. Sustainable, squat. Disadvantages: belt clutch. On such a “heavyweight” it was possible to do something more fatal. Cutters wound grass, you need mowing before milling. Noisy engine, tangible vibration, hands get tired after 30 minutes of work, you have to take breaks.

In general, there are no complaints about the characteristics of. A good, reliable unoic tractor for any soil. I recommend to everyone who really wants to work on the site and get a good result!””

Review of motor blocks Lynx. The lineup. Attachments and maintenance

Motoboblok Lynx are considered inexpensive and reliable agricultural equipment, which was developed taking into account farm needs.

This technique is produced by Belarusian and specialists. They offer their customers inexpensive equipment with high technical characteristics.

The line of walking around the walking around the lynx is not very large, but still has its own nuances.

And here are a few reviews about motor blocks Lynx MBR 7-10 collected from horticultural forums:

Artem:

“I have a plot of 10 acres. And the same option was considered an unoic tractor with 7 horses. And for a year now I have been working for lynx MBR 7-10. I would like to note its small consumption of combustible materials, stability of revolutions, minimal maintenance. It worked 20 cm with milling cutters, it grinds carefully.

Pros: simplicity of service, high.quality nodes, low price.

Cons: low speed even in second gear “

Vladimir:

“I am engaged in the sale of motoblocks. Now the market of small agricultural machinery is full of various models and manufacturers. Therefore, it is often difficult for the buyer to understand them. The lynx appeared relatively recently, and gradually gain their client base. Basically, positive reviews are going on about them. They have high technical characteristics, do not overheat during operation, support work with a large number of attachments. And more small farmers do not need “

Description

Before buying technology, you should study the characteristics and features of all the presented models of motoblocks Lynx: MBR 7-10, MBR-8, MBR-16. It is also necessary to inquire about the rules for the use and use of technology.

Lynx motor cultivators are multidisciplinary and compact devices that should be used in agricultural work.

Important! Cultivators are used on any type of soil, regardless of the area that needs to be treated.

To increase performance is equipped with a trailer.

In this video, you will learn about the walking around the lynx:

- Plowing the soil.

- Extermination of unnecessary plants.

- Cultivation and alignment of soil.

- Mixing various types of fertilizers with soil.

- Cutting tall grass and small shrubs.

- Helping plants.

- A work of landscape works.

- Snow cleaning.

- Digging root crops.

- Landing and sealing of grain and vegetable crops.

- Transportation of objects and goods

During the production of parts for motor blocks, specialists use high.quality materials, so that the motor.cultivator is used for a long time.

Reviews of farmers and ordinary consumers indicate that the equipment works without violations and does not require additional maintenance and repair.

All types of motoblocks are equipped with a four.stroke Lifan gas.cooled gasoline engine.

- Model MBR 7-10: Seven horsepower with an engine volume 170 cm³.

- Model MBR-8: has eight horsepower with an engine volume 170 cm³.

- Unine tractor lynx 16: 16 l. With. with an engine volume 440 cm³.

The internal combustion engine is made in China.

Review of the walk-behind tractor Lynx MBR 7-10. Specifications. Features of the application and maintenance of the model

The Type Rynius MBR 7-10 is assembled in the most popular layout: the transverse location of the motor and belt drive to the gearbox. During the switching of the speeds, a gear gearbox is used, which is controlled using a lever connected to the gearbox.

- The position of the steering rod can be adjusted in the vertical axis.

- The same.based tractor has sufficient power and weight to maintain work with a wide spectrum of attachment equipment.

- The delivery set includes a set of cutters, wide.profile tires and axes extensions.

- Active types of canopies are installed in front of the walk-behind tractor Lynx MBR 7-10 and are driven by belt transmission.

Specifications

| Class | average |

| PTO | there is |

| Type of | The same tractor |

| Power selection shaft type | pulley (belt) |

| Engine power | 7 l.With. |

| Manufacturer and engine model | Lifan 170f |

| engine’s type | gasoline, 4.stroke, cylinders: 1 |

| Engine volume | 212 cubic meters. cm |

| Number of programs | 2 forward, 1 ago |

| Drive (gearbox) | chain |

| Transmission | Mechanical |

| Reverse | there is |

| Type of adhesion | belt |

If you are the first owner of the walk-behind tractor Lynx MBR 7-10, then before proceeding to complete operation, it is necessary to run the engine. To do this, fuel and lubricant are poured into it, and the first 8 hours use the device at half the greatest power.

- During this time, motor nodes are carefully lubricated and begin to work as a whole.

- Upon completion of the running.in, be sure to replace the engine oil.

About hinged and trailer equipment for the livestocks “Lynx

Frases

It is the basic attachment equipment for the Lynx motornote, which is already included in the standard factory set of delivery. The milling cutter is used for high.quality loosening of the upper fertile layer of the soil, giving it uniformity and increase productivity. The curved knives turn the earth literally into “fluff”, and also save the upper layer of soil from the roots and rhizomes of weeds, tearing them out of the ground and grinding them. Motoblocks “Lynx” can work with cutters of capture width 120 cm or 150 cm (more powerful models).

If it is impossible to immediately start cultivation with milling stations, then dense lands can be treated with a plow. In the process of plowing, the track is made, after which one wheel is placed in it, the necessary level of immersion of the plow is set and a systematic plow is carried out.

Braids

Motoblocks “Lynx” can work effectively with rotary mowers. They are installed in front of the motor block and allow you to cut off high and medium.sized grass.

Helpers

They are used for hilling of potatoes and other agricultural cultures planted by rows, as well as for the inter.row processing and weeding of the garden. Potatoes are a very demanding culture, which care work is greatly facilitated with cummers.

Potato.cake and potato.resident

Landing and, in particular, the collection of potatoes has always been a laborious matter. For automation of this process, this additional equipment is used. The potato.resident is made according to the following design: the front is located in front, which makes a trench, and in the back there is a special device with a tank, from which potatoes are taken with a conveyor tape and planted in the soil. At the back of the unit, this home.made trench is buried with two cigns.

Potato.cuttling with the “Lynces” motoblock uses a roar type. She has a knife in front, which cuts a layer of earth and directs it to a roar, where it breaks, leaving potato root crops on the surface.

Snow-offers and dumps are

If you wish, you can make the “Lynx” one.based tractor work hard in winter. He will be able to help in cleaning territories from snow. To do this, two snowpress equipment can be attached to it. In particular, the snowmaker is a special bucket that selects a layer of snow and directs it to the rotor, which he spins and throws it to the side. A more budget option is a dumpling dump, which simply shifts snow to the side.

Soil.bearing and weighting

In standard configuration, any high.quality tires with an off.road tread, which provide reliable adhesion with the surface during processing of light soils.

However, when processing heavy. meadow and virgin lands, the same.based tractor can begin to slip, slip and “jump out” from the furrow. To improve its grip on the soil and optimize the walk.behind tract and additional installation of weighting and (or) soil.

Weighting agents are used by those made in the form of pancakes, and they are hung on a wheeled axis.

Trailers

Using the Lynx motor blocks, you can transport at short distances of goods weighing up to 500 kilograms, if you use a special trailer.

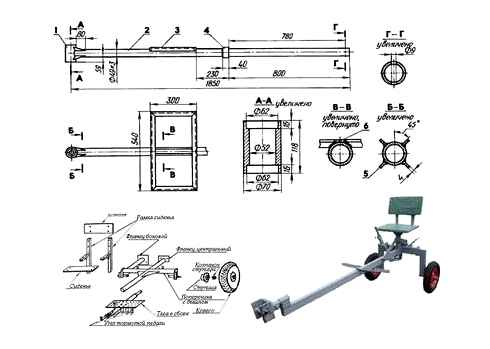

Adapter

The main disadvantage of any walk.behind box is that it has to move behind him. Because of this, rapid fatigue occurs, and this gives an increased load on the back (especially in the lower back). In order to eliminate this harmful effect on health, you can use a special adapter that is connected to the motor block from the back and provides the opportunity to control it sitting. To work with the trailer also needs an adapter.

About the disadvantages of the motoblocks “Lynx

Among the minuses of the motoblocks of this brand, a rather significant vibrational load is often mentioned, which comes from transmission elements to manual control organs of technology.

Large breakdowns of nickname from the owners of motoblocks of this brand for the first 2-3 seasons of their operation were not noted. In any case, they do not report such cases. But according to trifles, the one.based tractor “lynx” breaks quite often and a lot.

Often the point here is that the quality of the metal from which it itself is made and its individual spare parts leaves much to be desired (which, as you know, is not uncommon for Chinese technology). It is good that the spare parts for this technique are quite cheap, but in the case of a truly large breakdown (for example, the engine will “fly”)-it will be cheaper to purchase a new unoic tractor.

By the way, when working, it is necessary to ensure that the engine does not overheat. If you work in the heat, at a temperature of more than 25 degrees, then the motor begins to quickly heat up and at the same time loses its power.

Also, the quality of welds is far from always the same as it should be. At one of the owners of the “Lynx” motoblock, when the first attempt to plow dense virgin soil, the lobby was broken down.

According to the owners of the “Lynx” motor blocks, a belt pulley, with all its cheapness and undemanding lubrication, still more often other types of transmission need to be replaced and additional maintenance.

Another disadvantage, according to the reviews of the buyers of the motoblocks of this brand, can be the absence of a differential blocking function. an unequal and uneven load on the chassis and wheeled part complicates the maneuverability and rotation of the cultivator.

Often, when working from the engine and (or) transmission of the walk.behind tractor, it begins to ooze and gradually leak motor oil.

When working with a mowing, you have to independently make a homemade protective shield in front of the engine, otherwise, while mowing the grass of the cork, the engine flies away from it and quickly sticks out the engine, including clogging the ventilation holes.

In order to extend the motor.resource of the “Lynx” motoblocks, they advise not to forget that the durability of each technical means is determined by the care of caring for it, as well as the regularity of inspection and maintenance.

The same.based tractor needs to be drunk at minimal loads, during the first eight hours of its work. so that the details are established to each other properly. Since the quality of the assembly of the “Lynces” motoblocks is far from always decent quality (most often, on the contrary, it is quite careless), before starting the operation of a new walk.behind tractor, you need to check the tightening of all bolted and screw screeds, and do the same again after the completion of the runway is completed.

It is necessary to strictly monitor the level of the oil, change the oil and air filters in time.

Characteristics

| Engine model | 170f |

| Engine volume | 170 |

| Engine power (l.With) | 7.0 |

| The volume of the fuel tank (l) | 3.6 |

| Oil crankcase volume (l) | 0.9 |

| Clutch | Belt |

| Width of processing (cm) | 100 |

| Depth of processing (cm) | 36 |

| Programs (forward/up) | 2/1 |

| Wheels | four.010 |

| Weight, kg | 82 |

Motoboblock assemble according to the instructions provided. We also recommend that the seller consult on questions of interest and study the reviews of owners of similar models using the Internet forums of farmers.

Use the Unoa tractor according to the instructions:

- Change the oil in a timely manner, add gasoline (the quality of refueling materials should be high, so the engine will operate stably and without breakdowns).

- Serv the same tractor properly. clean from pollution, replace the filters in a timely manner (ideally, every 50 hours of work and immediately after running in).

- Do not reduce the terms of the running-in-at least 8 hours with the subsequent drain of oil and gasoline and filling fresh fuel (motor oil type 10W-40, 10W-30).

Программирование приводов An-Motors серии ASL – видеоинструкция

Reviews of the owners

There are many positive reviews about this model on the forums. Note its functionality, high performance, power and easy control.

Vitaly, Vologda:

“I consider the motoblocks lynx from Belarusians one of the best, I trust this manufacturer. Used earlier MBR7, then I sold it and bought myself MBR8, I liked it that they changed the clutch, in the 8th model it is disk, no need to fool your head with these belts: they wear out quite quickly, then you have to change it then. And then the oil flooded and that’s it. I will say this: he has excellent characteristics and he really justifies them as this. Does not work with milling cutters, it just flies. The earth is shallows into dust. But maybe the quality of the earth is important, we have black soil, the soil is good. I personally do not feel the weight of the walk.behind tractor, although it belongs to the heavy, heavy for me it is from 140 kg and more. A little later I plan to make a video how he drags a snowman. I’ll take it for a while from a neighbor and check how to clean the snow “.

Stepan, Izhevsk:

“I took a lynx according to reviews and characteristics, read on the network, plus the seller persuaded me. The same.based tractor is really standing, I will not say bad. But there are nuances in work, of course, where without them. But according to my preliminary assessment, it is cooler than the same non.ugly. I did not compare with foreign counterparts, there is no possibility.

Advantages: heavy but well.controlled. Gasoline for such a weight is really consuming modestly. At first we did not succeed with the cigns at first, but then I went like a nice. From the hinged I use everything that is in the barn: the plow, and the mower, and the hooks, I did not think to weight, but you can try.

Disadvantages: little practical information, instructions, let’s say, already written for those who communicate normally with technology. If from scratch. nothing will be clear. I would like more information on the characteristics and video on the network from the manufacturer, how foreign companies are filmed about their goods “.

The Type Type “Lynx” MBR-16

Opens a line of the most productive motor cultivators “Lynx” with a thrust of 16 liters.With. 32 mm shaft and passable 12 inch wheels differ from the older MB series. Due to the friction adhesion and a gear reducer, the device develops competitive power, which, according to customer reviews, allows us to adapt it for daily work lasting about 13 hours. It can be operated both on even surfaces and on the fields located under an insignificant (up to 10 0) slope.

- Lifan 190f motor with a compulsory cooling system;

- rear INOM, closed by a special casing;

- the presence of a spring.loaded footboard for stability;

- 3-speed gearbox with 1st rear gear;

- ergonomic location of control levers;

- Compactness for transportation by a passenger car.

Operational properties:

Установка электрозамка Motorlock C

Factory equipment of the tributons “Lynx”:

- a single tractor with a removable steering column;

- Soilines. 8 sections (2 x (31);

- Obstructive wings. 2 pcs.;

- Removable wheels. from 4 x 10 to 6 x 12;

- Extension cords of wheeled axes (2 bushings);

- Soshnik and plant protection disks-only in the ICBR series;

- User manual.

How to extend the motorsurs of cultivators “Lynx”?

The durability of each maintenance is determined by the care of care and the regularity of maintenance.

In order for this one.toe tractor to serve for glory, it is necessary:

- In detail study the description of a particular model and comply with all the requirements of the manufacturer set forth in the user manual;

- proceed to work only after checking the serviceability of its working nodes;

- refill the unit with a gasoline with an octane number of at least 92;

- Use oils recommended by the manufacturer-for example, for the spring period-“Briggs Stratton” SAE 30, “OREGON” 10W40 or “VIKing” HD 10 W-30-for winter.

Special attention should be paid to the run.in. the production of spare parts, which is relevant only for the newly acquired completely new motorblocks “Lynx”. This period lasts about 8 hours and should increase the reliability of the compounds and adapt the one.based tractor to work.

The processing process begins with the assembly of the structure in accordance with the operating instructions, after which:

- tighten the bolted and screw screeds;

- The motor is heated within a few minutes, after which the idle stroke is replaced by a small load;

- Gradually load the cultivator, letting it process the soil to a small depth (up to 10 cm). To do this, it is advisable to turn on the second gear;

- It is unacceptable to work at speeds with disconnected clutch.

After the running.in, check the oil level, change oil filters, add fuel and proceed to full work.